0% found this document useful (0 votes)

1K views4 pagesEmpty Carton Inspection SOP

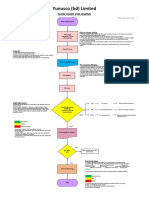

The document outlines an empty carton inspection procedure with the objective of ensuring accessories used in bulk production meet the buyer's standards. It describes responsibilities and inspection steps including collecting specifications, checking carton details like materials, size, finishing, and symbols. Inspectors are to check cartons according to the specifications and report results on an inspection report form. The procedure aims to verify empty cartons meet requirements before bulk production.

Uploaded by

FaysalCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views4 pagesEmpty Carton Inspection SOP

The document outlines an empty carton inspection procedure with the objective of ensuring accessories used in bulk production meet the buyer's standards. It describes responsibilities and inspection steps including collecting specifications, checking carton details like materials, size, finishing, and symbols. Inspectors are to check cartons according to the specifications and report results on an inspection report form. The procedure aims to verify empty cartons meet requirements before bulk production.

Uploaded by

FaysalCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd