Professional Documents

Culture Documents

GasTec PSA N2 Gen Systems Presentation

Uploaded by

dj22500Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GasTec PSA N2 Gen Systems Presentation

Uploaded by

dj22500Copyright:

Available Formats

An Introduction to

Pressure Swing Adsorption (PSA)

Nitrogen Generation System

On Site Hydrogen, Oxygen & Nitrogen Gas Production Systems

Main Features

Fully skid mounted, compact

design - ships in std. 20’

container

Shop integrated and tested.

Reduced site installation time &

cost

Low energy consumption – 0.4

kWh/Nm³

Conforms to ASME & IEC std.

Design for 24/7 operation

Flow to 1,500 Nm3/hr

Purity to 99.99%

On Site Hydrogen, Oxygen & Nitrogen Gas Production Systems

Main Features

Touch screen control for ease

of operation.

Continuous purity & flow

monitoring

Data logging for ease of

monitoring

Option to fill cylinders if

required.

Option for remote monitoring if

required.

On Site Hydrogen, Oxygen & Nitrogen Gas Production Systems

Basic system schematic

Air receiver Nitrogen generator N2 receiver

N2

N2 compressor N2 cylinders

Air compressor Air dryer

Compressed air system Nitrogen Generator Module Cylinder Refilling Module (optional)

Refills standard nitrogen

cylinders at site

Eliminate truck in supply

Produce nitrogen at site

Reduce logistic cost

On Site Hydrogen, Oxygen & Nitrogen Gas Production Systems

Carbon Molecular Sieves (CMS)

Contained within each Adsorber are “carbon molecular Nitrogen

sieves” (CMS). (up to 99.99%)

The nitrogen in air is separated from oxygen using carbon

molecular sieve (see right) that has the unique of

absorbing oxygen under pressure. Once the sieve is

saturated with oxygen, the cycle is reverse and oxygen is

Oxygen is

purged into the atmosphere. adsorbed

This is a batch process. Using two towers, we are able to by the

carbon

achieve a continuous nitrogen production with purity up molecular

to 99.99% for industrial uses. sieve

For a given nitrogen generator size, the purity is inversely

proportional to nitrogen output. Lower the flow, the

higher the purity.

Compressed Air

(21% O2, 78% N2, 1% Ar)

On Site Hydrogen, Oxygen & Nitrogen Gas Production Systems

Carbon Molecular Sieves (CMS) Properties

N2 N2

N2

4.3Å

3.9Å N2

N2 3.0Å O2

3-6mm 4Å 2.8Å

O

2

Magnified O2 O2

2.2-2.3mm

O2

N2

O2

CMS contains microscopic “pores”

O2

that is just the right size to adsorb O2

O2

molecules under pressure (like a

sponge)

On Site Hydrogen, Oxygen & Nitrogen Gas Production Systems

Typical Industrial Control Panel

Touch sensitive

LCD Screen

Start / Stop Alarm buzzer

Thermal mass

Flow meter Oxygen analyser

Phase indicator Power on / off

On Site Hydrogen, Oxygen & Nitrogen Gas Production Systems

User friendly control system

“One touch” sequential start / stop of entire

system

Entire system can be started & stopped

sequentially from a single button, reducing

operator involvement.

System mimic / system operation summary

Local LCD panel provide a system mimic /

operational summary for ease of operation

Local and remote alarm and status

monitoring

The system provided local as well as remote

monitoring capabilities.

