Professional Documents

Culture Documents

P3 Reviewer

Uploaded by

zskhyzeia30Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

P3 Reviewer

Uploaded by

zskhyzeia30Copyright:

Available Formats

TYPES OF WOOD FRAMMING

1. Light Wood Framing

a). Balloon Frame. This the lightest form of framing,

in which the studding and corner posts are set up in

continuous lengths from first floor line or sill to roof

plate. Boards called ribbons are notched and nailed

into the studs and corner posts at the proper height

to support the second story joists. A joist is brought

against a stud wherever possible. This type of frame is

lacking in rigidity and is liable to sway and tremble in

heavy winds.

c) Platform Frame. A system of framing for a building

of wood construction several stories high, in which

the studs are only one story high; the floor joists for

each story rest on the top plates of the story below or

on the sole plate of the first story. Also called Western

Framing.

b) Combination Frame. A modification of the old

braced frame which was of heavy timbers with every

joint mortised and tenoned. The modification consists

of lighter timbers and less mortising and pinning to

save material and labor.

Girts are framed into the corner posts at the second

story level joists as well as to brace the whole frame.

The girts which support the floor joist are called drop

2. Heavy Wood Framing of Beam Girder Framing

girts; those parallel to the joists are called raised or

flush girts. The studs run from sill to girt and from girt This is the type of framing used in the Philippines in

to roof plate. Diagonal braces run from sill to corner which the floor joists are carried by girders, and the

posts and from the corner posts to the roof plate. This roof trusses or rafters by girts which frame into the

type of construction is more rigid than the balloon posts. Studs rest on floor sills and extend up the girder

frame. or girt in every floor.

JOINT AND SPLICING

1. Plain Joint (Lap Joint). The plain joint is used in very

hasty construction for temporary framing and is made

by lapping one piece over the other and nailing then

together. It is not a very strong joint.

2. Butt or Square Joint (End Joint). The butt joint is

made by placing full thickness of wood directly against 7. Halved Joint. This joint is made by cutting half the

the second piece. The butt end should be squared and thickness of the wood from each piece at the ends to

the sides against which it butts smooth so that the be joined so as to bring the sides flush. The purpose of

pieces will be perpendicular to each other. The joint is this type of joint is to maintain a level surface at the

toe-nailed. joint.

3. Oblique Joint. This type of joint is made when the 8. Rabbet Joint. This joint is made by cutting a

two pieces do not meet at right angles, e.g. bracings. shoulder or edge from one piece to receive the other

One piece is cut at an angle to fit the other and the piece. It is used in window or door frames, or in shelf

two pieces nailed securely together. and drawer construction.

4. Spliced or Scabbed Joint. (See Splices) 9. Dado Joint. This is similar in shape and purpose to

the rabbet joint. In the dado joint a groove is made in

5. Scarf Joint. A joint by which the ends of two pieces one piece at right angles to the grain of the other

of timber are united to form a continuous piece; the board. If nails are used, they are needed only at the

mating surface may be beveled, chamfered, notched, end piece since the groove will provide the necessary

etc. before bolting, gluing, welding, etc. strength to hold the other piece in place.

6. Mortise and Tenon Joint. This type of joint is used

for building wooden framework where great strength

and rigidity are all important. It is made by cutting a

hole or mortise in one piece and a tenon or tongue in

the second piece to fit the hole in the other. The

tenon may extend fully through the other piece or

only part of the way.

10. Miter Joint. The miter is a joint between two

pieces which come together at a corner. It is a finish

VARIATION OF LAP JOINTS

joint and should not be used where strength is an

important requirement. It is made by cutting the two

ends at angles complementary to each other, usually

45 degree, and then butting them together. The joint

is secured by clamp nails or finishing nails, corrugated

fasteners or dowels, or by gluing.

11. Dovetail Joint. This type of joint, used for cabinet

work and furniture work, is strong and durable. It is

made by cutting a pin in the shape of a dovetail in one

piece to fit a groove similarly shaped in the other

piece.

VARIATIONS OF MORTISE AND TENON JOINTS

12. Coped Joint. The coped joint is used when fitting

one piece of moulding at right angles to the second

piece.

Other types of joints include the shiplapped joint and

the tongue and grooved joint

SPLICES

The function of a splice is to connect two or more

COMMON WOOD JOINTS FOR FURNITURE

pieces of timber in such a way that the joint will be as

strong as a single timber of equivalent size. Splices are

of three types: for compression, tension and bending.

