Professional Documents

Culture Documents

Process Equipment Design Lloyd E. Brownell, Edwin H. Young 1959

Uploaded by

rejaxe9230Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Equipment Design Lloyd E. Brownell, Edwin H. Young 1959

Uploaded by

rejaxe9230Copyright:

Available Formats

41

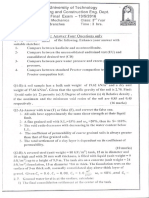

Ag. SA Oil-storage tanks of various height-to-diameter ratios. Three 96,000-bbl tanks 120 ft in diameter by 48 ft high with three ftre walls 172 ft in

tffometet by 24 ft high appear in the background. (Courtesy of Hammond Iron Works.)

'~of the foundations and lhe cost the lnnd in the tank C4 = annual cost of the installed foundation undt>r

area• tbat is clinrgeabl~ to the tank as well as by the cost of the vessel, dollars per s<1uare foot of tank-

lhc bottom, shell. and roof, if required. The value of the bottom area

land ch~rgeable to the tank may be in terms of an c5 = annual cost of the land in the uink area

annqal cost per unit area. For purposes of tank proportion- chargeable to the tank, dollars prr S<fUare

inir. it is alw convenient to express the cost of the founda- foot of tank-bottom area

tion. bottom. shPll. and roof, if used. in tenns of cost per C = total annual cost of the vessel, dollars per

unit arM al' follows. year

then

Let /) = 11imtit•tc•r of llw \t•s~·l.ft•t•t + ra + r1 + (3.2)

JI lwi1d1t of tlu• \t•ssrl. ft>t•t

c

or

4l' Simplifying the ..,,.,A .. ., .. ,..

H= (3.1)

of D, we

When A 1 = area of the shell, square fe<'t C=

A 2 = area of I he ves.'*11 bottom or

area of the roof, sc:1uare feet To determine the optimum tank

.,,D2 Eq. 3.3, it is necessary to determine which of the cost terrns

=--

4 are variables prior to differentiation.

c 1 = annual co~l of fabricated dollars per 3.3a Tanks Having Shell Thickness Independent /)

square fool and H. The stre~ in the shell is a functihn of holh

r 2 = annual cost of fabricated uu·l-•·u'1u, dollars per dmtmeiter and the of

"LJUare fool 3.18 and 3.19. Pemmns the minimum

c3 = annual cost of lhe fabricated dollars per shell thicknes.'l is limited to

SftUare fool of nrtnf•1N.P·n and to }:i in. for tanks of

356 Properties of Selected Rolled Structural Members

You might also like

- Ie5b02555 Si 001Document15 pagesIe5b02555 Si 001Akshay PatelNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- موارد مائية-ماجستيرDocument5 pagesموارد مائية-ماجستيرTahaNo ratings yet

- Alcorcon Engineering Review Center: I. Machine FoundationDocument5 pagesAlcorcon Engineering Review Center: I. Machine FoundationReinzo GallegoNo ratings yet

- Computational Techniques in Civil Engineering IOE BCE Past Questions CollectionDocument32 pagesComputational Techniques in Civil Engineering IOE BCE Past Questions CollectionFlush BinNo ratings yet

- Civil IV II PartDocument230 pagesCivil IV II PartAnonymous 8EYiR2EGQNo ratings yet

- Old Questions (1)Document49 pagesOld Questions (1)Siddharth UpretiNo ratings yet

- DRMDocument24 pagesDRMSujan ShresthaNo ratings yet

- Reinforcement requirements for openings in pressure pipingDocument163 pagesReinforcement requirements for openings in pressure pipingprasongNo ratings yet

- Technology of Itiachining: Semester - 5Document6 pagesTechnology of Itiachining: Semester - 5fotickNo ratings yet

- T-01-ME Key Bridge Design ParameterDocument9 pagesT-01-ME Key Bridge Design ParameterAnjali M SNo ratings yet

- Tutorial 1Document2 pagesTutorial 1Amal J AdhikaramNo ratings yet

- Flow through an earth dam clay coreDocument4 pagesFlow through an earth dam clay coreAntonio SotoNo ratings yet

- Flownets 11 PDFDocument4 pagesFlownets 11 PDFJeorge Esrom ChambiNo ratings yet

- UPDA Final2Document25 pagesUPDA Final2mohamed abdoNo ratings yet

- Bearing Capacity - ProblemsDocument15 pagesBearing Capacity - Problemsপ্রিয়দীপ প্রিয়ম100% (1)

- 5 Glacis FallDocument6 pages5 Glacis FallSahil ThakurNo ratings yet

- Foundation EngineeringDocument8 pagesFoundation EngineeringPrashant GCNo ratings yet

- Cost Control EngineeringDocument34 pagesCost Control Engineeringbonc omorogbeNo ratings yet

- F T Solution: ProblemsDocument2 pagesF T Solution: Problemstom meeteiNo ratings yet

- Industrial Section: Yu. M. Pochtman and M. M. FridmanDocument4 pagesIndustrial Section: Yu. M. Pochtman and M. M. FridmanAnonymous TmXuBtSNo ratings yet

