Professional Documents

Culture Documents

Ai01798 Al

Uploaded by

rajit kumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ai01798 Al

Uploaded by

rajit kumarCopyright:

Available Formats

NUMBER

ENGINEERING

APPARATUS INSTRUCTIONS 1798

ISSUED BY FIRST ISSUED

D.L. DeBraal June 24, 1953

APPROVED BY SUPERSEDES

M. Ephraim, Jr.

H.G. Gutekunst LA GRANGE, ILLINOIS

SUBJECT TORQUE SPECIFICATIONS

AFFECTS MODELS ALL LOCOMOTIVES AND INDUSTRIAL ASSEMBLIES

PART NOS AFFECTED

REF DRAWINGS 272572, 8307731, AI-1489, AI-1858, AI-2018, AI-2127, AI-2333

I. Certain applications of threaded fasteners require that they be tightened to definite torque values. This

AI outlines the torque values that are to be used when specified. For liquidtight flexible metal conduit

(LFMC) torque values, please refer to AI02748 Liquidtight Flexible Metal Conduit (LFMC) Assemblies.

II. The inch bolt torque values are generally based on those found in the EMD Engineering Standards

Book, Page B-2.051, for lubricated 280M bolts. This does not mean that bolts to be torqued are to be

oiled. It does mean that the lubricated torque values used herein are more generally appropriate for

our use than are the “dry” torque values since such things as the phosphate coating on some bolts, the

wax thread coating on lock nuts, and residual cutting oil in tapped holes tend to give a bolt clamp load

closer to the desired clamp load when using the so-called lubricated values. If for any reason a bolt is

to be oiled before application, such will be called for on the application drawing along with the

appropriate torque value.

Note – The values given in these tables are nominal values suitable only for use on applications

in the absence of better design information. The user is specifically warned that these are not

maximum values and that it is not necessarily conservative to use lower torques than the tabular

values. The risk associated with the use of torque lower than the nominal is at least as great as

the risk from higher torques.

III. The Quality Control Department is to establish the necessary audit procedures to ensure that bolts

having specified installation torque values are properly tightened. Refer to QAWI-006-02 (BOLT

TORQUE WITNESS MARKING).

A. When application drawings are marked thus , the torque values in Table 1 are to be used.

B. When application drawings are marked thus , the torque values in Table 2 are to be used.

C. Threaded fasteners without identification markings or nuts on fasteners without identification

markings shall be torqued to the values shown in Table 3. Inch threaded fasteners without

identification markings not shown in Table 3 shall have a nominal installation torque of 60% of the

value shown for Grade 5/280M fasteners. Metric threaded fasteners without identification markings

not shown in Table 3 shall have a nominal installation torque of 60% of the value shown for Class

8.8 fasteners.

D. Stainless steel fasteners shall be torqued according to instructions shown in AI-2333.

REV DATE CR PAGES AFFECTED CHANGED BY APPROVED BY

AL 08/06/2020 CR200995 1 T. GAJDA R. ZIBERNA

UPDATED 03/25/2019 REV. E

© 2020 Caterpillar. All Rights Reserved. The information hereon is the property of Progress Rail Locomotive Inc. and/or its subsidiaries. Without

written permission, any copying, transmittal to others, and any use except for which it is specifically provided, is prohibited.

Page 1 of 11

AI 1798

TORQUE SPECIFICATIONS

IV. When the torque on a bolt is checked, it is to be checked in the tightening direction, noting the value

when breakaway occurs. This value is then to be compared to the specified breakaway value.

NOTE: Since breakaway torque for a bolt used in a gasketed joint may be as low as 65% of

installation torque, checking breakaway torque for such a bolt may not be an

acceptable means of auditing that it had been applied at the correct installation value.

Therefore, columns B and C of Table 1 do not apply to bolts used in gasketed joints.

V. The Tables are constructed as follows. For each size bolt the specified installation torque is shown in

column A. Column B shows a breakaway value which is usually but not always 15% above the

installation torque. Surveys in the Locomotive Division have shown that the great majority of bolts

properly torqued at installation will breakaway at some value between the Column A value (installation

torque) and the Column B value.

VI. Column C shows breakaway value usually but not always 30% above the installation value. If the bolt

torque checks on breakaway above the Column C value, it has been overtightened. While the great

majority of properly torqued bolts will breakaway between the Column A value (installation torque) and

the Column B value, a very small percentage will be found to breakaway between the Column B value

and the Column C value. If a large percentage of bolts check near the Column C value, installation

procedures should be reviewed as many are being overtightened.

REV DATE CR PAGES AFFECTED CHANGED BY APPROVED BY

AL 08/06/2020 CR200995 1 T. GAJDA R. ZIBERNA

UPDATED 03/25/2019 REV. E

© 2020 Caterpillar. All Rights Reserved. The information hereon is the property of Progress Rail Locomotive Inc. and/or its subsidiaries. Without

written permission, any copying, transmittal to others, and any use except for which it is specifically provided, is prohibited.

Page 2 of 11

AI 1798

TORQUE SPECIFICATIONS

INCH BOLTS – GRADE 5/280M

TABLE 1 A B C

Normal Breakaway

Between This Value and

Nominal Installation Column A Value - see Max. Breakaway Value -

Size Torque paragraph V. See paragraph VI.

#10-24 18 Inch Lbs. 21 Inch Lbs. 24 Inch Lbs.

#10-32 22 Inch Lbs. 25 Inch Lbs. 28 Inch Lbs.

1/4-20 6 Ft. Lbs. 7 Ft. Lbs. 8 Ft. Lbs.

1/4-28 7 Ft. Lbs. 8 Ft. Lbs. 9 Ft. Lbs.

