Professional Documents

Culture Documents

28th Dec'23 - Crude Column Overhead Line Drop Wise Naphtha Leak Observed in CDU-1

28th Dec'23 - Crude Column Overhead Line Drop Wise Naphtha Leak Observed in CDU-1

Uploaded by

Sunil kumarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

28th Dec'23 - Crude Column Overhead Line Drop Wise Naphtha Leak Observed in CDU-1

28th Dec'23 - Crude Column Overhead Line Drop Wise Naphtha Leak Observed in CDU-1

Uploaded by

Sunil kumarCopyright:

Available Formats

LFI No.

:LFI20210548

LEARNING FROM INCIDENT

During Field round, drop wise Naphtha leak observed from C05 Column OVHD line

F

I

Title of incident: N

Crude Column Overhead line drop wise naphtha leak observed in CDU-1 A

Incident No: IM2021018358 Date: 11th Jan 21 L

Targeted Recipients: O&M and Support teams Risk Rating: Low

What happened:

On 11th Jan 2021, at 09:00 Hrs. leak was reported from 42 Inch overhead piping. The subject

piping comes out horizontally from top of Crude column and after two elbows, becomes vertical

until the third elbow. Piping downstream of third elbow is horizontal, going into Crude column

overhead condensers S48A/B. Leak was in the vertical section of the piping 2 meters above the

3rd elbow. Naphtha was found dripping through the insulation on this 42 Inch piping. The leak

location was at a height of approx. 48 meters from the ground level.

The leak was temporarily arrested using a cold compound and shutdown of the unit was avoided.

Later on a metal sleeve was welded over the leak location.

Why it happened

Leak in the Crude column overhead line is due to internal HCL dew point corrosion.

Even though Dew point monitoring is a part of IOW, existing Dew point calculations did not capture

the effects other critical parameters like Sulfates and Amines which are likely to elevate dew point

temperatures and cause condensation.

ACHIEVE GOAL ZERO DTA-SAFETY

RIL CONFIDENTIAL Date : 26/05/2021

LFI No. :LFI20210548

LEARNING FROM INCIDENT

During Field round, drop wise Naphtha leak observed from C05 Column OVHD line

F

Inherent weld defect aggravated corrosion in the immediate vicinity of the weld due to eddy’s at

I

the ID leading to localized wall loss which ultimately resulted into a leak. N

Strategic thickness measurements at the accessible locations on the vertical section were found

satisfactory and so corrosion was not envisaged in the 42 Inch vertical piping 20meters away from A

the Column Top. As a result, periodic complete scanning of the vertical section of overhead piping

was not included in the inspection strategy.

L

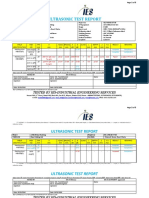

Photographs:

Radiograph of weld indicating leak locations

Thickness profile of vertical section of overhead piping

ACHIEVE GOAL ZERO DTA-SAFETY

RIL CONFIDENTIAL Date : 26/05/2021

LFI No. :LFI20210548

LEARNING FROM INCIDENT

During Field round, drop wise Naphtha leak observed from C05 Column OVHD line

F

I

Similar incidents N

Similar leaks have been observed in the vertical section of overhead piping in DTA & SEZ CDU A

trains.

L

Lessons learnt

Delta dew point calculations shall be dynamic and shall capture effects of sulphates and amines.

Any changes in these ingredients can disturb/elevate the dew point temperature in the overhead

circuit which can promote or accelerate corrosion.

Inspection strategy for overhead piping shall cover thorough inspection (volumetric) of complete

line in place of strategic or accessible locations.

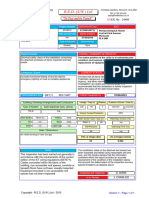

IMPACTED PSM ELEMENT IMPACTED OD IMPACTED OMS ELEMENTS

ELEMENT

Process Technology Procedures 5.3 Asset Operations

Mechanical Integrity 5.4 Inspection & Maintenance

Quality Assurance 5.2 Design & Construction

In case of any further clarification contact to undersign:

Name: Sujal Surendran

Mail ID: sujal.surendran@ril.com

ACHIEVE GOAL ZERO DTA-SAFETY

RIL CONFIDENTIAL Date : 26/05/2021

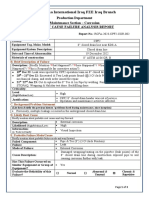

LFI No. :LFI20210548

LEARNING FROM INCIDENT

During Field round, drop wise Naphtha leak observed from C05 Column OVHD line

F

Sr.No. 1 What went wrong Existing Dew point monitored only for Column Top

I

Delta dew point calculations shall be dynamic and shall capture effects of

sulphates and amines. Any changes in these ingredients can disturb/

N

Learning from incident

elevate the dew point temperature in the overhead circuit which can

promote or accelerate corrosion.

