Professional Documents

Culture Documents

Components of A Centrifugal Pump

Uploaded by

Debabrata Mondal0 ratings0% found this document useful (0 votes)

3 views2 pagesOriginal Title

COMPONENTS OF A CENTRIFUGAL PUMP

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views2 pagesComponents of A Centrifugal Pump

Uploaded by

Debabrata MondalCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

COMPONENTS OF A CENTRIFUGAL PUMP

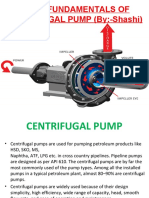

The main components of centrifugal pumps :-

1. Impeller,

2. Casing,

3. Suction pipe with a foot-valve and a strainer and

4. Delivery pipe.

1. Impeller: The rotating part of the centrifugal pump which is mounted on a

shaft is called impeller. It consists of a series of vanes usually backward curved.

2. Casing: It is an airtight passage which surrounds the impeller. The casing is

designed in such a way that the kinetic energy of the liquid leaving the impeller

is converted into pressure energy. Different types of casings commonly

employed.

3. Suction pipe with a foot-valve and a strainer: -Suction pipe is a pipe whose

one end is connected to the centre of the impeller and the other end dips into

liquid in a sump from which the liquid is to be lifted up.

4. Delivery pipe: It is a pipe whose one end is connected to the outlet of the

impeller and the other end delivers liquid in the storage reservoir.

WORKING PRINCIPLE OF A CENTRIFUGAL PUMP

1. The first step in the operation of a centrifugal pump is priming that is the

suction pipe and casing is filled with the liquid so that no air pocket is left.

2. The rotation of the pump impeller inside a casing full of liquid produces a

forced vortex which is responsible for imparting a centrifugal head to the

liquid.

3. Rotation of impeller effects a reduction of pressure at the centre. This

causes the liquid in the suction pipe to rush into the eye.

DIFFERENT HEADS IN A CENTRIFUGAL PUMP?

1. Suction head: The vertical height between the centre line of the pump and

the liquid level in the sump is called suction head (hg). This head is sometimes

referred as suction lift.

2. Delivery head: The vertical height between the liquid level in the storage

reservoir and the centre line of the pump is called delivery head.

3. Static head: The difference between the liquid level in the storage reservoir

and the sump is known as static head (Hs). It is therefore, the sum of the

suction head and delivery head and is given by HS= hs+hd

WORK DONE BY THE CENTRIFUGAL PUMP?

A centrifugal pump is a reverse of a radially inward flow reaction turbine. The

expression for work done by the impeller to the liquid can be obtained by

drawing the velocity triangles at the inlet and outlet of the impeller.

COMPONENTS OF A RECIPROCATING PUMP

The main components of centrifugal pumps :-

1. Cylinder with suitable valves at inlet (suction valve) and delivery (delivery

valve),

2. Plunger or piston with piston rings,

3. Connecting rod and crank mechanism,

4. Suction pipe and

5. Delivery pipe

WORKING PRINCIPLE OF A RECIPROCATING PUMP?

A reciprocating pump consists of a piston or a plunger executing reciprocating

motion inside a cylinder as shown in Figure 1. As the crank moves outwards

(from A to C), the piston moves towards right in the cylinder causing a vacuum

in the cylinder.

You might also like

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- PUMP TYPEDocument63 pagesPUMP TYPEKaushik SreenivasNo ratings yet

- Everything You Need to Know About Centrifugal PumpsDocument27 pagesEverything You Need to Know About Centrifugal PumpsNischal LgNo ratings yet

- Centrifugal PumpsDocument27 pagesCentrifugal PumpsHossam SalahNo ratings yet

- Cent Pum-NbDocument39 pagesCent Pum-NbDeva RajNo ratings yet

- Cent Pum-NbDocument27 pagesCent Pum-Nbmass3444No ratings yet

- Study Single-Stage Centrifugal Pump PerformanceDocument7 pagesStudy Single-Stage Centrifugal Pump PerformanceHa M ZaNo ratings yet

