Professional Documents

Culture Documents

Itb Task 3 Bamboo Straw

Itb Task 3 Bamboo Straw

Uploaded by

Muhammed ZeeshanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Itb Task 3 Bamboo Straw

Itb Task 3 Bamboo Straw

Uploaded by

Muhammed ZeeshanCopyright:

Available Formats

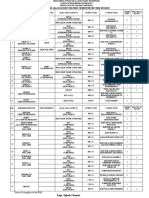

We work with local farmers that harvest bamboo sustainably and organically in the south Punjab

of Pakistan. They use no pesticides or chemicals. Once the stems are cut, our team transforms

them into straws using the bamboo splitting machine, bamboo sawing machine, disposable

bamboo straw polishing machine, bamboo set-size stick-cutting machine, and bamboo fixed

width and thickness slicing machine. We employ a flow manufacturing approach using

specialized machinery to speed up the manufacturing process. We will also use a standardized

production strategy where the product is manufactured continuously, the stock is guaranteed,

and delivery to the end user is not delayed.

Flow processes are beneficial for companies to reduce production time and achieve affordable

production per unit. In addition, automated machine production helps save a lot of manual costs

and time, resulting in shorter production times, which is a plus for our business. In addition,

standardized and continuous production ensures quality control. It allows us to apply the

Taguchi method, which facilitates research and development. In addition, it helps us maintain

quality control and experiment with new trendy designs. Our business ensures that our products

are free of bacteria and contaminants that can harm end users. That is why we focus on

laboratory testing and early product testing. We also practice continuous improvement methods

and adopt a kaizen philosophy with regular checks to inform everyone of the overall process

and employee concerns about the product. The quality of our product will be entirely about

satisfying the customer's expectations of our product. Therefore, we would also define the

quality standards from the customer's perspective by considering their views and making

changes to our product.

In addition, a quality management system process is initiated to record the product quality

regularly. A set of rules governs how products are manufactured and delivered to end users.

Standardized production rules ensure that our customers do not receive defective products. Our

team and I do our best to maintain product quality. When open discussions are held, we intend

to hear ideas from employees and solve their problems one-on-one. This will lead to overall

product improvement and customer satisfaction. This also helps the company deploy its

resources affordably and cost-effectively. Even if a problem is found with a product, timely

action allows employees to prevent the problem, eliminate the product issue, and ensure a rapid

recovery process so that the production scale is unimpeded.

You might also like

- Bosch Catalog - Edition 2014Document456 pagesBosch Catalog - Edition 2014longtrandang5867No ratings yet

- Agile Product Management: Streamlining Product Development with Agile PrinciplesFrom EverandAgile Product Management: Streamlining Product Development with Agile PrinciplesNo ratings yet

- Step Plus GramDocument35 pagesStep Plus Gramsathish kumar38% (8)

- MAN EDC7 Common Rail D0836LFDocument8 pagesMAN EDC7 Common Rail D0836LFMircea Gilca100% (3)

- Functional RequirementsDocument16 pagesFunctional RequirementsRamesh dodamaniNo ratings yet

- Strategic Management A Case Study of Pakola PDFDocument28 pagesStrategic Management A Case Study of Pakola PDFShahmir JadoonNo ratings yet

- 1 Pengantar Manajemen MutuDocument37 pages1 Pengantar Manajemen MutuRiza Nindiana Valery100% (1)

- 02-Quality and GMP Policy StatementDocument2 pages02-Quality and GMP Policy StatementMuhammad ImranNo ratings yet

- 01.05.2021 Method Statement For Electrical & InstrumentationDocument6 pages01.05.2021 Method Statement For Electrical & InstrumentationPangky Abasolo100% (1)

- Quality Assurance SystemsDocument7 pagesQuality Assurance SystemsJagtar Singh ChandelNo ratings yet

- Assignment On Quality Assurance SystemDocument7 pagesAssignment On Quality Assurance Systemruhilanita11100% (1)

