Professional Documents

Culture Documents

Rec Erc 84 318

Uploaded by

Alireza KhodabandehOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rec Erc 84 318

Uploaded by

Alireza KhodabandehCopyright:

Available Formats

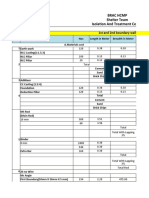

Table 6. - Average losses in pipe erosion specimens (from report No.

ChE-97)

Average losses ner run Total losses

Weight, Weight, Thickness, Thickness, Weight, Weight, Thickness, Thickness,

Pipe No. Lining Material percent grams percent mils percent grams percent mils Perf'onnance rating 1/ Pipe No.

3F Epoxy polysulfide mortar 0.5 8.2 1.0 2.4 9.0 33.0 4.0 9.5 Good 3F

4 coats of VR-3, top is white 17.2 12.2 17.4 1.3 68.8 49.0 69.6 5.4 Low 3-0

3-0

3P 4 coats of VR-3, top is red 13.3 12.0 13.1 1.4 53.2 48.0 52.4 5.5 Moderate 3P

3Q 4 coats of VR-3, top is white 12.7 13.6 15.3 2.0 50.8 54.5 61.2 8.1 Moderate 3Q

3R 4 coats of VR-3, top is white 18.4 15.8 20.2 1.5 73.6 63.5 80.8 6.0 Low 3R

35 Epoxy resin paint 9.6 20.1 15.1 3.4 38.4 85.0 60.4 13.8 Moderate 35

3T Epoxy resin paint 15.3 23.0 18.4 4.0 61.2 92.5 73.6 15.9 Moderate 3T

3U Neoprene adhesive, 4 coats 0.7 0.5 1.2 0.3 2.7 2.0 4.8 1.2 Good 3U

( ) 0.2 0.2 0.8 0.8 Good )

BluetJolyurethane elastomer ) 0.6 2.2 2.5 2.0 ) 3V

3V ( Pink polyurethane elastomer 0.5 0.3 2.0 1.2 Good

3W 4 coats of neoprene paint 0.6 0.6 0.8 0.1 2.4 2.5 3.2 0.4 Good 3W

3X 4 coats of neoprene paint 16.5 16.5 21.0 3.0 66.0 66.0 84.0 12.1 Low 3X

3Y Polysulfide rubber coating 25.0 17.0 25.0 1.2 100.0 68.0 100.0 4.6 Low 3Y

32 Polyurethane coating 0.3 0.5 0.8 0.2 1.2 1.0 3.2 0.7 Good 32

4A Epoxy resin paint 13.0 13.2 19.0 2.1 52.0 53.0 76.0 8.2 Moderate 4A

4B Polyurethane potting and molding compound 0.0 0.0 0.3 0.1 0.0 0.0 1.2 0.5 Good 4B

4c Asbestos-cement pipe with transparent

- 5.0 - - - 19.0 - - Good 4c

epoxy resin liner

40 Fused vinyl resin 2.6 4.5 4.0 1.3 10.4 18.0 16.0 5.3 Good 40

4E Fused epoxy resin - 15.0 23.0 2.3 - 61.0 'if.O 9.3 Poor 4E

4F Fused epoxy resin 22.5 24.0 25.0 2.3 90.0 97.0 100.0 9.0 Poor 4F

4G Fused epoxy resin 20.0 20.0 21.0 3.7 80.0 79.0 84.0 14.9 Low 4G

4H 3-coat epoxy resin paint 1.6 6.0 2.1 1.8 6.6 24.0 8.5 7.2 Good 4H

4I

4J

Fused chlorinated

Epoxy j oint sealer

polyether -- 4.2

2.2

10.1

4.0

1.0

2.8 -

- 17.0

9.0

40.4

16.0

5.8

2.9

Poor

-

4I

4J

4K Coal tar epoxy paint 15.1 43.7 18.2 11.8 60.6 175.0 72.8 35.4 Moderate 4K

4L Coal tar epoxy paint 21.6 30.5 23.1 4.8 86.5 122.0 92.6 19.1 Low 4L

~ 4M Polyurethane coating 0.0 81. gain 1.0 0.6 0.0 81. gain 2.4 4.0 Good 4M

4N Epoxy resin paint 33.3 20.0 33.3 2.3 100.0 59.0 100.0 7.0 Poor 4N

4-0 Filament wound epoxy pipe - Polyester 0.8 9.8 1.4 2.9 3.2 39.0 5.6 11.5 Good 4-0