- Fri. 22nd Sep. - HomeworkDocument2 pagesFri. 22nd Sep. - Homeworkdefrence.fitnessNo ratings yet

- Midsem 2020Document3 pagesMidsem 2020vallabha kaustubhaNo ratings yet

- CE2812 - Sieve Analysis and Hydrometer AnalysisDocument12 pagesCE2812 - Sieve Analysis and Hydrometer AnalysisRashmiNo ratings yet

- Design of A Reinforced Concrete Warehouse: Victor Robert SladekDocument23 pagesDesign of A Reinforced Concrete Warehouse: Victor Robert Sladekponh chanveasnaNo ratings yet

- Geotechnical Notes and Problems NotesDocument131 pagesGeotechnical Notes and Problems NotesNarcisa RudnicNo ratings yet

- Paper 2222Document16 pagesPaper 2222Abhijeet GholapNo ratings yet

- Question For Exam in BUETDocument8 pagesQuestion For Exam in BUETShaibal Ahmed0% (1)

- cHUTE SPILLWAY PDFDocument20 pagescHUTE SPILLWAY PDFFasil GeberemeskelNo ratings yet

- 2 Scour VentDocument8 pages2 Scour VentPrachi TaoriNo ratings yet

- 5630 MSDocument8 pages5630 MSdorian.axel.ptNo ratings yet

- Pile Foundation Part 5Document14 pagesPile Foundation Part 5Ayush KishoreNo ratings yet

- A Number of Area Designations Are Used in The Design of Sieve TraysDocument6 pagesA Number of Area Designations Are Used in The Design of Sieve TraysDheeraj ShuklaNo ratings yet

- Final Time:3: Building Construction ExamDocument9 pagesFinal Time:3: Building Construction ExamsosoNo ratings yet

- 4 - BC 2017-18 5-6.4 FTC and AverageDocument4 pages4 - BC 2017-18 5-6.4 FTC and AverageSamNo ratings yet

- Maths Notes For Class 10 Chapter 13 Surface Areas and VolumesDocument3 pagesMaths Notes For Class 10 Chapter 13 Surface Areas and VolumesKshitij BahukhandiNo ratings yet

- ChE - Old Papers (Before 2011-12 I)Document14 pagesChE - Old Papers (Before 2011-12 I)Mukul ParasharNo ratings yet

- PAPER 2222 With Mark AnswersDocument16 pagesPAPER 2222 With Mark AnswersAbhijeet GholapNo ratings yet

- Scantling Is A Measurement of Prescribed Size, Dimensions, or Cross Sectional Areas. ForDocument1 pageScantling Is A Measurement of Prescribed Size, Dimensions, or Cross Sectional Areas. Foralp_alpNo ratings yet

- Wind Turbine Design (Continued) : Lakshmi N Sankar Lsankar@ae - Gatech.eduDocument13 pagesWind Turbine Design (Continued) : Lakshmi N Sankar Lsankar@ae - Gatech.eduMAGRINo ratings yet

- Me Paper 1 Mains 2018Document8 pagesMe Paper 1 Mains 2018Abhishek DalalNo ratings yet

- Assignment - Max & Minima - 12thDocument2 pagesAssignment - Max & Minima - 12thmohitkumarr2411No ratings yet

- ξ fb fa b af ξ ′ − = −Document10 pagesξ fb fa b af ξ ′ − = −Asad MohammadNo ratings yet

- Ore Storage CalculationsDocument24 pagesOre Storage CalculationsmpwemboNo ratings yet

- Freeboard 2011Document45 pagesFreeboard 2011EnriqueNo ratings yet

- Taif University Introduction to Computer ProgrammingDocument4 pagesTaif University Introduction to Computer ProgrammingJk JkNo ratings yet

- M.SC - Physics - 2015.Document20 pagesM.SC - Physics - 2015.Ayaan bhNo ratings yet

- T,,.. I L-L - ' Men' I, X z3 .,) : Heat Removal Factor For A Flat-Plate Solar Collector With A Serpentine TubeDocument6 pagesT,,.. I L-L - ' Men' I, X z3 .,) : Heat Removal Factor For A Flat-Plate Solar Collector With A Serpentine TubeDr-Aditya ChauhanNo ratings yet

- ME4361Document2 pagesME4361Vihari RahulNo ratings yet

- LN 20190127224751 6829Document30 pagesLN 20190127224751 6829Mohammed KhalidNo ratings yet

- Flywheel TordilloDocument17 pagesFlywheel Tordillotisha revillaNo ratings yet

- Geometry Ws Similarity 2Document5 pagesGeometry Ws Similarity 2abrarjayNo ratings yet

- The Drag of Airships-Drag of Bare Hulls 1926Document59 pagesThe Drag of Airships-Drag of Bare Hulls 1926te.iubesc777No ratings yet

- App-D-Geometry of Lifting Surfaces PDFDocument23 pagesApp-D-Geometry of Lifting Surfaces PDFmiguelNo ratings yet

