Professional Documents

Culture Documents

Aron Valve

Uploaded by

networkhydraulicsukOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aron Valve

Uploaded by

networkhydraulicsukCopyright:

Available Formats

DIRECTIONAL CONTROL VALVES CETOP 3/NG6

INTRODUCTION

The ARON directional control valves NG6 are designed for subplate mounting with an

1 interface in accordance with UNI ISO 4401 - 03 - 02 - 0 - 94 standard (ex CETOP R 35 H

4.2-4-03), and can be used in all fields on account of their high flow rate and pressure capaci-

ties combined with compact overall dimensions.

The use of solenoids with wet armatures allows a very practical, safe construction completely

CETOP 3/NG06 dispensing with dynamic seals; the solenoid tube is screwed directly onto the valve chest whilst

the coil is kept in position by means of a lock nut.

STANDARD SPOOLS CH. I PAGE 10

AD.3.E... CH. I PAGE 11 The special, precise construction of the ports and the improvement of the spools enables

relatively high flow rates to be accommodated with a minimal pressure drop (Δp).

AD.3.E...J* CH. I PAGE 12 The operation of the directional valves may be electrical, pneumatic, oleodynamic, mechani-

AD.3.V... CH. I PAGE 13 cal or lever.

AD.3.L... CH. I PAGE 14 The centre position is obtained by means of calibrated length springs which reposition the

OTHER OPERATOR CH. I PAGE 15 spool in the centre or end of travel position once the action of the impulse is over.

AD.3.P... CH. I PAGE 16

The solenoids are constructed with a protection class of IP66 to DIN 40050 standards and

AD.3.O... CH. I PAGE 16 are available in either AC or DC form in different voltage and frequencies.

AD.3.M... CH. I PAGE 17 The new type DC coil "D15", of cause their high performance, allows to increasing the limits

AD.3.D... CH. I PAGE 17 of use respect to last series.

All types of electrical control are available, on request, with different types of manual emer-

"D15" DC COILS CH. I PAGE 18

gency controls.

"B14" AC SOLENOIDS CH. I PAGE 18

The solenoid coils are normally arranged for DIN 43650 ISO 4400 type connectors; is available

STANDARD CONNECTORS CH. I PAGE 19

on request these variant coils: with AMP Junior connections, with AMP junior and integrated

"LE" VARIANTS CH. I PAGE 20 diode, with Deutsch DT04-2P connections or solenoid with flying leads. Connectors with

L.V.D.T. CH. I PAGE 21 built in rectifiers or pilot lights are also available.

The valves are designed for use with DIN 51524 standard hydraulic mineral oils and it is

recommended that filters should be fitted to ensure a maximum contamination level of class

10 in accordance with NAS 1638, ß25≥75.

PRESSURE DROPS

1 2 The diagram at the side shows the pressure drop

3 curves for spools during normal usage. The fluid

used is a mineral oil with a viscosity of 46 mm2/s

4

at 40°C; the tests have been carried out at a fluid

5 temperature of 40°C. For higher flow rates than

those in the diagram, the losses will be those

Δp (bar)

6

expressed by the following formula:

Δp1 = Δp x (Q1/Q)2

where Δp will be the value for the losses for a

specific flow rate Q which can be obtained from

the diagram, Δp1 will be the value of the losses

for the flow rate Q1 that is used.

Q (l/min)

Spool Connections Spool Connections

type P→A P→B A→T B→T P→T type P→A P→B A→T B→T P→T

01 5 5 5 5 11 4 6

02 6 6 6 6 5 22 4 6

03 5 5 6 6 12 5 6

04 1 1 1 1 4 13 5 6 6

44 1 1 1 1 2 14 2 1 1 1 2

05 5 5 5 5 28 1 2 1 1 2

06 5 5 6 5 19 4 4 6 6

66 5 5 5 6 16 5 5 4 4

07 4 6 17 - 21 1 3

08 6 6 18 5 5

09 5 5 20 4 4 4 4

10 5 5 5 5 15 4 4 5 5

Curve No. Curve No.