A. Splices for Compression

1. Scabbed or Fished Splice. Two pieces of timber are

squared at their ends and fitted together. Two short

wood pieces called scabs or metal plates called

fishplates are fastened on either side of the pieces to

be joined. The scabs or fishplates serve to keep the

splice straight and to prevent buckling.

You might also like

- 7b Building Technology 1Document29 pages7b Building Technology 1Norbert James BentulanNo ratings yet

- 7b Building Technology 1Document30 pages7b Building Technology 1Gilbert DavidNo ratings yet

- Joinery & MillworksDocument29 pagesJoinery & MillworksRamcy AddulamNo ratings yet

- Carpentry JointsDocument6 pagesCarpentry JointsKrithigaNo ratings yet

- Building Technology 2: Arch - Carmela C. Quizana, MSCM, UapDocument17 pagesBuilding Technology 2: Arch - Carmela C. Quizana, MSCM, UapAngelae BorjaNo ratings yet

- Wood JointsDocument10 pagesWood JointsLeslie Joy Anastacio VizcarraNo ratings yet

- Woodwork Joints Grd 8Document8 pagesWoodwork Joints Grd 8sunbai samuelNo ratings yet

- Rough Framing Army FM5-426Document44 pagesRough Framing Army FM5-426john emerson YabutNo ratings yet

- Woodworking Joints: List of Wood JointsDocument5 pagesWoodworking Joints: List of Wood Jointsgalaxy82yngelNo ratings yet

- (I) Corner Angle JointsDocument5 pages(I) Corner Angle Jointsparag gemnaniNo ratings yet

- Reporters: Clemente, John Andrei de Pedro, John Paul Fajardo, Xandra Ale Soriano, AlgernonDocument19 pagesReporters: Clemente, John Andrei de Pedro, John Paul Fajardo, Xandra Ale Soriano, AlgernonJogz de PedroNo ratings yet

- Wood JointDocument19 pagesWood JointMache SebialNo ratings yet

- CON2910 Project B Basic Wood Joinery NotesDocument8 pagesCON2910 Project B Basic Wood Joinery NotesEd PawliwNo ratings yet

- Wood Joints1Document3 pagesWood Joints1Urvashi Bhati0% (1)

- Woodwork Joints How they are Set Out, How Made and Where Used.From EverandWoodwork Joints How they are Set Out, How Made and Where Used.Rating: 5 out of 5 stars5/5 (1)

- Industrial Arts 4Document18 pagesIndustrial Arts 4cynthiataculog35No ratings yet

- Module 6 COMMON WOOD JOINTSDocument20 pagesModule 6 COMMON WOOD JOINTSDaneNo ratings yet

- Wood JointsDocument3 pagesWood JointsNhatz Gallosa MarticioNo ratings yet

- Grantley Adams Memorial School Furniture Making JointsDocument7 pagesGrantley Adams Memorial School Furniture Making JointsPaul SealyNo ratings yet

- Bira Furniture Is One of The Oldest Wooden Factory in NepalDocument11 pagesBira Furniture Is One of The Oldest Wooden Factory in Nepalsamjhana shresthaNo ratings yet

- Joinery 2Document28 pagesJoinery 2Willie LassiterNo ratings yet

- Woodworking 150606073133 Lva1 App6892Document84 pagesWoodworking 150606073133 Lva1 App6892bereket gNo ratings yet

- Joining Wood: Joint FamiliesDocument8 pagesJoining Wood: Joint FamiliesAaron RalstonNo ratings yet

- TVL 12 Carpentry NC II w4 6 Types of Wood JointsDocument19 pagesTVL 12 Carpentry NC II w4 6 Types of Wood JointsBenjamin PanerNo ratings yet

- Carpentry 1Document10 pagesCarpentry 1Apple Anne GellicaNo ratings yet

- Wood JointsDocument11 pagesWood JointsmarthaNo ratings yet

- KINDS OF JOINTSDocument9 pagesKINDS OF JOINTSjojo bernabeNo ratings yet

- CH 5Document9 pagesCH 5crazybuttfulNo ratings yet

- Chapter-01 - Carpentry & JoineryDocument37 pagesChapter-01 - Carpentry & JoineryKAAM TodaNo ratings yet

