Professional Documents

Culture Documents

Rec Erc 84 313

Uploaded by

Alireza KhodabandehOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rec Erc 84 313

Uploaded by

Alireza KhodabandehCopyright:

Available Formats

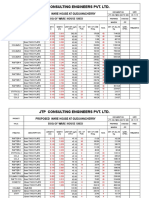

Table 2.

- Results of tests on pipe erosion specimens

Nominal Inner Lining Total losses Percent thickness

Pipe Pipe inside surface thickness loss based on lining Performance Pipe

No. material' diameter or liner (mils) Weight Weight Thickness Thickness (60 mil max.) RPM rating' No.

(inches) composition (percent)2 (grams) (percent) (mils) spec. criterion3

5L Steel 8 Butyl rubber sheet 250 0.2 .3.5 50.7 1.4 Good 5L

5M Steel 8 Neoprene rubber sheet 188 .3 4.0 5 .6 1.2 Good 5M

5N Steel 8 Natural rubber sheet 125 .6 4.0 5 .7 1.4 Good 5N

5P RPM 18 Polyester -resi n- rich 45 7.2 62.0 16.0 7.2 20.6 Good 5P

mortar

50 RPM 18 AbSi03-filied poly- 50 9.6 106.0 16.8 8.2 20.5 Good 50

ester resin

5S Steel 8 AbSi03-filied poly- 110 3.6 40.0 4.4 6.8 13.6 Good 5S

ester resin

5T Steel 8 AbSi03-filied poly- 116 4.4 40.0 3.2 4.8 9.6 Good 5T

ester resin

5U Nylon-yarn- 8 PVC 17.0 53.6 7.2 Good 5U

reinforced PVC

5V Nylon-yarn- 8 PVC 16.0 53.4 6.8 Good 5V

reinforced PVC

5X RPM 8 Al2Si03-filied poly- 25 75.6 106.0 78.4 19.5 100.0 Low 5X

ester resin

5Y RPM 8 Polyester-resin-rich 25 28.4 38.0 16.0 3.9 26.0 Good 5Y

mortar

5Z RPM 8 AbSi03-filled poly- 25 76.4 107.0 76.8 19.2 100.0 Low 5Z

ester resin

6A RPM 18 Polyester-resin-rich 30 10.8 67.0 24.0 7.4 37.0 Moderate 6A

mortar

68 RPM 18 AbSi03-filied poly- 30 16.4 99.0 9.2 2.5 13.5 Good 6B

ester resin

6C RPM 18 AbSi03-filied poly- 30 19.6 107.0 9.2 2.7 13.5 Good 6C

ester resin

6D Polyethylene 8 Polyethylene 3.0 5 .6 1.2 Good 6D

ASTM F678 ,

- 13.7 124.0 10.0 3.0 ;5.0 Good 18531A

18531A-RPM 24 '"

AbSiOa-filied polyester 30

(Ashland) resin

14.8 133.0 8.9 2.6 13.0 Good 18531B

18531 B-RPM 24 AbSi03-filied polyester 30

(Ashland) resin

13.3 60.0 17.3 5.2 26.0 Good 71676

71676- RPM 12 AbSi03-filied polyester 30

(Ashland) resin

16.0 144.0 17.7 5.3 265 Good 90876

90876- RPM 24 AbSi03-filied polyester 30

(Ashland) resin

11.2 66.0 21.6 20.6 41.2 Good D

D Steel 8 Coal-tar enamel 95

1 :: Reinforcedplastic mortar pipe.

"RPM"

2 Based on entire lining.

3 Calculation: Percent loss:: A -7-(8-10), where A:: erosion loss in mils; B ::originalliningthickness in mils, not to exceed 60 mils; less than 50 percent

loss is considered satisfactory.

4 Rating system: "Good"

- Good erosion resistance; includes linings losing 20 percent or less in thickness, no wear through liner.

" "Moderate"Moderate erosion resistance; includes linings losing 20 to 80 percent in thickness, less than 10 percent'wear

-

through.

"Low" - Low erosion resistance; includes linings losing more than 80 percent in thickness, more than 10 percent wear through.

