Professional Documents

Culture Documents

Test Plan CARBON BRUSH ASSEMBLY

Uploaded by

kamleshindhiringOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test Plan CARBON BRUSH ASSEMBLY

Uploaded by

kamleshindhiringCopyright:

Available Formats

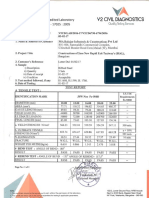

INSPECTION & TEST PLAN

CARBON BRUSH ASSEMBLY

FOR WHEEL SET EARTHING EQUIPMENT

(FOR LHB TYPE COACHES)

1. Specification/Drawing : RCF Drg. No. LW71239 Alt.-Nil & IS:13466/1992

2. Date of Inspection :

3. Place of Inspection :

4. Size of Lot :

5. Size of Sample :

As per Annexure C of IS:13466/1992 (Table 16)

1st Sample 2nd Sample Acceptance 1st Rejection 2nd Rejection

Lot Size

Size Size Number No. No.

(1) (2) (3) (4) (5) (6)

Up to 100 5 - 0 1 -

100 – 300 8 8 0 2 2

301 – 1000 13 13 0 2 2

1001 – 3000 20 20 0 3 4

3001 – 10000 32 32 1 4 5

10001 & above 50 50 2 5 7

In any consignment all the carbon brushes of the same designation, manufactured from the same material

under similar conditions of production shall be grouped together to constitute a lot.

6. Document Verification: a) Internal/ External test certificate for raw material & Bought-Out items

(i.e. Brush Block, Terminals, etc., as applicable)

b) Dimensional check report

c) Calibration record of gauges, measuring instruments & test equipment

7. Tests/Checks (to be witnessed/conducted by inspector):-

SS.

Parameter Value Specified Observations Remarks

No.

The brushes shall be examined

Ref. Cl. No.16.4 of

with a magnifying glass of

IS:13466/1992

magnification factor 10X min.,

for the following:

(i) Cracking, chipping or

(a) Visual distortion.

(ii) Smoothness of surfaces.

(iii) Sound and proper jointing of

pigtail to carbon brush.

(iv) Appropriate marking.

Prepared by- Checked by- Forwarded by-

IE: RY Technical Cell: RAS CM: CAK

INSPECTION & TEST PLAN

CARBON BRUSH ASSEMBLY

FOR WHEEL SET EARTHING EQUIPMENT

(FOR LHB TYPE COACHES)

S.

Parameter Value Specified Observations Remarks

No.

As per RCF Drg. No. LW71239

Alt.-Nil

& Dimensional Sheet

Ref. Cl. No.16.5 of IS:13466/92 attached

(i) The dimensions shall be Specially fabricated

measured with vernier callipers ‘go’ and ‘no-go’

(b) Dimensional

& screw gauges with their least gauges may be used

count not more than 0.01mm for checks of

dimensional accuracy

(ii) For measuring the curvatures on mass scale

& checking trueness of the flat production.

surfaces, dial gauge should be

used.

COMPONENTS

(c)

Ref. Material & Spec. as per RCF Drg. No. LW71239 Alt.-Nil

As per IS:13525/1992 Ref. Cl. No. 5.1 of

2 Nos. Copper Braded Cable IS:13466/92

Copper Braded Ø5x100 duly crimped with tongue

c.1

Cable type copper crimping sockets to OEM TC/Test

be embedded firmly in the Carbon Report may be

Brushes. reviewed/ verified

As per Cl. No.6.1 of IS:13466/92

Crimping Socket Crimping Socket Tongue Type OEM TC/Test

c.2 ETP Copper-99.9% purity & Silver Report may be

Tongue Type

plated, Coating thickness 5 reviewed/ verified

Micron or more.

Ref. Note- 4 of RCF

As per Cl. No. 4 of IS:13466/92

Drg. No. LW71239

The Brush Material (Metal- Alt.-Nil

Graphite-SKM9) used for

manufacture of carbon brushes Manufacturer’s T.C

shall be one of the grades :- may also be verified/

Metal Graphite reviewed.

c.3 BE-14/Z1 M/s Elka Carbon or

(Carbon Block) Mersen India or

BM-51 of M/s ACPL or any other

RDSO approved make.

