Professional Documents

Culture Documents

Home Gas by HHO

Home Gas by HHO

Uploaded by

nanoblack88Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Home Gas by HHO

Home Gas by HHO

Uploaded by

nanoblack88Copyright:

Available Formats

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Impact Factor (2012): 3.358

Home Gas by Hydrogen Fuel Cell

Akanksha1, P B L Chaurasia2

Department of M.Tech (energy), Suresh Gyan Vihar University, Jaipur, India

Dean of Engineering, Suresh Gyan Vihar University, Jaipur, India

Abstract: This paperrepresent about Hydrogen Fuel Cell which consist of a fuel tank and is filled with demineralized water (DM)

having zero conductivity and sodium hydroxide (NaOH). This fuel cell is designed to operate on the method of Electrolysis by separating

hydrogen and oxygen. The fuel cell uses electrochemical process to split hydrogen and water and recombine to form HHO gas

(hydroxyoxygen), which we can further use for generating heat and electricity. Hence gives us a conclusion of using the resultant heat

for various purposes like welding, cooking etc. But this paper gives a brief explanation about HHO gas for the purpose of cooking.

Keywords: electrolysis, home gas stove, burner, Hydrogen gas, bubbler.

1. Introduction 1.3 Hydrogen Fuel Cell Diagram

Nowadays, as the environment are becoming more and more

contaminated because of the increasing carbon dioxide and

pollutants an immediate action must be taken .This paper

tries to overcome these problem by showing the pros and

corns of using “home gas by hydrogen fuel cells”. It deals

with the use of hydrogen gas instead of LPG(liquefied

petroleum gas) for the purpose of cooking.

1.1Properties of hydrogen

Density: 0.0899g/l at STP and 0.085g/l at 15oC

Energy density : 120-140 MJ/kg at STP

Critical pressure : 12.96 bar

Triple point temperature : -259.19oC

Critical temperature : -240oC Figure 1: Fuel Cell

Molecular weight : 2

Triple point pressure : 0.077 bar 1.3.1 Reactor

If hydrogen gas doesn't leak, it'll produce 3X much energy It is made up of stainless steel and consists of 220 volts and

comparison to natural gas. 110 plates with gap less than 1mm. The input to the reactor

is water and NaOH. Thus the output obtained is HHO gas.

Octane no. : +130

1.2 Hydrogen Production Method

This paper uses electrolysis process for splitting of water

into hydrogen and oxygen. Here the fuel tank is filled with

demineralized water having zero conductivity and sodium

hydroxide (NaOH). As the reactor gets DC supply it will

ionize the molecules of hydrogen and oxygen and will

separate it and will form hydrogen and oxygen and further

recombine to form hydroxyoxygen (HHO).

HHO- hydroxyoxygen (HHO) is a diatomic structure made

from the molecules of two atoms of both the gases oxygen

and hydrogen.

HHO is emission free and considered as environmental Figure 2: Reactor

friendly as it does not produce any carbon and other

pollutants into the atmosphere when burned. 1.3.2 Bubbler

It is also made up of stainless steel .It has two nozzles for

During the production of hydrogen following reaction occur intake and outtake. It consists of a flash port at the top and

in the cell: flash port has glass ball inside so whenever the pressure get

rise glass ball will pup-up and release the pressure.

Volume 3 Issue 6, June 2014

www.ijsr.net

Paper ID: 02014716 2090

Licensed Under Creative Commons Attribution CC BY

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Impact Factor (2012): 3.358

Sometimes a water gauge is attached to the bubbler to

indicate the water level i.e. generally half of the complete

bubbler size. Rest part of the bubbler is filled will brass

wool to make fill of area so there must be no extra pressure

built inside of hydrogen.

1.3.3 Fuel Tank

A flash port on the fuel tankis made up of (CPVC)

Chlorinated polyvinyl chloride. It is a thermoplastic

produced by chlorination of polyvinyl chloride (PVC)

resin.It has intake and outtake of gas inside, the upper pipe

of fuel tank is connected with upper pipe of reactor and

similarly lower pipe of fuel tank is connected with lower

pipe of reactor on the both side. Here we have used NaoH

and water but KOH can also be used in place of NaoH.As

we know KOH has more pressure than NaoH and also it is a Figure 5:3D Printer

bit costlier than NaoH so here in this paper we are dealing

with NaoH. 1.3.6 Flash Pot

It is used for safety purpose of the HHO Generator. It is

made of Poly-vinyl chloride (PVC). Flash Port is a type of

pressure release faucet. It blows off the extra pressure

during back fire. It consist springs which is placed inside the

end cap As hydrogen flash back, glass ball pop-off and thus

hydrogen releases from the space provided on the flash port

into the surrounding environment and protect the device for

bursting .Hence also known as safety guards.