File: AD3E$$3_E I• 8 16/2011/e

DIRECTIONAL CONTROL VALVES CETOP 3/NG6

ORDERING CODE TAB.2 - VOLTAGE TAB.1- MOUNTING

STANDARD

AD

3

Directional valve

CETOP 3/NG6

A

B

AC SOLENOID B14

24V/50-60 Hz

48V/50-60 Hz

C 1

J 115V/50Hz - 120V/60Hz

D

Y 230V/50Hz - 240V/60Hz

E Type of operator K AC without coils

For other operator see Other voltages available on request. E

next pages

DC COIL D15 (30W)

L 12V F

** Spool see page I•10 115Vac/50Hz

M 24V 120Vac/60Hz SPECIALS (WITH PRICE INCREASING)

V 28V* with rectifier

* Mounting type (table 1) N 48V* G

Z 102V* 230Vac/50Hz

* Voltage (table 2) P 110V* 240Vac/60Hz

H

X 205V* with rectifier

** Variants (table 3) W DC without coils

Voltage codes are not stamped on the plate, their are I

readable on the coils.

* Serial No.

(*) Special voltage L

3 = DC voltage ("D15" coil) • AMP Junior coils (with or without diode)

and coils with flying leads and coils type M

3 = AC voltage ("B14" solenoid)

Deutsch, are available in 12V or 24V DC

voltage only. • Mounting type D is only for valves

with detent

• The pastic type coil (RS variant) is available

in 12V, 24V, 28V or 110V DC voltage only. • In case of mounting D with detent

a maximum supply time of 2 sec is

needed (only for AC coils).

TAB.3 - VARIANTS (*)

VARIANT CODE ♦ PAGE

No variant (without connectors) S1

Viton SV

Emergency control lever for directional control valves type ADC3 and AD3E LF I•20

Emergency button ES I•18

Rotary emergency button P2 I•18

Rotary emergency button (180°) R5 I•18

Preset for microswitch (E/F/G/H mounting only) (see below note ◊) MS ♦ I•11- I•14

Cable gland "PG 11" C1 I•19

Emergency button+ Viton VU

5 micron clearance SQ ♦

Spool movement speed control (only VDC) with ø 0.3 mm orifice 3S ♦ I•12

Spool movement speed control (only VDC) with ø 0.4 mm orifice JS ♦ I•12

Spool movement speed control (only VDC) with ø 0.5 mm orifice 5S ♦ I•12

Spool movement speed control (only VDC) with ø 0.6 mm orifice 6S ♦ I•12

AMP Junior coil - for12V or 24V DC voltage only AJ I•18

AMP Junior coil and integrated diode - for12V or 24V DC voltage only AD I•18

Coil with flying leads (175 mm) - for12V or 24V DC voltage only SL I•18

D15 plastic type coil - for12V, 24V, 28V or 110V DC voltage only RS

Deutsch DT04-2P coil - for12V or 24V DC voltage only CZ I•18

Other variants relate to a special design

◊ = Maximum counter-pressure on T port: 8 bar

♦ = Variant codes stamped on the plate

(*) All variants are considered without connectors. The connectors must be order separately.

See Ch. I Page 19

File: AD3E$$3_E I• 9 16/2011/e

TWO SOLENOIDS, SPRING CENTRED “C” MOUNTING DIRECTIONAL CONTROL VALVES

Spool

type

Covering Transient position

STANDARD SPOOLS CETOP 3/NG6

01 +

NOTE

02 - (*) Spool with price increasing

1 03 + • With spools 15 / 16 / 17 only mounting E / F are possible

• 16 / 19 / 20 / 21 spool not planned for AD.3.E...J*

04* -

• For lever operated the spools used are different.

44* - Available spools for this kind of valve are: 01 / 02 / 03 / 04 / 05 / 06 / 66 / 07

22 / 13 / 15 / 16 / 17

05 +

66 + ONE SOLENOID, SIDE B “F” MOUNTING

Spool Covering Transient position

06 + type

07* + 01 +

08* + 02 -

09* + 03 +

10* + 04* -

22* + 44* -

11* + 05 +

12* + 66 +

13* + 06 +

14* - 08* +

28* - 09* +

10* +

22* +

ONE SOLENOID, SIDE A “E” MOUNTING

Spool Covering Transient position 12* +

type

13* +

01 +

07* +

02 -

15 -

03 +

16 +

04* -

17 +

44* -

14* -

05 +

28* -

66 +

06 +

08* +

TWO SOLENOIDS “D” MOUNTING

10* + Spool Covering Transient position

type

12* +

19* -

15 -

20* +

16 +

21* +

17 +

14* -

28* -

File: TCRS003_E I • 10 05/2000/e

AD.3.E... DIRECTIONAL CONTROL VALVES SOLENOID OPERATED CETOP 3/NG6

Max. pressure port P/A/B 350 bar CALIBRATED

Max. pressure port T (for DC) see note (*) 250 bar DIAPHRAGMS (**)