The Brush material used shall

conforms to the requirements

given in IS:13584/1993

Prepared by- Checked by- Forwarded by-

IE: RY Technical Cell: RAS CM: CAK

INSPECTION & TEST PLAN

CARBON BRUSH ASSEMBLY

FOR WHEEL SET EARTHING EQUIPMENT

(FOR LHB TYPE COACHES)

S.

Parameter Value Specified Observations Remarks

No.

As per Note-5 of RCF Drg. No.

LW71239 Alt.-Nil

Manufacturer’s insignia shall be

legibly embossed on the Brush

Block above the worn out limit.

(d) Marking

As per Cl. 14.1 of IS:13466/92

Batch No. & Year of manufacture

may also be legibly & indelibly

marked on carbon brush.

As per Cl. 15.1 of IS:13466/92

Carbon brush shall be suitably

(e) Packing protected & packed so as to avoid

any damage to flexible, terminals

& carbons.

Name & Signature of IE

Prepared by- Checked by- Forwarded by-

IE: RY Technical Cell: RAS CM: CAK

INSPECTION & TEST PLAN

CARBON BRUSH ASSEMBLY

FOR WHEEL SET EARTHING EQUIPMENT

(FOR LHB TYPE COACHES)

S. Parameter Specified Observation Remarks

No. Dimension (for guidance

with tolerance only)

1 2 3 4 5 6 7 8 9 10 11 12 13

Length of carbon block

1 52/45 ± 0.8*

(with bevel top)

2 Width of carbon block 40 -0.15/-0.05*

3 Thickness 20 -0.13/-0.04*

Dia. of pigtail (copper

4 Ø5 ± 0.3**

braided cable) (2 Nos.)

5 Pigtail’s centre spacing 28 ± 0.5**

2 x 45°

6 Chamfer (bottom edges)

(±0.4/±1o)**

Worn-out limit Mark

7 8 ± 0.5**

from bottom

Side edge chamfer 1 x 45°

8

(3 edges) (±0.4/±1o)**

Side edge chamfer 4 x 45°

9

(1 edge) (±1/±1o)**

Terminal (Socket) length-

10 As per Table-10

(A)Tongue type

Terminal (Socket) width- of IS:13466/92

11 or PO

(B)Tongue type

requirement

12 Terminal slot hole Dia. (d)

(may be

Terminal slot centre clarified).

13

position (x)

*Tolerance as per IS:13466/92

**For untoleranced dimension, tolerance to be as per IS:2102(Part-1) Coarse.

Note- Specially fabricated ‘go’ and ‘no-go’ gauges may be used for checks of dimensional accuracy on mass scale production.

Name & Signature of IE

Prepared by- Checked by- Forwarded by-

IE: RY Technical Cell: RAS CM: CAK

You might also like

- Custom Auditing in SSIS: - Meghana VasavadaDocument39 pagesCustom Auditing in SSIS: - Meghana Vasavadajlcastilho2010No ratings yet

- Week 2 MineralsDocument23 pagesWeek 2 MineralsShuaib IsmailNo ratings yet

- BAY - API 510 Practice Exam #5 CB Questions PDFDocument18 pagesBAY - API 510 Practice Exam #5 CB Questions PDFAshish Patel100% (2)

- Specification: Hot Coiled Helical Springs Mainline Coaches, Emu and Freight Stock No. WD-01-HLS-94 (Rev.3)Document43 pagesSpecification: Hot Coiled Helical Springs Mainline Coaches, Emu and Freight Stock No. WD-01-HLS-94 (Rev.3)Anonymous PSNjTGUNo ratings yet

- Conversions and Calculations Used by Pharmacy TechniciansDocument47 pagesConversions and Calculations Used by Pharmacy Technicianstorres_jaime22100% (11)