liner

4p Ceramic spray coating 3.7 14.2 3.8 3.0 14.8 57.0 15.1 12.2 Good 4p

4Q

4R

Epoxy mortar

Epoxy mortar -- 31.2

5.0

0.0

1.0

0.0

1.0

-

-

125.0

19.0

-

4.0

0.0

4.0

Good

Good

4Q

4R

45 polyurethane coating 1.9 1.0 2.6 0.6 7.8 4.0 10.3 2.3 Good 45

4T Flamesprayed molybdenummetal - 6.8 13.8 0.4 - 27.0 55.2 1.6 Moderate 4T

4u Flame sprayed altnnim.nnoxide - 19.0 22.0 1.2 - 76.0 87.7 5.0 Low 4u

4v Flame sprayed bronze metal -- 7.3 6.0 1.1 - 29.0 24.2 4.4 Moderate 4v

4w Flame sprayed stainless steel 5.5 3.8 0.4 - 22.0 15.4 1.2 Good 4w

4x Flame sprayed stainless steel - 3.6 9.6 0.1 -6.0 14.5 38.6 0.5 Moderate 4x

4Y Filament wound pOlyester mortar pipe with 1.5 2.6 8.8 5.5 105.0 35.2 22.0 Moderate 4y

polyester resin liner

42 Filament wound polyester mortar pipe with 0.1 2.0 2.0 1.0 0.4 6.5 4.0 4.5 Good 4z

rubber liner

5A Filament WOW1dpolyester mortar pipe with 0.4 6.8 5.6 1.7 1.6 27.0 21.4 6.7 Good 5A

polyester mortar lining

5B Epoxy mortar 0.2 3.3 0.4 2.0 1.0 13.0 1.8 7.5 Good 5B

5C Epoxy mortar 1.0 25.2 2.8 10.9 4.0 101. 0 11.0 43.5 Good 5C

50 Epoxy mortar 0.1 1.8 0.8 3.0 0.5 7.0 3.G 12.0 Good 5D

5E Epoxy mortar 1.4 34.8 3.5 17.2 5.6 139.0 14.0 69.0 Good 5E

5F Epoxy mortar 11.4 54.0 13.5 20.8 45.5 216.0 54.0 83.0 Moderate 5F

5G Coal tar enamel 0.1 0.6 0.6 0.6 1.5 9.0 10.0 9.0 Good 5G

5H Coal tar enamel 0.4 2.0 0.2 0.2 5.0 27.0 2.8 2.5 Good 5H

5I 26-gage Type 304 stainless steel sheet 0.6 2.7 1.2 0.7 2.4 11.0 4.8 1.0 Good 5I

5J Neoprene-polyurethane elastomer 81. gain 51. gain 1.0 0.2 51. gain 81. gain 4.0 1.0 Good 5J

D Coal tar enamel 2.8 16.5 5.4 5.1 11.2 66.0 21.6 20.6 Good 0

!/ Rating system: "Good" - Good Moderate

erosion resistance; includes materials losing 5 percent or less in weight or thickness per ntn, no wear-through to steel.

"Moderate" - erosion resistance; includes materials losing 5 to 20 percent in weight or thickness per run, 10 percent or less wear-through to steel.

"Low"- Lowerosion resistance; includes materials losing more than 20 percent in weight or thickness per run, more than 10 percent wear-through to steel.

"Poor" - Poor erosion resistance; includes materials partly worn through to steel atter only one or two runs using sand as the erosive medim.

You might also like

- Innovene Pe ProductsDocument25 pagesInnovene Pe Productsghasem_726990287No ratings yet

- Rec Erc 84 317Document1 pageRec Erc 84 317Alireza KhodabandehNo ratings yet

- Rec Erc 84 313Document1 pageRec Erc 84 313Alireza KhodabandehNo ratings yet

- Divyanshu Srivastava@Project - Main DocumentDocument33 pagesDivyanshu Srivastava@Project - Main DocumentAkshay SengarNo ratings yet

- Cost Impact of Raw Material Rate IncreaseDocument1 pageCost Impact of Raw Material Rate IncreaseIqbal singh DhanjalNo ratings yet

- MCM - Final RoughDocument41 pagesMCM - Final RoughNaveen NatarajanNo ratings yet