- Dimitrios Serpanos, Marilyn Wolf-Internet-of-Things (IoT) Systems. Architectures, Algorithms, Methodologies-Springer (2018) PDFDocument98 pagesDimitrios Serpanos, Marilyn Wolf-Internet-of-Things (IoT) Systems. Architectures, Algorithms, Methodologies-Springer (2018) PDFDavid Rivera ANo ratings yet

- Volvo Yv1uz68tcj1103892 2023-02-08034105PMDocument3 pagesVolvo Yv1uz68tcj1103892 2023-02-08034105PMМирослав СобуцькийNo ratings yet

- 8 Principles of TQMDocument8 pages8 Principles of TQMMomina TariqNo ratings yet

- TQM Module 1Document21 pagesTQM Module 1Maroma AllenNo ratings yet

- Quality ControlDocument1 pageQuality ControlMark WatneyNo ratings yet

- BSG Catalogue - EditedDocument6 pagesBSG Catalogue - EditedPradeep BantaNo ratings yet

- SITXINV002 Learner Resource January 2017Document21 pagesSITXINV002 Learner Resource January 2017Carlos Andres OtaloraNo ratings yet

- Delivering Project Quality (2021 Update) - 042333Document16 pagesDelivering Project Quality (2021 Update) - 042333Joseph Kwafo MensahNo ratings yet

- Base Corporation Limited Village Nagli, Post Oachghat, Dist-Solan, HP PinDocument18 pagesBase Corporation Limited Village Nagli, Post Oachghat, Dist-Solan, HP PinVishal SrivastavaNo ratings yet

- The Institution of Engineers (India) : Vijayawada Local CenterDocument8 pagesThe Institution of Engineers (India) : Vijayawada Local CentervenkateshmukharjiNo ratings yet

- Group 1 Written ReportDocument7 pagesGroup 1 Written ReportCRISTINE JOY LAUZNo ratings yet

- E1 2 Total Quality Management Notes 1 44 - RemovedDocument41 pagesE1 2 Total Quality Management Notes 1 44 - RemovedKashif SuriNo ratings yet

- Supply Chain Management 1880575Document11 pagesSupply Chain Management 1880575Ravi KumawatNo ratings yet

- 'Just in Time' Approach in Automotive BusinessesDocument2 pages'Just in Time' Approach in Automotive BusinessesTharindu WeerasingheNo ratings yet

- Total Quality ManagementDocument10 pagesTotal Quality ManagementDikshita Jain100% (1)

- AQM AssignmnetDocument4 pagesAQM AssignmnetLibyaFlowerNo ratings yet

- Experience Letter SitaramDocument1 pageExperience Letter SitaramSubedi RuzaNo ratings yet

- Qauilty PoilcyDocument3 pagesQauilty Poilcyadham hatawiNo ratings yet

- Uc 10Document9 pagesUc 10Tadesse DakabaNo ratings yet

- Name Netid Group Number: Website Link: Tutorial Details Time Spent On AssignmentDocument10 pagesName Netid Group Number: Website Link: Tutorial Details Time Spent On AssignmentBinghuiQiuNo ratings yet

- Quality Assurance PPT 2035Document20 pagesQuality Assurance PPT 2035divensinglaNo ratings yet

- Internal Assessment Sukanya Mazumder Roll No: 90Document5 pagesInternal Assessment Sukanya Mazumder Roll No: 90Ankita GhoshNo ratings yet

- Bulad-On, Elisha (TQM)Document3 pagesBulad-On, Elisha (TQM)Elisha Garcia Bulad-onNo ratings yet

- Pom 324 PDFDocument249 pagesPom 324 PDFShubham KumarNo ratings yet

- PM Report RefDocument14 pagesPM Report RefCj SernaNo ratings yet

- Group 1 - Quality Control Written ReportDocument10 pagesGroup 1 - Quality Control Written Reportnagisafurukawa122333No ratings yet