5/16-18 13 Ft. Lbs. 15 Ft. Lbs. 17 Ft. Lbs.

5/16-24 15 Ft. Lbs. 17 Ft. Lbs. 19 Ft. Lbs.

3/8-16 24 Ft. Lbs. 28 Ft. Lbs. 31 Ft. Lbs.

3/8-24 27 Ft. Lbs. 31 Ft. Lbs. 35 Ft. Lbs.

7/16-14 38 Ft. Lbs. 44 Ft. Lbs. 50 Ft. Lbs.

7/16-20 42 Ft. Lbs. 48 Ft. Lbs. 55 Ft. Lbs.

1/2-13 58 Ft. Lbs. 67 Ft. Lbs. 75 Ft. Lbs.

1/2-20 65 Ft. Lbs. 75 Ft. Lbs. 85 Ft. Lbs.

9/16-12 84 Ft. Lbs. 96 Ft. Lbs. 110 Ft. Lbs.

9/16-18 93 Ft. Lbs. 107 Ft. Lbs. 120 Ft. Lbs.

5/8-11 115 Ft. Lbs. 132 Ft. Lbs. 150 Ft. Lbs.

5/8-18 130 Ft. Lbs. 150 Ft. Lbs. 170 Ft. Lbs.

3/4-10 205 Ft. Lbs. 235 Ft. Lbs. 265 Ft. Lbs.

3/4-16 230 Ft. Lbs. 265 Ft. Lbs. 300 Ft. Lbs.

7/8-9 330 Ft. Lbs. 380 Ft. Lbs. 430 Ft. Lbs.

7/8-14 365 Ft. Lbs. 420 Ft. Lbs. 475 Ft. Lbs.

1-8 495 Ft. Lbs. 570 Ft. Lbs. 645 Ft. Lbs.

1-14 555 Ft. Lbs. 640 Ft. Lbs. 720 Ft. Lbs.

1-1/8-7 610 Ft. Lbs. 700 Ft. Lbs. 800 Ft. Lbs.

1-1/8-12 685 Ft. Lbs. 790 Ft. Lbs. 890 Ft. Lbs.

1-1/4-7 860 Ft. Lbs. 990 Ft. Lbs. 1120 Ft. Lbs.

1-1/4-12 955 Ft. Lbs. 1100 Ft. Lbs. 1240 Ft. Lbs.

1-3/8-6 1130 Ft. Lbs. 1300 Ft. Lbs. 1470 Ft. Lbs.

1-3/8-12 1290 Ft. Lbs. 1485 Ft. Lbs. 1675 Ft. Lbs.

1-1/2-6 1500 Ft. Lbs. 1725 Ft. Lbs. 1950 Ft. Lbs.

1-1/2-12 1690 Ft. Lbs. 1950 Ft. Lbs. 2200 Ft. Lbs.

REV DATE CR PAGES AFFECTED CHANGED BY APPROVED BY

AL 08/06/2020 CR200995 1 T. GAJDA R. ZIBERNA

UPDATED 03/25/2019 REV. E

© 2020 Caterpillar. All Rights Reserved. The information hereon is the property of Progress Rail Locomotive Inc. and/or its subsidiaries. Without

written permission, any copying, transmittal to others, and any use except for which it is specifically provided, is prohibited.

Page 3 of 11

AI 1798

TORQUE SPECIFICATIONS

INCH BOLTS – GRADE 8/300M

TABLE 1 A B C

Normal Breakaway

Between This Value and

Nominal Installation Column A Value - see Max. Breakaway Value -

Size Torque paragraph V. See paragraph VI.

1/4-20 9 Ft. Lbs. 10 Ft. Lbs. 12 Ft. Lbs.

1/4-28 11 Ft. Lbs. 13 Ft. Lbs. 15 Ft. Lbs.

5/16-18 18 Ft. Lbs. 21 Ft. Lbs. 24 Ft. Lbs.

5/16-24 21 Ft. Lbs. 24 Ft. Lbs. 27 Ft. Lbs.

3/8-16 34 Ft. Lbs. 39 Ft. Lbs. 44 Ft. Lbs.

3/8-24 38 Ft. Lbs. 44 Ft. Lbs. 50 Ft. Lbs.

7/16-14 54 Ft. Lbs. 62 Ft. Lbs. 70 Ft. Lbs.

7/16-20 60 Ft. Lbs. 69 Ft. Lbs. 78 Ft. Lbs.

1/2-13 82 Ft. Lbs. 94 Ft. Lbs. 107 Ft. Lbs.

1/2-20 90 Ft. Lbs. 103 Ft. Lbs. 117 Ft. Lbs.

9/16-12 120 Ft. Lbs. 138 Ft. Lbs. 156 Ft. Lbs.

9/16-18 132 Ft. Lbs. 152 Ft. Lbs. 172 Ft. Lbs.

5/8-11 165 Ft. Lbs. 190 Ft. Lbs. 215 Ft. Lbs.

5/8-18 185 Ft. Lbs. 210 Ft. Lbs. 240 Ft. Lbs.

3/4-10 290 Ft. Lbs. 335 Ft. Lbs. 380 Ft. Lbs.

3/4-16 320 Ft. Lbs. 370 Ft. Lbs. 420 Ft. Lbs.

7/8-9 455 Ft. Lbs. 520 Ft. Lbs. 590 Ft. Lbs.

7/8-14 515 Ft. Lbs. 590 Ft. Lbs. 670 Ft. Lbs.

1-8 695 Ft. Lbs. 800 Ft. Lbs. 900 Ft. Lbs.

1-14 785 Ft. Lbs. 900 Ft. Lbs. 1020 Ft. Lbs.