- Estimate PlasteringDocument11 pagesEstimate PlasteringJohnNo ratings yet

- Nes D2188Document6 pagesNes D2188prasannaNo ratings yet

- 3 Materials - 3Document13 pages3 Materials - 3Kesava KalepuNo ratings yet

- Ipc - Birch Plywood Specifications PDFDocument7 pagesIpc - Birch Plywood Specifications PDFAnubhav MukherjeeNo ratings yet

- Takeoff MaguloDocument4 pagesTakeoff MaguloEngr RicardoNo ratings yet

- Painting Estimation Contact EnergyDocument1 pagePainting Estimation Contact EnergytanniayulianaNo ratings yet

- Effects of Fabric Alkalinity in Resin FinishingDocument4 pagesEffects of Fabric Alkalinity in Resin Finishingviathung02No ratings yet

- Astm A325m PDFDocument1 pageAstm A325m PDFFrose KhanNo ratings yet

- Exp-298 m76-Nr Blends 0Document2 pagesExp-298 m76-Nr Blends 0sugiharyantobanNo ratings yet

- Poplar Puls FBB GC2 - Shandong MillDocument1 pagePoplar Puls FBB GC2 - Shandong MillBill KingNo ratings yet

- Particle Size DistributionDocument10 pagesParticle Size DistributionSaraswati Noor100% (1)

- Pile Capacity PrecastDocument38 pagesPile Capacity Precastbasum matNo ratings yet

- Concrete Calculation For T1Document1 pageConcrete Calculation For T1Goku SaitoNo ratings yet

- RoofDek D159-Acoustic Load TableDocument1 pageRoofDek D159-Acoustic Load TableЙордан ЛиляновNo ratings yet

- Calculo Rapido DialisisDocument4 pagesCalculo Rapido DialisisAlvaro paxi quispeNo ratings yet

- Laboratory Test Result: Single Sieve For Concrete Materials SpecificationDocument2 pagesLaboratory Test Result: Single Sieve For Concrete Materials SpecificationAndry SetiawanNo ratings yet

- Aor Cantilever 6m SignDocument6 pagesAor Cantilever 6m SignDaljit624No ratings yet

- Isolation Centre (Boundary Wall)Document5 pagesIsolation Centre (Boundary Wall)Saker ahmedNo ratings yet

- Whatman Filtration Catalog PDFDocument68 pagesWhatman Filtration Catalog PDFJohn E. BeNo ratings yet

- MU19 Pinos Elasticos Din 1481 Iso 8752 TecemDocument1 pageMU19 Pinos Elasticos Din 1481 Iso 8752 Tecemmugiwara ruffyNo ratings yet

- Certificate of Analysis Conveyor Belt PT. Mutiara Tanjung Lestari Order Tahun 2022Document29 pagesCertificate of Analysis Conveyor Belt PT. Mutiara Tanjung Lestari Order Tahun 2022RestuNo ratings yet

- Brosur Pt. Srirejeki Perdana Steel-1Document16 pagesBrosur Pt. Srirejeki Perdana Steel-1Agus SofiansyahNo ratings yet

- 2nd Stock Report D.O. No. 04 (13.10.08)Document3 pages2nd Stock Report D.O. No. 04 (13.10.08)Maaz SheikhNo ratings yet

- GN 589 Lifting Points Continued: Safety InstructionsDocument1 pageGN 589 Lifting Points Continued: Safety InstructionsAlbertoNo ratings yet

- Planning & Installation of Warehouse Hoist CraneDocument1 pagePlanning & Installation of Warehouse Hoist CraneCobra OrayNo ratings yet

- CBA of TanksDocument25 pagesCBA of TanksNithinNo ratings yet

- Form Work NO Length Width Area: 1 0.8 0.6 0.48 Axis F14, C11Document117 pagesForm Work NO Length Width Area: 1 0.8 0.6 0.48 Axis F14, C11halieyNo ratings yet

- Public Works Department Government of Rajasthan: I. Source and Location of All MaterialsDocument50 pagesPublic Works Department Government of Rajasthan: I. Source and Location of All MaterialsSUNIL JHILMILNo ratings yet

- TDSDocument3 pagesTDSBassam SayedNo ratings yet

- Puri Orchard Construction Cost CalculationDocument37 pagesPuri Orchard Construction Cost CalculationKukuh Septa NugrohoNo ratings yet

- Comparison between Taiwan and Chinese CementDocument4 pagesComparison between Taiwan and Chinese CementNidDouNo ratings yet

