Professional Documents

Culture Documents

11 3367 01 Dowsil TC 2035 Adhesive Tds

Uploaded by

Clausio MeloOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

11 3367 01 Dowsil TC 2035 Adhesive Tds

Uploaded by

Clausio MeloCopyright:

Available Formats

Technical Data Sheet

DOWSIL™ TC-2035 Adhesive

DOWSIL™ TC-2035 Adhesive is a two-part heat cure silicone thermally conductive

adhesive with low bond line thickness

Features & High thermal conductivity

Benefits Adhesion to various substrates

Low bond line thickness

Stable performance at high temperature (up to 200°C)

Excellent thermal performance at various BLT

Mechanical reliability – maintain stable elastomeric properties after accelerated aging

test

Adhesive reliability – adhesion stable or improves after accelerated aging test

Excellent dielectric properties

Composition Two-part adhesive

Applications Designed to provide long term bonding and efficient thermal flow, especially where low

bond line thickness is required to enhance thermal conductivity

Typical applications include: bonding organic and ceramic substrates (i.e. PCB, HDI,

DBC) to heat sinks for transmission modules, power modules and conversion modules

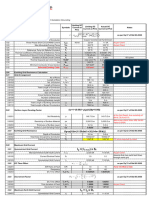

Typical Properties

Specification Writers: These values are not intended for use in preparing specifications.

Test Property Unit Result

CTM1 0176 B One or Two-part Two

CTM 0176 B Color: Part A White

Color: Part B Reddish brown

Mix Ratio (Weight or Volume) 1 to 1

CTM 1094 C Viscosity at 10 (1/s) (Part A) cP 130,000

Pa.sec 130

CTM 1094 C Viscosity at 10 (1/s) (Part B) cP 118,000

Pa.sec 118

CTM 1094 N Viscosity at 10 (1/s) (Mixed) cP 125,000

Pa.sec 125

1. CTM: Corporate Test Method, copies of CTMs are available upon request.

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

DOWSIL™ TC-2035 Adhesive

Page 1 of 5 © 2018–2022 The Dow Chemical Company. All rights reserved. Form No. 11-3367-01-0322 S2D

Typical Properties (Cont.)

Test Property Unit Result

Thixotropy Mixed Steady Shear 1s-1/10s-1 2.8

CTM 0022 B Density (Wet) g/cm3 3.0

Working Time at 25°C (Viscosity After 4 Hour) hours 4

CTM 0243 T Open Time at 25°C (Lap Shear Adhesion) hours 2

Heat Cure Time at 125°C minutes 30

Heat Cure Time at 150°C minutes 10

CTM 0099 M Hardness Shore A JIS Type A 95

CTM 0793 D Hardness Shore D Shore D 45

ASTM2 D2240

CTM 0137 Tensile Strength psi 522

MPa 3.6

kg/cm2 36.7

CTM 0137 AAH Elongation % 43

CTM 0243 A Adhesion – Lap Shear (Al) psi 381

mPa 2.63

N/cm2 263

CTM 0243 A Adhesion – Lap Shear (Copper) psi 416

mPa 2.87

N/cm2 287

CTM 0114 A Dielectric Strength at 1 mm volts/mil 533

kV/mm 21

CTM 0112 A Dielectric Constant at 100 Hz 6

CTM 0112 C Dielectric Constant at 100 kHz 5.9

CTM 0249 A Volume Resistivity Ohm.cm 5.5 E+15

CTM 0112 B Dissipation Factor at 100 Hz 7 E-03

CTM 0112 D Dissipation Factor at 100 kHz 4 E-03

ASTM E 831 Linear CTE (by TMA -50 to 200°C) ppm/K 92

CTM 1163 A Thermal Conductivity by Transient Method W/m.K 3.3

ASTM D 5470 Thermal Resistivity

at 50 μm °C/W 0.25

at 100 μm 0.44

Minimum BLT microns

DIN3 51007 Heat Capacity

at 25°C J/g.°C 0.83

at 100°C 0.98

at 150°C 1.09

2. ASTM: American Society for Testing and Materials.

3. DIN: Deutsche Industrie Norm.

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

DOWSIL™ TC-2035 Adhesive

Page 2 of 5 © 2018–2022 The Dow Chemical Company. All rights reserved. Form No. 11-3367-01-0322 S2D

Description The heat-cure, thermally conductive adhesives produce no by-products in the cure process,

allowing their use in deep section and complete confinement. These adhesives will develop

good, primerless adhesion to a variety of common substrates including metals, ceramics,

epoxy laminate boards, reactive materials and filled plastics. PCB system assemblies are

continually designed to deliver higher performance. Especially in the area of consumer

devices, there is also a continual trend towards smaller, more compact designs. In

combination these factors typically mean that more heat is generated in the device. Thermal

management of PCB system assemblies is a primary concern of design engineers. A cooler

device allows for more efficient operation and better reliability over the life of the device. As

such, thermally conductive compounds play an integral role here. Thermally conductive

materials act as the ambient via a heat transfer media (i.e. heat sink). These materials have

properties such as low thermal resistance, high thermal conductivity, and can achieve thin

Bond Line Thicknesses (BLTs) which can help to improve the transfer of heat away from the

device.