On Site Hydrogen, Oxygen & Nitrogen Gas Production Systems

User friendly control system

Nitrogen purity & flow trend graph

Provides continuous monitoring of the oxygen

content in nitrogen

Automatic purity correction

Low purity product is automatically vented to

atmosphere to prevent contamination of

downstream pipeline

Alarm indicator with data log

All alarm status is automatically logged to

provide ease of trouble shooting

Hour run base service reminder

Alerts user when service is required

On Site Hydrogen, Oxygen & Nitrogen Gas Production Systems

Typical PSA for industrial application

Cabinet Type Nitrogen Generator Skid Mounted Nitrogen Generator

On Site Hydrogen, Oxygen & Nitrogen Gas Production Systems

Typical PSA for hazardous area duty

80 Nm3/hr, 99%

400 Nm3/hr, 99.5%

On Site Hydrogen, Oxygen & Nitrogen Gas Production Systems

Contact Us:

GAS GENERATORS (MALAYSIA) SDN BHD

8, Jalan P10/21, Taman Industri Selaman

Bandar Baru Bangi, Selangor, Malaysia

Tel: ++603 - 8926 3268 Fax: 603 - 8926 3269

PT GAS GENERATORS INDONESIA

Wisma Tiara Buncit, Jl. Kemang Utara IX no 9 Blok D-12

Jakarta 12760, Indonesia.

Tel. +6221 791 80443, +6221 700 03200

Fax. +6221 791 96532

UNIVERSAL GAS GENERATORS (THAILAND) Co. Ltd.

3/3 Soi Saladaeng Road, Silom, Bangrak,

Bangkok 10500, Thailand

Tel: +66 2233 3546

Fax: +66 2235 5900

GAS GENERATORS (JAPAN) Co. Ltd.

2- Chome, 1-18 Kitayoshizu-Cho

Fukuyama, Hiroshima 720-0073, Japan

Tel +81-84-973-9302

Fax +81-84-926-3367

WWW.GASTEC.COM.MY

SALES@GASTEC.COM.MY

On Site Hydrogen, Oxygen & Nitrogen Gas Production Systems

You might also like

- Introduction To Hydrology by Warren ViessmanDocument751 pagesIntroduction To Hydrology by Warren ViessmanCharlie Chahua Vicencio100% (32)

- 30M3 PSA Medical Oxygen Plant ProposalDocument10 pages30M3 PSA Medical Oxygen Plant ProposalswopnilrNo ratings yet

- UOP Integration of Membranes For CO2 Removal Tech Paper PDFDocument15 pagesUOP Integration of Membranes For CO2 Removal Tech Paper PDFghasem_726990287No ratings yet

- The Institute of Energy's Second International Conference on COMBUSTION & EMISSIONS CONTROL: Proceedings of The Institute of Energy Conference Held in London, UK, on 4-5 December 1995From EverandThe Institute of Energy's Second International Conference on COMBUSTION & EMISSIONS CONTROL: Proceedings of The Institute of Energy Conference Held in London, UK, on 4-5 December 1995Rating: 5 out of 5 stars5/5 (1)

- RAC Question and AnsDocument5 pagesRAC Question and AnsAshif iqubalNo ratings yet

- Minor Irrigation WorksDocument420 pagesMinor Irrigation WorksRutuja BhawarNo ratings yet

- PSA-N2-Gen-FlyerDocument4 pagesPSA-N2-Gen-FlyerSevuango NzuziNo ratings yet

- Nox Emissions and Its Control: Abhishek Pundir (16105049)Document27 pagesNox Emissions and Its Control: Abhishek Pundir (16105049)SavitarNo ratings yet

- PSA PSA Nitrogen Gas Generation Nitrogen Gas Generation Systems Systems Systems SystemsDocument20 pagesPSA PSA Nitrogen Gas Generation Nitrogen Gas Generation Systems Systems Systems Systemssssf-dobojNo ratings yet

- Blunox SCRDocument8 pagesBlunox SCRSteenKahlerNo ratings yet

- Psa PDFDocument3 pagesPsa PDFUmair AhmedNo ratings yet

- Nitrogen PSA GeneratorsDocument8 pagesNitrogen PSA GeneratorsMilos Bajic100% (1)

- Denox DesoxDocument20 pagesDenox DesoxArzu AkarNo ratings yet

- Membrane Nitrogen Gas Generation Systems: Presented By: South-South-tek SystemsDocument17 pagesMembrane Nitrogen Gas Generation Systems: Presented By: South-South-tek SystemsWinda Nur'aini TwelvpatwoNo ratings yet

