Professional Documents

Culture Documents

Wall Thickness and Material Grade Selection: General

Uploaded by

Alireza KhodabandehOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wall Thickness and Material Grade Selection: General

Uploaded by

Alireza KhodabandehCopyright:

Available Formats

2 Wall Thickness and Material Grade

Selection

Chapter Outline

1. Introduction 23

General 23

Pipeline Design Codes 24

Pipeline Wall Thickness 25

2. Material Grade Selection 26

General 26

Fabrication, Installation, and Operating Cost Considerations 26

Material Grade Optimization 27

3. Pressure Containment Design 27

General 27

DNV-OS-F101 28

ABS Guide for Building and Classing Subsea Pipeline Systems 29

U.S. Codes of Federal Regulations 30

API-RP-1111 31

4. Equivalent Stress Criterion 32

5. Hydrostatic Collapse 33

6. Buckle Arrestors 35

Wall Thickness and Length for Buckle Arrestors 35

Buckle Arrestor Spacing 36

1. Introduction

General

In this chapter, the basis for the design of wall thickness is reviewed and compared

with industry practice. The codes reviewed are ABS [1]; API [2]; ASME B31 [3, 4];

BS 8010 [5]; DNV [6]; and ISO [7]. The selection of wall thickness is one of the most

important and fundamental tasks in the design of subsea pipelines. While this task

involves many technical aspects related to different design scenarios, primary design

loads relevant to the containment of the wall thickness are as follows:

l

Internal pressure loads.

l

External hydrostatic pressure loads.

l

Longitudinal functional loads.

Subsea Pipeline Design, Analysis, and Installation. http://dx.doi.org/10.1016/B978-0-12-386888-6.00002-X

Copyright Ó 2014 Elsevier Inc. All rights reserved.

You might also like

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- Bending Loads. External Impact Loads.: 24 Qiang Bai and Yong BaiDocument1 pageBending Loads. External Impact Loads.: 24 Qiang Bai and Yong BaiAlireza KhodabandehNo ratings yet

- Structural Design of RCC Building ComponentsDocument9 pagesStructural Design of RCC Building ComponentsAHSANNo ratings yet

- Brittle Fracture in Steel StructuresFrom EverandBrittle Fracture in Steel StructuresG.M. BoydNo ratings yet

- 05-Wall Thickness DesignDocument18 pages05-Wall Thickness DesignOlufemi AdeniyeNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Strain-Based Pipeline Design Criteria ReviewDocument8 pagesStrain-Based Pipeline Design Criteria ReviewAndrea De CintiNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- General Commentary Chapter 1 General 1.1 - Scope C1.1 - ScopeDocument19 pagesGeneral Commentary Chapter 1 General 1.1 - Scope C1.1 - ScopeRyan LasacaNo ratings yet

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceFrom EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNo ratings yet

- DesignDocument10 pagesDesignkefiyalew agegnNo ratings yet

- Production Planning and Design in The PRDocument25 pagesProduction Planning and Design in The PRabryant633777No ratings yet

- Corrosion: Corrosion ControlFrom EverandCorrosion: Corrosion ControlL L ShreirRating: 5 out of 5 stars5/5 (1)

- Comparison of Design Methods of Water Retaining Structueres Using The Provisons of International CodesDocument3 pagesComparison of Design Methods of Water Retaining Structueres Using The Provisons of International CodesAbhishek ShatagopachariNo ratings yet

- CISC Steel Design Series: ULC and cUL Spray-Applied Fire-Rated DesignsDocument11 pagesCISC Steel Design Series: ULC and cUL Spray-Applied Fire-Rated DesignsOussama AMARINo ratings yet

- ULC SteelDesignSeries - SDS-1-1Document11 pagesULC SteelDesignSeries - SDS-1-1Davoud MoradpourNo ratings yet

- 01 Appende PDFDocument21 pages01 Appende PDFArun VaithyanathanNo ratings yet

- Pipeline DesignDocument110 pagesPipeline DesignShaka Shalahuddin Shantika PutraNo ratings yet

- Sabp L 001Document6 pagesSabp L 001Li PengNo ratings yet

- PAPER - Comparison of Pipeline Design Installation Requirements Rigid V Flexible FINALDocument17 pagesPAPER - Comparison of Pipeline Design Installation Requirements Rigid V Flexible FINALC_unit08No ratings yet

- Companion ASME Vol. III-ch3Document22 pagesCompanion ASME Vol. III-ch3Siddhartha GaubaNo ratings yet