2. Literature Survey

Figure 3: Fuel Tank In 1802, Sir Humphrey Davy created the first simple fuel

cell based on compound like NH3/O2/C, C/H2O which was

1.3.4 PWM delivering an inadequate electrical shock. So this fuel cell

Pulse width modulation (PWM),a part of the fuel cell is for was not acceptable .The first fuel cell was firstly imagined

controlling the flame of HHO. PWM is also known for by Sir William Robert Grove in 1839, that why he is also

increasing the production of HHO gas without increasing the known as the father of the fuel cell. He has done an

current rating (amp). experiment by mixing hydrogen and oxygen in the existence

of an electrolyte and helped in the production of electricity

1.3.5 Gas stove and water. In 1882, a power generation attempt was made by

The flow rate of HHO can be varied from 2-13 liter per Thomas Edison. He built a power generation by burning

minutes. This gas can be used straight or with the coals. Fuel cell is named as fuel cell by Ludwig Mind and

combination of LPG. As LPG gas has carbon so there is no Charles Langer who has built the first fuel cell device using

risk of flash back. industrial coal gas and air, in 1889.In 1993, Sir Francis

Bacon started to work on fuel cell and developed a high

density AFC at very high pressure

3. Problem Definition

As we know hydrogen is a very explosive gas so the

problem in using hydrogen is the risks of fire or bursting. So

this paper deals with that problem by implementing the use

of flash back arrestor. With the help of this flash back

arrestor, at the time of back fire the entire system will be

protected from the fire causing no harm to the humans as

well as environments. Another problem of hydrogen

includes storage and its production cost. But this paper also

gives a good explanation about hydrogen production, as here

Figure 4: Home Gas Stove we are using water for hydrogen production which is

abundant in nature

Diameter of each hole in the stove is 0.3mm. There are 5

holes on a single burner top and there are total 4burner top.

This gas stove is printed by a 3D printer.

Volume 3 Issue 6, June 2014

www.ijsr.net

Paper ID: 02014716 2091

Licensed Under Creative Commons Attribution CC BY

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Impact Factor (2012): 3.358

4. Methodology # If we consider a domestic LPG: This can be very well

understood with the help of an example. As we see in our

This paper uses the method of electrolysis for the production homesvarious equipments and their rating, and here we are

of hydrogen gas or HHO gas by splitting of water into considering the following:

oxygen and hydrogen. Here as the fuel cell reactor gets the

DC supply it will ionize the molecules of hydrogen and Table 1

oxygen and will separate it and will form hydrogen and S. No Equipments Ratting

oxygen and further recombines to form hydroxyoxygen 1 Cooking burner 9MJ

(HHO). 2 Gas heater 15MJ

3 Continuous flow hot water heater(geyser) 130MJ

Total 154MJ

This gas will goes to the upper portion of the fuel tank and If we consider subsidized cylinder:

from their it will go to the bubbler through the pipe on its 14.2 kg LPG=194.54 (KWH) = 700344KJ

top. And from the first bubbler the gas will goes to the {194.54 KWH explanation:

another bubbler through the other pipe. And this gas from

the second bubbler can be used for producing heat. so we Composition of LPG in a cylinder is -

can use this heat for burning our home gas stove for the 40% propane – 13.83 Kwh\kg (calorific value)60% butane –

purpose of cooking. 13.62 Kwh\kg (calorific value)Domestic LPG cylinder

weight- 14.2kg.

Net calorific value- 13.83*0.4 + 13.62*0.6= 13.70kwh/kg

.Therefore,for a cylinder 14.2*13.70 =194.54 KWh}.