- Condition in Making Intermediate JointsDocument15 pagesCondition in Making Intermediate JointsRaffer Asis MorañoNo ratings yet

- Tle Assignment: Common Wood JointsDocument5 pagesTle Assignment: Common Wood JointsClaire LimsonNo ratings yet

- Timber Tech Types of JointsDocument33 pagesTimber Tech Types of JointsCamille YoungNo ratings yet

- Wood JoineryDocument34 pagesWood JoineryShubhi Shrivastava100% (3)

- Quantity Surveying / Engr. Romel N. VinguaDocument32 pagesQuantity Surveying / Engr. Romel N. VinguaBG GuillermoNo ratings yet

- Intro to carpentry toolsDocument8 pagesIntro to carpentry toolsIbrahim QariNo ratings yet

- Types of Joints - Aubrey Lynn Joyohoy - FinalDocument32 pagesTypes of Joints - Aubrey Lynn Joyohoy - FinalAubrey Lynn JoyohoyNo ratings yet

- Joints in Brick Work: Lecture - 3 By:-Ar - Mani KhannaDocument32 pagesJoints in Brick Work: Lecture - 3 By:-Ar - Mani KhannaRohit Khanna0% (1)

- CarpentaryDocument10 pagesCarpentaryvikrantNo ratings yet

- Types of Joints in Carpentry With DescriptionDocument5 pagesTypes of Joints in Carpentry With DescriptionYuuki ChanNo ratings yet

- Tongue and Groove and House JointDocument1 pageTongue and Groove and House JointNishimaNo ratings yet

- CabinetsDocument13 pagesCabinetsAlcohol You LaterNo ratings yet

- Wood DefectsDocument10 pagesWood DefectsTegha LucasNo ratings yet

- Wood JointsDocument2 pagesWood JointsRosalinda AtunNo ratings yet

- Wooden Joinaries Market Survey....Document51 pagesWooden Joinaries Market Survey....flower lilyNo ratings yet

- 1 Building Const 2Document89 pages1 Building Const 2Justine Rose AngolluanNo ratings yet

- The Same Them When: All Line, BitDocument1 pageThe Same Them When: All Line, BitreacharunkNo ratings yet

- Carpentry and Joine RY: Asi, Jemmrie P. ARC 1201Document21 pagesCarpentry and Joine RY: Asi, Jemmrie P. ARC 1201Victor EvangelioNo ratings yet

- Timber Structure Final - Complete VersionDocument44 pagesTimber Structure Final - Complete VersionMara ANo ratings yet

- Different Types of Wood JointDocument2 pagesDifferent Types of Wood Joint[AP-STUDENT] Resty GarciaNo ratings yet

- Carpentry and MasonryDocument12 pagesCarpentry and MasonryRAN DOM FUNNo ratings yet

- Earthquake Day PresentationDocument32 pagesEarthquake Day PresentationSandesh KhadkaNo ratings yet

- Wood Joinery for Beginners Handbook: The Essential Joinery Guide with Tools, Techniques, Tips and Starter ProjectsFrom EverandWood Joinery for Beginners Handbook: The Essential Joinery Guide with Tools, Techniques, Tips and Starter ProjectsRating: 5 out of 5 stars5/5 (1)

- CON3130 Module NotesDocument8 pagesCON3130 Module NotesEd PawliwNo ratings yet

- 1 Building Const 2Document89 pages1 Building Const 2Iyan Kenet HerodicoNo ratings yet

- Woodworking - Advance JointsDocument35 pagesWoodworking - Advance JointsLiezl Jeane TejamoNo ratings yet

- Wood ChemicalDocument12 pagesWood ChemicalArielle JohnNo ratings yet

- 3 Jointing TechniquesDocument32 pages3 Jointing TechniquesyabetymarthaNo ratings yet

- Traditional Timber RepairsDocument3 pagesTraditional Timber RepairscarlmorganNo ratings yet

- Building TechnologyDocument4 pagesBuilding TechnologyDanica LuarezNo ratings yet

- Watch TOWER BBSDocument72 pagesWatch TOWER BBShafiz100% (1)

- Minimum Loads: Thayer's Formula (From Steel Structures 3rd Ed 2012 by Z.A. Siddiqi, p.261)Document17 pagesMinimum Loads: Thayer's Formula (From Steel Structures 3rd Ed 2012 by Z.A. Siddiqi, p.261)JHON CLYDE SEPADANo ratings yet