- MG Air Separation PlantsDocument10 pagesMG Air Separation PlantsHatem AbdelnabiNo ratings yet

- Concord Fundamentals of SCRDocument40 pagesConcord Fundamentals of SCRPhani AwakeningNo ratings yet

- MESSER Gase For Life On-Site - Gas - Production PDFDocument12 pagesMESSER Gase For Life On-Site - Gas - Production PDFnefoussiNo ratings yet

- Report On Combustion Test Gramtech, TeamDocument26 pagesReport On Combustion Test Gramtech, TeamYousufNo ratings yet

- Low Cost Nitrogen Generator Project Report SummaryDocument8 pagesLow Cost Nitrogen Generator Project Report SummarySOHEL RANA SHAHNo ratings yet

- OptimaConcept - Nitrogen Generation Membrane Systems 2009 CATDocument4 pagesOptimaConcept - Nitrogen Generation Membrane Systems 2009 CATpolysourceNo ratings yet

- B442vs2 1Document10 pagesB442vs2 1Dario BonillaNo ratings yet

- ManualDocument7 pagesManualAsri GaniNo ratings yet

- Marine Nitrogen Generators, Pres Vac Brochure IDocument16 pagesMarine Nitrogen Generators, Pres Vac Brochure Idhlinva100% (1)

- HDFO-30 Technial BookDocument20 pagesHDFO-30 Technial BookMao SequeirosNo ratings yet

- IMT PN2250 260.4Nm hCapacityNitrogenGasGeneratorDocument6 pagesIMT PN2250 260.4Nm hCapacityNitrogenGasGeneratorRitche Lim BragaisNo ratings yet

- Nitrogen & Oxygen GeneratorsDocument16 pagesNitrogen & Oxygen GeneratorsRoozbeh PNo ratings yet

- Offshore Mobile n2 Prod Unit LetterDocument2 pagesOffshore Mobile n2 Prod Unit LetterLuisNo ratings yet

- Advertisement For Incubation of TechnologyDocument4 pagesAdvertisement For Incubation of TechnologyAman AgarwalNo ratings yet

- PSA Oxygen Generator Tech-Proposal WG-STD-3 With Piston BoosterDocument17 pagesPSA Oxygen Generator Tech-Proposal WG-STD-3 With Piston BoosterSimon Alissou100% (1)

- Irjet V7i6974Document9 pagesIrjet V7i6974mohamed.saih7128No ratings yet

- Atlas Copco Nitrogen Generators Extract Nitrogen from AirDocument12 pagesAtlas Copco Nitrogen Generators Extract Nitrogen from Airhitesh bhoiNo ratings yet

- Membrane Generator PDFDocument2 pagesMembrane Generator PDFSudar MyshaNo ratings yet

- Ultrafilter Scandinavia 2018 Gas Catalogue - WebDocument5 pagesUltrafilter Scandinavia 2018 Gas Catalogue - Webdj22500No ratings yet

- New Nitrogen Generator InstallationDocument8 pagesNew Nitrogen Generator InstallationahsanvirkNo ratings yet

- Nitrogen Generators Membrane TechnologyDocument10 pagesNitrogen Generators Membrane TechnologyVenkata Krishnan Ramanujam100% (1)

- AdblueDocument6 pagesAdblueابراهيم السعيديNo ratings yet

- MidigasDocument4 pagesMidigasbogachNo ratings yet

- Selective Catalytic ReductionDocument15 pagesSelective Catalytic ReductionJuan Esteban EnriquezNo ratings yet

- Hamworthy Moss: Moss Nitrogen Generator SystemDocument4 pagesHamworthy Moss: Moss Nitrogen Generator Systemdinos19921No ratings yet

- Economic N2 Removal Hydrocarbon EngineeringDocument8 pagesEconomic N2 Removal Hydrocarbon EngineeringSergio JavierNo ratings yet