Mixing Two-part materials should be mixed in the proper ratio either by weight or volume. The

presence of light-colored streaks or marbling indicates inadequate mixing.

Processing/Curing Addition-cure silicones should be cured at 100°C (212°F) or above. The cure rate is rapidly

accelerated with eat (see heat-cure times in Typical Properties table). For thicker sections, a

pre-cure at 70°C (158°F) may be necessary to reduce voids in the elastomer. Length of pre-

cure will depend on section thickness and confinement of adhesive. It is recommended that

30 minutes at 70°C (158°F) be used as a starting point for determining necessary pre-cure

time. Addition-curing materials contain all the ingredients needed for cure with no by-

products from the cure mechanism. Deep-section or confined cures are possible. Cure

progresses evenly throughout the material. These products generally have long working

times.

Pot Life and Cure Cure reaction begins with the mixing process. Initially, cure is evidenced by a gradual

Rate increase in viscosity, followed by gelation and conversion to its final state. Pot life is defined

as the time required for viscosity to double after Parts A and B (base and curing agent) are

mixed.

Adhesion Dow silicone adhesives are specially formulated to provide unprimed adhesion to many

reactive metals, ceramics and glass, as well as to selected laminates, resins and plastics.

However, good adhesion cannot be expected on non-reactive metal substrates or non-

reactive plastic surfaces such as Teflon, polyethylene or polypropylene. Special surface

treatments such as chemical etching or plasma treatment can sometimes provide a reactive

surface and promote adhesion to these types of substrates. Dow primers can be used to

increase the chemical activity on difficult substrates. For best results, the primer should be

applied in a very thin, uniform coating and then wiped off after application. After application,

primers should be thoroughly cured prior to application of the silicone elastomer. Poor

adhesion can be experienced on plastic or rubber substrates that are highly plasticized,

since the mobile plasticizers act as release agents. Small-scale laboratory evaluation of all

substrates is recommended before production trials are made. In general, increasing the

cure temperature and/or cure time will improve the ultimate adhesion.

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

DOWSIL™ TC-2035 Adhesive

Page 3 of 5 © 2018–2022 The Dow Chemical Company. All rights reserved. Form No. 11-3367-01-0322 S2D

Useful For most uses, silicone adhesives should be operational over a temperature range of

Temperature -45 to 200°C (-49 to 392°F) for long periods of time. However, at both the low and high

temperature ends of the spectrum, behavior of the materials and performance in particular

Ranges applications can become more complex and require additional considerations. For low-

temperature performance, thermal cycling to conditions such as -55°C (-67°F) may be

possible for most products, but performance should be verified for your parts or assemblies.

Factors that may influence performance are configuration and stress sensitivity of

components, cooling rates and hold times, and prior temperature history. At the high-

temperature end, the durability of the cured silicone elastomer is time and temperature

dependent. As expected, the higher the temperature, the shorter the time the material will

remain useable.

Solvent Exposure In general, the product is resistance to minimal or intermittent solvent exposure, however

best practice is to avoid solvent exposure altogether.

Handling PRODUCT SAFETY INFORMATION REQUIRED FOR SAFE USE IS NOT INCLUDED IN

Precautions THIS DOCUMENT. BEFORE HANDLING, READ PRODUCT AND SAFETY DATA SHEETS

AND CONTAINER LABELS FOR SAFE USE, PHYSICAL AND HEALTH HAZARD

INFORMATION. THE SAFETY DATA SHEET IS AVAILABLE ON THE DOW WEBSITE AT

DOW.COM, OR FROM YOUR DOW SALES APPLICATION ENGINEER, OR

DISTRIBUTOR, OR BY CALLING DOW CUSTOMER SERVICE.

Usable Life and The product should be stored in its original packaging with the cover tightly attached to

Storage avoid any contamination. Store in accordance with any special instructions listed on the

product label. The product should be used by the indicated Exp. Date found on the label.

Limitations This product is neither tested nor represented as suitable for medical or pharmaceutical

uses.