1-1/8-7 990 Ft. Lbs. 1140 Ft. Lbs. 1290 Ft. Lbs.

1-1/8-12 1110 Ft. Lbs. 1280 Ft. Lbs. 1450 Ft. Lbs.

1-1/4-7 1400 Ft. Lbs. 1610 Ft. Lbs. 1820 Ft. Lbs.

1-1/4-12 1550 Ft. Lbs. 1780 Ft. Lbs. 2020 Ft. Lbs.

1-3/8-6 1830 Ft. Lbs. 2100 Ft. Lbs. 2380 Ft. Lbs.

1-3/8-12 2085 Ft. Lbs. 2400Ft. Lbs. 2710 Ft. Lbs.

1-1/2-6 2430 Ft. Lbs. 2790 Ft. Lbs. 3160 Ft. Lbs.

1-1/2-12 2730 Ft. Lbs. 3140 Ft. Lbs. 3550 Ft. Lbs.

1-3/4-5 3840 Ft. Lbs. 4410 Ft. Lbs. 5000 Ft. Lbs.

2-4-1/2 5760 Ft. Lbs. 6620 Ft. Lbs. 7490 Ft. Lbs.

REV DATE CR PAGES AFFECTED CHANGED BY APPROVED BY

AL 08/06/2020 CR200995 1 T. GAJDA R. ZIBERNA

UPDATED 03/25/2019 REV. E

© 2020 Caterpillar. All Rights Reserved. The information hereon is the property of Progress Rail Locomotive Inc. and/or its subsidiaries. Without

written permission, any copying, transmittal to others, and any use except for which it is specifically provided, is prohibited.

Page 4 of 11

AI 1798

TORQUE SPECIFICATIONS

METRIC BOLTS – CLASS 8.8

TABLE 1 A B C

Normal Breakaway

Between This Value and

Nominal Installation Column A Value - See Max. Breakaway Value -

Size Torque paragraph V. See paragraph VI.

M8 X 1.00 23 Nm 26 Nm 29 Nm

M8 X 1.25 21 Nm 25 Nm 28 Nm

M10 X 1.25 45 Nm 52 Nm 58 Nm

M10 X 1.50 42 Nm 49 Nm 55 Nm

M12 X 1.25 81 Nm 93 Nm 105 Nm

M12 x 1.50 77 Nm 89 Nm 101 Nm

M12 x 1.75 74 Nm 85 Nm 96 Nm

M16 x 1.50 197 Nm 227 Nm 256 Nm

M16 x 2.00 185 Nm 213 Nm 240Nm

M20 x 1.50 401 Nm 462 Nm 522 Nm

M20 x 2.50 361 Nm 416 Nm 470 Nm

M24 x 2.00 680 Nm 782 Nm 884 Nm

M24 x 3.00 625 Nm 719 Nm 813 Nm

M30 x 2.00 1375 Nm 1582 Nm 1788 Nm

M30 x 3.50 1242 Nm 1429 Nm 1615 Nm

M36 x 3.00 2299 Nm 2644 Nm 2989 Nm

M36 x 4.00 2171 Nm 2497 Nm 2823 Nm

M42 x 4.20 3473 Nm 3994 Nm 4515 Nm

M48 x 5.00 5210 Nm 5992 Nm 6773 Nm

REV DATE CR PAGES AFFECTED CHANGED BY APPROVED BY

AL 08/06/2020 CR200995 1 T. GAJDA R. ZIBERNA

UPDATED 03/25/2019 REV. E

© 2020 Caterpillar. All Rights Reserved. The information hereon is the property of Progress Rail Locomotive Inc. and/or its subsidiaries. Without

written permission, any copying, transmittal to others, and any use except for which it is specifically provided, is prohibited.

Page 5 of 11

AI 1798

TORQUE SPECIFICATIONS

METRIC BOLTS – CLASS 10.9

TABLE 1 A B C

Normal Breakaway

Between This Value and

Nominal Installation Column A Value - See Max. Breakaway Value -

Size Torque paragraph V. See paragraph VI.

M8 X 1.00 32 Nm 37 Nm 42 Nm

M8 X 1.25 30 Nm 35 Nm 39 Nm

M10 X 1.25 63 Nm 73 Nm 82 Nm

M10 X 1.50 60 Nm 69 Nm 78 Nm

M12 x 1.25 114 Nm 69 Nm 69 Nm

M12 x 1.50 109 Nm 126 Nm 142 Nm

M12 x 1.75 104 Nm 120 Nm 136 Nm

M16 x 1.50 277 Nm 319 Nm 360 Nm

M16 x 2.00 260 Nm 299 Nm 338 Nm

M20 x 1.50 564 Nm 649 Nm 734 Nm

M20 x 2.50 508 Nm 585 Nm 661 Nm

M24 x 2.00 957 Nm 1101 Nm 1244 Nm

M24 x 3.00 879 Nm 1011 Nm 1143 Nm

M30 x 2.00 1934 Nm 2224 Nm 2514 Nm

M30 x 3.50 1747 Nm 2009 Nm 2271 Nm

M36 x 3.00 3233 Nm 3718 Nm 4203 Nm

M36 x 4.00 3053 Nm 3512 Nm 3970 Nm

M42 x 4.20 4884 Nm 5617 Nm 6350 Nm

M48 x 5.00 7327 Nm 8426 Nm 9525 Nm

REV DATE CR PAGES AFFECTED CHANGED BY APPROVED BY

AL 08/06/2020 CR200995 1 T. GAJDA R. ZIBERNA

UPDATED 03/25/2019 REV. E

© 2020 Caterpillar. All Rights Reserved. The information hereon is the property of Progress Rail Locomotive Inc. and/or its subsidiaries. Without

written permission, any copying, transmittal to others, and any use except for which it is specifically provided, is prohibited.

