Professional Documents

Culture Documents

Hoja de Especificaciones JX6H-NL

Uploaded by

osvaldoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hoja de Especificaciones JX6H-NL

Uploaded by

osvaldoCopyright:

Available Formats

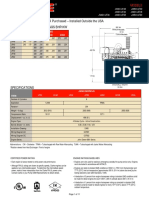

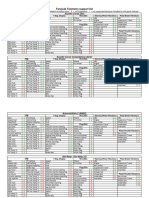

MODELS

JX6H-NL50

JX6H-NL30 JX6H-NL60

FIRE PUMP DRIVERS JX6H-NL40 JX6H-NL70

Non-listed NFPA Like - Heat Exchanger Engines

*Gross Power Rating BHP/kW

JX6H OPERATING SPEED

MODEL 1470 1760 1800 2000 2100

NL30 350 462 463 470 473

287 344.5 345 350.5 353

NL40 418 506 509 525 533.5

312 377 380 392 398

NL50 445.5 533.5 537 553 561

332 398 400.5 412.5 418

NL60 473 561 563 573 577.5

353 418 419 428 431

NL70 533.5 632.5 632.5 632.5 632.5

398 472 472 472 472

*Power rating: a 10% deduction in power must be made to determine the maximum allowable pump load.

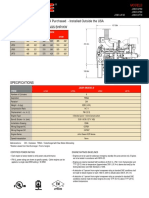

Engine Equipment JX6H-NL70

Overall Width

Equipment Standard Optional 881[34.69]

Air Cleaner Direct Mounted, Washable, Disposable, Drip proof,

Indoor Service Indoor Service Equipment Standard Optional

Outdoor Type Heat Exchanger Tube & Shell Type, 60 PSI

Alternator 24V-DC, 40 Amps; w/Belt w/NPTF Connections

Guard Instrument Multimeter to display:

Coupling Falk Coupling, Engine Half Panel Tachometer, Hourmeter,

1090T10 Coupling Water Temperature & Oil

Drive Shaft & Guard; Pressure. Voltmeter with

SC2140 for UF30 & selector switch

UF40 models, Junction Box Integral with Instrument

SC2155 for UF50, UF60 & Panel; For DC Wiring

UF70 models Interconnection to Engine

Bare Flywheel Controller

Droop 4% 0% Lube Oil Cooler Engine Water Cooled,

Plate Type

Exhaust For Manifolds & Turbo-

charger Lube Oil Filter Full Flow w/By-Pass Valve

Blankets*

Lube Oil Pump Gear Driven, Gear Type

Exhaust Flex SS Flex, Clamped, 6" SS Flex, 150# Flange, 8"

Connection SS Flex, Clamped, 8" SS Flex, 150# Flange, 6" Manual Start On Instrument Panel

Controls

Flywheel S.A.E. #2

Housing Overspeed Electronic w/Reset

Control

Flywheel Power 11.5" S.A.E. Industrial Fly-

Take Off wheel Connection Raw Water Automatic from Engine

Solenoid Controller & from

Fuel Fire Resistant Flexible Instrument Panel

Supply & Return Lines Operation

Connections*

Run-Stop On Instrument Panel With

Fuel Filter Primary Filter w/Priming

Control Position Warning

Pump Control

Light

Fuel Injection Unit Injectors w/electronic

Starter One (1) 24V-DC w/2 Start

System control

Contactors

Engine Heater* 230V-AC, 2500 Watt Throttle Control Adjustable Speed Control by

115V-AC, 2500 Watt increase/decrease button,

Tamper Proof

Governor, Speed Electronic, dual electronic

controle modules Water Pump Gear Driven, Centrifugal Type

Note: Engine Controller needs 2 additional signals: Injector Failure, Alternate ECM Selected

*Required to comply with NFPA-20

MODELS

JX6H-NL50

JX6H-NL30 JX6H-NL60

FIRE PUMP DRIVERS JX6H-NL40 JX6H-NL70

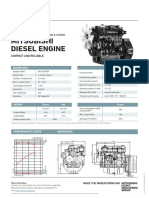

Specifications

JX6H Models

Item

NL30 NL40 NL50 NL60 NL70

Number of Cylinders 6

Aspiration TJWA TRWA

Rotation* CounterClockwise (CCW)