- QMSDocument4 pagesQMSnitin_798443935No ratings yet

- StandardizationDocument4 pagesStandardizationshamizNo ratings yet

- Quality, Health, Safety and Environment (Qhse) Policy of Bayer CropscienceDocument1 pageQuality, Health, Safety and Environment (Qhse) Policy of Bayer CropsciencepapaconfiNo ratings yet

- Quality Assurance Dissertation TopicsDocument6 pagesQuality Assurance Dissertation TopicsWhereCanYouBuyResumePaperUK100% (1)

- TQM Assignment-6Document14 pagesTQM Assignment-6api-546637261No ratings yet

- TASK1: Prepare A Short Paper On The Topic Quality: When Is Enough? Who Is Responsible? AfterDocument3 pagesTASK1: Prepare A Short Paper On The Topic Quality: When Is Enough? Who Is Responsible? AfterJonathanNo ratings yet

- Suggested SOPs - Marie GaleDocument3 pagesSuggested SOPs - Marie GaleMICRONo ratings yet

- Main Doc GP JuryDocument66 pagesMain Doc GP JuryVishwanath KrNo ratings yet

- Lesson 1 - Concepts of Quality, Total Quality and TQMDocument15 pagesLesson 1 - Concepts of Quality, Total Quality and TQMcelestetorino1No ratings yet

- Operations ManagementDocument4 pagesOperations ManagementSir Stephen Maverick N CrudaNo ratings yet

- Concepts of Quality, Total Quality and Total Quality ManagementDocument3 pagesConcepts of Quality, Total Quality and Total Quality Managementbshm thirdNo ratings yet

- Divya Pruthvi Agronomics PVTDocument33 pagesDivya Pruthvi Agronomics PVTPiyush ChaturvediNo ratings yet

- PM - Unit 4Document20 pagesPM - Unit 4K. Snega K. SnegaNo ratings yet

- Jurnal Topo PepeDocument8 pagesJurnal Topo PepeniaNo ratings yet

- STA 577 Statistical Quality Control (Assignment 1)Document6 pagesSTA 577 Statistical Quality Control (Assignment 1)Atiqah JilisNo ratings yet

- Framework For Quality and Performance ExcellenceDocument7 pagesFramework For Quality and Performance Excellencebshm thirdNo ratings yet

- MSP - 20 &operations ManagementDocument5 pagesMSP - 20 &operations ManagementMeiyappan RmNo ratings yet

- Name Netid Group Number: Website Link: Tutorial Details Time Spent On AssignmentDocument11 pagesName Netid Group Number: Website Link: Tutorial Details Time Spent On AssignmentWu AngelaNo ratings yet

- Sv. College of Engineering: Kadapa: EntrepreneurshipDocument27 pagesSv. College of Engineering: Kadapa: EntrepreneurshipK VenkatasivaNo ratings yet

- Term Paper: Manufacturing SciencesDocument15 pagesTerm Paper: Manufacturing SciencesArpit BajajNo ratings yet

- Asheesh MishraDocument3 pagesAsheesh MishraviditajmeraNo ratings yet

- TQM in Msil (Amit & Pranav)Document41 pagesTQM in Msil (Amit & Pranav)Amit AnandNo ratings yet

- Name Netid Group Number: Website Link: Tutorial Details Time Spent On AssignmentDocument11 pagesName Netid Group Number: Website Link: Tutorial Details Time Spent On AssignmentWu AngelaNo ratings yet

- Student Name: Gurusevak SinghDocument4 pagesStudent Name: Gurusevak SinghekamNo ratings yet

- For Accepting Our Invitation and Delivering An Excellent PresentationDocument4 pagesFor Accepting Our Invitation and Delivering An Excellent Presentationashok kecheNo ratings yet

- Quality MGTDocument10 pagesQuality MGTLablay LaerNo ratings yet

- Quality ControlDocument9 pagesQuality Controlsunnykumar.m2325No ratings yet

- Quality Management SystemDocument9 pagesQuality Management SystemUmar AliNo ratings yet

- Organization Policy For OrganicDocument5 pagesOrganization Policy For OrganicVinod ChaudhariNo ratings yet