Page 6 of 11

AI 1798

TORQUE SPECIFICATIONS

METRIC BOLTS – CLASS 12.9

TABLE 1 A B C

Normal Breakaway

Between This Value and

Nominal Installation Column A Value - See Max. Breakaway Value -

Size Torque paragraph V. See paragraph VI.

M8 X 1.00 39 Nm 45 Nm 50 Nm

M8 X 1.25 36 Nm 42 Nm 47 Nm

M10 X 1.25 76 Nm 88 Nm 99 Nm

M10 X 1.50 72 Nm 83 Nm 93 Nm

M12 x 1.25 137 Nm 158 Nm 178 Nm

M12 X 1.50 131 Nm 151 Nm 171 Nm

M12 X 1.75 125 Nm 144 Nm 163 Nm

M16 X 1.50 332 Nm 382 Nm 432 Nm

M16 X 2.00 312 Nm 359 Nm 406 Nm

M20 X 1.50 677 Nm 779 Nm 880 Nm

M20 X 2.50 610 Nm 702 Nm 793 Nm

M24 X 2.00 1148 Nm 1320 Nm 1492 Nm

M24 X 3.00 1055 Nm 1214 Nm 1372 Nm

M30 X 2.00 2321 Nm 2669 Nm 3017 Nm

M30 X 3.50 2096 Nm 2411 Nm 2725 Nm

M36 X 3.00 3880 Nm 4462 Nm 5044 Nm

M36 X 4.00 3664 Nm 4214 Nm 4764 Nm

M42 X 4.20 5861 Nm 6741 Nm 7620 Nm

M48 X 5.00 8792 Nm 10111 Nm 11430 Nm

REV DATE CR PAGES AFFECTED CHANGED BY APPROVED BY

AL 08/06/2020 CR200995 1 T. GAJDA R. ZIBERNA

UPDATED 03/25/2019 REV. E

© 2020 Caterpillar. All Rights Reserved. The information hereon is the property of Progress Rail Locomotive Inc. and/or its subsidiaries. Without

written permission, any copying, transmittal to others, and any use except for which it is specifically provided, is prohibited.

Page 7 of 11

AI 1798

TORQUE SPECIFICATIONS

TABLE 2 A B C

Normal

Breakaway

Between this

Nominal Value and Column Max. Breakaway

Installation A Value - See Value - See

Bolt Size Application Torque Paragraph V. Paragraph VI.

1/4-28 Clamp between exhaust manifolds 70 Inch Lbs. 80 Inch Lbs. 90 Inch Lbs.

1/2-13 Step Thread Sq. Hd. Bolts 30 Ft. Lbs. 35 Ft. Lbs. 39 Ft. Lbs.

1/2-20 Exhaust stack to turbocharger-

stainless steel bolts

* * *

1/2-20 Sheave Retaining Bolt-Switcher 90 Ft. Lbs. 103 Ft. Lbs. 117 Ft. Lbs.

Fan Drive

9/16-18 Aux. Gen. Drive rubber coupling 100 Ft. Lbs. 110 Ft. Lbs. 120 Ft. Lbs.

bolts

“EMD” Coupling to Drive shaft at 100 Ft. Lbs. 110 Ft. Lbs. 120 Ft. Lbs.

engine end and compressor end

5/8-11 Hub to Aux. Gen Shaft 90 Ft. Lbs. 105 Ft. Lbs. 120 Ft. Lbs.

5/8-11 F40PH Alternator Rotor to Gear 165 Ft. Lbs. 185 Ft. Lbs. 210 Ft. Lbs.

Box

5/8-18 Exhaust manifold mounting bolts --

normally aspirated engines

* * *

3/4-10 Compressor mounting 165 Ft. Lbs. 190 Ft. Lbs. 215 Ft. Lbs.

Gear Box Drive Flange-F40PH 375 Ft. Lbs. 430 Ft. Lbs. 487 Ft. Lbs.

Aux. Gen. Mounting 290 Ft. Lbs. 335 Ft. Lbs. 380 Ft. Lbs.

3/4-16 Engine - Gen. Coupling 295 Ft. Lbs. 325 Ft. Lbs. 350 Ft. Lbs.

Speed increaser fan drive rubber 230 Ft. Lbs. 265 Ft. Lbs. 300 Ft. Lbs.

coupling bolts

Gen. Dr. Cplg. to shaft F40PH 380 Ft. Lbs. 437 Ft. Lbs. 494 Ft. Lbs.

7/8-14 Fan drive gear box mounting 335 Ft. Lbs. 385 Ft. Lbs. 435 Ft. Lbs.

1-8x2 1/2 1g Engine Mtg. Bolts 445 Ft. Lbs. 525 Ft. Lbs. 590 Ft. Lbs.

1-8x4 1/2 1g Engine Mtg. Bolts 650 Ft. Lbs. 750 Ft. Lbs. 850 Ft. Lbs.

1-8 Eyebolt - Long hood 200 Ft. Lbs. 230 Ft. Lbs. 260 Ft. Lbs.

1-14 Oil rig generator gears to drive 400 Ft. Lbs. 460 Ft. Lbs. 520 Ft. Lbs.

flange

1-1/8-12 Oil rig adapter to main gear support 500 Ft. Lbs. 575 Ft. Lbs. 650 Ft. Lbs.

1-1/4-7 Main generator mounting 800 Ft. Lbs. 925 Ft. Lbs. 1050 Ft. Lbs.

1-1/2-6 Draft Gear Carrier Bolts 1050 Ft. Lbs. 1207 Ft. Lbs. 1365 Ft. Lbs.