A

Recommendation Type Technology L

Re-visit existing dew point calculations and implement necessary changes

Recommendation to current monitoring and sampling frequency to capture the dips in delta

dew point.

Sr.No. 2 What went wrong Localized Corrosion Observed at few locations

Inspection strategy for overhead piping shall cover thorough inspection

Learning from incident

(volumetric) of complete line in place of strategic or accessible locations.

Recommendation Type EAM

Comprehensive inspection of overhead piping in Crude units shall be

carried out. For on-stream inspection, grid thickness scan with conventional

UT shall be done or explore feasibility of high temperature LRUT (Long

Recommendation

Range Ultrasonic Testing). Turnaround inspection strategy for crude column

overhead lines shall include LRUT for identifying thickness loss and

carrying out preventive repairs.

RIL CONFIDENTIAL Date : 26/05/2021

You might also like

- Ready For Telecom Installation (Rfti) Inspection Checklist: Participants Name Position Contact No. CompanyDocument15 pagesReady For Telecom Installation (Rfti) Inspection Checklist: Participants Name Position Contact No. Companyjohn helyNo ratings yet

- Rolls Royce TT Thrusters - EAL LubricantsDocument2 pagesRolls Royce TT Thrusters - EAL Lubricantsjohn smithNo ratings yet

- 2020 07 18 Transformer Bushing FailuresDocument34 pages2020 07 18 Transformer Bushing FailuresPradeep SinghNo ratings yet

- Chariot Cavalier ManualDocument21 pagesChariot Cavalier ManualRandyNo ratings yet

- 23rd Mar'23 - Plant Air OSBL Header Leak PDFDocument4 pages23rd Mar'23 - Plant Air OSBL Header Leak PDFSunil kumarNo ratings yet

- RCFA-2022-CPF2 - COR-007-Pneumatic Water Supply Skid SK-24150's Pump Inlet Line 1'' Drain Line (04-10-22)Document2 pagesRCFA-2022-CPF2 - COR-007-Pneumatic Water Supply Skid SK-24150's Pump Inlet Line 1'' Drain Line (04-10-22)Vignesh PanchabakesanNo ratings yet

- Welding Reports 29-OCT-2022Document4 pagesWelding Reports 29-OCT-2022SalesNo ratings yet

- Sel-411l - Line DifferentialDocument25 pagesSel-411l - Line Differentialm khNo ratings yet

- Generic EICRDocument6 pagesGeneric EICRKuljinder VirdiNo ratings yet

- LegendDocument6 pagesLegendDheska AgungwNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- G69173-D1001-Y965 - Protocolo SAT VFDs Sinamics G120 - REV1Document4 pagesG69173-D1001-Y965 - Protocolo SAT VFDs Sinamics G120 - REV1Adriana UstarizNo ratings yet

- H02 Duobias Relay Report 87TDocument4 pagesH02 Duobias Relay Report 87TKalimuthuNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Site 05Document2 pagesSite 05Andy LeakNo ratings yet

- Ultrasonic Test Report: Tested by Ies-Industrial Engineering ServicesDocument3 pagesUltrasonic Test Report: Tested by Ies-Industrial Engineering ServicesMD Shadikul Huq ShezanNo ratings yet

- RCFA-2023-CPF2-COR-002-8'' CD Leak Near EDS-A (12-02-23)Document3 pagesRCFA-2023-CPF2-COR-002-8'' CD Leak Near EDS-A (12-02-23)Vignesh PanchabakesanNo ratings yet

- Sel-411l - Line Distance DifferentialDocument38 pagesSel-411l - Line Distance DifferentialAnielaNo ratings yet

- Sel-411l - Line DifferentialDocument21 pagesSel-411l - Line DifferentialRatheesh KumarNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: LINE DIFF & DIST. PROT. - SEL-411LDocument38 pagesCommissioning Service Department Commissioning Standard Test Formats Description: LINE DIFF & DIST. PROT. - SEL-411LGANESH KNo ratings yet

- LegendDocument6 pagesLegendDheska AgungwNo ratings yet

- LegendDocument6 pagesLegendDheska AgungwNo ratings yet

- Thermowell Calculation Guide V1.3Document19 pagesThermowell Calculation Guide V1.3Hunnymijie NorNo ratings yet

- Thermowell Calculation Guide V1.3Document19 pagesThermowell Calculation Guide V1.3jerrybsNo ratings yet

- Site 39Document2 pagesSite 39Andy LeakNo ratings yet

- Site 34Document2 pagesSite 34Andy LeakNo ratings yet

- 20agn22191410pp259 - 12-Ac123-67-Cw-3034-VDocument3 pages20agn22191410pp259 - 12-Ac123-67-Cw-3034-VDheska AgungwNo ratings yet

- EICR PennycomequickDocument6 pagesEICR PennycomequickTAJUDEEN AZEEZNo ratings yet

- K15 - 11kV BS-1 - F25 PDFDocument7 pagesK15 - 11kV BS-1 - F25 PDFmadhavanNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Cro DC 01Document22 pagesCro DC 01فايز الحارثيNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- TR-1 VPS-2 Rev0 12.5.2019Document3 pagesTR-1 VPS-2 Rev0 12.5.2019Ryuzo GotoNo ratings yet

- 11RCFA-CPF2-HP Gas CompBDocument5 pages11RCFA-CPF2-HP Gas CompBJinlong SuNo ratings yet

- PowerShot A95Document21 pagesPowerShot A95silictronicNo ratings yet

- Ptneg0032 - Ns-Ntg20-E94 - Rfti Inspection Checklist - 06152022Document17 pagesPtneg0032 - Ns-Ntg20-E94 - Rfti Inspection Checklist - 06152022john helyNo ratings yet

- VW 276 - Action PlanDocument9 pagesVW 276 - Action PlanbenindalsiNo ratings yet

- POF 301 ILI Pipeline Questionnaire - Nov 2021Document7 pagesPOF 301 ILI Pipeline Questionnaire - Nov 2021Dheeraj Chowdary DhanekulaNo ratings yet

- غرف القفل داخل موقع الخزانات 25Document4 pagesغرف القفل داخل موقع الخزانات 25Mohamed AliNo ratings yet

- Sample Transformer Life Assessment SheetDocument10 pagesSample Transformer Life Assessment SheetMuhammed Zubair NNo ratings yet

- Traceability ReportDocument4 pagesTraceability ReportSalesNo ratings yet

- Condensate Tank - 0220-TB-001BDocument3 pagesCondensate Tank - 0220-TB-001BOsama MohamedNo ratings yet

- Site 43Document2 pagesSite 43Andy LeakNo ratings yet

- SitehandoverDocument2 pagesSitehandoverCity Creek ConstructionNo ratings yet

- Non Destructive Testing: As Recieve Final Solvent Cleaning Others Black Ink Fluorescent RepairDocument3 pagesNon Destructive Testing: As Recieve Final Solvent Cleaning Others Black Ink Fluorescent RepairAkhmad RamdaniNo ratings yet

- Naf-2021-Fsr-793 X03Document3 pagesNaf-2021-Fsr-793 X03Wissem AmaraNo ratings yet

- BPF-V-270 Test Separator-Cm-Pvir-Xxxxx-20Document32 pagesBPF-V-270 Test Separator-Cm-Pvir-Xxxxx-20Agung Prastyo WibowoNo ratings yet

- 4197 Emsco 602 DWR SignedDocument11 pages4197 Emsco 602 DWR SignedMohammed Ali YoussefNo ratings yet

- Advanced Generator Ground Fault Protections: A Revisit With New InformationDocument52 pagesAdvanced Generator Ground Fault Protections: A Revisit With New InformationMariano Salomon PaniaguaNo ratings yet

- MicomP546 AcceptanceDocument26 pagesMicomP546 AcceptanceHaythem Mohamed AliNo ratings yet

- ARGUS ReportDocument22 pagesARGUS ReportNguyễn Tường MinhNo ratings yet

- F 04 SitehandoverDocument2 pagesF 04 SitehandoverZeshan HaydarNo ratings yet

- SEL 351 RelayDocument7 pagesSEL 351 RelayMohammed shamaaNo ratings yet

- Rfi OkiDocument1 pageRfi Okisafetyofficer752No ratings yet

- Updated Cable Schedule (FF (12-04-17)Document58 pagesUpdated Cable Schedule (FF (12-04-17)josejohn1No ratings yet

- Electronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionFrom EverandElectronics for Technicians: The Commonwealth and International Library: Electrical Engineering DivisionRating: 5 out of 5 stars5/5 (1)

- Train TicketDocument2 pagesTrain TicketSunil kumarNo ratings yet

- 30th Dec'23 - Finger Injury To A TechnicianDocument1 page30th Dec'23 - Finger Injury To A TechnicianSunil kumarNo ratings yet

- HAZOP Study and Safety Layers of Protection Analysis in Delayed Coker UnitDocument26 pagesHAZOP Study and Safety Layers of Protection Analysis in Delayed Coker UnitIskandar ZulkarnainNo ratings yet

- Syllabus For CBT For The Post of Field Engineer (Environment)Document8 pagesSyllabus For CBT For The Post of Field Engineer (Environment)Sunil kumarNo ratings yet

- 17 Apr 2018 145049667RK72FRU1ProcdescriptionPRFCCDocument5 pages17 Apr 2018 145049667RK72FRU1ProcdescriptionPRFCCSunil kumarNo ratings yet