- NTFO-14 PSA Oxygen Generator (USD)Document24 pagesNTFO-14 PSA Oxygen Generator (USD)felipecastillogodoyNo ratings yet

- Oxymat High Purity N2 OPASDocument4 pagesOxymat High Purity N2 OPASddadaraNo ratings yet

- GMS Air Emission Test ReportDocument6 pagesGMS Air Emission Test ReportDyeing DyeingNo ratings yet

- WDG 1200/INSITU and WDG 1210/INSITU: Flue Gas Oxygen Analyzers With Modbus CommunicationDocument2 pagesWDG 1200/INSITU and WDG 1210/INSITU: Flue Gas Oxygen Analyzers With Modbus Communicationashis chatterjeeNo ratings yet

- BHCS38717 PanametricsXMO2 - SmartOxygenAnalyzer - R7Document7 pagesBHCS38717 PanametricsXMO2 - SmartOxygenAnalyzer - R7Engenharia03No ratings yet

- 5B2. Nox Reduction Technology: Environmental Protection Technologies (Flue Gas Treatment and Gas Cleaning Technologies)Document2 pages5B2. Nox Reduction Technology: Environmental Protection Technologies (Flue Gas Treatment and Gas Cleaning Technologies)Hussein AlyahriNo ratings yet

- CO2 Stack Gas Recovery SystemsDocument4 pagesCO2 Stack Gas Recovery SystemsRodrigo Lagos EscobarNo ratings yet

- Revised Presentation On Oxygen PlantDocument39 pagesRevised Presentation On Oxygen Plantrajib ranjan panda100% (1)

- Neuman & Esser: CO - CompressorsDocument6 pagesNeuman & Esser: CO - CompressorsHariri Dwi KusumaNo ratings yet

- Gas Analyzers 21C2 E 0005cDocument20 pagesGas Analyzers 21C2 E 0005cmohammadgouseNo ratings yet

- NOx Reduction TA Study Feb2010Document70 pagesNOx Reduction TA Study Feb2010naikNo ratings yet

- Catalogue IMT-PN ENDocument2 pagesCatalogue IMT-PN ENWahyu Ramadhani KustiabudiNo ratings yet

- Nitrogen Generators Nitrogen On Wall: Series: NOW CP-211Document2 pagesNitrogen Generators Nitrogen On Wall: Series: NOW CP-211Rajendra LabadeNo ratings yet

- Kurs Zavarivanja Ch-1-2Document9 pagesKurs Zavarivanja Ch-1-2Ivan FemicNo ratings yet

- Xmo 2Document4 pagesXmo 2dante224No ratings yet

- CO2 Stack Gas Recovery SystemsDocument4 pagesCO2 Stack Gas Recovery SystemsrelojucaNo ratings yet

- 06.01 Thermal and Catalytic Conversion NOx 07-12-2020Document27 pages06.01 Thermal and Catalytic Conversion NOx 07-12-2020Abdelhadi BentouamiNo ratings yet

- Uhde GMBHDocument18 pagesUhde GMBHonejako12100% (1)

- Engine EmissionDocument11 pagesEngine EmissionOsama AL HawiNo ratings yet

- Folder Glasstec EDocument8 pagesFolder Glasstec EHardikNo ratings yet

- Nitrogen: Experis® Ultra-High Purity Gases Technical SpecificationDocument2 pagesNitrogen: Experis® Ultra-High Purity Gases Technical Specificationgauravtech1988No ratings yet

- Synthesis and Applications of Semiconductor NanostructuresFrom EverandSynthesis and Applications of Semiconductor NanostructuresNo ratings yet

- Process Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationFrom EverandProcess Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationAthanasios I. PapadopoulosNo ratings yet

- Forged Fittings - SNPDocument40 pagesForged Fittings - SNPdj22500No ratings yet

- 2-In-1 Catalog (2013) - NufloDocument20 pages2-In-1 Catalog (2013) - Nuflodj22500No ratings yet

- Presentation-For Pioneer (20230518)Document52 pagesPresentation-For Pioneer (20230518)dj22500No ratings yet