- A Good Place To Start: Tip 2: For ASD, Consider Using The 2011 MSJC ProvisionsDocument12 pagesA Good Place To Start: Tip 2: For ASD, Consider Using The 2011 MSJC ProvisionsconstrucciontotalNo ratings yet

- A Comparison of American, Norwegian, and Russian Standards in Calculating The Wall Thickness of Submarine Gas PipelineDocument4 pagesA Comparison of American, Norwegian, and Russian Standards in Calculating The Wall Thickness of Submarine Gas PipelineHarjasa AdhiNo ratings yet

- Luisezap Diapositivas Flexión 1.0Document85 pagesLuisezap Diapositivas Flexión 1.0Santiago DallosNo ratings yet

- The 2005 American Steel Structures Design Code: Reidar BjorhovdeDocument9 pagesThe 2005 American Steel Structures Design Code: Reidar BjorhovdeWimpsNo ratings yet

- Saer 5711Document161 pagesSaer 5711sethu1091100% (1)

- Design Jacking Pipa Australia STDDocument10 pagesDesign Jacking Pipa Australia STDDaniel SalehNo ratings yet

- Preprints202305 0065 v1Document7 pagesPreprints202305 0065 v1Victor M MarquezNo ratings yet

- Water Transmission Pipelines An Updated Design GuideDocument13 pagesWater Transmission Pipelines An Updated Design GuideponjoveNo ratings yet

- ASME B31.12 Hydrogen Piping and Pipeline Code Design Rules and Their Interaction With Pipeline Materials Concerns, Issues and ResearchDocument9 pagesASME B31.12 Hydrogen Piping and Pipeline Code Design Rules and Their Interaction With Pipeline Materials Concerns, Issues and Researchchannu rolliNo ratings yet

- Overview of Pressure Vessel Design Using ASME Boiler and Pressure Vessel Code Section VIII Division-1 and Division-2Document2 pagesOverview of Pressure Vessel Design Using ASME Boiler and Pressure Vessel Code Section VIII Division-1 and Division-2Ricardo Peña AraozNo ratings yet

- Ipc 2022 87078 A Comprehensive New Look at Type B SleevesDocument7 pagesIpc 2022 87078 A Comprehensive New Look at Type B SleevesOswaldo MontenegroNo ratings yet

- Considerations of Linepipe and Girth Weld Tensile Properties For Strain-Based Design of PipelinesDocument10 pagesConsiderations of Linepipe and Girth Weld Tensile Properties For Strain-Based Design of PipelinesIke OnyegiriNo ratings yet

- CVG3147 - Introduction To Limit State Design - S20171 PDFDocument28 pagesCVG3147 - Introduction To Limit State Design - S20171 PDFGreg LoncaricNo ratings yet

- Future Directions For Design, Specification, Testing, and Construction of Durable Concrete StructuresDocument17 pagesFuture Directions For Design, Specification, Testing, and Construction of Durable Concrete StructuresSophia LiuNo ratings yet

- Chapter - 3Document23 pagesChapter - 3Tadele BekeleNo ratings yet

- Guia de Diseño Anclajes Basf CCDocument49 pagesGuia de Diseño Anclajes Basf CCBECKET ULLOANo ratings yet

- PVC Pipe Design StressDocument2 pagesPVC Pipe Design Stresssnappish1No ratings yet

- Structural Design Report-OFFICE (LV ROOM) PDFDocument36 pagesStructural Design Report-OFFICE (LV ROOM) PDFreganNo ratings yet

- 1343-2012 Prestressed ConcreteDocument62 pages1343-2012 Prestressed Concretekapinjal_No ratings yet

- Civileng 04 00023Document25 pagesCivileng 04 00023fadialkasrawiNo ratings yet

- DNV Structure Steel Fabrication PDFDocument0 pagesDNV Structure Steel Fabrication PDFmastorfaizalNo ratings yet

- Anchor Bolts in Light-Frame Construction at Small Edge Distances PDFDocument8 pagesAnchor Bolts in Light-Frame Construction at Small Edge Distances PDFmlamourNo ratings yet

- DesignersHandbookToEurocode2 Pages1 113Document125 pagesDesignersHandbookToEurocode2 Pages1 113Petko Petkov100% (3)

- Diapositivas Flexión 1.0Document69 pagesDiapositivas Flexión 1.0jhoan castellanosNo ratings yet

- Csec2013 Gen 147Document11 pagesCsec2013 Gen 147김대경No ratings yet

- BPVC Sec VIII Div 1 and 2: March 2020Document3 pagesBPVC Sec VIII Div 1 and 2: March 2020dr2246No ratings yet

