Professional Documents

Culture Documents

Ds 12 Oil Pressure Calculation Sheet

Uploaded by

Rolando Loayza0 ratings0% found this document useful (0 votes)

16 views2 pagesOriginal Title

ds-12-oil-pressure-calculation-sheet (2)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views2 pagesDs 12 Oil Pressure Calculation Sheet

Uploaded by

Rolando LoayzaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

OIL PRESSURE CALCULATION SHEET

The formula widely used to calculate the oil pressure to be used with a bolt tensioning tool is given below along with

definitions of the terms used;

Grip Length

BOLT LOAD

Residual Bolt Load required when the tensioning operation is complete.

TENSIONING FORCE

The load that will be applied by the bolt tensioner during the tensioning operation.

LOAD TRANSFER FACTOR

Grip Length

The ratio of tensioning force to bolt load.

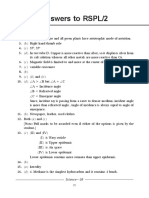

Load Transfer Factor = Tensioning Force = 1.01 + Bolt Diameter (mm)

Bolt Load Grip Length (mm)

If the Load Transfer Factor calculates to less than 1.10 then use 1.10.

Tensioning Force = Bolt Load x Load Transfer Factor

Oil Pressure (bar) = 10 x Tensioning Force (Newtons)

Tool Pressure Area (mm2) Always check that the tensioning

force will not exceed 95% of the yield

Check that the oil pressure calculated does not exceed the maximum working strength of the bolt material. If it

pressure of the bolt tensioning tool. Users who require highly accurate residual does, the grip length of the bolt must

bolt stresses should perform a bolt extension measurement before and after

be increased. Please contact your

tensioning. In this way residual bolt stresses can be calculated from the actual

bolt extensions measured. representative for advice on this.

Load Transfer Factor Graph

IMPORTANT - The chart and formula 1.50

should only be used as a guide. The

actual residual load can be affected by 1.45

many factors including but are not limited 1.40

to, damage to bolt and nut threads,

Load Transfer Factor

squareness of the nut washer face to 1.35

the nut threads, squareness of the joint

faces, condition of the joint face under the 1.30

nut, and the use of washers. Users who

1.25

require very accurate and known residual

bolt loads should use measurements 1.20

to determine the actual residual load

achieved. For example perform a bolt 1.15

length measurement before and after

tensioning, then calculate the residual 1.10

load from the measured bolt extension. 1.05

Boltight accepts no responsibility for the

actual residual loads achieved with it's 1.00

bolt tensioning tools. 1 2 3 4 5 6 7 8 9 10 11 12 13

Ratio Bolt Grip Length /Bolt Diameter

WORKED EXAMPLE

Flange 18 inch 900 lb

Bolt diameter (D) 1-7/8 inch UN8

No. of bolts 20

Bolt grip length (G) 204 mm

Residual bolt stress required 275 N mm2 (40,000 psi)

Bolt tensioning tool no. Tool No. 23A

Hydraulic pressure area 5489.8 mm2

Calculate residual load

Bolt stress area 1567 sq mm (2.43 inch2)

Residual load per bolt = 275 x 1567 / 1000

= 430.9 kN

Calculate load transfer factor

Load transfer factor (LTF) = 1.01 + D/G where :-

D = 1.875 x 25.4 = 47.652 mm

G = 204 mm

= 1.01 + (47.625 / 204)

= 1.01 + 0.233

= 1.243

Calculate initial bolt load required

Initial bolt load = Residual bolt load x load transfer factor

= 430.9 kN x 1.243

= 525.6 kN

Calculate Oil pressure B

Oil pressure B = Initial bolt load / Hydraulic pressure area

= 525.6 kN / 5489.8 mm2 x 10

= 957.4 bar (say 960 bar)

Calculate Oil pressure A

Oil pressure A = 1.25 x Oil pressure B = 957.4 x 1.25

= 1196.7 bar (say 1200 bar)

DS12_2019_03_EN1/A

Production Site Sales Office

Boltight Limited Nord-Lock Ltd

Tel: +44 (0) 1922 669222 Tel: +44 (0) 1264 355557

Email: sales.boltight.uk@nord-lock.com Email: enquiries@nord-lock.co.uk

www.nord-lock.com www.nord-lock.com

You might also like

- Allowable External Forces on Vessel NozzlesDocument3 pagesAllowable External Forces on Vessel Nozzlesvenkatrangan2003No ratings yet