So this cylinder will last: 700.344MJ\154MJ = 4.54hr. In

Figure 6: Complete setup process

India, subsidized cost of LPG = Rs.425. per unit production

cost will be = Rs2.18.So accordingly, cylinder will consume

This method can be well understood with the help of a flow

154MJ = 42.5 unit. So cost of cylinder will be 42.5*2.18 =

chart describe in the following figure:

Rs92.65

Flow chart describing the methodology of hydrogen fuel

Table 2:

cell City Chennai Kolkata Mumbai Delhi

Subsidized 432 440 435 414

cylinder cost in

Rupees

Cost in Rupees 94 95 94 90

for 154mz

Non- Subsidized 1234 1270 1264 1240

Cylinder cost in

rupees

Cost in rupees 269.5 277.45 276.13 270.85

for 154MJ

I.e. since 700.344Mj = Rs435 (subsidized cylinder cost in

Mumbai)so,1Mj = 425\700.344 .Therefore for 154mj= 435*

154\700.344 =94(approx.)

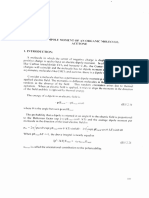

Hydrogen calculation: To get a desirable output, we must

consider:

Plate- 2-2.2 volt per plate

Current- 0.54amp per inch2active surface area of the plate.

Let the plate size be (7.5*7)”, diameter of circle is 1.4cmand

gasket is 2*.

Therefore surface area = (rectangle area) - {(4*triangle area)

+ (2* circle area) +area exposed to H2.}.

(14*12.8) – (4*0.5*2.8*2.5) – (2*3.14*0.7*0.7) –

(7.8*0.9*0.5) = 158.62cm2.

5. Results and Discussion

This paper shows that we can use hydrogen in place of LPG.

Volume 3 Issue 6, June 2014

www.ijsr.net

Paper ID: 02014716 2092

Licensed Under Creative Commons Attribution CC BY

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Impact Factor (2012): 3.358

future, by replacing petrol with hydrogen. It can be used for

generating electricity by electrochemical process. Fuel cell

can power any portable device like laptops, computer,

cellular phone etc. Among all, the best part of using

hydrogen fuel cell is “the use of hydrogen fuel cell

provides us a greener future.” As hydrogen is considered

as ecofriendly, non-toxic which provide us clean energy.

References

[1] Hydrogen production methods (2006), Available: http://

www.iea.org/ publications/ freepublications/ publication/

hydrogen.pdf.

[2] Energy statistics 2013, Available:

http://mospi.nic.in/mospi_new/upload/Energy_Statistics_

Figure 7: H2 calculation 2013.pdf.

[3] [Online]. Price of non-subsidized LPG hiked by 220

Maximum current which can pass in the reactor (with its full rupees per cylinder (Jan2, 2014), JAGRAN JOSH

efficiency) is Available: http://www.jagranjosh.com/current-

Current =24.58*0.54 = 13.27 amp. affairs/price-of-the-nonsubsidized-lpg-hiked-by-220-

For 220 volt DC supply, having 11amp: rupees-per-cylinder-1388657536-1.

H2 output is: 12.6 LPM [4] HHO Cell configurator, Available:

Output HHO: 756 liters http://www.hho4free.com/configurator/cell_configurator.

H2: 504 liters htm

O2:252 liters in an hour.

Author Profile

Energy density of H2=130MJ/kg

Density of H2 = 0.085 gm/l at room temperature. I have completed my bachelor of technology (B.

Tech) in 2013 in electrical engineering from Suresh

Gyan Vihar University, Jaipur. And presently

So, Energy output = 504*0.085*0.001*130 = 5.57 MJ/hr. pursuing M. Tech under dual degree program in

To attain 154MJ, this HHO fuel cell will take 27.64 hr.If we energy from Gyan Vihar University, Jaipur,

calculate for average electricity cost in India (250KWH) Rajasthan, India.

then cost is 3.70 Rs/units = 3.70*(2.42*27.64) =

Rs245.44.This provide us result that presently H2 is more

economical.

6. Conclusion

Home gas by hydrogen fuel cells gives us a wonderful

conclusion by discussing the use of HHO gas for cooking

purpose. As already discussed above, the HHO gas in the

hydrogen fuel cell is prepared by the electrolysis process by

splitting of water. So, the primary source used in the

production of HHO gas is water which is well known for its

abundance. So fuel cell helps in dealing with one of the

major problem by reducing the production cost of hydrogen.

Hence by the use of “home gas by hydrogen fuel cell” we

can save money up to a great extent. And we also know the

hydrogen gas is eco-friendly, thus it is emission free and

produces no carbon during the use. In this way we can also

save LPG for future.