- Nitrogen Blanketing For ShipsDocument2 pagesNitrogen Blanketing For Shipsdj22500No ratings yet

- Nbs Bfy ValveDocument72 pagesNbs Bfy Valvedj22500No ratings yet

- Intergraph ICAS DocumentDocument102 pagesIntergraph ICAS Documentdj22500No ratings yet

- Technical Data Handbook for Butt Weld Pipe Fittings and Forged Steel FittingsDocument244 pagesTechnical Data Handbook for Butt Weld Pipe Fittings and Forged Steel Fittingschairul anwarNo ratings yet

- STC FittingDocument32 pagesSTC Fittingdj22500No ratings yet

- Activated Carbon Adsorber (L1000V L8200V) BEKODocument48 pagesActivated Carbon Adsorber (L1000V L8200V) BEKOdj22500No ratings yet

- 45 14550DEnglishForWebDocument12 pages45 14550DEnglishForWebravi308No ratings yet

- Vpsa O2 Systems Brochure ML IND0032Document8 pagesVpsa O2 Systems Brochure ML IND0032kalaiNo ratings yet

- AirSep As-W DatasheetDocument2 pagesAirSep As-W Datasheetdj22500No ratings yet

- As P Cut Sheet ML IND0018 RevCDocument2 pagesAs P Cut Sheet ML IND0018 RevCmeloszNo ratings yet

- OXYPLUS Tech Catalog-MedicalDocument16 pagesOXYPLUS Tech Catalog-Medicaldj22500No ratings yet

- Flanges: KPC CorporationDocument6 pagesFlanges: KPC Corporationdj22500No ratings yet

- ASTM MATERIAL COMPARISON TABLEDocument10 pagesASTM MATERIAL COMPARISON TABLEMardeOpamenNo ratings yet

- Chemical Resistance Charts: WarningDocument9 pagesChemical Resistance Charts: WarningMarllory LoNo ratings yet

- Flow Considerations in Industrial Silencer DesignDocument8 pagesFlow Considerations in Industrial Silencer DesignktsnlNo ratings yet

- Manitou 2000 SuspensionTuning ManualDocument16 pagesManitou 2000 SuspensionTuning Manualdj22500No ratings yet

- ONF Reference Design SEBA 032919Document54 pagesONF Reference Design SEBA 032919anhpfievNo ratings yet

- MTB CommissairesDocument34 pagesMTB CommissairesubcbgNo ratings yet

- 07TK OM EnglishDocument41 pages07TK OM EnglishSocrates KontosNo ratings yet

- Industrial Noise Control ManualDocument357 pagesIndustrial Noise Control Manualdj22500No ratings yet

- Glaunach Silencer HandbookDocument67 pagesGlaunach Silencer Handbookriff100% (4)

- Pressure Loss Calculation Procedures For High Speed Gas FlowDocument153 pagesPressure Loss Calculation Procedures For High Speed Gas Flowmariusandrei77No ratings yet

- Vent Silencer Application Guide Confidential ReportDocument44 pagesVent Silencer Application Guide Confidential Reportdj22500100% (1)

- Vent Sys E-06Document28 pagesVent Sys E-06عمرو دراغمةNo ratings yet

- Gas Injection Technology.Document49 pagesGas Injection Technology.Irfan AliNo ratings yet

- New Understanding Compressor CapacityDocument7 pagesNew Understanding Compressor CapacityJose SanchezNo ratings yet

- Water Resources Engineering - Section 1: A. B. C. D. EDocument15 pagesWater Resources Engineering - Section 1: A. B. C. D. EajaydevmalikNo ratings yet

- Assessment of Domestic Water Supply at Barangay Libertad Municipalty of QuezonDocument18 pagesAssessment of Domestic Water Supply at Barangay Libertad Municipalty of QuezonEmanoAce100% (1)

- A307 Ius Uv DS 1201Document2 pagesA307 Ius Uv DS 1201smartravi222No ratings yet