- FOS User Guide PDFDocument96 pagesFOS User Guide PDFadsrjmNo ratings yet

- Saudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Receiving Inspection of Pressure Vessels-External SAIC-D-2002 24-Jul-18 Mechnisha_khanNo ratings yet

- BAY.t - 510 Close Prac Exam #5Document18 pagesBAY.t - 510 Close Prac Exam #5Moustafa Fares100% (2)

- Technical Specs of Paint CoatingDocument117 pagesTechnical Specs of Paint CoatingPabitra MohantyNo ratings yet

- Steel Test ResultsDocument2 pagesSteel Test ResultsDevendra SinghNo ratings yet

- Sis Book1Document99 pagesSis Book1Hamza AlamNo ratings yet

- Cone Penetration Testing: Methods and InterpretationFrom EverandCone Penetration Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (3)

- CBB QuestionPapersDocument83 pagesCBB QuestionPapersVaibhav Bode100% (2)

- Panduit PLT2M M Cable TiesDocument192 pagesPanduit PLT2M M Cable TiesРоман ДяченкоNo ratings yet

- Getco - r1 Al59 Zebra & MooseDocument27 pagesGetco - r1 Al59 Zebra & Mooseakib javed100% (1)

- Tank Paint SpecDocument106 pagesTank Paint SpecJack100% (1)

- Manual 610p Eng PDFDocument103 pagesManual 610p Eng PDFDaniel Maldonado ForinNo ratings yet

- Procedure D'inspectionDocument9 pagesProcedure D'inspectionsalahjallali100% (2)

- Pig Launchers Recievers PDFDocument9 pagesPig Launchers Recievers PDFgalih santosoNo ratings yet

- BHEL Creep Test Boiler Tube PDFDocument3 pagesBHEL Creep Test Boiler Tube PDFGopal RamalingamNo ratings yet

- TDG 0018, 0019 & 0020 Rev - 0Document10 pagesTDG 0018, 0019 & 0020 Rev - 0Preeti goswamiNo ratings yet

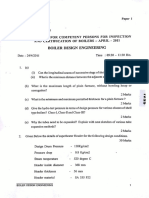

- Xamination For Competent P Rsons For Inspection AND Certification of Boilers - April - 2011Document3 pagesXamination For Competent P Rsons For Inspection AND Certification of Boilers - April - 2011RAJKUMARNo ratings yet

- Cs-Rites-Door Link Mechanism (Single Link)Document3 pagesCs-Rites-Door Link Mechanism (Single Link)sohelNo ratings yet

- 2009FDocument26 pages2009FdaimaheshNo ratings yet

- Grey CIDocument5 pagesGrey CIsaurabhsinh ranjitsinh bhattiNo ratings yet

- TDC 429 Rev.00Document2 pagesTDC 429 Rev.00bhavin178No ratings yet

- Spec Tn1946Document8 pagesSpec Tn1946Kumara SubramanianNo ratings yet

- Appendix 4 Worked Example: Type C Strategy: Esr-In-Confidence HOIS-G-103 Issue 1Document8 pagesAppendix 4 Worked Example: Type C Strategy: Esr-In-Confidence HOIS-G-103 Issue 1Mo BlackNo ratings yet

- Guide To Quality Control Inspection Duties: EchnologyDocument3 pagesGuide To Quality Control Inspection Duties: EchnologyThanhTaiVoNo ratings yet

- Indian Railway: WD-60-Misc-2009Document6 pagesIndian Railway: WD-60-Misc-2009harsh anandNo ratings yet

- IRS T 31 Revision 4Document30 pagesIRS T 31 Revision 4Mallikarjun GNo ratings yet

- PROCEDURE-Direct Supply of DLC Pins From Ancillary To SPRL Doc. No. IMS/CP / Edition No.:00 Rev. No Pistons and Rings Ltd. Date: 06.07.2020Document2 pagesPROCEDURE-Direct Supply of DLC Pins From Ancillary To SPRL Doc. No. IMS/CP / Edition No.:00 Rev. No Pistons and Rings Ltd. Date: 06.07.2020Deepak SharmaNo ratings yet