2-8 Compressor flywheel nut 500 Ft. Lbs. 575 Ft. Lbs. 650 Ft. Lbs.

Gear Box Compr. Cplg. Nut- F40PH 500 Ft. Lbs. 575 Ft. Lbs. 650 Ft. Lbs.

(*) Refer to AI 1489 (567 Engines) or AI 2127 (645 Engines)

REV DATE CR PAGES AFFECTED CHANGED BY APPROVED BY

AL 08/06/2020 CR200995 1 T. GAJDA R. ZIBERNA

UPDATED 03/25/2019 REV. E

© 2020 Caterpillar. All Rights Reserved. The information hereon is the property of Progress Rail Locomotive Inc. and/or its subsidiaries. Without

written permission, any copying, transmittal to others, and any use except for which it is specifically provided, is prohibited.

Page 8 of 11

AI 1798

TORQUE SPECIFICATIONS

NOTE: Tighten set screw (14 Ft. Lbs.) but do not stake.

INCH THREADED FASTENERS WITHOUT IDENTIFICATION MARKINGS

TABLE 3 A B C

Normal Breakaway

Between This Value and

Nominal Installation Column A Value - see Max. Breakaway Value -

Size Torque paragraph V. See paragraph VI.

1/4-20 3 Ft. Lbs. 4 Ft. Lbs. 4 Ft. Lbs.

5/16-18 8 Ft. Lbs. 10 Ft. Lbs. 11 Ft. Lbs.

3/8-16 14 Ft. Lbs. 17 Ft. Lbs. 19 Ft. Lbs.

7/16-14 23 Ft. Lbs. 27 Ft. Lbs. 31 Ft. Lbs.

1/2-13 36 Ft. Lbs. 42 Ft. Lbs. 48 Ft. Lbs.

METRIC THREADED FASTENERS WITHOUT IDENTIFICATION MARKINGS

TABLE 3 A B C

Normal Breakaway

Between This Value and

Nominal Installation Column A Value - See Max. Breakaway Value -

Size Torque paragraph V. See paragraph VI.

M6 X 1.00 3 Nm 4 Nm 5 Nm

M8 x 1.00 13 Nm 16 Nm 18 Nm

M10 x 1.50 27 Nm 32 Nm 36 Nm

M12 x 1.75 48 Nm 56 Nm 63 Nm

REV DATE CR PAGES AFFECTED CHANGED BY APPROVED BY

AL 08/06/2020 CR200995 1 T. GAJDA R. ZIBERNA

UPDATED 03/25/2019 REV. E

© 2020 Caterpillar. All Rights Reserved. The information hereon is the property of Progress Rail Locomotive Inc. and/or its subsidiaries. Without

written permission, any copying, transmittal to others, and any use except for which it is specifically provided, is prohibited.

Page 9 of 11

AI 1798

TORQUE SPECIFICATIONS

VII. Where this AI is to be used as part of the specification of an assembly, reference to the AI will be made

as an “X” quantity in the Bill of Material. The specific fasteners to which torque wrench tightening is to

be applied will be indicated by a symbol or on the assembly drawing.

Also a note will appear on the face of the drawing as follows:

“All fasteners signaled thus and/or are to be tightened per AI 1798.”

VIII. There are some application drawings which carry torque notes and specific torque values and which do

not refer to this AI. These cases are usually because better design information on the specific bolted

joint has been calculated or has been observed in field service. The establishment of practical

breakaway values for checking these special torque bolt applications should be done as follows:

(Note - similar methods for establishing break away torque can be used for “dry” installation torques as

shown on page B-2.051 of EMD Engineering Standards Book.)

Case 1. 300 M bolt with specified installation torque same as value in table 1 on page 4 of this AI.

Example: 3/4-10 with installation torque of 290 Ft. Lbs. Add 15 percent for normal

breakaway value and use 335 Ft. Lbs. Add 30 percent for maximum breakaway value and

use 380 Ft. Lbs.

Case 2. 300 M bolt with specified installation torque below value in table 1 on page 4 of this AI.

Example: 3/4-10 with installation torque of 225 Ft. Lbs. Add 15 percent for normal

breakaway and use 260 Ft. Lbs. Add 30 percent for maximum breakaway and use 290 Ft.

Lbs.

Case 3. 300M bolt with specified installation torque above value in table 1 on page 4 of this AI.

Example: 3/4-10 with installation torque of 320 Ft. Lbs. Use same maximum breakaway

value as for Case 1 -- i.e., 380 Ft. Lbs. (30 percent above page B-2.051 value). Use mean

between 320 and 380 or 350 Ft. Lbs. for normal breakaway value. This then is the only

9-1/2 percent above the installation value instead of the usual 15 percent.

IX. Torque Values

1. Models AR10, A20, D32 or variations thereof using bolt 272572 (1 1/2-6) for generator mounting

hold down.

Production torque value = 1500 Ft. Lbs.

(nominal wrench setting) using Texaco threadtex lubricant #2303 (8307731) on threads, washer

and washer face of bolt.

Inspection limit 1350 to 1650 # ft.

REV DATE CR PAGES AFFECTED CHANGED BY APPROVED BY

AL 08/06/2020 CR200995 1 T. GAJDA R. ZIBERNA

UPDATED 03/25/2019 REV. E

© 2020 Caterpillar. All Rights Reserved. The information hereon is the property of Progress Rail Locomotive Inc. and/or its subsidiaries. Without

written permission, any copying, transmittal to others, and any use except for which it is specifically provided, is prohibited.