- International Experiences With Cathodic Protection of Offshore PipelinesDocument46 pagesInternational Experiences With Cathodic Protection of Offshore Pipelinesrajscribd148100% (1)

- Concrete Pipes and Portal Culverts HandbookDocument52 pagesConcrete Pipes and Portal Culverts HandbookKenya Ayallew Asmare100% (3)

- CPAA Guidance Note NZ Loads On Circular Precast Concrete Manholes and MoreDocument8 pagesCPAA Guidance Note NZ Loads On Circular Precast Concrete Manholes and Morejunhe898No ratings yet

- Pressure Vessel Design ASME Section VIII Divison1 and Division 2Document3 pagesPressure Vessel Design ASME Section VIII Divison1 and Division 2sammar_10No ratings yet

- Concrete Pipe Deflection LimitsDocument18 pagesConcrete Pipe Deflection LimitsAhmed KarimNo ratings yet

- Design Consideration Pressure VesselDocument17 pagesDesign Consideration Pressure VesselQasim JavedNo ratings yet

- (2014 Balh) Design of Steel Sheathed CFS Framed Shear WallsDocument11 pages(2014 Balh) Design of Steel Sheathed CFS Framed Shear WallsCynthiaNo ratings yet

- Chinese Design Code DL T 5180 2003Document31 pagesChinese Design Code DL T 5180 2003Asif MuhammadNo ratings yet

- Piping CodesDocument47 pagesPiping CodesSankar MukaNo ratings yet

- Overhead Line Design Handbook V7Document126 pagesOverhead Line Design Handbook V7Mohd Bilal100% (5)

- Berke, 1992, Estimating Life CycleDocument25 pagesBerke, 1992, Estimating Life CycleÁlvaro MendozaNo ratings yet

- Finite Element Analysis: Pipeline Installation by Tow or PullDocument1 pageFinite Element Analysis: Pipeline Installation by Tow or PullAlireza KhodabandehNo ratings yet

- 23Document1 page23Alireza KhodabandehNo ratings yet

- Pipe Laying by Lay Vessel: Mode 1 Buckle Mode 2 Buckle Mode 3 Buckle Mode 4 BuckleDocument1 pagePipe Laying by Lay Vessel: Mode 1 Buckle Mode 2 Buckle Mode 3 Buckle Mode 4 BuckleAlireza KhodabandehNo ratings yet

- References: 20 Qiang Bai and Yong BaiDocument1 pageReferences: 20 Qiang Bai and Yong BaiAlireza KhodabandehNo ratings yet

- Untitled 3Document1 pageUntitled 3Alireza KhodabandehNo ratings yet

- Untitled 1Document1 pageUntitled 1Alireza KhodabandehNo ratings yet

- Rec Erc 84 329Document1 pageRec Erc 84 329Alireza KhodabandehNo ratings yet

- Untitled 6Document1 pageUntitled 6Alireza KhodabandehNo ratings yet

- 16 Qiang Bai and Yong Bai: Pipeline InstallationDocument1 page16 Qiang Bai and Yong Bai: Pipeline InstallationAlireza KhodabandehNo ratings yet

- Untitled 2Document1 pageUntitled 2Alireza KhodabandehNo ratings yet

- Rec Erc 84 334Document1 pageRec Erc 84 334Alireza KhodabandehNo ratings yet

- 2 S. K. Gawali Et Al.: 1.1.1 Additive ManufacturingDocument1 page2 S. K. Gawali Et Al.: 1.1.1 Additive ManufacturingAlireza KhodabandehNo ratings yet

- Rec Erc 84 313Document1 pageRec Erc 84 313Alireza KhodabandehNo ratings yet

- Rec Erc 84 317Document1 pageRec Erc 84 317Alireza KhodabandehNo ratings yet

- Rec Erc 84 332Document1 pageRec Erc 84 332Alireza KhodabandehNo ratings yet

- Rec Erc 84 322Document1 pageRec Erc 84 322Alireza KhodabandehNo ratings yet

- Rec Erc 84 311Document1 pageRec Erc 84 311Alireza KhodabandehNo ratings yet

- Rec Erc 84 315Document1 pageRec Erc 84 315Alireza KhodabandehNo ratings yet

- Rec Erc 84 36Document1 pageRec Erc 84 36Alireza KhodabandehNo ratings yet

- Rec Erc 84 38Document1 pageRec Erc 84 38Alireza KhodabandehNo ratings yet

- 14 S. K. Gawali Et AlDocument1 page14 S. K. Gawali Et AlAlireza KhodabandehNo ratings yet