5 Thickness loss calculated from weight loss.

6 Weight loss due to erosion of liner obscured by absorption of water into pipe wall.

7 No erosion test on these sections; there was only water in the rotating pipe to ascertain integrity of the liner.

You might also like

- Rec Erc 84 321Document1 pageRec Erc 84 321Alireza KhodabandehNo ratings yet

- Rec Erc 84 320Document1 pageRec Erc 84 320Alireza KhodabandehNo ratings yet

- Rec Erc 84 318Document1 pageRec Erc 84 318Alireza KhodabandehNo ratings yet

- Rec Erc 84 319Document1 pageRec Erc 84 319Alireza KhodabandehNo ratings yet

- Rec Erc 84 322Document1 pageRec Erc 84 322Alireza KhodabandehNo ratings yet

- Material List Warehouse PT KIEDocument6 pagesMaterial List Warehouse PT KIEPutra MakmurNo ratings yet

- BOQ - Base Rate FileDocument3 pagesBOQ - Base Rate FileSaleem khanNo ratings yet

- Contoh MHPS PastiDocument105 pagesContoh MHPS Pastimohamad alfiantoNo ratings yet

- Properties of MaterialDocument3 pagesProperties of Materialwanglingheng0330No ratings yet

- Analysis of Rates.1Document45 pagesAnalysis of Rates.1Ratnesh PatelNo ratings yet

- Allowable Velocity and Maximum Shear Stress Streambank and Shoreland Protection Code 580Document2 pagesAllowable Velocity and Maximum Shear Stress Streambank and Shoreland Protection Code 580toantutoantuNo ratings yet

- Rec Erc 84 317Document1 pageRec Erc 84 317Alireza KhodabandehNo ratings yet

- BoqDocument76 pagesBoqArnold LundayNo ratings yet

- Abrasive BlastingDocument1 pageAbrasive BlastingRinush Fedrikdo Bushido OdaNo ratings yet

- Beta BrosurDocument1 pageBeta BrosurMizziNo ratings yet

- Renewsys India Pvt. LTD.: Form Factor - 18 Cells Reference Drawing Numbers: Bom For C06 - 5Wp With Elmex JB Per ModuleDocument31 pagesRenewsys India Pvt. LTD.: Form Factor - 18 Cells Reference Drawing Numbers: Bom For C06 - 5Wp With Elmex JB Per Modulesandeep devabhaktuniNo ratings yet

- Bill of Quantity Schedule For Boiler SystemDocument4 pagesBill of Quantity Schedule For Boiler SystemshakibNo ratings yet

- Pressure VesselsDocument2 pagesPressure VesselsDeepak SridharNo ratings yet

- Bulk Material StockDocument8 pagesBulk Material StockAshanmugam SunfaceNo ratings yet

- JTP-199-PMSC-S03 To S09-R0 (BOQ of Steel Structure For Ware House Shed)Document12 pagesJTP-199-PMSC-S03 To S09-R0 (BOQ of Steel Structure For Ware House Shed)VasanthakumarNo ratings yet

- Glass Data - v4 Low ResDocument15 pagesGlass Data - v4 Low ResPatrick SyNo ratings yet

- Schedule B: Providing Air-Conditioning System For New Frozen Semen Station at Ta. Mandavi, Dist. SuratDocument6 pagesSchedule B: Providing Air-Conditioning System For New Frozen Semen Station at Ta. Mandavi, Dist. SuratKalpit ShahNo ratings yet

- Mechanical Properties of PlasticsDocument4 pagesMechanical Properties of PlasticsVainin WiselinkNo ratings yet

- 18552134595e2e843e917bf - TEKIRODocument28 pages18552134595e2e843e917bf - TEKIRONovia SariNo ratings yet

- Base Plate CoverDocument1 pageBase Plate CoverhangloqueNo ratings yet

- Data Sheet Kabelindo Nyfgby Cable Based On Kabelindo Datasheet PDF FreeDocument10 pagesData Sheet Kabelindo Nyfgby Cable Based On Kabelindo Datasheet PDF FreeRisa RidmaNo ratings yet

- Dec Month Production DetailsDocument8 pagesDec Month Production DetailsqualityNo ratings yet

- Saudi Cable Catalogue - Low VoltageDocument1 pageSaudi Cable Catalogue - Low VoltageMd SaquibNo ratings yet

- Datasheet DIN - 200809 1Document4 pagesDatasheet DIN - 200809 1Ramiro FelicianoNo ratings yet

- B-312 Series E-1532 Technical BrochureDocument4 pagesB-312 Series E-1532 Technical BrochureAnonymous 7xHNgoKE6eNo ratings yet

- SS RoadDocument16 pagesSS RoadKartik KandangkelNo ratings yet

- S. No Distance Lead Description of Material Source of Material Total Distance Cart Track Sandy Track Metal TrackDocument173 pagesS. No Distance Lead Description of Material Source of Material Total Distance Cart Track Sandy Track Metal TrackRatnesh PatelNo ratings yet