Max. pressure port T (for AC) see note (*) 160 bar

Max. flow

Max. excitation frequency

Duty cycle

60 l/min

3 Hz

100% ED

ø (mm)

blind

0.5

Code

M52.05.0023/4

M52.05.0023/1

1

Fluid viscosity 10 ÷ 500 mm2/s 0.6 M52.05.0023/6

Fluid temperature -25°C ÷ 75°C 0.7 M52.05.0023/8

Ambient temperature - 25°C ÷ 60°C 0.8 M52.05.0023

A max. counter-pressure of 8 bar at T is permitted Max. contamination level class 10 in accordance 1.0 M52.05.0023/2

for the variant with a microswitch (MS). with NAS 1638 with filter ß25 ≥75 1.2 M52.05.0023/3

Weight with one DC solenoid 1,65 Kg 1.5 M52.05.0023/7

(*) DC: Dynamic pressure allowed for Weight with two DC solenoids 2 Kg 2.0 M52.05.0023/10

2 millions of cycles. Weight with one AC solenoid 1,31 Kg 2.2 M52.05.0023/9

AC: Dynamic pressure allowed for Weight with two AC solenoids 1,72 Kg 2.5 M52.05.0023/5

350.000 of cycles. For dynamic pressure of

100 bar are allowed 1 milion cycles.

(**) For high differential pressure please

OVERALL DIMENSIONS contact our technical department.

E E

E = Manual override

MS = Microswitch

Calibrated diaphragm

MS

Fixing screws UNI 5931 M5x30

with material specifications min. 8.8

Support plane

specifications

Tightening torque 5 Nm / 0.5 Kgm

LIMITS OF USE (MOUNTING C-E-F)

The tests have been carried out with solenoids at operating temperature and a voltage 10% less than rated voltage with a fluid temperature

of 40°C. The fluid used was a mineral oil with a viscosity of 46 mm2/s at 40°C. The values in the diagram refers to tests carried out with the oil

flow in two directions simultaneously T = 2 bar (e.g.. from P to A and the same time B to T). In the case where valves 4/2 and 4/3 were used

with the flow in one direction only, the limits of use could have variations which may even be negative. Rest times: the values are indicative and

depend on following parameters: hydraulic circuit, fluid used and variations in hydraulic scales (pressure P, flow Q, temperature T). The limit of

use for AC solenoids were detected with 50 Hz power.

Direct current: Energizing 30 ÷ 50 ms. Alternating current: Energizing 8 ÷ 30 ms.

De-energizing 10 ÷ 30 ms. De-energizing 15 ÷ 55 ms.

DIRECT CURRENT SOLENOIDS (DC) ALTERNATING CURRENT SOLENOIDS (AC)

1 Spool Solenoids

3 4 5 2 6

type DC AC 320

9

8 17 12 11

01 1 9 280 16

15

02 1 9 10

7 240

03 8 10 13

3 04 6 15 200

P (bar)

16

6 4 44 1 9 160 14

17

05 3 16 11

5 120

06 - 66 5 13 13

80 12

11 - 22 4 17

14 - 28 2 12 40

2-7 15 7 14

1

0

0 10 20 30 40 50 60

16 1 11

Q (l/min) Curves

File: AD3E003_E I • 11 11/2010/e

You might also like

- IEC - Sybols (Eplan)Document53 pagesIEC - Sybols (Eplan)Urzica Andrei100% (4)

- Hillier's Fundamentals of Motor Vehicle Technology Book3Document272 pagesHillier's Fundamentals of Motor Vehicle Technology Book3Njabulo Simon Ncube90% (20)

- For Exchanger Tube Rupture PDFDocument3 pagesFor Exchanger Tube Rupture PDFNikhil DivateNo ratings yet

- Cat TransfDocument15 pagesCat Transfaliarababadi100% (1)

- Hybrid Inverter Project ReportDocument39 pagesHybrid Inverter Project ReportErole Technologies Pvt ltd Homemade Engineer100% (1)

- Pressure Drop in Air Piping SystemsDocument12 pagesPressure Drop in Air Piping SystemsDamith Buddhika Sri WimalarathnaNo ratings yet

- TB8102 Rupture Disc SizingDocument9 pagesTB8102 Rupture Disc SizingtuimeqNo ratings yet