Page 10 of 11

AI 1798

TORQUE SPECIFICATIONS

Marginal Indicia:

A change bar ( | ) located in the left margin is for the convenience of the user in locating areas of

technical revisions made from the previous issue of this document. The word “ALL” specified in the

pages affected footer indicates a complete revision of this document; no change bars will be shown.

Change bars are not used in original publications.

REV DATE CR PAGES AFFECTED CHANGED BY APPROVED BY

AL 08/06/2020 CR200995 1 T. GAJDA R. ZIBERNA

UPDATED 03/25/2019 REV. E

© 2020 Caterpillar. All Rights Reserved. The information hereon is the property of Progress Rail Locomotive Inc. and/or its subsidiaries. Without

written permission, any copying, transmittal to others, and any use except for which it is specifically provided, is prohibited.

Page 11 of 11

You might also like

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- SB 1289a NavajoDocument7 pagesSB 1289a NavajoDiego LlNo ratings yet

- All The Words I Should Have Said - Rania NaimDocument167 pagesAll The Words I Should Have Said - Rania NaimNan Nan100% (2)

- L200 VGT Setup ProcedureDocument7 pagesL200 VGT Setup ProcedureDraganKostovski100% (1)

- DM-27 Part2Document14 pagesDM-27 Part2Adrian CantaragiuNo ratings yet

- CC4109 O&M Manual PDFDocument379 pagesCC4109 O&M Manual PDFCindy HNo ratings yet

- Engineering Apparatus Instructions 2400Document13 pagesEngineering Apparatus Instructions 2400rajit kumarNo ratings yet

- Norma CMAA 70Document90 pagesNorma CMAA 70Marcelo Navarro100% (7)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Apex CheatsheetDocument4 pagesApex CheatsheetAmit GangwarNo ratings yet

- Aec3414 Philosophy FinalDocument5 pagesAec3414 Philosophy Finalapi-532996380No ratings yet

- SSP-1776-4 Table of Limits - Complete PDFDocument191 pagesSSP-1776-4 Table of Limits - Complete PDFGabriel SantosNo ratings yet

- TCM Torque SB96 7DDocument14 pagesTCM Torque SB96 7DИван КоньковNo ratings yet

- SB96-7C Torque Limits TCMDocument13 pagesSB96-7C Torque Limits TCMChristian Enrique Casique PajarNo ratings yet

- 60RT/80RT/100RT - MM Rough Terrain: Triple No Free Lift MastDocument38 pages60RT/80RT/100RT - MM Rough Terrain: Triple No Free Lift MastХелфор УкраинаNo ratings yet

- CC200 - CC400 CRIMPER Operators ManualDocument15 pagesCC200 - CC400 CRIMPER Operators ManualPTCNo ratings yet

- Er 108 1 PDFDocument3 pagesEr 108 1 PDFDIEGO YECID MILLAN MENDOZANo ratings yet

- Er 108 1Document3 pagesEr 108 1DIEGO YECID MILLAN MENDOZANo ratings yet

- TP CSL A-2019Document9 pagesTP CSL A-2019turboshaftNo ratings yet

- 206-19-42 July 2019Document9 pages206-19-42 July 2019turboshaftNo ratings yet

- 407-19-23 July 2019Document9 pages407-19-23 July 2019turboshaftNo ratings yet

- MSB23 01aDocument44 pagesMSB23 01aSAMUEL OLIVEIRANo ratings yet

- SB19 02a PDFDocument10 pagesSB19 02a PDFJohn GotschallNo ratings yet

- Tapping Screw Performance Specifications: Greenslade & Company, IncDocument22 pagesTapping Screw Performance Specifications: Greenslade & Company, Inco_l_0No ratings yet

- SI1098Q Propeller Flange Bushing LocationDocument12 pagesSI1098Q Propeller Flange Bushing Locationjkloepping_634367970No ratings yet

- Hydraulic Bolt TensionDocument24 pagesHydraulic Bolt TensionEhtisham AndrAbi100% (1)

- Piper SB 955 Engine Mount Nose Gear AttachmentDocument6 pagesPiper SB 955 Engine Mount Nose Gear AttachmentGeorgios AsimakopoulosNo ratings yet

- Osn 407-19-23Document22 pagesOsn 407-19-23ferbmdNo ratings yet

- ON A/C FSN 551-600: Customization Aircraft Types Doctypes Revision Date Title Tail Number - MSN - FSNDocument7 pagesON A/C FSN 551-600: Customization Aircraft Types Doctypes Revision Date Title Tail Number - MSN - FSNEdson CarvalhoNo ratings yet

- Northwest: Maintenance Manual DC9Document10 pagesNorthwest: Maintenance Manual DC9Erik Joan Quiroga RamirezNo ratings yet

- Construction Check Sheet Synchronous A.C. Generator E-018A: ElectricalDocument1 pageConstruction Check Sheet Synchronous A.C. Generator E-018A: ElectricalhrimklimNo ratings yet

- Oil Seal Service BulletinDocument11 pagesOil Seal Service BulletinjisuuuNo ratings yet

- Anchr Bolt RefDocument9 pagesAnchr Bolt ReferleosNo ratings yet

- FAA 2018 0866 0009 - Attachment - 1Document5 pagesFAA 2018 0866 0009 - Attachment - 1hadiNo ratings yet

- Check Valve CV1 08: UcsonDocument2 pagesCheck Valve CV1 08: UcsonpavankumarNo ratings yet

- gdm-5410 Sun Chassis g1 PDFDocument63 pagesgdm-5410 Sun Chassis g1 PDFbarrilonNo ratings yet

- Return To TOC: Dowty Propellers Standard Practices ManualDocument22 pagesReturn To TOC: Dowty Propellers Standard Practices ManualNicolás PiratovaNo ratings yet