7. Future Scope

We all know that generally fuel cell is used for

transportation purpose and in portable uses. Here, in this

paper we have shown the use of hydrogen fuel cell for

cooking. Sometimes, we are facing lack of LPG so it can be

imagined that there may be no LPG for the future use, so

this home gas by hydrogen fuel cell can be used in future for

cooking in the absence of LPG. On other hand, the fuel cell

can be very helpful for supplying power to ours cars in

Volume 3 Issue 6, June 2014

www.ijsr.net

Paper ID: 02014716 2093

Licensed Under Creative Commons Attribution CC BY

You might also like

- SXV RXV 450 550 Engine English 2006-02Document132 pagesSXV RXV 450 550 Engine English 2006-02Loic TrocmeNo ratings yet

- Ochsner 2008 Carbon Dioxide Heat Pipe in ConjuncDocument6 pagesOchsner 2008 Carbon Dioxide Heat Pipe in ConjuncHugo PeresNo ratings yet

- Steam From Cavitation PDFDocument4 pagesSteam From Cavitation PDFNiculae George RazvanNo ratings yet

- Water Gas Shift Reaction: Research Developments and ApplicationsFrom EverandWater Gas Shift Reaction: Research Developments and ApplicationsNo ratings yet

- Upgraded Design For Flash Port of HHO Dry Cell GeneratorDocument7 pagesUpgraded Design For Flash Port of HHO Dry Cell GeneratorNam stareNo ratings yet

- F02990376S19Document3 pagesF02990376S19Peter DouseNo ratings yet

- Steam InjectionDocument5 pagesSteam InjectiondragonNo ratings yet

- Oxy-Hydrogen Fuel As Supplement For Gasoline Vehicles Using Dry Cell GeneratorDocument6 pagesOxy-Hydrogen Fuel As Supplement For Gasoline Vehicles Using Dry Cell GeneratorNam stareNo ratings yet

- Test File - 3Document8 pagesTest File - 3global-marketin8184No ratings yet

- Utilizing Waste Hydrogen For Energy Recovery Using Fuel Cells and Associated TechnologiesDocument9 pagesUtilizing Waste Hydrogen For Energy Recovery Using Fuel Cells and Associated TechnologiesVaishnavi. V.pathakNo ratings yet

- The Performance of Ic Engine With (Diesel-Hydrogen) Dual FuelDocument7 pagesThe Performance of Ic Engine With (Diesel-Hydrogen) Dual FuelrassNo ratings yet

- Hydrogen Production in Underwater CuttinDocument26 pagesHydrogen Production in Underwater CuttinДенис ПронинNo ratings yet

- HHO Gas Generation in Hydrogen Generator Using EleDocument9 pagesHHO Gas Generation in Hydrogen Generator Using EleNishanNo ratings yet

- Hho 2Document5 pagesHho 2Prittam Kumar JenaNo ratings yet

- Hidrogeno Combustible Del Futuro Parte 1Document6 pagesHidrogeno Combustible Del Futuro Parte 1Jose OlaNo ratings yet

- Evaluation On The Harm Effects of Accidental Releas - 2013 - International JournDocument9 pagesEvaluation On The Harm Effects of Accidental Releas - 2013 - International Journhridoy bosuniaNo ratings yet

- 2.2 GHZ Laser HHODocument32 pages2.2 GHZ Laser HHOalkatrash100% (3)

- VIT Journal 2Document4 pagesVIT Journal 2Abhinav KumarNo ratings yet

- How Its MadeDocument6 pagesHow Its MadeKefli KhooNo ratings yet

- Bob BoyceDocument47 pagesBob BoyceDmitryRussuNo ratings yet

- A Practical Guide To Free Energy' Devices: What Is An Electrolyser?Document47 pagesA Practical Guide To Free Energy' Devices: What Is An Electrolyser?lucas123No ratings yet

- Electrolyser Designs - Free Energy InfoDocument49 pagesElectrolyser Designs - Free Energy InfoCorTermorshuizenNo ratings yet

- Brown GasDocument9 pagesBrown GasSagar Sachdeva100% (1)

- HHO G A: Eneration PplicationDocument6 pagesHHO G A: Eneration Pplicationsameh tawfeekNo ratings yet

- Taguchi Based Design of Experiments To o 325c85edDocument12 pagesTaguchi Based Design of Experiments To o 325c85edRezha ApriansyahNo ratings yet

- Manual Book HHO Generator Joko Energy 20Document72 pagesManual Book HHO Generator Joko Energy 20HusamZarourNo ratings yet

