Professional Documents

Culture Documents

Technical Specifications-Compressor

Technical Specifications-Compressor

Uploaded by

masud0 ratings0% found this document useful (0 votes)

27 views5 pagesOriginal Title

Technical Specifications-compressor

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

27 views5 pagesTechnical Specifications-Compressor

Technical Specifications-Compressor

Uploaded by

masudCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 5

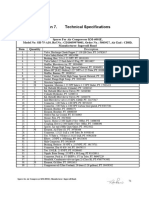

Technical Specifications

COMPLETE AIR COMPRESSOR WITH ELECTRIC MOTOR: 01 (ONE)

SET

Offered

SL Specifications Requirement of the client Specifications

Compressor:

1 Type Reciprocating / Screw

1.1 Air capacity/Flow 500 Nm3/hr

1.2.1 Discharge pressure 10 barg

1.2.2 Discharge temperature 40 °C (Max)

1.3.1 Suction pressure Atmospheric Pressure

1.3.2 Suction temperature 10°C Min, 40°C Max

1.3.3 Relative humidity 60% Min, 90 % Max.

1.4 Fluid handled Ambient air

1.5 Coupling Flexible coupling

1.6 Compression type Oil Free

Pump should be driven by

Forced feed lubrication

1.7 crankshaft

1.8 Location Outdoor (Under shed)

1.9 Duty Continuous

No load at starting condition; Load

Loading condition Step: 0-50%-100% load control

1.10 both automatically & manually

1.11 Cooling System Air Cooled/ Water Cooled

1.11.

Cooling Water Condition: Closed loop cooling water circuit

1

1.11.

CW Inlet Header Pressure 1.8 barg

2

1.11.

CW Outlet Header Pressure 1.2 barg

3

1.11.

CW Inlet Temperature 30 °C Min, 40 °C Max.

3

Compressor Package &

1.12 Accessories:

Compressor set with motor and

transmission mounted on a steel

1.12. Assembly

skid. Fully assembled with all

1 accessories and tested

1.12. Reduction gear Drive/ Direct Drive/

Transmission

2 Belt-driven

I) Vessel-type Flanged pulsation

suppression devices and separators

(As per ASME code section-VIII)

1.12. with welded vent and purging

Dampeners, coolers & Separators

3 line with solenoid valve.

II) Shell & tube type stage cooler

(Material of Tube Sheet, Tubes,

Baffle Plates should be Brass).

Offered

SL Specifications Requirement of the client Specifications

Compressor

1.13 Instrumentation:

a) Pressure gauges on each stage air

suction and discharge, on lube oil

main pump discharge and on cooling

water inlet & outlet header.

b) Temperature gauges on each stage

air suction and discharge, on inlet

& outlet of each cooler and on oil

pump discharge.

c) Pressure safety valves located on

discharge of each stage.

d) Alarm:

I) Low lube oil pressure.

II) High discharge air of temperature

of each stage

Compressor

1.13. e) Shutdown:

Instrumentation &

1 I) Low lube oil pressure.

control

II) High discharge air of temperature of

each stage

f) Control voltage for Instrumentation

110V, 50Hz, lph or 24VDC or380V,

50Hz, 3ph along with neutral.

g) All instrumentation should be ATEX

standard.

h) If PLC is used for instrumentation;

software, Communication cable should be

supplied with compressor.

i) All enclosure for instrumentation

control should be ATEX standard.

j) Panel front will be supplied with

necessary amount of start-stop-reset push

buttons, indicating lights.

Technical Offer shall

2.0 include:

Outline drawing of complete set of

Compressor & motor, Compressor &

motor data sheet, product catalogue for

2.1 the offered Compressor model & motor.

SL Specifications Requirement of the client Offered Specifications

List of spare to be provided with Technical Offer

2.2 Spare parts to be supplied without price

I) Piston ring for each stage - 02 sets

II) Rider ring for each stage - 02 sets

III) Main packing for each stage - 02 sets

IV) Secondary packing (if any) for each stage

- 02 sets

V) Suction valve for each stage - 02 sets

VI) Discharge valve for each stage - 02 sets

If offered Compressor is VII) Oil packing - 02 sets.

2.2.

Reciprocating Compressor VIII) Piston rod with nut for each stage - 01

1 than spare parts list will be: set

IX) All O-ring, Gasket & filters - 06 sets

X) Air filter - 06 sets

XI) Oil filter element - 06 sets.