- And Seawater: G 2.24 0.02 GAG 2.46 0.02 AGA 2.67 0.03 A 2.73 0.04Document2 pagesAnd Seawater: G 2.24 0.02 GAG 2.46 0.02 AGA 2.67 0.03 A 2.73 0.04Ahmet ErkliğNo ratings yet

- PST 590 Results Lab Composite FabricationDocument1 pagePST 590 Results Lab Composite FabricationAmniNo ratings yet

- Is 19781982Document5 pagesIs 19781982Padakandla SumanNo ratings yet

- Bab 4.1 Dan 4.4 PenlitDocument9 pagesBab 4.1 Dan 4.4 PenlitElan Patria NusadiNo ratings yet

- Pipe Wall Thickness Calculation-ASME B31.3Document4 pagesPipe Wall Thickness Calculation-ASME B31.3Rajul MuraliNo ratings yet

- DS-KM LV SINGLECORE - PVC Latest Spec From June OnwardsDocument2 pagesDS-KM LV SINGLECORE - PVC Latest Spec From June OnwardsavivekprasathNo ratings yet

- Kurva S Final ReportDocument3 pagesKurva S Final ReportHendrika A. IrawanNo ratings yet

- Road Infrastructure Development Company of Rajasthan LTD.: I. Source and Location of All MaterialsDocument53 pagesRoad Infrastructure Development Company of Rajasthan LTD.: I. Source and Location of All Materialssunil kuldeepNo ratings yet

- Grafik Macam Sampel Terhadap Nilai Hedonik Warna TapeDocument7 pagesGrafik Macam Sampel Terhadap Nilai Hedonik Warna TapeFajar SaputraNo ratings yet

- Estimate of A Reservoir - 2.5x2.5x2.5Document4 pagesEstimate of A Reservoir - 2.5x2.5x2.5Engr'Shemaiah JimenezNo ratings yet

- Metsaboard Pro FSB Cup en IsoDocument1 pageMetsaboard Pro FSB Cup en IsooleoproteusNo ratings yet

- Monoprice 3D Printing Filament: All Filament Diameter: 1.75 .05mmDocument1 pageMonoprice 3D Printing Filament: All Filament Diameter: 1.75 .05mmDutsan RojasNo ratings yet

- Bearing Capacity SPTM27 1 2Document5 pagesBearing Capacity SPTM27 1 2Tarek AbulailNo ratings yet

- 2022 05 Arri Formatsandresolutionsoverview 4 1 DataDocument3 pages2022 05 Arri Formatsandresolutionsoverview 4 1 Datagigih kartikaNo ratings yet

- Chapter Three Material Characterization and Laboratory TestsDocument25 pagesChapter Three Material Characterization and Laboratory TestsHANAN HUSSNo ratings yet

- SR - No Material Name Req - Qty Available Qyt. Date RemarkDocument3 pagesSR - No Material Name Req - Qty Available Qyt. Date RemarkAmandeep SinghNo ratings yet

- Fire Fighting: Amount S.N Description Unit Qty G1 Qty G3 Qty G5 Qty G7 Total Quantity Rate Contingency 3% CostingDocument2 pagesFire Fighting: Amount S.N Description Unit Qty G1 Qty G3 Qty G5 Qty G7 Total Quantity Rate Contingency 3% CostingAditi AgrawalNo ratings yet

- Dominus Brochure v1Document8 pagesDominus Brochure v1leila lolita leila lilasNo ratings yet

- Fisa Tehnica UTP Cat6 LSZH Q5+Document1 pageFisa Tehnica UTP Cat6 LSZH Q5+William AndersonNo ratings yet

- Materials TestDocument20 pagesMaterials TestDanish MohdNo ratings yet

- Glass Data - v4 Low ResDocument15 pagesGlass Data - v4 Low ResPatrick SyNo ratings yet

- Material List Warehouse PT KIEDocument6 pagesMaterial List Warehouse PT KIEPutra MakmurNo ratings yet

- Chapter 3 PDFDocument8 pagesChapter 3 PDFHatim ValiNo ratings yet

- Elastomers and Rubber Compounding MaterialsFrom EverandElastomers and Rubber Compounding MaterialsI FrantaRating: 4.5 out of 5 stars4.5/5 (3)

- Wall Thickness and Material Grade Selection: GeneralDocument1 pageWall Thickness and Material Grade Selection: GeneralAlireza KhodabandehNo ratings yet