- Mccauley Industsal Corporation: 00X 1. Aoofcvfll Sia. - Oaiion. Ohio 0411 Code 511 26X.3541 Addrc S Mccjui4YDocument4 pagesMccauley Industsal Corporation: 00X 1. Aoofcvfll Sia. - Oaiion. Ohio 0411 Code 511 26X.3541 Addrc S Mccjui4YoscarNo ratings yet

- 212 Asb 08 130Document7 pages212 Asb 08 130Walberto PachecoNo ratings yet

- Solar SB 21-0-112Document7 pagesSolar SB 21-0-112jussmeeeNo ratings yet

- 02 50061-MR-003-ST Equipment Installation Description For Ammonia Flare SystemDocument10 pages02 50061-MR-003-ST Equipment Installation Description For Ammonia Flare SystemPhucChuVanNo ratings yet

- Optibelt Installation and Maintenance InstructionsDocument24 pagesOptibelt Installation and Maintenance InstructionsFabian BaezaNo ratings yet

- Service Bulletin: Piper Considers Compliance MandatoryDocument10 pagesService Bulletin: Piper Considers Compliance MandatoryJean AbrialNo ratings yet

- CH 400 B - NewDocument36 pagesCH 400 B - NewBimo Cungkring IINo ratings yet

- PA44 Lycoming Ovehaul Manual 76 Series 60294-9 Rev Jun 1996Document91 pagesPA44 Lycoming Ovehaul Manual 76 Series 60294-9 Rev Jun 1996aditya nugrahaNo ratings yet

- Asb-081 ADocument13 pagesAsb-081 AProar Aeronaves e Revisões Ltda. OficinaNo ratings yet

- Catalogo de Uso Convert Id Ores GMDocument21 pagesCatalogo de Uso Convert Id Ores GMsamuelzunigaNo ratings yet

- Saic L 2015Document8 pagesSaic L 2015Engr IrfanNo ratings yet

- AWS G2.1.tmpDocument12 pagesAWS G2.1.tmpgazaliNo ratings yet

- ON A/C 001-150, 301-350, 504-504, 550-550, 601-850: Reference Qty DesignationDocument27 pagesON A/C 001-150, 301-350, 504-504, 550-550, 601-850: Reference Qty Designationkien Duy PhanNo ratings yet

- Steam HeaderDocument9 pagesSteam Headervijayanmks100% (1)

- Tata Consulting Engineers Design Guide For Auxiliary Steam HeaderDocument10 pagesTata Consulting Engineers Design Guide For Auxiliary Steam HeadervijayanmksNo ratings yet

- Saic D 2025Document10 pagesSaic D 2025jerinNo ratings yet

- Ti Mi 0028 Rev 2Document8 pagesTi Mi 0028 Rev 2Himalaya ChoureNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Scutarus Schiavo M. - 07 JUL 2023 IssuedDocument1 pageScutarus Schiavo M. - 07 JUL 2023 Issuedrajit kumarNo ratings yet

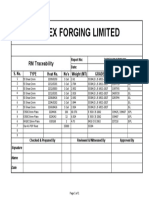

- RM TracebilityDocument1 pageRM Tracebilityrajit kumarNo ratings yet

- C-9202 Rev.3 - Corrected - 08.09.20Document29 pagesC-9202 Rev.3 - Corrected - 08.09.20rajit kumarNo ratings yet

- Signature Not VerifiedDocument1 pageSignature Not Verifiedrajit kumarNo ratings yet

- Engineering Apparatus Instructions: R.C. Niss 2009Document3 pagesEngineering Apparatus Instructions: R.C. Niss 2009rajit kumarNo ratings yet

- 000 000 447 904 - 001 - 00Document1 page000 000 447 904 - 001 - 00rajit kumarNo ratings yet

- Scutarus Schiavo M. - 07 JUL 2023 IssuedDocument1 pageScutarus Schiavo M. - 07 JUL 2023 Issuedrajit kumarNo ratings yet

- Scutarus Schiavo M. - 07 JUL 2023 IssuedDocument1 pageScutarus Schiavo M. - 07 JUL 2023 Issuedrajit kumarNo ratings yet

- Adobe Scan 10-Apr-2023-3Document1 pageAdobe Scan 10-Apr-2023-3rajit kumarNo ratings yet

- Job Summary About The Business & Position Overview: Company NameDocument3 pagesJob Summary About The Business & Position Overview: Company Namerajit kumarNo ratings yet

- Ind Nifty PseDocument2 pagesInd Nifty Pserajit kumarNo ratings yet

- Fabrication IRSB1CorrecteduptoACS 11Document59 pagesFabrication IRSB1CorrecteduptoACS 11SelvamChidambaramNo ratings yet

- Adobe Scan 10-Apr-2023-2Document1 pageAdobe Scan 10-Apr-2023-2rajit kumarNo ratings yet

- 01 Tuojh 2021 Ls 30 Twu 2021 RD : (01 January 2021 To 30 June 2021.)Document268 pages01 Tuojh 2021 Ls 30 Twu 2021 RD : (01 January 2021 To 30 June 2021.)ManojNo ratings yet

- Irs B1 2001Document51 pagesIrs B1 2001ghaghra bridge100% (9)

- Summer Training Project Report: Mr. Vikrama Prasad (Sr. Section Engineer)Document53 pagesSummer Training Project Report: Mr. Vikrama Prasad (Sr. Section Engineer)rajit kumarNo ratings yet

- Jws Login Procedure-Pki Based SecurityDocument4 pagesJws Login Procedure-Pki Based Securityrajit kumarNo ratings yet

- Revised Wagon Maintenance ManualDocument604 pagesRevised Wagon Maintenance Manualarun1389% (9)

