Professional Documents

Culture Documents

Calculation of Safe Distance For Hydrotest

Uploaded by

Hussein HishamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calculation of Safe Distance For Hydrotest

Uploaded by

Hussein HishamCopyright:

Available Formats

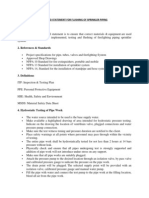

Calculation of safe distance for hydrotest

System to be tested: 00-02-01

System Description: Pipe-Line system

Company DOCG

Location and date: FH-37 flow-line Jan-08-2024

D-Internal diameter (m) : 0.2 Meter Change the Main Pipe Size as per Spool Drawing

0.380731

a – Length/diameter of the piece (m) 3500 Meter m Change Linear meter of pipe spool

88.9

p – Test pressure (bar) 50 Bar m Change the Test Pressure 4.781762

as mentioned in Test Pack

Safe Distance will be change automatically

SAFE DISTANCE 8 Meter base on Test Pressure, Size & Linear Meter

Safety Recommendations:

•Safety valves to be fitted when the pressurizing medium pressure Single, continuous pressure envelope is the preferable method.

•The Responsible Engineer should authorize tests above normal working pressure.

•Persons supervising pressure/leak tests must be trained, competent, and qualified.

•Effective communication should be established.

•Access to the test area must be limited to essential personnel only – barriers, warning signs, PA announcements, patrolling the test boundaries.

•Testing should be carried out under PTW, which is required for each test or at least a test package for the same location.

•Pressuring equipment shall be provided with suitably calibrated pressure control/regulator devices.

•These devices should be clearly visible to the person controlling the pressure.

•Pressuring equipment should not be left unattended at any time during the test.

•When the test pressure has been reached, the pressuring equipment shall be isolated from the equipment under test and where performable

disconnected.

•The pressuring valve should be locked in a closed position.

•Ensure the equipment tested by a competent person, prior to testing.

Note:

Prepare By: Approve By:

Name :_____________________________ Name :_____________________________

Date :________________________ Date :________________________

You might also like

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Module 3Document219 pagesModule 3Sourav PoddarNo ratings yet

- Standard Test Method For Pneumatic Leak Testing of TubingDocument5 pagesStandard Test Method For Pneumatic Leak Testing of TubingWilliam Chang100% (1)

- High Voltage Measurement Techniques: Fundamentals, Measuring Instruments, and Measuring MethodsFrom EverandHigh Voltage Measurement Techniques: Fundamentals, Measuring Instruments, and Measuring MethodsNo ratings yet

- Pressure Testing & QC Test PackDocument10 pagesPressure Testing & QC Test Packravi00098No ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- SIKA Pressure Gauges PDFDocument44 pagesSIKA Pressure Gauges PDFMohamed Elseman100% (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Hydro Test Key PointsDocument16 pagesHydro Test Key PointsRahulNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Pressure Measuring Instrument PDFDocument8 pagesPressure Measuring Instrument PDFcnrk777No ratings yet

- Pneumatic Leak Testing of Tubing: Standard Test Method ForDocument5 pagesPneumatic Leak Testing of Tubing: Standard Test Method ForAmjad AlQasrawiNo ratings yet

- ASTM A1047A1047M 05 Standard Test Method For Pneumatic Leak Testing of TubingDocument5 pagesASTM A1047A1047M 05 Standard Test Method For Pneumatic Leak Testing of TubingABAID ULLAHNo ratings yet

- Hydro TestDocument12 pagesHydro TestEndika Alfan100% (2)

- Pressure Testing PresentationDocument37 pagesPressure Testing PresentationManish Sharma83% (6)

- D6723.1203165 1 DirectTensionTesterDocument13 pagesD6723.1203165 1 DirectTensionTesterAnantNo ratings yet

- Method of Statement Testing of PipeDocument5 pagesMethod of Statement Testing of PipevpamatyaNo ratings yet

- Meter ProverDocument5 pagesMeter Proverjivajive100% (2)