- 23Document1 page23Alireza KhodabandehNo ratings yet

- 23Document1 page23Alireza KhodabandehNo ratings yet

- Bending Loads. External Impact Loads.: 24 Qiang Bai and Yong BaiDocument1 pageBending Loads. External Impact Loads.: 24 Qiang Bai and Yong BaiAlireza KhodabandehNo ratings yet

- References: 20 Qiang Bai and Yong BaiDocument1 pageReferences: 20 Qiang Bai and Yong BaiAlireza KhodabandehNo ratings yet

- Finite Element Analysis: Pipeline Installation by Tow or PullDocument1 pageFinite Element Analysis: Pipeline Installation by Tow or PullAlireza KhodabandehNo ratings yet

- Untitled 1Document1 pageUntitled 1Alireza KhodabandehNo ratings yet

- 16 Qiang Bai and Yong Bai: Pipeline InstallationDocument1 page16 Qiang Bai and Yong Bai: Pipeline InstallationAlireza KhodabandehNo ratings yet

- Wall Thickness and Material Grade Selection: GeneralDocument1 pageWall Thickness and Material Grade Selection: GeneralAlireza KhodabandehNo ratings yet

- Rec Erc 84 329Document1 pageRec Erc 84 329Alireza KhodabandehNo ratings yet

- References: 20 Qiang Bai and Yong BaiDocument1 pageReferences: 20 Qiang Bai and Yong BaiAlireza KhodabandehNo ratings yet

- Bending Loads. External Impact Loads.: 24 Qiang Bai and Yong BaiDocument1 pageBending Loads. External Impact Loads.: 24 Qiang Bai and Yong BaiAlireza KhodabandehNo ratings yet

- Rec Erc 84 322Document1 pageRec Erc 84 322Alireza KhodabandehNo ratings yet

- Pipe Laying by Lay Vessel: Mode 1 Buckle Mode 2 Buckle Mode 3 Buckle Mode 4 BuckleDocument1 pagePipe Laying by Lay Vessel: Mode 1 Buckle Mode 2 Buckle Mode 3 Buckle Mode 4 BuckleAlireza KhodabandehNo ratings yet

- Untitled 3Document1 pageUntitled 3Alireza KhodabandehNo ratings yet

- Untitled 6Document1 pageUntitled 6Alireza KhodabandehNo ratings yet

- Untitled 2Document1 pageUntitled 2Alireza KhodabandehNo ratings yet

- Rec Erc 84 311Document1 pageRec Erc 84 311Alireza KhodabandehNo ratings yet

- Rec Erc 84 315Document1 pageRec Erc 84 315Alireza KhodabandehNo ratings yet

- Rec Erc 84 332Document1 pageRec Erc 84 332Alireza KhodabandehNo ratings yet

- 14 S. K. Gawali Et AlDocument1 page14 S. K. Gawali Et AlAlireza KhodabandehNo ratings yet

- Rec Erc 84 334Document1 pageRec Erc 84 334Alireza KhodabandehNo ratings yet

- 2 S. K. Gawali Et Al.: 1.1.1 Additive ManufacturingDocument1 page2 S. K. Gawali Et Al.: 1.1.1 Additive ManufacturingAlireza KhodabandehNo ratings yet

- Rec Erc 84 36Document1 pageRec Erc 84 36Alireza KhodabandehNo ratings yet

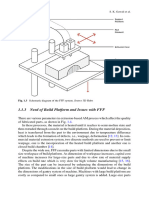

- 1.1.3 Need of Build Platform and Issues With FFF: 4 S. K. Gawali Et AlDocument1 page1.1.3 Need of Build Platform and Issues With FFF: 4 S. K. Gawali Et AlAlireza KhodabandehNo ratings yet

- Rec Erc 84 38Document1 pageRec Erc 84 38Alireza KhodabandehNo ratings yet

- 1.2.1 Design Methodology: 6 S. K. Gawali Et AlDocument1 page1.2.1 Design Methodology: 6 S. K. Gawali Et AlAlireza KhodabandehNo ratings yet

- CERTILAS EN Edition2023 317Document1 pageCERTILAS EN Edition2023 317Alireza KhodabandehNo ratings yet

- Report Bioplastics - Market-Data - 2018Document4 pagesReport Bioplastics - Market-Data - 2018Jorge Alberto Cuellar BolivarNo ratings yet