- Igcc UnitsDocument40 pagesIgcc UnitsEverton CollingNo ratings yet

- Auto-Ignition of Spontaneous Hydrogen LeaksDocument10 pagesAuto-Ignition of Spontaneous Hydrogen LeaksAli GNo ratings yet

- Making Nanoparticules at Match 2.6Document5 pagesMaking Nanoparticules at Match 2.6Lisbeth Roos RoosNo ratings yet

- 1 PBDocument7 pages1 PBCITRA DEWI 2001081No ratings yet

- Bubble PowerDocument25 pagesBubble PowerAnn RoseNo ratings yet

- Production of Browns Gas Using Hydroxy GeneratorDocument3 pagesProduction of Browns Gas Using Hydroxy GeneratorBoyan StoyanovNo ratings yet

- SAE 1999-01-3325 JSAE 9938080: Sae Technical Paper SeriesDocument6 pagesSAE 1999-01-3325 JSAE 9938080: Sae Technical Paper SerieskarakondjoNo ratings yet

- Water (R718) Cooling System (With CO2 Cycle)Document21 pagesWater (R718) Cooling System (With CO2 Cycle)192113No ratings yet

- Ijer - 2014 Ncetmesd 08Document8 pagesIjer - 2014 Ncetmesd 08Luciana FigueiredoNo ratings yet

- Theory of FireDocument46 pagesTheory of FireJohn FredyNo ratings yet

- Chapterinabook ElectrolysisDocument11 pagesChapterinabook ElectrolysisAhmed MostafaNo ratings yet

- Alternative Technology For Cooling: September 2015Document5 pagesAlternative Technology For Cooling: September 2015samsurendran_mech4020No ratings yet

- Research On Ash Clogging of Rotary Air Preheater in Coal-Fired Power PlantDocument4 pagesResearch On Ash Clogging of Rotary Air Preheater in Coal-Fired Power PlanttruongtxNo ratings yet

- Development of A Steam Jet Refrigeration Cycle For PDFDocument10 pagesDevelopment of A Steam Jet Refrigeration Cycle For PDFJepoy Salvacion BaquirquirNo ratings yet

- Testing of A Low-Cost Loop Heat Pipe Design: Cosimo BuffoneDocument6 pagesTesting of A Low-Cost Loop Heat Pipe Design: Cosimo BuffoneAsifMutahirNo ratings yet

- Gerador HidrogenioDocument44 pagesGerador HidrogenioKleiber FerreiraNo ratings yet

- CP5054 Chapter 1Document8 pagesCP5054 Chapter 1lianghong.koh5914No ratings yet

- LeskerTech - Issue4 How Low Can You GoPart 1Document4 pagesLeskerTech - Issue4 How Low Can You GoPart 1lram70No ratings yet

- c02 ExchangerDocument6 pagesc02 ExchangershaunsingerjesusNo ratings yet

- Design of Solar Powered Vapour Absorption System: V.K.BajpaiDocument5 pagesDesign of Solar Powered Vapour Absorption System: V.K.BajpaiP Venkata SureshNo ratings yet

- Chapter 2Document4 pagesChapter 2Ray Allen Bionson RomeloNo ratings yet

- A Review of Granulation Process For Blast FurnaceDocument4 pagesA Review of Granulation Process For Blast FurnaceAbhay RanjanNo ratings yet

- Liquid Nitrogen AsDocument16 pagesLiquid Nitrogen Assafal shaNo ratings yet

- Words:: Thus Enhancing The Power Output. With Low Temperature ResourcesDocument3 pagesWords:: Thus Enhancing The Power Output. With Low Temperature ResourcesBogdanPNo ratings yet

- Performance Test of A 6L Liquid Hydrogen Fuel Tank For Unmanned Aerial VehiclesDocument8 pagesPerformance Test of A 6L Liquid Hydrogen Fuel Tank For Unmanned Aerial Vehicles이경률No ratings yet

- 2 - Classification of ReactorsDocument28 pages2 - Classification of Reactorspothuraju harithaNo ratings yet

- Week 5 PDFDocument39 pagesWeek 5 PDFdonyaNo ratings yet

- The Effect of Electrode Gap Distance On Brown's GasDocument6 pagesThe Effect of Electrode Gap Distance On Brown's GasWahyu DwilestariNo ratings yet