XII) All indicator, switches, Pressure relief

valves, Temperature sensors, solenoid valves

& relay - 02 sets

XIII) Two years schedule maintenance

complete spare kit

I) Air filter - 06 sets

II) Oil filter element - 06 sets.

III) Suction valve for each stage - 02 sets

IV) Discharge valve for each stage - 02 sets

If offered Compressor is

2.2.

Screw Compressor than spare V) All indicator, switches, Pressure relief

2 parts list will be valves, Temperature sensors, solenoid valves

& relay-02 sets

VI) All O-ring, Gasket, packing, oil rings and

filters - 06 sets

VII)Two years schedule maintenance

complete spare kit

Commissioning spare parts

and Special tools (if any)

should be supplied with Commissioning spare parts and Special tools

compressor (List to be (if any) should be supplied with compressor

2.3 provided with Technical Offer) (List to be provided with Technical Offer)

Offered

SL Specifications Requirement of the client Specifications

The following information

shall be provided on every Compliance with these documents must be

3.0 drawing & Document mentioned in the technical offer

The Purchaser / Customer’s Name (Eastern

3.1 Refinery Limited)

3.2 The Purchaser Order No.

The Purchaser Equipment item No.: KM

3.3 6001

The vendor’s Shop Order and/ or Serial

3.4 Number.

4 Motor

4.1 Type Squirrel Cage Induction motor

4.2 Power (KW) Must not exceed 90 KW

4.3 Speed (RPM) As required

4.4 Supply Voltage 380V

4.5 Frequency 50 Hz

4.6 Phase 3

4.7 Insulation Class F

EE×dll BT4 (ATEX Certification is

4.8 Type of Protection required)

4.9 Degree of Protection IP 55

4.1 Efficiency Class IE3

4.11 Starting System D.O.L (Direct-On-Line)

4.12 Duty S1 (Continuous at full load )

4.13 Frame size As required

4.14 Ambient Temperature 40° C (Max.)

Vibration Class B

4.15 Mounting Foot Mounting (IMB3)

4.16 Direction of Rotation Both

The terminal box is to be located on the top

of the motor and it can be rotated through

90° intervals in order to adjust the input of

4.17 Terminal Box the supply cable

A Double compression Exd type standard

cable gland must be supplied with the

4.18 Cable Gland motor

IEC standard local control panel must

4.19 Electrical Installation contain followings:

a) Main Circuit Breaker : As required rating

b) Compressor start & stop switch

c) Compressor lock switch

4.2 d) Auxiliary oil pump start/stop switch (if

any)

e) Ammeter for showing main motor

f) Interlock switch for motor start without

compressor etc.

Offered

SL Specifications Requirement of the client Specifications

The successful

bidder will

have to provide

the following

documents (in

English) with Compliance with these documents must be mentioned in the

5.0 shipment Technical Offer

For Compressor

5.1 As-Built Data-Sheet

5.2 As built Outline Drawing for Compressor Assembly

5.3 Certified Hydrostatic Test data

5.4 Certified Performance Test data

5.5 Vibration data

5.6 Civil foundational drawing for Installation

5.7 Cooling or Heating schematic (If any)

Cross-sectional Drawing (showing all paerts & design running

clearance) & complete parts lists with quantity & material of

5.8 construction.

5.9 Coupling Assembly Drawing & parts list with materials

Instruction Manual for the equipment and any auxiliaries. The

Manual shall include: Instruction covering Installation, Start-up,

Operation & Maintenance Procedures. The recommended

Clearance and max. & min. Design Clearance of the mating parts

5.10 shall be clearly stated.

5.11 Material Compliance Certificate

5.12 Warranty Certificate

5.13 Certificate of conformity

5.14 Certificate for the country of Origin

For Motor

5.15 As-Built Dimensional Drawing

5.16 Data sheet

5.17 Vibration Test Certificate

5.18 Performance Test Certificate

5.19 Warranty Certificate

5.20 Certificate for the country of origin

Third Party pre-shipment inspection for compressor and motor

assembly following agency: Lloyds/SGS / Bureau Veritas/

ABS/DNV/TUV- to conform the country of origin of all

6.0 components, specifications, Brand new product and quality

Inspection report should be provided to us for review before

shipment. Compliance with these documents must be mentioned

6.1 in the Technical Offer

7.0 Third party inspection charge should be mentioned separately

Warranty: 18 months after shipment or 12 months after start-up,

whichever comes later covering defective materials or

8.0 workmanship.