- Lot Inspection Report For LPG New CylindersDocument3 pagesLot Inspection Report For LPG New CylindersJagannath MajhiNo ratings yet

- Concreteliningofcanals - Compound - Specification: Indian StandardDocument5 pagesConcreteliningofcanals - Compound - Specification: Indian StandardyurendraNo ratings yet

- Checklist & QAP Fabrication, Painting of Steel GirderDocument19 pagesChecklist & QAP Fabrication, Painting of Steel GirderSse SteelNo ratings yet

- Product Manual For Pressed Ceramic Tiles ACCORDING TO IS 15622: 2017Document13 pagesProduct Manual For Pressed Ceramic Tiles ACCORDING TO IS 15622: 2017Abhijit KarpeNo ratings yet

- 51final STR - M&C - PCN - 051 - 2011Document11 pages51final STR - M&C - PCN - 051 - 2011Ashish Khandelwal100% (1)

- 9pages From AIIAP Vol V Financial Bid and BOQ - PDF-10Document10 pages9pages From AIIAP Vol V Financial Bid and BOQ - PDF-10Muhammad ArslanNo ratings yet

- IRS T - 31 - Revision 4Document28 pagesIRS T - 31 - Revision 4priyaranjan kunwarNo ratings yet

- Product Manual 7098 1 V2Document10 pagesProduct Manual 7098 1 V2KaustubhDabeerNo ratings yet

- PQR# Welder: Welder Id#Document2 pagesPQR# Welder: Welder Id#tjeffNo ratings yet

- Bench Mark Quiz: API 510 PreparatoryDocument5 pagesBench Mark Quiz: API 510 PreparatoryRajkumar ArikumarNo ratings yet

- PM IS 1364 Part 1 April 2020Document9 pagesPM IS 1364 Part 1 April 2020jyoti prakash singhNo ratings yet

- Bogie Technical RequirementsDocument8 pagesBogie Technical RequirementsAmit shahNo ratings yet

- Final Revised Spec IRST-29-2016Document44 pagesFinal Revised Spec IRST-29-2016Sumit Shyamal100% (1)

- Is 1786 Product Manual Revision 3Document9 pagesIs 1786 Product Manual Revision 3HARINDRA PRASAD RNo ratings yet

- Specification Aa10109 1440410164 PDFDocument5 pagesSpecification Aa10109 1440410164 PDFParthi NatarajNo ratings yet

- Product Manual For High Strength Deformed Steel Bars and Wires For Concrete Reinforcement ACCORDING TO IS 1786: 2008Document9 pagesProduct Manual For High Strength Deformed Steel Bars and Wires For Concrete Reinforcement ACCORDING TO IS 1786: 2008N.J. PatelNo ratings yet

- PuneDocument2 pagesPuneARINDAM SETTNo ratings yet

- Is 1786 Product ManualDocument9 pagesIs 1786 Product ManualarkpNo ratings yet

- Saic D 2022Document7 pagesSaic D 2022sureshNo ratings yet

- Check List For Prefabrication Stage: 1 Stage - (As Per BS 110R-Inspectionof Steel Girders)Document2 pagesCheck List For Prefabrication Stage: 1 Stage - (As Per BS 110R-Inspectionof Steel Girders)Lakhwant Singh KhalsaNo ratings yet

- Draft (STR) Item Specific Guidelines For TWS - 12 - 03 - 2021Document11 pagesDraft (STR) Item Specific Guidelines For TWS - 12 - 03 - 2021nitindhiman11No ratings yet

- Bare Copper & Earthing Accessories SpecificationDocument14 pagesBare Copper & Earthing Accessories SpecificationJayantha SampathNo ratings yet

- Hazira-Sor 20200702 181418Document11 pagesHazira-Sor 20200702 181418Suaib VCSNo ratings yet

- 2 STR-100KVDocument22 pages2 STR-100KVraj_stuff006No ratings yet

- Sabic Specification Master List For Sharq Project: Al Rushaid Construction Co., LTDDocument21 pagesSabic Specification Master List For Sharq Project: Al Rushaid Construction Co., LTDrex valencia100% (1)