- MW 323Document8 pagesMW 323dio prabowoNo ratings yet

- Forum: Carbon Dioxide (Co) For The Food Processing and Cold Storage IndustriesDocument8 pagesForum: Carbon Dioxide (Co) For The Food Processing and Cold Storage IndustrieszhyhhNo ratings yet

- 1.1 What Is Pulse Detonation Engine?: 1.2 Mach No.Document20 pages1.1 What Is Pulse Detonation Engine?: 1.2 Mach No.dhaneshNo ratings yet

- Increasing Efficiency of Icengine Using Electrolysis ProcessDocument5 pagesIncreasing Efficiency of Icengine Using Electrolysis ProcessrassNo ratings yet

- U.S. Patent 4,293,314: Gelled Fuel-Air Explosive October 6, 1981.From EverandU.S. Patent 4,293,314: Gelled Fuel-Air Explosive October 6, 1981.No ratings yet

- Project B Final AssessmentDocument2 pagesProject B Final Assessmentchristopher ng'ang'a kamauNo ratings yet

- Africa Ref02Document1 pageAfrica Ref02christopher ng'ang'a kamauNo ratings yet

- Overcurrent Protection RelayDocument2 pagesOvercurrent Protection Relaychristopher ng'ang'a kamauNo ratings yet

- Owner'S Manual: Model: Ref12v2 Product ID: Ref12v2d417Document2 pagesOwner'S Manual: Model: Ref12v2 Product ID: Ref12v2d417christopher ng'ang'a kamauNo ratings yet

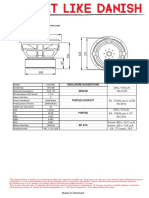

- Model: X2c24: (Custom Coated Paper Cone)Document2 pagesModel: X2c24: (Custom Coated Paper Cone)christopher ng'ang'a kamauNo ratings yet

- HN10 / HN12 / HN15: Owner'S ManualDocument4 pagesHN10 / HN12 / HN15: Owner'S Manualchristopher ng'ang'a kamauNo ratings yet

- Hnx65 / Hnx8: Owner'S ManualDocument2 pagesHnx65 / Hnx8: Owner'S Manualchristopher ng'ang'a kamauNo ratings yet

- Model: XM Product Id:: Sweet Like DanishDocument1 pageModel: XM Product Id:: Sweet Like Danishchristopher ng'ang'a kamauNo ratings yet

- Instruction Manual For Mig/Mag (Co2) Welding Machine: Warpp Engineers Pvt. LTDDocument14 pagesInstruction Manual For Mig/Mag (Co2) Welding Machine: Warpp Engineers Pvt. LTDchristopher ng'ang'a kamauNo ratings yet

- Owner'S Manual: Model: M12R Product Id:M12R15DDocument5 pagesOwner'S Manual: Model: M12R Product Id:M12R15Dchristopher ng'ang'a kamauNo ratings yet

- SLD5k: Owner'S ManualDocument12 pagesSLD5k: Owner'S Manualchristopher ng'ang'a kamauNo ratings yet

- XM15/XM18/xm21: Owner'S ManualDocument4 pagesXM15/XM18/xm21: Owner'S Manualchristopher ng'ang'a kamauNo ratings yet

- 4TNV98T: Engine Technical DataDocument1 page4TNV98T: Engine Technical Datachristopher ng'ang'a kamauNo ratings yet

- Owner'S Manual: Model: Sld600 Product Id:Sld60015DDocument9 pagesOwner'S Manual: Model: Sld600 Product Id:Sld60015Dchristopher ng'ang'a kamauNo ratings yet

- Ref Four: Eet Like DaniDocument10 pagesRef Four: Eet Like Danichristopher ng'ang'a kamauNo ratings yet

- Zero.7: Owner'S ManualDocument10 pagesZero.7: Owner'S Manualchristopher ng'ang'a kamauNo ratings yet

- Zero.7: Owner'S ManualDocument12 pagesZero.7: Owner'S Manualchristopher ng'ang'a kamauNo ratings yet

- Komatsu Pc200 7 SpecDocument2 pagesKomatsu Pc200 7 Specchristopher ng'ang'a kamauNo ratings yet

- FAMCO Marelli Motori Explosion Proof Electric Motor CatalogDocument8 pagesFAMCO Marelli Motori Explosion Proof Electric Motor CatalogMustafaNo ratings yet

- Plate Tectonics: © Boardworks LTD 2003Document26 pagesPlate Tectonics: © Boardworks LTD 2003Junimar AggabaoNo ratings yet