- Entrifugal Pump, Pressure Variation, Work Done, EfficiencyDocument12 pagesEntrifugal Pump, Pressure Variation, Work Done, EfficiencygonriNo ratings yet

- Cent PumDocument24 pagesCent PumAhmed MostafaNo ratings yet

- Classification of PumpsDocument23 pagesClassification of PumpsRam Krishna SinghNo ratings yet

- InducerDocument54 pagesInducerYaswanthNo ratings yet

- By: Ricky S. Alegre Gabrel C ArsenioDocument19 pagesBy: Ricky S. Alegre Gabrel C ArsenioVictor GuijoNo ratings yet

- Basic Fundamentals of CENTRIFUGAL PUMP (By:-Shashi)Document42 pagesBasic Fundamentals of CENTRIFUGAL PUMP (By:-Shashi)RaduIon100% (1)

- Unit 8 Centrifugal Pumps: Hydraulics and Hydraulic Machines (10CV45)Document10 pagesUnit 8 Centrifugal Pumps: Hydraulics and Hydraulic Machines (10CV45)tonydisojaNo ratings yet

- Centrifugal Pumps Guide: Types, Parts, Working PrincipleDocument57 pagesCentrifugal Pumps Guide: Types, Parts, Working Principlemmr315No ratings yet

- Debre Markos University Institute of Technology School of Mechanical and Industrial Engineering Meng3201Document59 pagesDebre Markos University Institute of Technology School of Mechanical and Industrial Engineering Meng3201birlieNo ratings yet

- Theory Centrifugal PumpDocument4 pagesTheory Centrifugal PumpMuhammad NasifNo ratings yet

- Module 5: Centrifugal PumpsDocument24 pagesModule 5: Centrifugal PumpsJoy CharlesNo ratings yet

- Centrifugal PumpDocument27 pagesCentrifugal Pumpdivmech1988100% (2)

- Centrifugal PumpDocument5 pagesCentrifugal Pumpsankarsuper83No ratings yet

- Section 1Document59 pagesSection 1pattan madhuNo ratings yet

- ReciprocatingDocument15 pagesReciprocatingRohit soniNo ratings yet

- ME 421 - Pump (09) - 2 - 2Document57 pagesME 421 - Pump (09) - 2 - 2Mila HuqNo ratings yet

- Centrifugal Pump NotesDocument13 pagesCentrifugal Pump NotesHimanshu Garg0% (1)

- Study of Centrifugal PumpDocument3 pagesStudy of Centrifugal Pumptalk2mesreejuNo ratings yet

- Chapter 7 Centrifugal PumpDocument37 pagesChapter 7 Centrifugal Pump01fe20bme014No ratings yet

- Centrifugal PumpDocument12 pagesCentrifugal PumpLalith SunkojuNo ratings yet

- Pumps: Pumps and Its TypesDocument34 pagesPumps: Pumps and Its TypesAmir Hamza100% (1)

- Centrifugal PumpDocument36 pagesCentrifugal PumpshubhamNo ratings yet

- Assignment: Name Muhammad ArsalanDocument8 pagesAssignment: Name Muhammad ArsalanMuhammad Arsalan TariqNo ratings yet

- Centrifugal Pump Components and OperationDocument13 pagesCentrifugal Pump Components and Operationgaurav pandey1212No ratings yet

- Unit VDocument26 pagesUnit VArwaz KhanNo ratings yet

- PumpsDocument11 pagesPumpsamk3745No ratings yet

- Components of centrifugal pumps: Impeller, casing, suction pipe, delivery pipe, shaftDocument21 pagesComponents of centrifugal pumps: Impeller, casing, suction pipe, delivery pipe, shaftrohan sharmaNo ratings yet

- pump 111Document44 pagespump 111m7394197No ratings yet

- Transfer liquid or circulate fluid with a mechanical pumpDocument27 pagesTransfer liquid or circulate fluid with a mechanical pumpBhbNo ratings yet

- Lecture Notes in Fluid MachineryDocument54 pagesLecture Notes in Fluid MachineryJoshuaPeralta78% (41)