- Fascia Frame Details: Foundation PlanDocument1 pageFascia Frame Details: Foundation PlanRod NajarroNo ratings yet

- Building Structural System ReportDocument32 pagesBuilding Structural System ReportHuiyiChang100% (3)

- Tributary Area For 2ND FloorDocument7 pagesTributary Area For 2ND FloorDave Khyl Josol BosqueNo ratings yet

- Calmar Land Development Corp. Proposed Two Storey Residential Building " Model Aurora"Document3 pagesCalmar Land Development Corp. Proposed Two Storey Residential Building " Model Aurora"C.T VillamarNo ratings yet

- Two Way Concrete Floor Slab With Beams Design DetailingDocument70 pagesTwo Way Concrete Floor Slab With Beams Design DetailingBryanTiznadoAguilarNo ratings yet

- Project Report: Model File: Etabs Kursus, Revision 0Document35 pagesProject Report: Model File: Etabs Kursus, Revision 0Miguel SantosNo ratings yet

- 5.Bmc 2018 RoofsDocument17 pages5.Bmc 2018 Roofsmohana gNo ratings yet

- Design Methods for Timber Bridges and Structural SystemsDocument41 pagesDesign Methods for Timber Bridges and Structural SystemsAgung TriraharjoNo ratings yet

- SP47Document177 pagesSP47Venkata Bhaskar DameraNo ratings yet

- Timber Frame Solutions 03Document20 pagesTimber Frame Solutions 03sertackcdgNo ratings yet

- Footing Schedule and Reinforcement DetailsDocument1 pageFooting Schedule and Reinforcement Detailsarif_rubinNo ratings yet

- Research Library: Wood Design Manual 2017 Wood Design Manual 2017Document1 pageResearch Library: Wood Design Manual 2017 Wood Design Manual 2017Ver LibertadoresNo ratings yet

- Structural Systems Factors in Senior Housing DesignDocument8 pagesStructural Systems Factors in Senior Housing DesignAbdoullah AlbizrehNo ratings yet

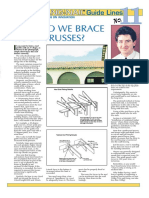

- Guidelines 11Document1 pageGuidelines 11Zac Francis DaymondNo ratings yet

- Convention Pitched Roof Tafe NSW1.PDF Complete1Document70 pagesConvention Pitched Roof Tafe NSW1.PDF Complete1solomonNo ratings yet

- Bolted Moment ConnectionDocument9 pagesBolted Moment ConnectionAmey Gudigar100% (1)

- Modification of Portal Method For Analyzing The Frames: ArticleDocument21 pagesModification of Portal Method For Analyzing The Frames: ArticleMălíķ ĂsfęnđýårNo ratings yet

- ACI 318-08 Design of Retaining Wall With Counterfort - Rev1.0 - 08-Apr-2014Document4 pagesACI 318-08 Design of Retaining Wall With Counterfort - Rev1.0 - 08-Apr-2014Janmesh Nivrutti KhedkarNo ratings yet

- General Structural Notes Drawing List: Sheet Title Sheet NoDocument7 pagesGeneral Structural Notes Drawing List: Sheet Title Sheet NoAzllina Anuar100% (1)

- Structural: Drawing ListDocument2 pagesStructural: Drawing ListAdnanNo ratings yet

- PROBLEM 6.39: SolutionDocument10 pagesPROBLEM 6.39: SolutionWilliam HendersonNo ratings yet

- Approved 7 Storey Structural and General NotesDocument20 pagesApproved 7 Storey Structural and General Notesnasohig539No ratings yet

- Structural Drawing SampleDocument11 pagesStructural Drawing SampleEng.wissam SafaaNo ratings yet

- GazeboDocument1 pageGazeboChristopher NiadasNo ratings yet

- Building Construction TermsDocument6 pagesBuilding Construction TermsCharisse Bernadette Dela CruzNo ratings yet

- Advanced CatalogDocument202 pagesAdvanced CatalogHenry SantosNo ratings yet

- ICH Courier V16 Web 4Document1 pageICH Courier V16 Web 4DANIEL LOUISSE STA. MARIANo ratings yet

- Bill of Materials PoolDocument1 pageBill of Materials PoolJustine Yap100% (1)