- Notice For Extension of Schedule Advertisement No. C-HR (TA&CP) ADVT. 2023-5Document1 pageNotice For Extension of Schedule Advertisement No. C-HR (TA&CP) ADVT. 2023-5Sunil kumarNo ratings yet

- 1375 PDFDocument6 pages1375 PDFSunil kumarNo ratings yet

- 23rd Mar'23 - Plant Air OSBL Header Leak PDFDocument4 pages23rd Mar'23 - Plant Air OSBL Header Leak PDFSunil kumarNo ratings yet

- 25th Mar'23 - Head Injury While Arranging Material in File CabinetDocument2 pages25th Mar'23 - Head Injury While Arranging Material in File CabinetSunil kumarNo ratings yet

- Flat Slab Equivalent Frame MethodDocument3 pagesFlat Slab Equivalent Frame MethodNp Pw100% (1)

- Compressors For Industry: Tailored To Your RequirementsDocument40 pagesCompressors For Industry: Tailored To Your Requirementsst_calvoNo ratings yet

- Cowan Dynamics - Dart ValveDocument8 pagesCowan Dynamics - Dart ValveTylerNo ratings yet

- The Bearing Faults Detection Methods For ElectricaDocument54 pagesThe Bearing Faults Detection Methods For ElectricaMohamad MohamadNo ratings yet

- RDE10.1 Datasheet enDocument8 pagesRDE10.1 Datasheet enReparatii CncNo ratings yet

- 2021 LWRC W40 007Document1 page2021 LWRC W40 007Jay ar TenorioNo ratings yet

- Group 4 - Ideal Gas Vs Real Gas Experiment PDFDocument5 pagesGroup 4 - Ideal Gas Vs Real Gas Experiment PDFHumaira NabilaNo ratings yet

- 17 - CLI1 - Float & Chord Level IndicatorDocument1 page17 - CLI1 - Float & Chord Level IndicatoryogeshroshanNo ratings yet

- 2005 Failure Analyis of M16 BoltDocument9 pages2005 Failure Analyis of M16 BoltCharles PowellNo ratings yet

- PL-2651 (PLSLR-10-900) Miami Int'l TradersDocument40 pagesPL-2651 (PLSLR-10-900) Miami Int'l TradersDavid NahNo ratings yet

- ChE204 20181HWIIDocument1 pageChE204 20181HWIIGG MMNo ratings yet

- Assignment 2Document2 pagesAssignment 2Bhimani HirenNo ratings yet

- Air Diffusers: General Technical DescriptionDocument5 pagesAir Diffusers: General Technical DescriptionJaponec PicturesNo ratings yet

- Spoljne Resetke - TPI 03 PZ - ENDocument6 pagesSpoljne Resetke - TPI 03 PZ - ENKundzoNo ratings yet

- Method Statement Hot InsulationDocument14 pagesMethod Statement Hot InsulationSaleem AkhtarNo ratings yet

- As Applied Unit 7 Kinematics 1 (Constant Acceleration) QPDocument2 pagesAs Applied Unit 7 Kinematics 1 (Constant Acceleration) QPKelvinNo ratings yet

- Droppper PopperDocument5 pagesDroppper Popperapi-302421116No ratings yet

- 1 s2.0 S0360544218323739 MainDocument12 pages1 s2.0 S0360544218323739 MainAltaccount KıvançNo ratings yet

- IMTE Register NEWDocument11 pagesIMTE Register NEWsumitNo ratings yet

- Machine CapabilityDocument1 pageMachine CapabilityAnurag SrivastavaNo ratings yet

- Esquema Hidraulico - 320D2 - Uenr3603Document11 pagesEsquema Hidraulico - 320D2 - Uenr3603Oseas BimNo ratings yet

- Vav - 1Document10 pagesVav - 1perezismaelNo ratings yet

- Product Documentation CamFFU Compact SolutionDocument1 pageProduct Documentation CamFFU Compact SolutionJeghiNo ratings yet

- Grundfos Submersible JOCKEYDocument18 pagesGrundfos Submersible JOCKEYdanilolabreNo ratings yet

- Analogy Between The Electromagnetic and Hydrodynamic Equations - Application To TurbulenceDocument60 pagesAnalogy Between The Electromagnetic and Hydrodynamic Equations - Application To Turbulencesunil481No ratings yet

- Lagrangian MechanicsDocument13 pagesLagrangian MechanicsAlda Novita SariNo ratings yet

- Venturimeter and Orifice MeterDocument5 pagesVenturimeter and Orifice MeterVrushiket Patil100% (1)

- Design and Comparison of Mufflers Having Different Arrangements For Diesel EngineDocument8 pagesDesign and Comparison of Mufflers Having Different Arrangements For Diesel EngineWaruna PasanNo ratings yet