Health and To support customers in their product safety needs, Dow has an extensive Product

Environmental Stewardship organization and a team of product safety and regulatory compliance

specialists available in each area.

Information

For further information, please see our website, dow.com or consult your local Dow

representative.

Disposal Dispose in accordance with all local, state (provincial) and federal regulations. Empty

Considerations containers may contain hazardous residues. This material and its container must be

disposed in a safe and legal manner.

It is the user’s responsibility to verify that treatment and disposal procedures comply with

local, state (provincial) and federal regulations. Contact your Dow Technical Representative

for more information.

Product Dow has a fundamental concern for all who make, distribute, and use its products, and for

Stewardship the environment in which we live. This concern is the basis for our product stewardship

philosophy by which we assess the safety, health, and environmental information on our

products and then take appropriate steps to protect employee and public health and our

environment. The success of our product stewardship program rests with each and every

individual involved with Dow products - from the initial concept and research, to

manufacture, use, sale, disposal, and recycle of each product.

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow

DOWSIL™ TC-2035 Adhesive

Page 4 of 5 © 2018–2022 The Dow Chemical Company. All rights reserved. Form No. 11-3367-01-0322 S2D

Customer Notice Dow strongly encourages its customers to review both their manufacturing processes and

their applications of Dow products from the standpoint of human health and environmental

quality to ensure that Dow products are not used in ways for which they are not intended or

tested. Dow personnel are available to answer your questions and to provide reasonable

technical support. Dow product literature, including safety data sheets, should be consulted

prior to use of Dow products. Current safety data sheets are available from Dow.

How Can We Help Tell us about your performance, design, and manufacturing challenges. Let us put our

You Today? silicon-based materials experience, application knowledge, and processing experience to

work for you.

For more information about our materials and capabilities, visit dow.com.

To discuss how we could work together to address your specific needs, go to dow.com for a

contact close to your location. Dow has customer service teams, science and technology

centers, application support teams, sales offices, and manufacturing sites around the globe.

dow.com NOTICE: No freedom from infringement of any patent owned by Dow or others is to be inferred. Because use conditions and

applicable laws may differ from one location to another and may change with time, Customer is responsible for determining

whether products and the information in this document are appropriate for Customer's use and for ensuring that Customer's

workplace and disposal practices are in compliance with applicable laws and other government enactments. The product shown

in this literature may not be available for sale and/or available in all geographies where Dow is represented. The claims made

may not have been approved for use in all countries. Dow assumes no obligation or liability for the information in this document.

References to "Dow" or the "Company" mean the Dow legal entity selling the products to Customer unless otherwise expressly

noted. NO WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED.

Page 5 of 5 ®Trademark of The Dow Chemical Company Form No. 11-3367-01-0322 S2D

You might also like

- C95500 ASTM - Nickel Aluminum BronzeDocument2 pagesC95500 ASTM - Nickel Aluminum BronzethuykvNo ratings yet

- Styroflex 2G66: Styrene Butadiene Copolymer (SBC)Document3 pagesStyroflex 2G66: Styrene Butadiene Copolymer (SBC)Ronaldo CamargoNo ratings yet

- GM5340PRK enUS ASTMDocument2 pagesGM5340PRK enUS ASTMDuongthithuydungNo ratings yet

- c95500 Spec SheetDocument2 pagesc95500 Spec SheetOrnella MancinelliNo ratings yet

- DOWSIL+Q1-9226+Thermally+Conductive+Adhesive+TDS ENDocument3 pagesDOWSIL+Q1-9226+Thermally+Conductive+Adhesive+TDS ENMisikEENo ratings yet

- CuClad Laminates Data SheetDocument4 pagesCuClad Laminates Data SheetDenis CarlosNo ratings yet

- Technical Data Sheet: Hi-Therm BC-346-ADocument16 pagesTechnical Data Sheet: Hi-Therm BC-346-Avignesh vikkyNo ratings yet

- H6105JUDocument1 pageH6105JUhunghiepvanNo ratings yet

- 2012 Under Water SpecsDocument2 pages2012 Under Water SpecsSuresh SubbarayanNo ratings yet

- Spur Gear Spec Some Manufactures Dimension PDFDocument52 pagesSpur Gear Spec Some Manufactures Dimension PDFagus wahyudiNo ratings yet

- LG Chem TDS SP988 EnglishDocument1 pageLG Chem TDS SP988 EnglishSérgio BarbosaNo ratings yet

- Sabic BM 1052Document2 pagesSabic BM 1052ifahNo ratings yet

- T800S Technical Data Sheet 1 PDFDocument2 pagesT800S Technical Data Sheet 1 PDFAmal AvNo ratings yet