Weight - kg (lb) 1429 (3150) 1474 (3250)

Compression Ratio 16:1

Displacement - l (cu. in.) 12.5 (766)

Engine Type 4 Cycle - Inline

Bore & Stroke - mm (in.) 127 (5.00) x 165 (6.5)

Installation Drawing D - 546

Wiring Diagram C07957

Engine Series John Deere 6125 Series

Abbreviations: CCW – CounterClockwise TJWA – Turbocharged with Jacket Water Aftercooling

TRWA – Turbocharged with Raw Water Aftercooling *Rotation viewed from Flywheel CW Rotation is not available.

Engine intended for Indoor use or inside weatherproof enclosure only

†

ENGINE RATINGS BASELINES

Engines are rated at standard SAE conditions of 29.61 in. (7521 mm) Hg barometer and 77˚F (25˚C) inlet air temperature [approximates 300 ft. (91.4

m) above sea level] by the testing laboratory (see SAE Standard J 1349).

A deduction of 3 percent from engine horsepower rating at standard SAE conditions shall be made for diesel engines for each 1000 ft. (305 m) altitude

above 300 ft. (91.4 m).

A deduction of 1 percent from engine horsepower rating as corrected to standard SAE conditions shall be made for diesel engines for every 10˚F

(5.6˚C) above 77˚F (25˚C) ambient temperature.

GUARANTEED POWER AT ANY SPEED

Although Guaranteed BHP ratings are shown at specific speeds, Clarke engines can be applied at any

intermediate speed, but must be factory set for final desired speed. To determine the intermediate certi-

fied power, make a linear interpolation from the Clarke Guaranteed power curve. Contact Clarke or your

Pump OEM representative to obtain details.

www.clarkefire.com Fire Protection Products

CLARKE Fire Protection Products, Inc. CLARKE UK, Ltd.

3133 E. Kemper Rd. Grange Works, Lomond Rd.

Cincinnati, Ohio 45241 Coatbridge, ML5-2NN

United States of America United Kingdom

Tel +1-513-771-2200 Fax +1-513-771-0726 Tel +44-1236-429946 Fax +44-1236-427274

C132546 2/08 Specifications and information contained in this brochure subject to change without notice. Printed in U.S.A.

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Op Amps: Design, Application, and TroubleshootingFrom EverandOp Amps: Design, Application, and TroubleshootingRating: 5 out of 5 stars5/5 (2)

- Hoja de Especificaciones JW6H-NLDocument2 pagesHoja de Especificaciones JW6H-NLosvaldoNo ratings yet

- JW6HDocument5 pagesJW6HMaurilio Batista de LimaNo ratings yet

- Low Speed Models Ju4h Nl20 Ju4h Nl52 Ju6h Nl50 Fire Pump Incendiocontra IncendioDocument2 pagesLow Speed Models Ju4h Nl20 Ju4h Nl52 Ju6h Nl50 Fire Pump Incendiocontra IncendioTrirat NoguchiNo ratings yet

- Clarke JU6H Specification SheetDocument2 pagesClarke JU6H Specification Sheetabhayundale100% (1)

- Bomba MecanicaDocument2 pagesBomba MecanicaBanupriya BalasubramanianNo ratings yet

- GeneratePDF (1) - Proposal JU6H-UFDO - 144 HP@ 2100 RPMDocument11 pagesGeneratePDF (1) - Proposal JU6H-UFDO - 144 HP@ 2100 RPMMaurilio Batista de LimaNo ratings yet

- Proposal - JU6H-UF30 - 160 HP at 2350 RPMDocument11 pagesProposal - JU6H-UF30 - 160 HP at 2350 RPMMaurilio Batista de Lima100% (1)

- 31050862Document11 pages31050862farukNo ratings yet

- Motores Auxiliares 3508BDocument10 pagesMotores Auxiliares 3508BIris IlsasNo ratings yet

- 14 NTQ Electric Actuator enDocument6 pages14 NTQ Electric Actuator enCristian PisitelloNo ratings yet