- Crane Loads N Wharf StructureDocument77 pagesCrane Loads N Wharf StructureMichael Dixon100% (1)

- Solid RC Slab BridgeDocument18 pagesSolid RC Slab BridgeEngineeri TadiyosNo ratings yet

- Fs Curtis Fac 110p 110pc 110b 110bc Service Manual Isuzu PDFDocument60 pagesFs Curtis Fac 110p 110pc 110b 110bc Service Manual Isuzu PDFJeddy SantikaNo ratings yet

- The Stability of Frames: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandThe Stability of Frames: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- 1/11 Engine Model: 4He1-X: Ass'y No.: 107492-1112Document11 pages1/11 Engine Model: 4He1-X: Ass'y No.: 107492-1112Marco100% (3)

- Work Shop Manual - BUKH DV 20 ME PDFDocument306 pagesWork Shop Manual - BUKH DV 20 ME PDFTom KooleNo ratings yet

- Drilling Torque & DragDocument66 pagesDrilling Torque & DragShamit Rathi100% (1)

- Bolted JointDocument9 pagesBolted JointkhanhtruongNo ratings yet

- Motor CleaningMethods Bishop 0620Document21 pagesMotor CleaningMethods Bishop 0620Rolando LoayzaNo ratings yet

- PDS390-400 SM Compressor Air ScrewDocument60 pagesPDS390-400 SM Compressor Air Screwandi yusuf100% (5)

- Interference Fit Calculation GuideDocument23 pagesInterference Fit Calculation GuideEMRENo ratings yet

- MITICSDocument748 pagesMITICSfersky100% (5)

- GE Zenith Controls: MX150 Microprocessor Controller Transfer Switch Control PanelDocument28 pagesGE Zenith Controls: MX150 Microprocessor Controller Transfer Switch Control PanelricharsonNo ratings yet

- Calculate Bearing Life (Timken)Document8 pagesCalculate Bearing Life (Timken)jacksonholland8335100% (2)

- 8DK32C英文セットDocument168 pages8DK32C英文セットValdoados100% (1)

- How Unbalance Affects Bearing LifeDocument8 pagesHow Unbalance Affects Bearing Lifeagrocel_bhv5591No ratings yet

- High Mast Design Calculation PDFDocument24 pagesHigh Mast Design Calculation PDFSandip Sengupta60% (5)

- Example Calculation TorqueDocument8 pagesExample Calculation TorquePenchalaiah PodalakuruNo ratings yet

- Vibration Versus Bearing Life HandoutDocument11 pagesVibration Versus Bearing Life Handoutscribdtaker12345No ratings yet

- Zoomlion ZCT900V532.1 Telescopic Crawler Crane Technical SpecificationsDocument15 pagesZoomlion ZCT900V532.1 Telescopic Crawler Crane Technical SpecificationsSlamat BasukiNo ratings yet

- Conveyor Pulley DesignDocument2 pagesConveyor Pulley DesignZoebair100% (1)

- Crane Loads & Wharf Structure DesignDocument79 pagesCrane Loads & Wharf Structure DesignSatanapong ChantanakomNo ratings yet

- Winch Testing RequirementsDocument4 pagesWinch Testing Requirementsksangeeth2000No ratings yet

- Practical Research 2 Activity 1Document1 pagePractical Research 2 Activity 1Pepito Manloloko100% (1)

- Practice 24 - PDB Cloning and Relocation Using DBCADocument11 pagesPractice 24 - PDB Cloning and Relocation Using DBCALogis M100% (1)

- Impact of JetDocument8 pagesImpact of JetbandarNo ratings yet

- Foundation Pads - MPA - EC2Document1 pageFoundation Pads - MPA - EC2mayphyoNo ratings yet

- Thesis FinalDocument186 pagesThesis FinalLouiseBundgaard0% (1)

- Oil Pressure Calculation: Bolt LoadDocument3 pagesOil Pressure Calculation: Bolt LoadFarzadNo ratings yet

- Euronorm Slewing Rings Manual (ENG)Document8 pagesEuronorm Slewing Rings Manual (ENG)Gladwin JesNo ratings yet

- Symposium On The Lift and Escalator TechnologiesDocument5 pagesSymposium On The Lift and Escalator TechnologiesfreddyjoertyNo ratings yet

- Friction in Mechanism JointsDocument4 pagesFriction in Mechanism JointsPonsamuelNo ratings yet

- Bearings Types, Design and SelectionDocument40 pagesBearings Types, Design and SelectionHariom KumarNo ratings yet