- Materials Used For Packaging of Pharmaceutical Products: PlasticDocument8 pagesMaterials Used For Packaging of Pharmaceutical Products: PlasticAnuj ZanjurneNo ratings yet

- Introduction to Polyurethane ChemistryDocument31 pagesIntroduction to Polyurethane ChemistryMohammed ShaabanNo ratings yet

- Mckeen2014 PDFDocument28 pagesMckeen2014 PDFashok_abclNo ratings yet

- Document PDFDocument134 pagesDocument PDFOoj GenNo ratings yet

- How Plastics WorkDocument20 pagesHow Plastics WorkdidacbrNo ratings yet

- Freudenberg - en - Technical Elastomers-Web PDFDocument37 pagesFreudenberg - en - Technical Elastomers-Web PDFdhowardjNo ratings yet

- Usage: Aircraft Car Bus Motorbike Tram Window Laminated Safety Glass Glass Plastic Laminated Acrylic PlasticDocument1 pageUsage: Aircraft Car Bus Motorbike Tram Window Laminated Safety Glass Glass Plastic Laminated Acrylic PlasticNikhil MittalNo ratings yet

- FDM Systems and Materials Overview - en BrochureDocument13 pagesFDM Systems and Materials Overview - en BrochureShabi HadashNo ratings yet

- Plastic ProcessesDocument27 pagesPlastic Processesnitouch3564No ratings yet

- UF - ASTM G21 Free PDF DownloadDocument3 pagesUF - ASTM G21 Free PDF DownloadL tNo ratings yet

- Chem-Trend Thermoplastics BrochureDocument10 pagesChem-Trend Thermoplastics Brochurebap06No ratings yet

- GLTE405 Diagram For Fourcault Method and PPGDocument2 pagesGLTE405 Diagram For Fourcault Method and PPGEmmanuel AlemakaNo ratings yet

- Shailey Project ReportDocument17 pagesShailey Project Reportmahendrabpatel100% (1)

- Lamination of Paper With PlasticDocument18 pagesLamination of Paper With PlasticKaran_Luniya_3388No ratings yet

- CHAPTER 3 SYNTHETIC FIBRES AND PLASTICSDocument7 pagesCHAPTER 3 SYNTHETIC FIBRES AND PLASTICSDhyani PanchalNo ratings yet

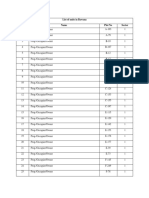

- List of Units in BawanaDocument65 pagesList of Units in BawanaPrasuk JainNo ratings yet

- BLOWENGINEERING PLASTIC MACHINES Blow Molding Machine Manufacturer PDFDocument6 pagesBLOWENGINEERING PLASTIC MACHINES Blow Molding Machine Manufacturer PDFJoenetDarmawanNo ratings yet

- PlasticizersDocument19 pagesPlasticizersPathik ShahNo ratings yet

- Uticaj Procesa Recikliranja Na Svojstva Materijala Na Osnovu PolilaktidaDocument7 pagesUticaj Procesa Recikliranja Na Svojstva Materijala Na Osnovu PolilaktidamakiNo ratings yet

- Upload 5Document8 pagesUpload 5Knupi OpoNo ratings yet

- Polymer Synthesis and Fabrication ReportDocument37 pagesPolymer Synthesis and Fabrication ReportKhuert Jirioz CooperNo ratings yet

- 10 1016@j Matpr 2020 02 258 PDFDocument9 pages10 1016@j Matpr 2020 02 258 PDFNilekh ANo ratings yet

- GLASSDocument8 pagesGLASSNowella MendozaNo ratings yet

- Unit 14: Polymers Classification and PropertiesDocument31 pagesUnit 14: Polymers Classification and PropertiesShivangani RawatNo ratings yet

- TLE Grade 8 Ilas: Food Processing EntrepDocument5 pagesTLE Grade 8 Ilas: Food Processing EntrepJeah mae TauleNo ratings yet

- Corrosion Survey Database (COR - SUR) © 2002 NACE International 1Document2 pagesCorrosion Survey Database (COR - SUR) © 2002 NACE International 1hen1911No ratings yet

- PWRSLMDocument3 pagesPWRSLMGANESH MURUGANNo ratings yet

- Characteristics Standard Pagina: 1/10 DataDocument14 pagesCharacteristics Standard Pagina: 1/10 Dataerik0007No ratings yet