- Ficha T. Motor JU6H-UFD0Document9 pagesFicha T. Motor JU6H-UFD0Nelson IglesiasNo ratings yet

- AE JSP ANNA+ MistralDocument2 pagesAE JSP ANNA+ MistralAchmad MustakimNo ratings yet

- EU EUM Series Data SheetDocument2 pagesEU EUM Series Data SheetRikiNo ratings yet

- Product Information PacketDocument5 pagesProduct Information PacketPablo OsoriaNo ratings yet

- Model DVSU Model DVSHU: Submersible Semi-Open Vortex Sewage PumpDocument12 pagesModel DVSU Model DVSHU: Submersible Semi-Open Vortex Sewage PumpVũ Đình QuangNo ratings yet

- Clarke Proposal - JW6H-UF50 - 340 HP@ 2100 RPMDocument11 pagesClarke Proposal - JW6H-UF50 - 340 HP@ 2100 RPMMaurilio Batista de LimaNo ratings yet

- brochure-o-e-w34dfDocument2 pagesbrochure-o-e-w34dfalex.lenagroNo ratings yet

- 710713RA Solenoid ValvesDocument2 pages710713RA Solenoid ValvesEDUARDOMTZNo ratings yet

- T50P Spec SheetDocument4 pagesT50P Spec SheetBen TanNo ratings yet

- Mitsubishi - Commercial Spec Sheets - Industrial Engine - Variable Speed - S4S-Z3DT65SPDocument1 pageMitsubishi - Commercial Spec Sheets - Industrial Engine - Variable Speed - S4S-Z3DT65SPInkanata SacNo ratings yet

- YC6T Series Marine Engines Under 40 CharactersDocument2 pagesYC6T Series Marine Engines Under 40 Charactersanto starlinNo ratings yet

- KV650C2 diesel generator specificationsDocument4 pagesKV650C2 diesel generator specificationsAnonymous DuwQk4iNo ratings yet

- Bijur TM-5 LubeDocument4 pagesBijur TM-5 Lubeprsking187No ratings yet

- Marine Auxiliary Engine: SpecificationsDocument2 pagesMarine Auxiliary Engine: SpecificationsContessa JamesNo ratings yet

- Service Station Manual: Typhoon 50 4t 4vDocument188 pagesService Station Manual: Typhoon 50 4t 4vJoelPineau100% (1)

- Peugeot Fans Club - Peugeot 406 XU10J2CTE - Electrical and Wiring DiagramDocument5 pagesPeugeot Fans Club - Peugeot 406 XU10J2CTE - Electrical and Wiring Diagramluis vilela100% (1)

- High Performance Applications: Marine Propulsion EngineDocument2 pagesHigh Performance Applications: Marine Propulsion EngineRocco SilfieddiNo ratings yet

- 30HXC IOM 60hz Appendix 13403Document12 pages30HXC IOM 60hz Appendix 13403Cucup SupriatnaNo ratings yet

- Ficha Tecnica Motor DP6H-UFAA88Document9 pagesFicha Tecnica Motor DP6H-UFAA88SYA33% (3)

- Split Piso Techo - OnOff - 10SEERDocument4 pagesSplit Piso Techo - OnOff - 10SEERDiego SoplaNo ratings yet

- Goulds 3885 WE CatalogoDocument8 pagesGoulds 3885 WE CatalogoToleditos y masNo ratings yet

- Patterson Pump Company LTD: Model: 5x4x12 SSC Size: 5x4x12 Qty: 1Document27 pagesPatterson Pump Company LTD: Model: 5x4x12 SSC Size: 5x4x12 Qty: 1Hany SalahNo ratings yet

- Manual Bomba EspumaDocument108 pagesManual Bomba EspumaFrancisco ManriquezNo ratings yet

- MOVA CN BW EngDocument1 pageMOVA CN BW Engfopoku2k2No ratings yet

- Edwards EH MechanicalDocument2 pagesEdwards EH MechanicalBanupriya BalasubramanianNo ratings yet

- Pool Full Catalog 2019-20Document146 pagesPool Full Catalog 2019-20Bipin PrasadNo ratings yet