- Edc DanfossDocument16 pagesEdc Danfosstomirueda0% (1)

- Laminar Flow Valve Sizing Made EasyDocument8 pagesLaminar Flow Valve Sizing Made Easy1940LaSalleNo ratings yet

- Basic InstrumentationDocument65 pagesBasic Instrumentationsaqib javaid100% (2)

- ADTEk - RX PDFDocument43 pagesADTEk - RX PDFedilbertos_4100% (1)

- Fi-4340c CE Manual P3PA03277-B00X6-07Document162 pagesFi-4340c CE Manual P3PA03277-B00X6-07Sherri DingerNo ratings yet

- 1 Afrl GN JF2 XB NST KTZP Ra 3 K E6 YBdc Le CM 4 Vxog DH W85 J VW Q9 Hs I7 O0 Iu MZ UPyq 1472213481Document7 pages1 Afrl GN JF2 XB NST KTZP Ra 3 K E6 YBdc Le CM 4 Vxog DH W85 J VW Q9 Hs I7 O0 Iu MZ UPyq 1472213481Roddy Razakarison lawNo ratings yet

- AD3E Brevini PDFDocument4 pagesAD3E Brevini PDFTavip Endro YuwonoNo ratings yet

- CraneNuclear USletter Apr2013 Section8 PDFDocument8 pagesCraneNuclear USletter Apr2013 Section8 PDFCircus_MaximusNo ratings yet

- Wsp32ga - 400 P 131152 e 00Document4 pagesWsp32ga - 400 P 131152 e 00Eng-Mohammed SalemNo ratings yet

- 4-2 Directional Spool Valve 4WE6DDocument2 pages4-2 Directional Spool Valve 4WE6DRaphael SasdelliNo ratings yet

- Thermo Fluids - ME 439: Arab Academy For Science, Technology and Maritime TransportationDocument24 pagesThermo Fluids - ME 439: Arab Academy For Science, Technology and Maritime TransportationFrank Masing FrancisNo ratings yet

- Rupture Disc SizingDocument9 pagesRupture Disc SizingShruti JoshiNo ratings yet

- Philips Miniwatt Battery Receiving TubesDocument75 pagesPhilips Miniwatt Battery Receiving TubesFlyForFunNo ratings yet

- XDP.5.A... / XDP.5.C ... P: Roportional Directional Valves Open LoopDocument2 pagesXDP.5.A... / XDP.5.C ... P: Roportional Directional Valves Open LoopPitupyNo ratings yet

- BYPASSDocument2 pagesBYPASSSting DâuNo ratings yet

- 4-3 Directional Spool Valve 4WE6EDocument2 pages4-3 Directional Spool Valve 4WE6ERaphael SasdelliNo ratings yet

- HL Losse in Diff Pipes-1Document13 pagesHL Losse in Diff Pipes-1Tadesse AyalewNo ratings yet

- Pipe Flow CalculationsDocument12 pagesPipe Flow CalculationsUmair KhanNo ratings yet

- Adc3001 eDocument3 pagesAdc3001 eDiego IencinellaNo ratings yet

- Model: Differential / Vacuum/ Low Pressure SwitchDocument4 pagesModel: Differential / Vacuum/ Low Pressure Switchzinstr1No ratings yet

- IFD TOC Vol2 No4final 1.5fc6a7e70036bDocument7 pagesIFD TOC Vol2 No4final 1.5fc6a7e70036bCARLOSNo ratings yet

- 4-3 Directional Spool Valve 4WE 6 HDocument2 pages4-3 Directional Spool Valve 4WE 6 HRaphael SasdelliNo ratings yet

- 2 SESSION5 Transformers ApplicationDocument3 pages2 SESSION5 Transformers ApplicationAmirul AmranNo ratings yet

- ChokeDocument8 pagesChokeMuhd EizadNo ratings yet

- WR22G o - 400 P 121120 e 00Document4 pagesWR22G o - 400 P 121120 e 00Eng-Mohammed SalemNo ratings yet

- Water Cooled Condensers 2008Document24 pagesWater Cooled Condensers 2008Christopher ThomasNo ratings yet

- 48 - 25795 - ME362 - 2020 - 1 - 2 - 1 - Lecture 11 - Fluid 1 - Flow Through Pipes - Part IDocument20 pages48 - 25795 - ME362 - 2020 - 1 - 2 - 1 - Lecture 11 - Fluid 1 - Flow Through Pipes - Part IHussien El-masryNo ratings yet