- High Pressure Boiler Water TreatmentDocument90 pagesHigh Pressure Boiler Water Treatmentak_thimiri100% (1)

- Flujo Multifasico 4.4Document14 pagesFlujo Multifasico 4.4Ramses SuárezNo ratings yet

- Vysotsk CryogasDocument125 pagesVysotsk Cryogasloercher01No ratings yet

- Sources of WaterDocument49 pagesSources of WaterGaya GayodanNo ratings yet

- Ideal Gas, Processes PresDocument36 pagesIdeal Gas, Processes PresNicah Dela Viña BuhiaNo ratings yet

- Oil and Gas Well Rate Estimation by Choke Formula: Semi-Analytical ApproachDocument12 pagesOil and Gas Well Rate Estimation by Choke Formula: Semi-Analytical ApproachAarthy RamanNo ratings yet

- Catalogo Inyectores de QuimicoDocument6 pagesCatalogo Inyectores de QuimicoOscar Mauricio Santos MNo ratings yet

- 1.0-Introduction: Technical Proposal R.O. SystemDocument13 pages1.0-Introduction: Technical Proposal R.O. SystemZarkKhanNo ratings yet

- Fluid Mechanics Fundamentals Chapter 2 Pressure VariationDocument90 pagesFluid Mechanics Fundamentals Chapter 2 Pressure VariationVincentius VickyNo ratings yet

- Water & Wastewater Engineering Head LossDocument105 pagesWater & Wastewater Engineering Head LossMA. MATEA MARTINEZ100% (3)

- Business Initiatives and Opportunities in India in The Water SectorDocument27 pagesBusiness Initiatives and Opportunities in India in The Water SectorINDOPURE WATER SOLUTIONSNo ratings yet

- Experiment No: 01 Experiment Name: Determination of GPM, Heating Value & Wobbe Number of Chattak Gas ObjectiveDocument4 pagesExperiment No: 01 Experiment Name: Determination of GPM, Heating Value & Wobbe Number of Chattak Gas ObjectiveShimu AnwarNo ratings yet

- 1ST STAGE Hand Over Blind ChecklistDocument5 pages1ST STAGE Hand Over Blind ChecklistMuhammad Abdul RaufNo ratings yet

- UntitledDocument1 pageUntitledJehana NaolNo ratings yet

- TBL 31 B HA en DC 004 A Safety Valve Design CalculationDocument37 pagesTBL 31 B HA en DC 004 A Safety Valve Design CalculationDangolNo ratings yet

- Fresh water consumption and circulation in pulp mill processesDocument3 pagesFresh water consumption and circulation in pulp mill processesSrinivasa Rao VenkumahanthiNo ratings yet

- Me206 QPDocument2 pagesMe206 QPMohammed Jihad PmNo ratings yet

- Performance of Evaporators: Factors Affecting On Boiling Points Temp. in EvaporatorsDocument4 pagesPerformance of Evaporators: Factors Affecting On Boiling Points Temp. in EvaporatorsSerena SerenaNo ratings yet

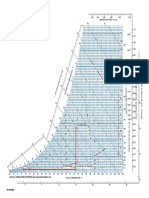

- State Point & Process Report: Psychrometric Chart Psychrometric ChartDocument1 pageState Point & Process Report: Psychrometric Chart Psychrometric ChartLee ChorneyNo ratings yet

- 6 - Reaction Force in Pelton TurbinesDocument8 pages6 - Reaction Force in Pelton TurbinesManolis RogakisNo ratings yet

- QDocument21 pagesQtonytizzleNo ratings yet

- Flowmeter GuideDocument6 pagesFlowmeter GuidevuongNo ratings yet

- Lvgo Water Cooler Data Sheet E-0107Document6 pagesLvgo Water Cooler Data Sheet E-0107mohsen ranjbarNo ratings yet

- Thermophysical Properties of Refrigerants 20.11Document1 pageThermophysical Properties of Refrigerants 20.11Gvbo rA9No ratings yet