- LRUT ProcedureDocument10 pagesLRUT ProcedureD_D1216No ratings yet

- What's The Min &max Range of Pressure Gauge For Hydro TestDocument4 pagesWhat's The Min &max Range of Pressure Gauge For Hydro TestdushyantNo ratings yet

- Petrochemical Industry Calibration SolutionsDocument2 pagesPetrochemical Industry Calibration SolutionsAnonymous IXswcnWNo ratings yet

- M0627Document24 pagesM0627subhransubaral1No ratings yet

- Bee - Code Development Project: Draft Code ON Fluid Piping SystemsDocument49 pagesBee - Code Development Project: Draft Code ON Fluid Piping SystemsNaveen ShettyNo ratings yet

- 10130-02-091-PD-0013-tmp 18-Pressure Testing Checklist (Revised After TR Head Office Comments)Document1 page10130-02-091-PD-0013-tmp 18-Pressure Testing Checklist (Revised After TR Head Office Comments)caovanthien10121992No ratings yet

- Preauction TestingDocument8 pagesPreauction TestingbalajiNo ratings yet

- Pe Pipelines Pressure Testing Handbook En805Document26 pagesPe Pipelines Pressure Testing Handbook En805Alin Dumitru100% (1)

- Ebs1 Aaaa00 Saqa Prqa 0006Document10 pagesEbs1 Aaaa00 Saqa Prqa 0006SERT-QA/QC- BUZNo ratings yet

- Piping Fundamentals Part 3 (Testing) RevisedDocument86 pagesPiping Fundamentals Part 3 (Testing) RevisedJazille LardizabalNo ratings yet

- Guide Wave Ultrasonic Pipe Test ProcedureDocument10 pagesGuide Wave Ultrasonic Pipe Test ProcedurejeswinNo ratings yet

- Hydrotest Vs Pneumatic TestDocument5 pagesHydrotest Vs Pneumatic TestMidhun K Chandrabose100% (1)

- Piping Hydrotest ProcedureDocument9 pagesPiping Hydrotest Procedurewendypost73100% (1)

- 83 Calibration Ultrasonic Flowmeters PDFDocument6 pages83 Calibration Ultrasonic Flowmeters PDFMalouk CheniouniNo ratings yet

- D 2143 - 94 - Rdixndmtukve PDFDocument5 pagesD 2143 - 94 - Rdixndmtukve PDFAndre CasteloNo ratings yet

- Hydrotest ProcedureDocument6 pagesHydrotest ProcedureIkhsan Hj SiratNo ratings yet

- (SS0V003) Uni-Directional Sphere Type ProverDocument2 pages(SS0V003) Uni-Directional Sphere Type ProverRoberto Carlos TeixeiraNo ratings yet

- 1U5793 Pressure Diferential Gauge USBR1055Document6 pages1U5793 Pressure Diferential Gauge USBR1055Fidel MachadoNo ratings yet

- Instrumentations Symbols Diagrams Technologies: Maintenance and Repair Work. Instrument P&ID'sDocument31 pagesInstrumentations Symbols Diagrams Technologies: Maintenance and Repair Work. Instrument P&ID'sAngeel MalicseNo ratings yet

- 4008-Pi-Pro-001 - 0 - Piping Hydrotest Procedure-1Document8 pages4008-Pi-Pro-001 - 0 - Piping Hydrotest Procedure-1Randu WatangNo ratings yet

- ST 9122 Experimental Techniques and InstrumentationDocument18 pagesST 9122 Experimental Techniques and InstrumentationananthaaNo ratings yet

- Experimental Techniques and InstrumentationDocument18 pagesExperimental Techniques and InstrumentationMaharajan McsNo ratings yet

- Pressure Test ProcedureDocument11 pagesPressure Test ProcedureRolando Nicanor0% (1)

- Method Statement For Flushing of Sprinkler PipingDocument2 pagesMethod Statement For Flushing of Sprinkler PipingMoizuddin Khaja71% (17)

- Procedure For Hydro Testing: Pressure TestDocument5 pagesProcedure For Hydro Testing: Pressure TestDevang ShahNo ratings yet

- Hydrostatic and Pneumatic Testing ProcedureDocument8 pagesHydrostatic and Pneumatic Testing ProcedurejorgekarlosprNo ratings yet