- 10 - Ball ValvesDocument12 pages10 - Ball ValvesJosh WhiteNo ratings yet

- PT. Tekenomiks IndonesiaDocument4 pagesPT. Tekenomiks IndonesiaAhmat RamadaniNo ratings yet

- 5200FCDocument5 pages5200FC夏斌No ratings yet

- Valvula Compuerta Os&y 1 14'' Mod. BGV 175psi Roscado Bronce Ul-Fm, FivalcoDocument1 pageValvula Compuerta Os&y 1 14'' Mod. BGV 175psi Roscado Bronce Ul-Fm, FivalcoAngeloNo ratings yet

- Gujarat Packaging Industries: Paper Cups (Single Wall)Document3 pagesGujarat Packaging Industries: Paper Cups (Single Wall)Khyati KamdarNo ratings yet

- 101 Factors Affecting Welding Capbility and CostDocument5 pages101 Factors Affecting Welding Capbility and CostdayalramNo ratings yet

- Detailed Estimate: Project Title: LocationDocument3 pagesDetailed Estimate: Project Title: LocationTop TrenDz TVNo ratings yet

- Exp-298 m76-Nr Blends 0Document2 pagesExp-298 m76-Nr Blends 0sugiharyantobanNo ratings yet

- AHU New CostingDocument48 pagesAHU New Costingmohammed RizwanNo ratings yet

- BE/BE12: ISO 5599/1 ValvesDocument12 pagesBE/BE12: ISO 5599/1 ValvesDaniel MilenkovicNo ratings yet

- Owner Storey Residential Cost EstimateDocument33 pagesOwner Storey Residential Cost EstimateLouis James BonsayNo ratings yet

- General - Fillers GBDocument2 pagesGeneral - Fillers GBDraganNo ratings yet

- PVCLWVTG h15t11 Nyy 1coreDocument2 pagesPVCLWVTG h15t11 Nyy 1coreRusdi DidiNo ratings yet

- Jameel Auto Parts: SN Parts Name Parts Number Machine Brand Rate Per QTYDocument4 pagesJameel Auto Parts: SN Parts Name Parts Number Machine Brand Rate Per QTYateeq khanNo ratings yet

- LRRB Project 879: Ally Akkari, MndotDocument31 pagesLRRB Project 879: Ally Akkari, MndotBanNo ratings yet

- 208B Válvulas RWVDocument1 page208B Válvulas RWVПабло Рамирес РамиресNo ratings yet

- Hoja de Datos para Conjunto Motor-Acople-Bomba Ansi 2196 Watercol 4X6-13 Mto 200522 Agua CorrosivaDocument4 pagesHoja de Datos para Conjunto Motor-Acople-Bomba Ansi 2196 Watercol 4X6-13 Mto 200522 Agua CorrosivaArturo Camacho SalazarNo ratings yet

- MSTwall PDFDocument1 pageMSTwall PDFdinesh panchalNo ratings yet

- Boq For Ifad Pump Project (Solar System With Drip & Microsprinkler Water Distribution)Document4 pagesBoq For Ifad Pump Project (Solar System With Drip & Microsprinkler Water Distribution)Mr. 420No ratings yet

- Soldering Fluid Fulley SPB 355-2 Ring Plat Bogi King Nipple 1/2" Bearing 22220Document2 pagesSoldering Fluid Fulley SPB 355-2 Ring Plat Bogi King Nipple 1/2" Bearing 22220Naldy NaldyNo ratings yet

- Sheltor CostDocument1 pageSheltor CostBalajiYachawadNo ratings yet

- Summary Planning Fabrication & Installation Hoist Crane Warehouse JakateDocument1 pageSummary Planning Fabrication & Installation Hoist Crane Warehouse JakateCobra OrayNo ratings yet

- Senju OZSeries - 63 221CM ZDocument1 pageSenju OZSeries - 63 221CM ZAlexsander CamargoNo ratings yet

- Submersible Pumps For Deep WellsDocument7 pagesSubmersible Pumps For Deep WellsThanos DimouNo ratings yet

- ESM Inert Support BallsDocument1 pageESM Inert Support BallsBamrung SungnoenNo ratings yet

- WSA 109 - 2011 Flange Gaskets Working SheetDocument1 pageWSA 109 - 2011 Flange Gaskets Working SheetAbit BronjaNo ratings yet