- Bolted Joint - Wikipedia v123Document8 pagesBolted Joint - Wikipedia v123Juan F CrsNo ratings yet

- Lubrication: 9.1 Lubrication Amount For The Forced Lubrication MethodDocument12 pagesLubrication: 9.1 Lubrication Amount For The Forced Lubrication MethodedinsonNo ratings yet

- STIKO Documentation Calibration EquipmentDocument16 pagesSTIKO Documentation Calibration EquipmentBoùhàfs AkeNo ratings yet

- TRQDocument29 pagesTRQMohamed BakheetNo ratings yet

- Liquid Ring Vacuum Pumps: LPH 75320, LPH 75330, LPH 75340Document10 pagesLiquid Ring Vacuum Pumps: LPH 75320, LPH 75330, LPH 75340pablodugalNo ratings yet

- Cilindro Penta Hydraulic PowerDocument1 pageCilindro Penta Hydraulic PowerUniversity FilesNo ratings yet

- Pipe Rack Hilti Bolt CalculationsDocument6 pagesPipe Rack Hilti Bolt CalculationsAnonymous MAQrYFQDzVNo ratings yet

- Louvers 1Document7 pagesLouvers 1alex robinNo ratings yet

- Bolt Loading NotesDocument10 pagesBolt Loading NotesAnonymous 7vljJzHNo ratings yet

- Precision Motion Components GuideDocument38 pagesPrecision Motion Components GuideJaikrishnaNo ratings yet

- Steel Beam AnalysisDocument3 pagesSteel Beam AnalysiskevinNo ratings yet

- Lubrication: 9.1 Lubrication Amount For The Forced Lubrication MethodDocument12 pagesLubrication: 9.1 Lubrication Amount For The Forced Lubrication Methodjorgeluis2000No ratings yet

- Program CharacteristicsDocument10 pagesProgram Characteristicssiva shankarNo ratings yet

- Thin Cylinder Stress ExperimentDocument2 pagesThin Cylinder Stress ExperimentPriyanshuNo ratings yet

- Thincyl PDFDocument2 pagesThincyl PDFPriyanshuNo ratings yet

- 2007-013 Slew Ring Bolt Check Exchange Rev3 01Document4 pages2007-013 Slew Ring Bolt Check Exchange Rev3 01Luis EaNo ratings yet

- WPL 21 Fund Torque-TensionDocument15 pagesWPL 21 Fund Torque-TensionnapoleonmNo ratings yet

- altalanos_nyomatek_fogalom_attekinteseDocument5 pagesaltalanos_nyomatek_fogalom_attekintesepmf engineering limitedNo ratings yet

- Calculating rolling bearing life expectancyDocument2 pagesCalculating rolling bearing life expectancySRINIVAS KOMMINENINo ratings yet

- Top Reooler InspectionDocument3 pagesTop Reooler InspectionaungaungoomanualNo ratings yet

- Values Highlighted in GREEN Are Calculated ValuesDocument1 pageValues Highlighted in GREEN Are Calculated ValuesOkky Putra Widodo OkkyNo ratings yet

- Pump maintenance standard documentDocument4 pagesPump maintenance standard documentNaing Min HtunNo ratings yet

- Bolt Torq 0309Document3 pagesBolt Torq 0309jakkakiransNo ratings yet

- Tri P10Document10 pagesTri P10Dvd Davide La CruzNo ratings yet

- 1 - Pdfsam - JSN-20-008-LOP-WPS3-OS-001 Rev 00Document1 page1 - Pdfsam - JSN-20-008-LOP-WPS3-OS-001 Rev 00ibnu rizalNo ratings yet

- Rolling Element BearingDocument7 pagesRolling Element BearingkrishNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Slip Ring Motor CheckDocument3 pagesSlip Ring Motor CheckRolando LoayzaNo ratings yet

- Ot8gb AbbDocument186 pagesOt8gb AbbRolando LoayzaNo ratings yet

- 287SVD Detector de VoltajeDocument1 page287SVD Detector de VoltajeRolando LoayzaNo ratings yet

- Vacon OPT A8 ManualDocument4 pagesVacon OPT A8 ManualRolando LoayzaNo ratings yet

- Zone Selective Interlocking v2 5 enDocument35 pagesZone Selective Interlocking v2 5 enRolando LoayzaNo ratings yet

- 3M - SVHC - FF 9200 1180 7Document4 pages3M - SVHC - FF 9200 1180 7Rolando LoayzaNo ratings yet