- PP802-TN Leak TestDocument5 pagesPP802-TN Leak TestGerardo SepulvedaNo ratings yet

- MA Staugitter DLT8005 15 AEN 001Document4 pagesMA Staugitter DLT8005 15 AEN 001sumit_waghmareNo ratings yet

- Pilin Project Hydrostatic Test InstructionDocument5 pagesPilin Project Hydrostatic Test Instructionคุณพ่อน้อง บิ๊กบอสNo ratings yet

- Pressure Testing Ensures Safety, Reliability and Leak TightnessDocument4 pagesPressure Testing Ensures Safety, Reliability and Leak TightnessRakesh RanjanNo ratings yet

- Pressure MeterDocument17 pagesPressure MeterRakesh7770No ratings yet

- Pressure Test in Piping Systems - Hydro and Pneumatic TestsDocument3 pagesPressure Test in Piping Systems - Hydro and Pneumatic Testssj22No ratings yet

- TIMAS-PR-PI-005 - Piping Pressure Test, Flushing, BLW & Reinstate ProcedureDocument16 pagesTIMAS-PR-PI-005 - Piping Pressure Test, Flushing, BLW & Reinstate ProcedureMechanical Static WRKNo ratings yet

- Unidirectional ProverDocument2 pagesUnidirectional ProverGanjar Al Kaspandi100% (1)

- Astm D2290-00Document5 pagesAstm D2290-00T Mathew TholoorNo ratings yet

- Piping Hydrotest Procedure GuideDocument3 pagesPiping Hydrotest Procedure GuideFrank100% (6)

- P3-PTP-001 R0 Piping Pressure Test ProceduresDocument8 pagesP3-PTP-001 R0 Piping Pressure Test ProceduresHengNo ratings yet

- Testing Procedure SprinklerDocument2 pagesTesting Procedure SprinklerBea RullanNo ratings yet

- Calibration and leak testing of Saudi Aramco instrumentation systemsDocument10 pagesCalibration and leak testing of Saudi Aramco instrumentation systemsNAVANEETHNo ratings yet

- SOP of PrehydrotestDocument7 pagesSOP of PrehydrotestVenkateswarlu BoduguNo ratings yet

- MS#Deep well anode installtion (2)Document1 pageMS#Deep well anode installtion (2)Hussein HishamNo ratings yet

- Surveillance Record 002Document1 pageSurveillance Record 002Hussein HishamNo ratings yet

- Surveillance Record 004Document1 pageSurveillance Record 004Hussein HishamNo ratings yet

- TRA035-Drilling for Anode InstallationDocument1 pageTRA035-Drilling for Anode InstallationHussein HishamNo ratings yet

- PIPELINEMAN NO.2877Document3 pagesPIPELINEMAN NO.2877Hussein HishamNo ratings yet

- PIPELINEMAN NO.2882Document3 pagesPIPELINEMAN NO.2882Hussein HishamNo ratings yet

- PIPELINEMAN NO.2876Document3 pagesPIPELINEMAN NO.2876Hussein HishamNo ratings yet

- AGT & FA Ni ChengzhenDocument2 pagesAGT & FA Ni ChengzhenHussein HishamNo ratings yet

- AGT & FA Jiao EnpengDocument2 pagesAGT & FA Jiao EnpengHussein HishamNo ratings yet

- FH 32Document4 pagesFH 32Hussein HishamNo ratings yet

- FH 7Document4 pagesFH 7Hussein HishamNo ratings yet

- FH 6LDRDocument4 pagesFH 6LDRHussein HishamNo ratings yet

- Ogs CadDocument1 pageOgs CadHussein HishamNo ratings yet

- Topographic Map of Mount NeboDocument1 pageTopographic Map of Mount NeboHistoricalMapsNo ratings yet

- 3.1. Optical Sources - LED - FOC - PNP - February 2022 - NewDocument49 pages3.1. Optical Sources - LED - FOC - PNP - February 2022 - NewyashNo ratings yet