- Mix Typ e Wa Ter Rati o W/B T o Bin Der Crush Ing (Tons) Loa Ds Stren GTH (Psi)Document9 pagesMix Typ e Wa Ter Rati o W/B T o Bin Der Crush Ing (Tons) Loa Ds Stren GTH (Psi)Asghar Hussain Shah S/o Zubair Shah MS Engg. Management (Swat Campus)No ratings yet

- Wall Thickness and Material Grade Selection: GeneralDocument1 pageWall Thickness and Material Grade Selection: GeneralAlireza KhodabandehNo ratings yet

- References: 20 Qiang Bai and Yong BaiDocument1 pageReferences: 20 Qiang Bai and Yong BaiAlireza KhodabandehNo ratings yet

- 23Document1 page23Alireza KhodabandehNo ratings yet

- 16 Qiang Bai and Yong Bai: Pipeline InstallationDocument1 page16 Qiang Bai and Yong Bai: Pipeline InstallationAlireza KhodabandehNo ratings yet

- Bending Loads. External Impact Loads.: 24 Qiang Bai and Yong BaiDocument1 pageBending Loads. External Impact Loads.: 24 Qiang Bai and Yong BaiAlireza KhodabandehNo ratings yet

- Untitled 2Document1 pageUntitled 2Alireza KhodabandehNo ratings yet

- Pipe Laying by Lay Vessel: Mode 1 Buckle Mode 2 Buckle Mode 3 Buckle Mode 4 BuckleDocument1 pagePipe Laying by Lay Vessel: Mode 1 Buckle Mode 2 Buckle Mode 3 Buckle Mode 4 BuckleAlireza KhodabandehNo ratings yet

- Untitled 6Document1 pageUntitled 6Alireza KhodabandehNo ratings yet

- Untitled 3Document1 pageUntitled 3Alireza KhodabandehNo ratings yet

- Finite Element Analysis: Pipeline Installation by Tow or PullDocument1 pageFinite Element Analysis: Pipeline Installation by Tow or PullAlireza KhodabandehNo ratings yet

- Untitled 1Document1 pageUntitled 1Alireza KhodabandehNo ratings yet

- Rec Erc 84 332Document1 pageRec Erc 84 332Alireza KhodabandehNo ratings yet

- 2 S. K. Gawali Et Al.: 1.1.1 Additive ManufacturingDocument1 page2 S. K. Gawali Et Al.: 1.1.1 Additive ManufacturingAlireza KhodabandehNo ratings yet

- Rec Erc 84 311Document1 pageRec Erc 84 311Alireza KhodabandehNo ratings yet

- Rec Erc 84 334Document1 pageRec Erc 84 334Alireza KhodabandehNo ratings yet

- Rec Erc 84 329Document1 pageRec Erc 84 329Alireza KhodabandehNo ratings yet

- Rec Erc 84 317Document1 pageRec Erc 84 317Alireza KhodabandehNo ratings yet

- Rec Erc 84 315Document1 pageRec Erc 84 315Alireza KhodabandehNo ratings yet

- Rec Erc 84 36Document1 pageRec Erc 84 36Alireza KhodabandehNo ratings yet

- Rec Erc 84 38Document1 pageRec Erc 84 38Alireza KhodabandehNo ratings yet

- 14 S. K. Gawali Et AlDocument1 page14 S. K. Gawali Et AlAlireza KhodabandehNo ratings yet

- 1.2.1 Design Methodology: 6 S. K. Gawali Et AlDocument1 page1.2.1 Design Methodology: 6 S. K. Gawali Et AlAlireza KhodabandehNo ratings yet

- 7th Congr Mat TestDocument6 pages7th Congr Mat TestAlireza KhodabandehNo ratings yet

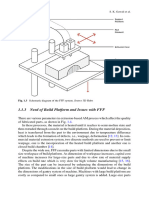

- 1.1.3 Need of Build Platform and Issues With FFF: 4 S. K. Gawali Et AlDocument1 page1.1.3 Need of Build Platform and Issues With FFF: 4 S. K. Gawali Et AlAlireza KhodabandehNo ratings yet

- CERTILAS EN Edition2023 315Document1 pageCERTILAS EN Edition2023 315Alireza KhodabandehNo ratings yet

- CERTILAS EN Edition2023 317Document1 pageCERTILAS EN Edition2023 317Alireza KhodabandehNo ratings yet

- Ni SiC AISI 304Document9 pagesNi SiC AISI 304Alireza KhodabandehNo ratings yet

- Fluid KinematicsDocument49 pagesFluid KinematicsJM Jusay CarabLeNo ratings yet

- Data Sheet For Al 800 AltairDocument4 pagesData Sheet For Al 800 Altairirfan vpNo ratings yet

- Design of Staircase: Prof Ts DR Abd Latif Saleh Assoc Prof DR Izni Syahrizal IbrahimDocument95 pagesDesign of Staircase: Prof Ts DR Abd Latif Saleh Assoc Prof DR Izni Syahrizal IbrahimRuben OoiNo ratings yet

- 10 Erodible ChannelsDocument32 pages10 Erodible ChannelsLee CastroNo ratings yet

- BS6297 - Code of Practice For The Design and Installation of Drainage Field For Use in Wastewater TreatmentDocument44 pagesBS6297 - Code of Practice For The Design and Installation of Drainage Field For Use in Wastewater TreatmentArvin Bhurtun100% (1)

- The Effect of Surcharge Loading Adjacent To Piles, TRLDocument84 pagesThe Effect of Surcharge Loading Adjacent To Piles, TRLFEiv Seba Ramirez100% (1)

- Cost Estimate For Pumps, Valves & Piping For Roll Cooling Pump HouseDocument3 pagesCost Estimate For Pumps, Valves & Piping For Roll Cooling Pump HouseBimal DeyNo ratings yet

- Soil Mix CementDocument8 pagesSoil Mix CementM Alfian FaruqiNo ratings yet

- Indira-Paryavaran-Bhawani GrihaDocument2 pagesIndira-Paryavaran-Bhawani GrihaVikash Kumar1999No ratings yet

- Shrinkage Cracks & PreventionDocument3 pagesShrinkage Cracks & PreventionKarambir SinghNo ratings yet

- 10-11 - Shear in BeamsDocument7 pages10-11 - Shear in BeamsOsama TamariNo ratings yet

- Themaar 1 Building-Investigation ReportDocument53 pagesThemaar 1 Building-Investigation ReportRamsha YasirNo ratings yet

- Design of Horizontal Vessels Supported On Saddles With PV EliteDocument34 pagesDesign of Horizontal Vessels Supported On Saddles With PV Elitepowder18100% (5)

- Brochure - Sikafloor - Sikagard Coating Systems - ETAG 022Document5 pagesBrochure - Sikafloor - Sikagard Coating Systems - ETAG 022baspiskoposNo ratings yet

- EPFM - Elasto Plastic Fracture MechanicsDocument11 pagesEPFM - Elasto Plastic Fracture MechanicsSaima naazNo ratings yet

- Review: Cross-Laminated Timber: Design and PerformanceDocument1 pageReview: Cross-Laminated Timber: Design and PerformanceJulian TumielewiczNo ratings yet

- 11 - Concrete Flexural DesignDocument20 pages11 - Concrete Flexural Designleona Grace MendozaNo ratings yet

- 3 - Plumbing MEP - Drainage-RevDocument57 pages3 - Plumbing MEP - Drainage-Revsardarmkhan100% (10)

- P.E. Civil Exam Review: Structural AnalysisDocument46 pagesP.E. Civil Exam Review: Structural AnalysisBrandonNo ratings yet

- GEOGRIDS Final ReportDocument58 pagesGEOGRIDS Final ReportJovan BucolNo ratings yet

- Stresses & SettlementDocument2 pagesStresses & SettlementJumari CaselesNo ratings yet

- Ashraecertified Hvac Designer (CHD)Document104 pagesAshraecertified Hvac Designer (CHD)MUBASHIR100% (2)

- IGS News Jul-Sept 2021Document32 pagesIGS News Jul-Sept 2021GurpreetNo ratings yet

- AITC Technical Note 19Document7 pagesAITC Technical Note 19klb75No ratings yet

- Design and Analysis of Bridge Girders Using Different Codes IJERTV8IS070188Document8 pagesDesign and Analysis of Bridge Girders Using Different Codes IJERTV8IS070188Pritesh RAINo ratings yet

- Side GirtsDocument11 pagesSide Girtsapi-265624085No ratings yet

- Damp ProofingDocument18 pagesDamp Proofingchristelle do100% (2)

- Physicschapter 6Document14 pagesPhysicschapter 6Owais FarooqNo ratings yet

- GFC Appfly Tanks 05.12Document2 pagesGFC Appfly Tanks 05.12Robert Eshwer100% (1)

- Esteem Projects Pvt. LTD.: Noida, IndiaDocument66 pagesEsteem Projects Pvt. LTD.: Noida, IndiamonugeniNo ratings yet