- Painting DPR PDFDocument2 pagesPainting DPR PDFNityaprakash NayakNo ratings yet

- Inspection and Maintenance of Steel girders-IRICEN PDFDocument351 pagesInspection and Maintenance of Steel girders-IRICEN PDFANOOP AGRAWALNo ratings yet

- STR PART A FinalDocument9 pagesSTR PART A Finalrajit kumarNo ratings yet

- Container WagonDocument4 pagesContainer Wagonrajit kumarNo ratings yet

- Quality ManualDocument22 pagesQuality ManualRajeeb MohammedNo ratings yet

- ChecklistDocument12 pagesChecklistrajit kumarNo ratings yet

- Qualification PersonnelsDocument1 pageQualification Personnelsrajit kumarNo ratings yet

- WPS & PQRDocument13 pagesWPS & PQRrajit kumarNo ratings yet

- Meet Minitab 14Document138 pagesMeet Minitab 14damirzeNo ratings yet

- Research Designs & Standards Organization: 1.0 Amendment HistoryDocument8 pagesResearch Designs & Standards Organization: 1.0 Amendment Historynvnrajesh123No ratings yet

- Outsourced ProcessedDocument1 pageOutsourced Processedrajit kumarNo ratings yet

- Outsourced Records FormatDocument4 pagesOutsourced Records Formatrajit kumarNo ratings yet

- Ground Effect Aerodynamics PDFDocument12 pagesGround Effect Aerodynamics PDFChegrani Ahmed100% (1)

- A Simple Guide To Energy Budgets: Number 167 WWW - Curriculum-Press - Co.ukDocument4 pagesA Simple Guide To Energy Budgets: Number 167 WWW - Curriculum-Press - Co.ukKamaria ThomasNo ratings yet

- 2 Unit2Document28 pages2 Unit2BrahimeNo ratings yet

- Getachew Final EditedDocument76 pagesGetachew Final EditedDesalegn DgaNo ratings yet

- Industrial Mechanical Vapour Recompression 1Document2 pagesIndustrial Mechanical Vapour Recompression 1Gaurav UpaNo ratings yet

- jOB aNALYSIS POWERPOINTDocument34 pagesjOB aNALYSIS POWERPOINTdushyant12288No ratings yet

- Four Gears ModelDocument13 pagesFour Gears ModelPratik PatilNo ratings yet

- PGDBA From MIT PuneDocument2 pagesPGDBA From MIT PuneMIT,PuneNo ratings yet

- MKTED208071EN CatalogueDocument618 pagesMKTED208071EN Cataloguecarlos augustoNo ratings yet

- Data Privacy Notice TemplateDocument1 pageData Privacy Notice TemplateangeloNo ratings yet

- Module 5 Utilitarianism Part IDocument30 pagesModule 5 Utilitarianism Part IDenver Acenas100% (1)

- Comparing 18650 Lithium Ion NMC Cells With 32650 Lifepo4 Cells - Which One Is Right For Your Application?Document9 pagesComparing 18650 Lithium Ion NMC Cells With 32650 Lifepo4 Cells - Which One Is Right For Your Application?Rommel Angeles PeronaNo ratings yet

- 1000-211-V8-0000-01003 Concrete Works (Trial Mix)Document38 pages1000-211-V8-0000-01003 Concrete Works (Trial Mix)hodigojiggfjlgkdgiohghfdiohghjfNo ratings yet

- Ces511 - Structural Engineering Laboratory Lab Experiment: Bending Moment and Shear Force in Beams (Co2:Po5)Document13 pagesCes511 - Structural Engineering Laboratory Lab Experiment: Bending Moment and Shear Force in Beams (Co2:Po5)elhammeNo ratings yet

- Momentum Equation in Cylindrical Coordinate: Appendix BDocument8 pagesMomentum Equation in Cylindrical Coordinate: Appendix BAbdul Rauf AttariNo ratings yet

- Scheme and Syllabus FOR M. Tech. Degree Programme IN Civil Engineering With SpecializationDocument60 pagesScheme and Syllabus FOR M. Tech. Degree Programme IN Civil Engineering With SpecializationAdila AbdullakunjuNo ratings yet

- Curriculum Map in Introduction To The World ReligionDocument7 pagesCurriculum Map in Introduction To The World ReligionRaizza Vanizza SiguenzaNo ratings yet

- 1020 Aseguramiento de Calidad GeneralDocument10 pages1020 Aseguramiento de Calidad GeneralJennifer Tatiana DíazNo ratings yet

- SB-165 - ASME BPVC 2021 Sección II Part BDocument6 pagesSB-165 - ASME BPVC 2021 Sección II Part BMohammad TaherNo ratings yet

- M Pump - Plunger 300Document30 pagesM Pump - Plunger 300hebert perezNo ratings yet

- 6 Bhel - Noida ElectricalDocument9 pages6 Bhel - Noida Electricaldeepti sharmaNo ratings yet

- Rumus Fizik 2021Document1 pageRumus Fizik 2021Azizi Abdullah100% (1)

- Personal Surveyor 200 User Handbook: Gas Measurement Instruments LTDDocument92 pagesPersonal Surveyor 200 User Handbook: Gas Measurement Instruments LTDGiang TrườngNo ratings yet

- Manual Hydraulic Power UnitsDocument20 pagesManual Hydraulic Power UnitsabdiNo ratings yet

- 20 6 17 Draft Final ReportDocument38 pages20 6 17 Draft Final ReportKapi BandaNo ratings yet

- Phy12l E301Document5 pagesPhy12l E301Arvn Christian Santicruz FloresNo ratings yet

- Jasmi HashimDocument364 pagesJasmi HashimRudraraju ChaitanyaNo ratings yet