Manufacturing Country of origin of Motor & Compressor:

USA/JAPAN/ GERMANY/ BELGIUM/ SWEDEN/ AUSTRIA/

9.0 DENMARK

Manufacturer’s name & Manufacturing country of origin of

MOTOR, COMPRESSOR and all components of the compressor

(if components are manufactured in different countries) must be

10.0 he mentioned in the offer.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Manufacturer Warranty Siemens PDFDocument1 pageManufacturer Warranty Siemens PDFmasudNo ratings yet

- ERL Specs - Spares For Air Compressor KM-6001E - 75-76Document2 pagesERL Specs - Spares For Air Compressor KM-6001E - 75-76masudNo ratings yet

- REoI NOTICEDocument1 pageREoI NOTICEmasudNo ratings yet

- Forms For REOIDocument12 pagesForms For REOImasudNo ratings yet

- Notice Desco UG LineDocument1 pageNotice Desco UG LinemasudNo ratings yet

- ReticulateDocument2 pagesReticulatemasudNo ratings yet

- Tender Purchase LetterDocument1 pageTender Purchase LettermasudNo ratings yet

- Fas 2Document70 pagesFas 2masudNo ratings yet

- SL Item: 11 KV CT & PT Operated HT Net Metering Unit (15/5 A CT Ratio)Document2 pagesSL Item: 11 KV CT & PT Operated HT Net Metering Unit (15/5 A CT Ratio)masudNo ratings yet

- Documentation Type TestDocument4 pagesDocumentation Type TestmasudNo ratings yet

- SL Item: The Following Tests Should Be Done During The Type Test, Routine Test and Special TestDocument1 pageSL Item: The Following Tests Should Be Done During The Type Test, Routine Test and Special TestmasudNo ratings yet

- Price ScheduleDocument1 pagePrice SchedulemasudNo ratings yet

- Insulators PriceDocument2 pagesInsulators PricemasudNo ratings yet

- Power Transformer 33KV Switchgear VCB 11KV Switchgear: HS CodeDocument3 pagesPower Transformer 33KV Switchgear VCB 11KV Switchgear: HS CodemasudNo ratings yet

- Transformers Increase in SizeDocument2 pagesTransformers Increase in SizemasudNo ratings yet

- Products: Fire Alarm Systems, CCTV (Video Surveillance), Access Control, Intrusion Alarm SystemDocument2 pagesProducts: Fire Alarm Systems, CCTV (Video Surveillance), Access Control, Intrusion Alarm SystemmasudNo ratings yet

- Price Offer Siemens PDFDocument15 pagesPrice Offer Siemens PDFmasudNo ratings yet

- Sample SubmitDocument1 pageSample SubmitmasudNo ratings yet

- Packing Details: 11 KV Single Core XLPE Copper Cable 2x1Cx300mm Sq. 3600Document1 pagePacking Details: 11 KV Single Core XLPE Copper Cable 2x1Cx300mm Sq. 3600masudNo ratings yet

- Check List of Bid CheckingDocument2 pagesCheck List of Bid CheckingmasudNo ratings yet

- D O Current PDFDocument7 pagesD O Current PDFmasudNo ratings yet

- WWW - Eprocure.gov - BD Partner Tender Document Payment DetailsDocument1 pageWWW - Eprocure.gov - BD Partner Tender Document Payment DetailsmasudNo ratings yet

- Technical Statement Siemens Energy, 2015-10-15Document8 pagesTechnical Statement Siemens Energy, 2015-10-15masudNo ratings yet

- Origin-&-Source-Certificate To Nawshi InternationalDocument1 pageOrigin-&-Source-Certificate To Nawshi InternationalmasudNo ratings yet

- Manufacturer's Authorization Siemens PDFDocument1 pageManufacturer's Authorization Siemens PDFmasud0% (1)

- Manufacturer Authorisation To Nawshi InternationalDocument1 pageManufacturer Authorisation To Nawshi InternationalmasudNo ratings yet

- TTC (7ut85-P1f487069) PDFDocument7 pagesTTC (7ut85-P1f487069) PDFmasudNo ratings yet

- TTC (7ut85-P1f487069) PDFDocument7 pagesTTC (7ut85-P1f487069) PDFmasudNo ratings yet

- DataSheet (Line Differential 7SD87-P1B177029) PDFDocument7 pagesDataSheet (Line Differential 7SD87-P1B177029) PDFmasudNo ratings yet