- PUMPS 1-NotesDocument16 pagesPUMPS 1-NotesPortifer Harrison Ray Mubanga100% (1)

- PumpsDocument57 pagesPumpsJai Acharya100% (1)

- Pump & Types of PumpsDocument33 pagesPump & Types of PumpsAhmad JuttNo ratings yet

- Experiment No-5: Pumps Are The Fluid Moving Machineries Which Increase The Mechanical Energy ofDocument9 pagesExperiment No-5: Pumps Are The Fluid Moving Machineries Which Increase The Mechanical Energy ofAbhishek MishraNo ratings yet

- PUMPS-ME14 (5)Document30 pagesPUMPS-ME14 (5)WIIGEENNo ratings yet

- Process Equipment Design and DrawingDocument35 pagesProcess Equipment Design and DrawingKutty Krishnan MankaraNo ratings yet

- Fluid Book For FinalDocument76 pagesFluid Book For FinalMk EkaNo ratings yet

- FM-II Week 5Document28 pagesFM-II Week 5khizeraftab1018No ratings yet

- Hydraulic PumpsDocument40 pagesHydraulic PumpsRanjith KNo ratings yet

- Pumps: Types, Parts, and Head CalculationsDocument54 pagesPumps: Types, Parts, and Head CalculationsMark GotasNo ratings yet

- Lesson 6 PumpsDocument9 pagesLesson 6 PumpsBon Adrian IsabedraNo ratings yet

- Applications of Pumps in MinesDocument21 pagesApplications of Pumps in MinesAnshul yadavNo ratings yet

- Types of PumpsDocument7 pagesTypes of PumpservaishaliNo ratings yet

- Chapter 2Document32 pagesChapter 2Uzair MaswanNo ratings yet

- Centrifugal PumpDocument54 pagesCentrifugal PumpBia Mughal0% (1)

- Subject of Technical Report Date Submitted: June 16, 2020 Plasencia, Jerome G. TMEC 5-1Document14 pagesSubject of Technical Report Date Submitted: June 16, 2020 Plasencia, Jerome G. TMEC 5-1Bimby FaggotNo ratings yet

- Industrial Plant Engineering Reviewer Complete PDFDocument93 pagesIndustrial Plant Engineering Reviewer Complete PDFNovaCastillo100% (2)

- CENTRIFUGAL PUMPS Notes For StudentsDocument35 pagesCENTRIFUGAL PUMPS Notes For Studentsbukboy100% (12)

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- Net Positive Suction Head for Rotodynamic Pumps: A Reference GuideFrom EverandNet Positive Suction Head for Rotodynamic Pumps: A Reference GuideRating: 5 out of 5 stars5/5 (1)

- The Petrol Engine: A Text-book dealing with the Principles of Design and Construction, with a Special Chapter on the Two-stroke EngineFrom EverandThe Petrol Engine: A Text-book dealing with the Principles of Design and Construction, with a Special Chapter on the Two-stroke EngineNo ratings yet

- Manual de Servicio Balanza de Humedad MB45 OhausDocument52 pagesManual de Servicio Balanza de Humedad MB45 OhausOscar Sev50% (4)

- Advances in Cryojet Machining: Development and Improvement AreasDocument11 pagesAdvances in Cryojet Machining: Development and Improvement AreasAnupama ChattorajNo ratings yet

- Inspector of Boilers in Boilers DepartmentDocument20 pagesInspector of Boilers in Boilers DepartmentrameshNo ratings yet

- Parts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 10L902-0488-E1Document17 pagesParts Manual Parts Manual Parts Manual Parts Manual: Mfg. No: 10L902-0488-E1Chris LaPetersNo ratings yet

- Physics II Problems PDFDocument1 pagePhysics II Problems PDFBOSS BOSSNo ratings yet

- B3656M-L Brochure y CurvasDocument44 pagesB3656M-L Brochure y Curvasrodriguez.gaytanNo ratings yet