- Risma Aldi PrasetyaDocument3 pagesRisma Aldi PrasetyaErdiansyah SeputroNo ratings yet

- Filtering FailureDocument8 pagesFiltering Failurerosca_eugen_mihaiNo ratings yet

- Radio Frequencies Explosive Magnetic Flux Compression Generator and Its Military ApplicationsDocument7 pagesRadio Frequencies Explosive Magnetic Flux Compression Generator and Its Military ApplicationsRuben's OscarNo ratings yet

- Scenecom Evo Da2 Scenecom Evo Da2 - Multi-Channel Lighting ControllerDocument5 pagesScenecom Evo Da2 Scenecom Evo Da2 - Multi-Channel Lighting ControllerArístides Pérez CabreraNo ratings yet

- MK PPR KD Do en 72Document32 pagesMK PPR KD Do en 72Bandit PolskaNo ratings yet

- Test Bank Business Intelligence Grant MaiDocument51 pagesTest Bank Business Intelligence Grant MaiHoàng ThànhNo ratings yet

- Ethiopia Enhances Rocket and Artillery CapabilitiesDocument12 pagesEthiopia Enhances Rocket and Artillery CapabilitiesTsegay TeklayNo ratings yet

- M5 - T-GCPFCI-B - Core Infrastructure v5.1.0 - ILTDocument27 pagesM5 - T-GCPFCI-B - Core Infrastructure v5.1.0 - ILTSandy LinNo ratings yet

- Opportunities at Cygnius ConsultingDocument3 pagesOpportunities at Cygnius ConsultingIkramul HaqueNo ratings yet

- Course Allocation For First Semester 2017/2018 SessionDocument9 pagesCourse Allocation For First Semester 2017/2018 SessionlivityhotNo ratings yet

- A Quick Reference For QLab V3Document49 pagesA Quick Reference For QLab V3Anonymous e5eIzKYBmx100% (1)

- United States Patent: Lyndon - James Et AlDocument24 pagesUnited States Patent: Lyndon - James Et AlAlex MungaiNo ratings yet

- Cybersecurity Policy: Cerow Agency, IncDocument8 pagesCybersecurity Policy: Cerow Agency, Incep230842No ratings yet

- Remote File InclusionDocument1 pageRemote File InclusionrheyzthNo ratings yet

- Sapp Balancing Market: Traders and Controllers Training - Day 1Document69 pagesSapp Balancing Market: Traders and Controllers Training - Day 1Addie Hatisari DandaNo ratings yet

- Design and Construction of Vertical Axis Wind TurbineDocument6 pagesDesign and Construction of Vertical Axis Wind TurbineDivyabharathi JanakiramanNo ratings yet

- LogDocument2 pagesLogЯрослав ПелипенкоNo ratings yet

- Multilevel Inverter With Reducing Device Count:: Project Batch-15Document20 pagesMultilevel Inverter With Reducing Device Count:: Project Batch-15madhu madhaviNo ratings yet

- Experiment 8Document8 pagesExperiment 8Uberapp DealsNo ratings yet

- Biren PatelDocument3 pagesBiren PatelDilip DasNo ratings yet

- ANSYS EMA3D Cable Aerospace ACE ExternalDocument38 pagesANSYS EMA3D Cable Aerospace ACE ExternalSamuel ThomasNo ratings yet

- Sentinel Radeye G: Portable Dose and Dose Rate MeterDocument2 pagesSentinel Radeye G: Portable Dose and Dose Rate MeterAndika JuliandahriNo ratings yet

- Familiarization With MDA8086 and MTS86C Microprocessor TrainersDocument18 pagesFamiliarization With MDA8086 and MTS86C Microprocessor TrainersAnik Mazumder100% (1)

- Primavera P6 Professional R8.4 Windows Windows 8 Installation Instructions PDFDocument17 pagesPrimavera P6 Professional R8.4 Windows Windows 8 Installation Instructions PDFIrwany AzharNo ratings yet