- Humidity Indicator-CircuitFig 4Document1 pageHumidity Indicator-CircuitFig 4S ANo ratings yet

- Dynamic Behavior of Closed-Loop Control SystemsDocument24 pagesDynamic Behavior of Closed-Loop Control SystemsBhowmickNo ratings yet

- Re29215 2005-09Document20 pagesRe29215 2005-09juan camilo gutierrezNo ratings yet

- Medidore de Flujo Chinmnea PAG-504 - Boiler - Combustion - Air - Flow - Measurement - UsDocument1 pageMedidore de Flujo Chinmnea PAG-504 - Boiler - Combustion - Air - Flow - Measurement - UsJuan Carlos Cahuasquí IntriagoNo ratings yet

- Válvula Limitadora Proporcional Kcg-KacgDocument14 pagesVálvula Limitadora Proporcional Kcg-KacgNíkolas BorgesNo ratings yet

- LCD Monitor Power Supply 9940Document12 pagesLCD Monitor Power Supply 9940miltonhmbddsNo ratings yet

- 3-Way Flow Control Valves: 1 DescriptionsDocument6 pages3-Way Flow Control Valves: 1 Descriptionsmuhammad taufik rahmanNo ratings yet

- MDRP G 10 - 400 P 610101 enDocument8 pagesMDRP G 10 - 400 P 610101 ennaprawa21No ratings yet

- General Radio 1650-BDocument60 pagesGeneral Radio 1650-BkrendelaNo ratings yet

- Pages From 112006967 PRV Sizing For Exchanger Tube Rupture 3Document1 pagePages From 112006967 PRV Sizing For Exchanger Tube Rupture 3Ghasem BashiriNo ratings yet

- Axial Piston Variable Pump A10VO (US-Version)Document60 pagesAxial Piston Variable Pump A10VO (US-Version)Edison YesidNo ratings yet

- Proportional 2-Way Flow Control Cartridge M22 X 1,5: Direct Operated Q 25 L/min Q 25 L/min P 350 BarDocument4 pagesProportional 2-Way Flow Control Cartridge M22 X 1,5: Direct Operated Q 25 L/min Q 25 L/min P 350 Barbiomed2083No ratings yet

- Hf-Vhf-Uhf Voltage Controlled OscillatorsDocument6 pagesHf-Vhf-Uhf Voltage Controlled OscillatorsAKISNo ratings yet

- Frictional Losses in Hydraulic Pipelines: Reynolds No. yDocument10 pagesFrictional Losses in Hydraulic Pipelines: Reynolds No. yMuhammed RazzaqueNo ratings yet

- 60W Wide-Range Power Supply For LCD Monitor or TV, Using The L5991Document17 pages60W Wide-Range Power Supply For LCD Monitor or TV, Using The L5991Grzegorz WegnerNo ratings yet

- Series 42 Self-Operated Regulators ANSI Version: T 3010 EN Type 42-10 RS Check Valve (Backflow Protection)Document8 pagesSeries 42 Self-Operated Regulators ANSI Version: T 3010 EN Type 42-10 RS Check Valve (Backflow Protection)Yesid RodríguezNo ratings yet

- Manual Instruction CPAM-EKA AIR C16 EKA KOOL V2Document8 pagesManual Instruction CPAM-EKA AIR C16 EKA KOOL V2Tam DuongNo ratings yet

- 4-3 Directional Spool Valve 4WE-6-GDocument2 pages4-3 Directional Spool Valve 4WE-6-GRaphael SasdelliNo ratings yet

- Technical Principles of Valves: Symbols and Circuit FunctionsDocument9 pagesTechnical Principles of Valves: Symbols and Circuit Functionsanon_436633026No ratings yet

- Flowmeters and Switches For Very Low Flows: KDF-9/KDG-9Document4 pagesFlowmeters and Switches For Very Low Flows: KDF-9/KDG-9Sorin IordacheNo ratings yet

- Elastic Transducers-2Document30 pagesElastic Transducers-2Hello WorldNo ratings yet

- HydraulicsDocument3 pagesHydraulicsIZNo ratings yet

- SAMSON 2005 Valve Sizing Sample Problems PDFDocument12 pagesSAMSON 2005 Valve Sizing Sample Problems PDFSatit hunsaNo ratings yet

- Advance Fluid Lab ManualDocument55 pagesAdvance Fluid Lab ManualchristianNo ratings yet