- Topic 14Document41 pagesTopic 14Torres JeromeNo ratings yet

- Government Policy Statement - President Ranil Wickremesinghe - 07 Feb 2024Document11 pagesGovernment Policy Statement - President Ranil Wickremesinghe - 07 Feb 2024Adaderana OnlineNo ratings yet

- Case Expension - LVDT SensorDocument6 pagesCase Expension - LVDT Sensortrung2iNo ratings yet

- Normal Shutdown of BoilerDocument2 pagesNormal Shutdown of BoilerLuqman Sahlan RomadhonaNo ratings yet

- Sirsasana As Viparita Karani MudraDocument4 pagesSirsasana As Viparita Karani MudraPradosh Kumar PanigrahyNo ratings yet

- Key Challenges For European Aerospace SuppliersDocument16 pagesKey Challenges For European Aerospace Suppliersvigneshkumar rajanNo ratings yet

- Prof. Girish Kumar's Comments On The Book - "Mobile Phones and Public Health - Myths and Reality"Document10 pagesProf. Girish Kumar's Comments On The Book - "Mobile Phones and Public Health - Myths and Reality"Neha KumarNo ratings yet

- Work Report On Automated Hydraulic Jack SystemDocument20 pagesWork Report On Automated Hydraulic Jack Systemcoolrohitkumar666100% (2)

- Upgrading of On-Load Tap-Changer Types UCG/UCL To Vacuum Types VUCG/VUCLDocument4 pagesUpgrading of On-Load Tap-Changer Types UCG/UCL To Vacuum Types VUCG/VUCLKushtrim MalaNo ratings yet

- Resilite 2735Document2 pagesResilite 2735pwmvsi100% (1)

- End of Year TestDocument8 pagesEnd of Year TestKatarzyna Agata KrzyczmonikNo ratings yet

- Engineer's 12-Year Renewable Energy ExperienceDocument4 pagesEngineer's 12-Year Renewable Energy ExperienceHeera RamjiNo ratings yet

- Flat-Band Potential of A Semiconductor: Using The Mott-Schottky EquationDocument4 pagesFlat-Band Potential of A Semiconductor: Using The Mott-Schottky EquationmahlaNo ratings yet

- Sizing Calculations RW CW HD ADDocument27 pagesSizing Calculations RW CW HD ADBhavesh Panchal100% (1)

- MBSM - Pro, Compressor, Aspera, B3119Z, 234 W, 1/4 HP, R134a: Publié Le 25 Mai 2022 - ParDocument7 pagesMBSM - Pro, Compressor, Aspera, B3119Z, 234 W, 1/4 HP, R134a: Publié Le 25 Mai 2022 - Parأبو زينب المهندسNo ratings yet

- Digest RR 13-2018Document9 pagesDigest RR 13-2018Maria Rose Ann BacilloteNo ratings yet

- PuffingDocument13 pagesPuffingArisha AliNo ratings yet

- What is a TEC? Thermoelectric Cooler ExplainedDocument8 pagesWhat is a TEC? Thermoelectric Cooler ExplainedShubham TiwariNo ratings yet

- OME553 Question BankDocument6 pagesOME553 Question BankSundaravalli0% (1)

- Construction and Building Materials: Sundararaman Chithiraputhiran, Narayanan NeithalathDocument10 pagesConstruction and Building Materials: Sundararaman Chithiraputhiran, Narayanan Neithalathhichem aliouiNo ratings yet

- Pump Control Output Flow AdjustDocument3 pagesPump Control Output Flow AdjustSteven Manuputty100% (2)

- Ab Initio and Semiempirical MethodsDocument58 pagesAb Initio and Semiempirical MethodsElisha Niña75% (4)

- Detailed Design and Engineering Deliverable List (Sample) - The Project DefinitionDocument7 pagesDetailed Design and Engineering Deliverable List (Sample) - The Project DefinitionMathias OnosemuodeNo ratings yet

- Green Hydrogen AgreementsDocument3 pagesGreen Hydrogen Agreementsishika VermaNo ratings yet