- Air Vacuum & Blow Gun Kit for Car Repair ShopsDocument31 pagesAir Vacuum & Blow Gun Kit for Car Repair ShopsRolando LoayzaNo ratings yet

- Models For Bearing Damage Detection in Induction MDocument7 pagesModels For Bearing Damage Detection in Induction MRolando LoayzaNo ratings yet

- Product Information DIGSI4 V4 90 PDFDocument70 pagesProduct Information DIGSI4 V4 90 PDFShid JullNo ratings yet

- Adventures in Lead Times PDFDocument20 pagesAdventures in Lead Times PDFAvinash RoutrayNo ratings yet

- IOP Conference Series: Materials Science and Engineering - Comprehensive model of a hermetic reciprocating compressorDocument11 pagesIOP Conference Series: Materials Science and Engineering - Comprehensive model of a hermetic reciprocating compressorFrancisco OppsNo ratings yet

- Thailand International Mathematical Olympiad Syllabus: Kindergarten GroupDocument5 pagesThailand International Mathematical Olympiad Syllabus: Kindergarten GroupEly SoemarniNo ratings yet

- Red Soil and Bentonite As LinerDocument8 pagesRed Soil and Bentonite As LinerGKNo ratings yet

- Science 10 - Set 2 - DS 1Document10 pagesScience 10 - Set 2 - DS 1DhejehNo ratings yet

- 1 1 6 Blood Splatter Analysis Experimental DesignDocument4 pages1 1 6 Blood Splatter Analysis Experimental Designapi-343751193100% (1)

- Lecture 10, 11, 12 - Chapter 5 Distributed ForcesDocument43 pagesLecture 10, 11, 12 - Chapter 5 Distributed Forcesrobel metikuNo ratings yet

- Apr24-3g CDocument4 pagesApr24-3g COscar Payan ViamonteNo ratings yet

- Appendix ADocument13 pagesAppendix Ajuha04No ratings yet

- Video Surveillance 2012 MailDocument76 pagesVideo Surveillance 2012 MailcoreloneNo ratings yet

- Curtain Wall Conn2Document11 pagesCurtain Wall Conn2Raveendra Babu CherukuriNo ratings yet

- Log AssignmentDocument4 pagesLog AssignmentguranshsaranNo ratings yet

- UML Diagram Types GuideDocument17 pagesUML Diagram Types GuideahmedNo ratings yet

- OSY Practical No.1Document18 pagesOSY Practical No.1aniket bhoirNo ratings yet

- Touch screen wheelchair controlDocument3 pagesTouch screen wheelchair controlKhatriZabirNo ratings yet

- Update On The Modeling of Semiautogenous Grinding Processes in A Moly-Cop Tools EnvironmentDocument15 pagesUpdate On The Modeling of Semiautogenous Grinding Processes in A Moly-Cop Tools EnvironmentTecnoExpress CHILENo ratings yet

- AM054KNMDCH1AZDocument3 pagesAM054KNMDCH1AZaandresleo86No ratings yet

- Control Valve Packing Guide - PTFE, Graphite, & EPA Compliant Options in 40 CharactersDocument2 pagesControl Valve Packing Guide - PTFE, Graphite, & EPA Compliant Options in 40 Charactersmilton1987No ratings yet

- Research Paper: Jimmy Persson (pt98jpr) Gustav Evertsson (Pt99gev) Blekinge Institute of Technology, SwedenDocument10 pagesResearch Paper: Jimmy Persson (pt98jpr) Gustav Evertsson (Pt99gev) Blekinge Institute of Technology, SwedenAnjali SoniNo ratings yet

- EC6802-Wireless Network Unit-1Document21 pagesEC6802-Wireless Network Unit-1Mprabha KaranNo ratings yet

- SKF Mounting Guide for 22318 EJA/VA405Document4 pagesSKF Mounting Guide for 22318 EJA/VA405cumtjerryNo ratings yet

- Power Systems Dynamics NotesDocument47 pagesPower Systems Dynamics Notessetsindia3735100% (1)

- Hysteretic Energy DissipationDocument22 pagesHysteretic Energy Dissipationdharma raj upadhyayaNo ratings yet

- Schott Ky DiodesDocument3 pagesSchott Ky DiodesAmarnath M DamodaranNo ratings yet

- Giant Salt Basin in Peru OverlookedDocument18 pagesGiant Salt Basin in Peru OverlookedFred LuqueNo ratings yet

- Is 1646 1997 PDFDocument24 pagesIs 1646 1997 PDFamitabha0107No ratings yet