- ENTREPORT 2018 BrochureDocument1 pageENTREPORT 2018 BrochureSebastianNo ratings yet

- Owp404t 50 8 - DsDocument2 pagesOwp404t 50 8 - DsPunto CheapNo ratings yet

- jw6h Ufaam8 UsaDocument8 pagesjw6h Ufaam8 UsaRoronoa ZorroNo ratings yet

- Mitsubishi - Commercial Spec Sheets - Industrial Engine - Variable Speed - S4S-Z365SPDocument1 pageMitsubishi - Commercial Spec Sheets - Industrial Engine - Variable Speed - S4S-Z365SPHanan Saedawi100% (1)

- General Characteristics: DescriptiveDocument5 pagesGeneral Characteristics: DescriptiveXuân Huy Nguyễn100% (1)

- Parts Catalog: 25, 30 HP (521cc) 2 Stroke ModelsDocument32 pagesParts Catalog: 25, 30 HP (521cc) 2 Stroke ModelsRonei MartinsNo ratings yet

- Hydro 350X: Instruction Manual For ModelDocument13 pagesHydro 350X: Instruction Manual For Modelpython78No ratings yet

- Spec Sheet Jw6h-Ufaa-Ad c133422Document4 pagesSpec Sheet Jw6h-Ufaa-Ad c133422janter edward marpaung100% (1)

- Wärtsilä 34DF: Key Benefits Typical ApplicationsDocument2 pagesWärtsilä 34DF: Key Benefits Typical ApplicationsImamHambaliiiNo ratings yet

- Technical Data: Cos Φ = 0.8 3-Phase 60 HzDocument4 pagesTechnical Data: Cos Φ = 0.8 3-Phase 60 HzHectrateNo ratings yet

- J5S, J5SH, J7S, J10S, J15S: Technical BrochureDocument4 pagesJ5S, J5SH, J7S, J10S, J15S: Technical BrochuremorjafNo ratings yet

- U-Match GOOD R410A SpecificationsDocument20 pagesU-Match GOOD R410A SpecificationsmiguelNo ratings yet

- Dp6h Ufaa62 ProposalDocument10 pagesDp6h Ufaa62 ProposalFerdinan Tulus Yones TobingNo ratings yet

- TME/TLE Series Multicompressor Pack System without condenserDocument7 pagesTME/TLE Series Multicompressor Pack System without condenserIon ZabetNo ratings yet

- SPX Power Team Electric Pump Pump Parts SheetDocument18 pagesSPX Power Team Electric Pump Pump Parts SheetB R PAUL FORTIN100% (1)

- Marathon Electric - 184TTFBD6006 - SpecificationsDocument4 pagesMarathon Electric - 184TTFBD6006 - SpecificationsJonalou ArominNo ratings yet

- USA Purchased - Installed Outside The USA Fm-Ul-Cul Approved Ratings BHP/KWDocument11 pagesUSA Purchased - Installed Outside The USA Fm-Ul-Cul Approved Ratings BHP/KWhector mauricioNo ratings yet

- Silent Type: Engine Specifica Ons Main Specifica OnsDocument2 pagesSilent Type: Engine Specifica Ons Main Specifica OnsMarketing CTNNo ratings yet

- KD110 generator specificationsDocument5 pagesKD110 generator specificationsXuân Huy NguyễnNo ratings yet

- Broadcrown John Deere BCJD 40-60Document4 pagesBroadcrown John Deere BCJD 40-60marlon073050No ratings yet

- TECHNICAL DATA SHEET TITLEDocument4 pagesTECHNICAL DATA SHEET TITLEJuan Leonardo Fonseca ValderramaNo ratings yet

- Bomba Proteccion Contra IncendioDocument9 pagesBomba Proteccion Contra IncendioYairton Vargas MuñozNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument2 pagesPump Performance Datasheet: Operating Conditions LiquidosvaldoNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument2 pagesPump Performance Datasheet: Operating Conditions LiquidosvaldoNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument2 pagesPump Performance Datasheet: Operating Conditions LiquidosvaldoNo ratings yet