- A Novel Recovery Process of Metal Values From SpentDocument152 pagesA Novel Recovery Process of Metal Values From SpentJose Luis FloresNo ratings yet

- Peterhead - 11.097 Well Completion Concept Select ReportDocument148 pagesPeterhead - 11.097 Well Completion Concept Select ReportF SedighiNo ratings yet

- LESSON PLAN IN PHYSICAL SCIENCE (Sample Only)Document2 pagesLESSON PLAN IN PHYSICAL SCIENCE (Sample Only)Charmine AbuanNo ratings yet

- PhysicsLabI Exp5Document9 pagesPhysicsLabI Exp5Jessica RossNo ratings yet

- Continuum MechanicsDocument12 pagesContinuum Mechanicsরোহন করNo ratings yet

- 2 Unit DynamicsDocument5 pages2 Unit DynamicsmanojNo ratings yet

- Sri Vidya College of Engineering & Technology Oed - Question Bank - Unit - 4Document5 pagesSri Vidya College of Engineering & Technology Oed - Question Bank - Unit - 4Jai RamNo ratings yet

- Principles of Material Corrosion Hmie 514 and Materials and Containment 112 Assignment 2 Sem. 1 2020Document2 pagesPrinciples of Material Corrosion Hmie 514 and Materials and Containment 112 Assignment 2 Sem. 1 2020Trust NematadziraNo ratings yet

- Report #13 - Stereochemistry & H.H.Document24 pagesReport #13 - Stereochemistry & H.H.Kelvin ZhandaNo ratings yet

- Chapter 2 Electrostatic Potential and CapacitanceDocument47 pagesChapter 2 Electrostatic Potential and CapacitanceThej ThanayNo ratings yet

- Dehydration of Aqueous Ethanol Mixtures by Extractive DistillationDocument15 pagesDehydration of Aqueous Ethanol Mixtures by Extractive DistillationMaria Catalina Pinzon SilvaNo ratings yet

- S I: T N G S M: Imulation Ntelligence Owards A EW Eneration OF Cientific EthodsDocument109 pagesS I: T N G S M: Imulation Ntelligence Owards A EW Eneration OF Cientific EthodsArch WongNo ratings yet

- Year 2018Document119 pagesYear 2018Arpith Mishael DanielNo ratings yet

- Exercise 1Document3 pagesExercise 1Carlos SanchezNo ratings yet

- (Annual Reports On NMR Spectroscopy 1) E.F. Mooney (Eds.) - Elsevier, Academic Press (1968) PDFDocument365 pages(Annual Reports On NMR Spectroscopy 1) E.F. Mooney (Eds.) - Elsevier, Academic Press (1968) PDFyury1102No ratings yet

- Abstract Marketing Plan by SlidesgoDocument51 pagesAbstract Marketing Plan by SlidesgoNam Vu HuyNo ratings yet

- Kinetics FormulaDocument1 pageKinetics FormulaImran GaniNo ratings yet

- Chemical ProcessDocument18 pagesChemical ProcessErik WeeksNo ratings yet

- Transport Phenomena (Transfer Processes)Document38 pagesTransport Phenomena (Transfer Processes)esiri aluyaNo ratings yet

- Seminar On Effect of Particle Size, MoistureDocument16 pagesSeminar On Effect of Particle Size, Moisturenoddyy3363No ratings yet

- Haramaya University - Summer 2011Document4 pagesHaramaya University - Summer 2011aakuma100% (2)

- Ce 8302 Unit 1Document45 pagesCe 8302 Unit 1durai muruganNo ratings yet

- vis-uvvis-spectroscopy-solutions-industrial-labs-FL52993 Genesys 30Document2 pagesvis-uvvis-spectroscopy-solutions-industrial-labs-FL52993 Genesys 30ReneNo ratings yet

- Dipole Moment AcetoneDocument6 pagesDipole Moment AcetoneP NaveenNo ratings yet

- Master Jee Classes: JEE-ADVANCE-2014-P2-ModelDocument42 pagesMaster Jee Classes: JEE-ADVANCE-2014-P2-ModelkamalNo ratings yet

- BR Fomblin HC ENDocument8 pagesBR Fomblin HC ENrk7bpsNo ratings yet

- Chem Exam 5/finalDocument2 pagesChem Exam 5/finalKim Angelica AbongNo ratings yet