- For Exchanger Tube Rupture PDFDocument3 pagesFor Exchanger Tube Rupture PDFNikhil DivateNo ratings yet

- WK - 13Document26 pagesWK - 13shanza678No ratings yet

- Tawackolian-Kriegel2022 Article TurbulenceModelPerformanceForVDocument11 pagesTawackolian-Kriegel2022 Article TurbulenceModelPerformanceForVMEnrique ForocaNo ratings yet

- Instructions AK-PC 351 (Інструкція)Document6 pagesInstructions AK-PC 351 (Інструкція)nikolaNo ratings yet

- Lab Report 4Document8 pagesLab Report 4Yohannes AlemayehuNo ratings yet

- Unit-1 Semiconductor Diodes PDFDocument103 pagesUnit-1 Semiconductor Diodes PDFRajarao MandaNo ratings yet

- Datasheet 1N4001Document2 pagesDatasheet 1N4001Cyntia GodoyNo ratings yet

- Dokumen - Tips - Sedecal HF Series X Ray Generator Advanced Service ManualDocument89 pagesDokumen - Tips - Sedecal HF Series X Ray Generator Advanced Service ManualBasheer Mohamed100% (1)

- Chapters in Word PDFDocument97 pagesChapters in Word PDFKarthik VanamNo ratings yet

- 95439710pa SM04 Ver1 Setup GuideDocument2 pages95439710pa SM04 Ver1 Setup GuideDavidMendezNo ratings yet

- Sdmo Telecoms Generator SolutionsDocument18 pagesSdmo Telecoms Generator SolutionsHani IssaNo ratings yet

- 2W005G - 2W10G-Bridge RectifiersDocument3 pages2W005G - 2W10G-Bridge RectifiersbmmostefaNo ratings yet

- Power Electronics Lab ManualDocument52 pagesPower Electronics Lab ManualShikharNo ratings yet

- AksDocument11 pagesAksAnil ShahNo ratings yet

- Glass Passivated: Bridge RectifierDocument3 pagesGlass Passivated: Bridge RectifierManuel Merino rojasNo ratings yet

- Golap 2014 PDFDocument6 pagesGolap 2014 PDFgolapkantideyNo ratings yet

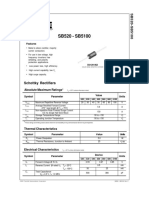

- SB520 - SB5100: Schottky RectifiersDocument3 pagesSB520 - SB5100: Schottky RectifiersHéctor Eduardo Baptista CastilloNo ratings yet

- General Purpose Rectifier: 1N4001-G 1N4007-GDocument2 pagesGeneral Purpose Rectifier: 1N4001-G 1N4007-GCarloz FriazNo ratings yet

- VA500 VV500 ALL e Ver1 0Document9 pagesVA500 VV500 ALL e Ver1 0Hasaan HussainNo ratings yet

- Modeling and Simulation of PFC ConvertersDocument93 pagesModeling and Simulation of PFC ConvertersSanjeev Singh100% (1)

- NotesDocument176 pagesNoteskalyanNo ratings yet

- Chapter Three Technology Used: 3.1 ArduinoDocument9 pagesChapter Three Technology Used: 3.1 ArduinoNityanand ThakurNo ratings yet

- Liebert Gxt4 UPS 230 V, 700 VA - 3000 VA: User ManualDocument73 pagesLiebert Gxt4 UPS 230 V, 700 VA - 3000 VA: User ManualAbdelwhab ElsaftyNo ratings yet

- Linear Power Supply WiDocument7 pagesLinear Power Supply WiBASEER AHMAD0% (1)

- ZXD3000 V6.0R03 Rectifier Datasheet V2.1 - 20201117 - ENDocument6 pagesZXD3000 V6.0R03 Rectifier Datasheet V2.1 - 20201117 - ENVictor ArticaNo ratings yet

- BW HPS48 4s WebDocument3 pagesBW HPS48 4s WebEng M ElseaidyNo ratings yet

- S124-Solar Based Mobile Charger For Rural AreasDocument4 pagesS124-Solar Based Mobile Charger For Rural AreasYellaturi Siva Kishore ReddyNo ratings yet

- Ferroresonant Transformers White PaperDocument10 pagesFerroresonant Transformers White PaperMilannet MilannetNo ratings yet

- LEC 3, Parameter Performance - 10 SeptDocument30 pagesLEC 3, Parameter Performance - 10 SeptنورالغامديNo ratings yet