- 1.2.1 Design Methodology: 6 S. K. Gawali Et AlDocument1 page1.2.1 Design Methodology: 6 S. K. Gawali Et AlAlireza KhodabandehNo ratings yet

- 7th Congr Mat TestDocument6 pages7th Congr Mat TestAlireza KhodabandehNo ratings yet

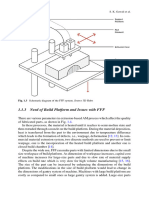

- 1.1.3 Need of Build Platform and Issues With FFF: 4 S. K. Gawali Et AlDocument1 page1.1.3 Need of Build Platform and Issues With FFF: 4 S. K. Gawali Et AlAlireza KhodabandehNo ratings yet

- CERTILAS EN Edition2023 315Document1 pageCERTILAS EN Edition2023 315Alireza KhodabandehNo ratings yet

- CERTILAS EN Edition2023 317Document1 pageCERTILAS EN Edition2023 317Alireza KhodabandehNo ratings yet

- Ni SiC AISI 304Document9 pagesNi SiC AISI 304Alireza KhodabandehNo ratings yet

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!From EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Rating: 4 out of 5 stars4/5 (3)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- Digital Twin Development and Deployment on the Cloud: Developing Cloud-Friendly Dynamic Models Using Simulink®/SimscapeTM and Amazon AWSFrom EverandDigital Twin Development and Deployment on the Cloud: Developing Cloud-Friendly Dynamic Models Using Simulink®/SimscapeTM and Amazon AWSNo ratings yet

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- Building with Virtual LEGO: Getting Started with LEGO Digital Designer, LDraw, and MecabricksFrom EverandBuilding with Virtual LEGO: Getting Started with LEGO Digital Designer, LDraw, and MecabricksNo ratings yet

- Artificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsFrom EverandArtificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsRating: 5 out of 5 stars5/5 (3)

- SAM: One Robot, a Dozen Engineers, and the Race to Revolutionize the Way We BuildFrom EverandSAM: One Robot, a Dozen Engineers, and the Race to Revolutionize the Way We BuildRating: 5 out of 5 stars5/5 (5)

- ChatGPT: The Future of Intelligent ConversationFrom EverandChatGPT: The Future of Intelligent ConversationRating: 3.5 out of 5 stars3.5/5 (8)

- The AI Generation: Shaping Our Global Future with Thinking MachinesFrom EverandThe AI Generation: Shaping Our Global Future with Thinking MachinesRating: 4 out of 5 stars4/5 (2)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.From EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Rating: 4 out of 5 stars4/5 (5)

- A Welder’s Handbook to Robotic ProgrammingFrom EverandA Welder’s Handbook to Robotic ProgrammingRating: 5 out of 5 stars5/5 (3)

- The Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityFrom EverandThe Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityRating: 3.5 out of 5 stars3.5/5 (22)

- Practical Robotics in C++: Build and Program Real Autonomous Robots Using Raspberry Pi (English Edition)From EverandPractical Robotics in C++: Build and Program Real Autonomous Robots Using Raspberry Pi (English Edition)No ratings yet

- Artificial Intelligence: Machine Learning, Deep Learning, and Automation ProcessesFrom EverandArtificial Intelligence: Machine Learning, Deep Learning, and Automation ProcessesRating: 5 out of 5 stars5/5 (2)

- Artificial Intelligence: From Medieval Robots to Neural NetworksFrom EverandArtificial Intelligence: From Medieval Robots to Neural NetworksRating: 4 out of 5 stars4/5 (4)

- Mastering Drones - A Beginner's Guide To Start Making Money With DronesFrom EverandMastering Drones - A Beginner's Guide To Start Making Money With DronesRating: 2.5 out of 5 stars2.5/5 (3)

- Arduino: The ultimate Arduino guide for beginners, including Arduino programming, Arduino cookbook, tips, tricks, and more!From EverandArduino: The ultimate Arduino guide for beginners, including Arduino programming, Arduino cookbook, tips, tricks, and more!Rating: 3 out of 5 stars3/5 (1)

- Evil Robots, Killer Computers, and Other Myths: The Truth About AI and the Future of HumanityFrom EverandEvil Robots, Killer Computers, and Other Myths: The Truth About AI and the Future of HumanityRating: 4.5 out of 5 stars4.5/5 (3)

- Artificial You: AI and the Future of Your MindFrom EverandArtificial You: AI and the Future of Your MindRating: 4 out of 5 stars4/5 (3)

- Atlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceFrom EverandAtlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceRating: 5 out of 5 stars5/5 (9)