- LEP 4.1.07 Semiconductor Thermogenerator: Related TopicsDocument3 pagesLEP 4.1.07 Semiconductor Thermogenerator: Related Topicsjrfisico2011No ratings yet

- ARM ArchitectureDocument26 pagesARM ArchitectureKiran KumarNo ratings yet

- ALEJDocument6 pagesALEJAlejandro OdinNo ratings yet

- IBM System x3250 M3: IBM Redbooks Product GuideDocument29 pagesIBM System x3250 M3: IBM Redbooks Product Guidegopi_hcNo ratings yet

- Medical ImagingDocument412 pagesMedical Imagingalexandraiuliana0% (1)

- 3d AutoCad Test 11 (06-03-2020)Document9 pages3d AutoCad Test 11 (06-03-2020)nadirNo ratings yet

- Chemistry Paper (12 TH New Pattern)Document2 pagesChemistry Paper (12 TH New Pattern)Suyog TekamNo ratings yet

- Feature Selection Using Kernel Based Local Fisher Discriminant Analysis For Hyperspectral Image ClassificationDocument4 pagesFeature Selection Using Kernel Based Local Fisher Discriminant Analysis For Hyperspectral Image ClassificationVarun BhardwajNo ratings yet

- Python Interactive Mode: Anaconda Navigator SpyderDocument5 pagesPython Interactive Mode: Anaconda Navigator SpyderDeeshpreet Kaur sonaNo ratings yet

- TM841S-L, TM861S-L: TO-220F 8A TriacDocument2 pagesTM841S-L, TM861S-L: TO-220F 8A TriacEulerMartinsDeMelloNo ratings yet

- Dumpstate - Log 2020 03 23 21 37 39 12783Document4 pagesDumpstate - Log 2020 03 23 21 37 39 12783Nurlan JakenaiNo ratings yet

- Proselect Psts21np and Psts11np Installation ManualDocument1 pageProselect Psts21np and Psts11np Installation ManualRyan Murray33% (6)

- Apex Basic Program For PracticeDocument7 pagesApex Basic Program For PracticeKRUNAL RAJURKARNo ratings yet

- Cisco Virtual Update Cisco Sdwan ViptelaDocument55 pagesCisco Virtual Update Cisco Sdwan ViptelaSanjeev MoghaNo ratings yet

- Hb2637l-Evk-301 DPT HSDocument10 pagesHb2637l-Evk-301 DPT HSAlec NanetteNo ratings yet

- 1 General Physics PDFDocument39 pages1 General Physics PDFHakim Abbas Ali PhalasiyaNo ratings yet

- NotepadDocument9 pagesNotepadteenapalNo ratings yet

- January 2019 Paper 2Document16 pagesJanuary 2019 Paper 2Anderson AlfredNo ratings yet

- WIMO Final 2018 Mock P1fDocument8 pagesWIMO Final 2018 Mock P1fDo Yun100% (1)

- Field Installation HandbookDocument88 pagesField Installation HandbookRamiro RamirezNo ratings yet

- OxidesDocument27 pagesOxidesJuan KorNo ratings yet

- Basic Calculus 3rd DTDocument6 pagesBasic Calculus 3rd DTGrazeNo ratings yet

- Part #Description Quantity TotalDocument2 pagesPart #Description Quantity TotalsergioNo ratings yet

- Alia AUF790 Ultrasonic Open Channel FlowmeterDocument4 pagesAlia AUF790 Ultrasonic Open Channel FlowmeterRexCrazyMindNo ratings yet

- Chemistry Webquest Introduction to AtomsDocument3 pagesChemistry Webquest Introduction to AtomsMarx GomesNo ratings yet

- Generation of High Voltages & CurrentsDocument79 pagesGeneration of High Voltages & CurrentshamzaNo ratings yet

- Mitsubishi Electric MXZ-2D-6D VA Service Manual EngDocument542 pagesMitsubishi Electric MXZ-2D-6D VA Service Manual EngAnonymous wsOiKPMNo ratings yet

- (Revised) Syllabus+Blue Print (Class-6th)Document9 pages(Revised) Syllabus+Blue Print (Class-6th)vipsinNo ratings yet