- Soil EngineeringDocument20 pagesSoil Engineeringnatrix029No ratings yet

- Sheet 2 HeatDocument2 pagesSheet 2 Heatmustafa1011No ratings yet

- Power Consumption and Mixing Time in an Agitated Vessel with Double ImpellerDocument6 pagesPower Consumption and Mixing Time in an Agitated Vessel with Double ImpellerJose Davi Rodrigues Silva UFCNo ratings yet

- Falling Head Permeability Test Lab ReportDocument11 pagesFalling Head Permeability Test Lab Reportshahrolhazrien83% (63)

- Torque IT SCHED Iso RSC JHBDocument1 pageTorque IT SCHED Iso RSC JHBletumarNo ratings yet

- Paper Thermo Mechanical EngineeringDocument14 pagesPaper Thermo Mechanical EngineeringAdif HerawanNo ratings yet

- Pipe Fitting Dimensions CatalogueDocument22 pagesPipe Fitting Dimensions CatalogueMuhammad AfzaalNo ratings yet

- Open Source Frequency Counter DIY Kit 10Hz-250MHzDocument10 pagesOpen Source Frequency Counter DIY Kit 10Hz-250MHzBruno Santos de Miranda100% (1)

- HCL - Acid Regeneration Plant: Tyasa I E VDocument107 pagesHCL - Acid Regeneration Plant: Tyasa I E Vjose santiago vazquezNo ratings yet

- MODEL NO: 417-4032 Hydraulic Systems: Revision: 2 GROUP NUMBER: 64546336 5-1Document47 pagesMODEL NO: 417-4032 Hydraulic Systems: Revision: 2 GROUP NUMBER: 64546336 5-1Jesus Angel AVNo ratings yet

- Flow ThermDocument4 pagesFlow ThermDinesh KanaujiyaNo ratings yet

- 1 PBDocument12 pages1 PBRazan Nuhad Dzulfaqor razannuhad.2020No ratings yet

- ComponentsDocument39 pagesComponentskarthikv83No ratings yet

- Volume 3 Drainage PDFDocument508 pagesVolume 3 Drainage PDFTani RicafrenteNo ratings yet

- Rize Build June 2ND WeekDocument8 pagesRize Build June 2ND WeekAbhishek RajputNo ratings yet

- Marketing Plan for International MarketsDocument4 pagesMarketing Plan for International MarketsAhmed HusseinNo ratings yet

- LPG Cylinder Rate ChartDocument4 pagesLPG Cylinder Rate ChartBest Movie scenesNo ratings yet

- Basics of Indoor Pool Air DistributionDocument4 pagesBasics of Indoor Pool Air DistributionNebojsa GolubovicNo ratings yet

- Question 1 - Mounting MethodDocument3 pagesQuestion 1 - Mounting MethodMuhd IlyasNo ratings yet

- Consumer Reports Buying Guide 2013: Home AppliancesDocument66 pagesConsumer Reports Buying Guide 2013: Home Appliancesdesijnk100% (1)

- Rudiger Urbanke Lecture PDFDocument70 pagesRudiger Urbanke Lecture PDFArdevaNo ratings yet

- Securiton Smoke Detector Performance DeclarationDocument2 pagesSecuriton Smoke Detector Performance DeclarationAnonymous YWmB9HDgNo ratings yet

- E-Choke Design UKDocument13 pagesE-Choke Design UKtehnotonNo ratings yet

- XoaracvanDocument3 pagesXoaracvanSoftprovt TranNo ratings yet

- ULN200x, ULQ200x High-Voltage, High-Current Darlington Transistor ArraysDocument39 pagesULN200x, ULQ200x High-Voltage, High-Current Darlington Transistor ArraysRadoNo ratings yet

- Plan Budget Healthcare PDFDocument299 pagesPlan Budget Healthcare PDFAboubacar Sompare100% (1)

- Brittle Coating and Strain GaugeDocument29 pagesBrittle Coating and Strain GaugeAavash ShresthaNo ratings yet

- Students InfoDocument3 pagesStudents InfoShanto Mohammad Salah UddinNo ratings yet

- Data Sheet Multivariable ABB 266JSTDocument20 pagesData Sheet Multivariable ABB 266JSTzhamyrNo ratings yet

- Radial Piston PumpDocument10 pagesRadial Piston PumpRavikumar GangadharanNo ratings yet

- Cps STRC Ifc Sept 25 2018Document57 pagesCps STRC Ifc Sept 25 2018Manimaran PNo ratings yet

- Aung Ye Htun3409894643578177227Document3 pagesAung Ye Htun3409894643578177227Aungye HtunNo ratings yet

- New Features For INSITE 8.1.0: 1. Installation and Compatibility A. Upgrade CapabilityDocument6 pagesNew Features For INSITE 8.1.0: 1. Installation and Compatibility A. Upgrade CapabilityMisael CaffarelNo ratings yet

- XPC Target UgDocument450 pagesXPC Target UgliznNo ratings yet