- Acsr Conductor SpecificationDocument34 pagesAcsr Conductor SpecificationrajensamaNo ratings yet

- Fitp For Concrete Works & GabionDocument4 pagesFitp For Concrete Works & GabionSofda ImelaNo ratings yet

- Work Scope - Francis Turbine Refurbishment WorkDocument6 pagesWork Scope - Francis Turbine Refurbishment WorkmanikanthNo ratings yet

- ACS124Document5 pagesACS124sankardevNo ratings yet

- Miadata 19Document8 pagesMiadata 19Antonio AtayanNo ratings yet

- 5 CQM Manual Appendix IRC SP 47 1998 (Page 46to79)Document29 pages5 CQM Manual Appendix IRC SP 47 1998 (Page 46to79)Rupesh KumarNo ratings yet

- 14 C - BridgesDocument4 pages14 C - Bridgesgurumurthy38No ratings yet

- Glued JointsDocument5 pagesGlued Jointsanildondapati1No ratings yet

- Hardrock Romangranit ECatalogDocument22 pagesHardrock Romangranit ECatalogYuli PurnomoNo ratings yet

- Zebra TLP 2844Document2 pagesZebra TLP 2844Elyass DaddaNo ratings yet

- TN048 PDFDocument2 pagesTN048 PDFmjferrari76No ratings yet

- Concurrent Manager QueriesDocument51 pagesConcurrent Manager QueriesnamrataNo ratings yet

- Bind Peeking - The Endless Tuning Nightmare: SAGE Computing ServicesDocument30 pagesBind Peeking - The Endless Tuning Nightmare: SAGE Computing ServiceskruemeL1969No ratings yet

- Electronegativity ScalesDocument8 pagesElectronegativity ScalesrashidNo ratings yet

- Bangalore Electronic Components Database Samples 2022Document3 pagesBangalore Electronic Components Database Samples 2022Pradeep KNo ratings yet

- Export SocialDocument45 pagesExport SocialM-IENTIST GamingNo ratings yet

- Aws Interview QuestionsDocument49 pagesAws Interview Questionsyuva razNo ratings yet

- Assembly Chapter6 BDocument4 pagesAssembly Chapter6 BMr hacksNo ratings yet

- Gk247a A-008Document35 pagesGk247a A-008WidiMufantoNo ratings yet

- Lesson PlanDocument8 pagesLesson PlanKendall HenryNo ratings yet

- Physuics Class 10Document9 pagesPhysuics Class 10Vidhun 8ANo ratings yet

- 11Document21 pages11Sumeet Gupta0% (2)

- PK45I en 01 Drive-In PiezometersDocument5 pagesPK45I en 01 Drive-In PiezometersSDLCNo ratings yet

- D 850 - 99 - Rdg1mc05oueDocument6 pagesD 850 - 99 - Rdg1mc05oueCasey RybackNo ratings yet

- Readme!Document1 pageReadme!satheeshvicky234No ratings yet

- Final Project Report Sachin Basavarajappa KenchammanagathihalliDocument14 pagesFinal Project Report Sachin Basavarajappa KenchammanagathihalliSachin BkNo ratings yet

- Short Questions... DbmsDocument10 pagesShort Questions... DbmsMuhammad Jamal ShahNo ratings yet

- Zener DiodeDocument14 pagesZener Diodes211053176No ratings yet

- OL Maths - MR Ambessi PRE MOCK P2Document2 pagesOL Maths - MR Ambessi PRE MOCK P2Jonas OkaleNo ratings yet

- Arithmetic SequenceDocument17 pagesArithmetic SequenceRogelio Canuel Jr.No ratings yet

- CRo NotesDocument31 pagesCRo Notesgrs8940No ratings yet

- Fitting Iintinstructiontins Super Light Clutch Utinit Fionr T-MAX 500 / 530 EVODocument6 pagesFitting Iintinstructiontins Super Light Clutch Utinit Fionr T-MAX 500 / 530 EVOGustavo Fleischfresser MüllerNo ratings yet