- Hidraulica General - Gilberto Sotelo DavilaDocument284 pagesHidraulica General - Gilberto Sotelo DavilaCarlos SandovalNo ratings yet

- Wireless power transfer feasibility study for lunar base facilitiesDocument36 pagesWireless power transfer feasibility study for lunar base facilitiesNikhil ReddyNo ratings yet

- CS Practical File - Term IDocument6 pagesCS Practical File - Term ITanay MaheshwariNo ratings yet

- SAP Business Planning and Consolidation and Consolidation: Inese Jargane 30.10.2008Document23 pagesSAP Business Planning and Consolidation and Consolidation: Inese Jargane 30.10.2008shah744No ratings yet

- Cyber Security Challenges - How To Deal With ItDocument54 pagesCyber Security Challenges - How To Deal With ItLawrence LauNo ratings yet

- Marine power and energy management control systemsDocument51 pagesMarine power and energy management control systemssj_hecklers67% (3)

- K.Pavan KumarDocument4 pagesK.Pavan KumarvenkateshpappuNo ratings yet

- Project Management R1Document9 pagesProject Management R1owjNo ratings yet

- Flatpack2 48V HE Rectifiers: The Original HE RectifierDocument2 pagesFlatpack2 48V HE Rectifiers: The Original HE RectifierAhmed ZeharaNo ratings yet

- References LinkdnDocument15 pagesReferences LinkdnJamie JordanNo ratings yet

- Over ModulationDocument5 pagesOver ModulationAbenk's BembenkNo ratings yet

- BTH Company ProfileDocument24 pagesBTH Company ProfileMXufianNo ratings yet

- UTF-8'en'QRadar SIEM and ZscalerDocument20 pagesUTF-8'en'QRadar SIEM and ZscalerDens Can't Be PerfectNo ratings yet

- Uhpc 9628 EkenelDocument10 pagesUhpc 9628 EkenelM. Murat ErginNo ratings yet

- MP4000 SD Card SetupDocument3 pagesMP4000 SD Card SetupElvisor VisorNo ratings yet

- Qse q9 QB Owners ManualDocument36 pagesQse q9 QB Owners ManualCarlos CarlosNo ratings yet

- Baja Sae Fox Racing ProgramDocument8 pagesBaja Sae Fox Racing ProgramChristian MavarezNo ratings yet

- Shantui SG17-B6 Motor Grader enDocument2 pagesShantui SG17-B6 Motor Grader enFranco SartoriNo ratings yet

- ¿Qué Son Los Object Pronouns y para Qué Sirven?Document17 pages¿Qué Son Los Object Pronouns y para Qué Sirven?Valeria FrancoNo ratings yet

- Method Statement - Elect. Jerry ShellDocument5 pagesMethod Statement - Elect. Jerry ShellnayumNo ratings yet

- IVMS 8600 Platform Software IntroductionDocument37 pagesIVMS 8600 Platform Software Introductionbob felarcaNo ratings yet

- Trinh Bui Resume 10 20 2020Document1 pageTrinh Bui Resume 10 20 2020api-531960027No ratings yet

- High Potential Cable TestingDocument1 pageHigh Potential Cable TestingAries dNo ratings yet

- FanaLab Telemetry Support ListDocument8 pagesFanaLab Telemetry Support ListRidasNo ratings yet

- Prso KM S - : Durgapur Public SchoolDocument2 pagesPrso KM S - : Durgapur Public SchoolPrasoon Singh RajputNo ratings yet

- Learn Essential Productivity Tools with Google DriveDocument50 pagesLearn Essential Productivity Tools with Google DriveAoi HorisakoNo ratings yet

- Republic ActDocument4 pagesRepublic ActGwen CaldonaNo ratings yet

- Role of Computers in TransportDocument36 pagesRole of Computers in TransportPrateek Singla100% (2)

- OneOcean Regs4ships Leaflet 2022 210x297mmDocument3 pagesOneOcean Regs4ships Leaflet 2022 210x297mmPetrica NeculaNo ratings yet

- A Combination of Newton-Raphson Method and HeuristDocument14 pagesA Combination of Newton-Raphson Method and Heuristpat juvNo ratings yet