- Styrolux 684D SBC Ineos TDS enDocument3 pagesStyrolux 684D SBC Ineos TDS enfabianmendez2875No ratings yet

- Dow Corning 813C Construction and Concrete Silicone Sealant: Product InformationDocument4 pagesDow Corning 813C Construction and Concrete Silicone Sealant: Product InformationVRVNo ratings yet

- Lldpe - LL7410D PDSDocument1 pageLldpe - LL7410D PDSchinchotarngNo ratings yet

- RT-duroid 6202 Laminate Data SheetDocument2 pagesRT-duroid 6202 Laminate Data SheetAditya Bonnerjee 21BEC0384No ratings yet

- PDF Kingboard KB 6160A Data SheetDocument2 pagesPDF Kingboard KB 6160A Data SheetAlex Prim NavajasNo ratings yet

- TD Quintolubric 888 68 PDFDocument2 pagesTD Quintolubric 888 68 PDFaneesh awasthiNo ratings yet

- 4622 Product InfoDocument4 pages4622 Product InfoVendy KurniawanNo ratings yet

- Innoplus 1100J PDFDocument1 pageInnoplus 1100J PDFindahNo ratings yet

- Diclad Series: Ptfe/Woven Fiberglass LaminatesDocument5 pagesDiclad Series: Ptfe/Woven Fiberglass LaminatesmaamriaNo ratings yet

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 pagesDTM Bonding Primer: Protective & Marine CoatingsAna CabreraNo ratings yet

- High Density Polyethylene HS5407: Descrip OnDocument1 pageHigh Density Polyethylene HS5407: Descrip OnJosiola MariledoNo ratings yet

- High Alumina Wear Resistance Liners (Cumituff) : S.No Attributes Unit ValueDocument1 pageHigh Alumina Wear Resistance Liners (Cumituff) : S.No Attributes Unit ValueRivky Haris RizaldyNo ratings yet

- 3m VHB Tape 5958frDocument9 pages3m VHB Tape 5958frDonald A HuntNo ratings yet

- Novatec Premium Ii: Technical Data SheetDocument1 pageNovatec Premium Ii: Technical Data SheetRuben PauwelsNo ratings yet

- 9421 - 66408 - Pipe Extrusion (Normal) - Datasheet ASTMDocument2 pages9421 - 66408 - Pipe Extrusion (Normal) - Datasheet ASTMqcsupNo ratings yet

- Halene - P: Technical Data Sheet F103Document1 pageHalene - P: Technical Data Sheet F103Dharmendrasinh ZalaNo ratings yet

- Kocetal K700 Property DataDocument1 pageKocetal K700 Property DataRanjan GnanaoliNo ratings yet

- Material Spec For 6600Document1 pageMaterial Spec For 6600Namelezz ShadowwNo ratings yet

- HD Smooth Geomembrane MetricDocument1 pageHD Smooth Geomembrane MetricAndreas Erdian WijayaNo ratings yet

- PALL FILTER - Process Data SheetDocument2 pagesPALL FILTER - Process Data SheetThirukkumaranBalasubramanianNo ratings yet

- Tecasint 1011 Natural 0Document1 pageTecasint 1011 Natural 0Suraj_73No ratings yet

- TDS Loctite Nordbak Wearing - CompoundDocument3 pagesTDS Loctite Nordbak Wearing - CompoundSadamNo ratings yet

- TECASINT 1011 Natural - Stock ShapesDocument2 pagesTECASINT 1011 Natural - Stock ShapesGreeshmaNo ratings yet

- TDS HBMDocument1 pageTDS HBMP Singh KarkiNo ratings yet

- Aluminum Conductors Carbon Fiber Core Reinforced-LAPWINGDocument6 pagesAluminum Conductors Carbon Fiber Core Reinforced-LAPWINGgabriel yair sanchez henandezNo ratings yet

- PBT GF30 - Vampter 3026 V0 DFDocument1 pagePBT GF30 - Vampter 3026 V0 DFarmandoNo ratings yet

- SYLGARD™ 184 Silicone Elastomer: Features & Benefits ApplicationsDocument4 pagesSYLGARD™ 184 Silicone Elastomer: Features & Benefits ApplicationsZhan FangNo ratings yet

- 002DP48 PDFDocument2 pages002DP48 PDFDiadam SharmaNo ratings yet

- Lldpe 20100326-165732-Tds-02-Uf1810t-1Document1 pageLldpe 20100326-165732-Tds-02-Uf1810t-1Addison FregilNo ratings yet

- B-TVL-M: Standard Barrier Metallized BOPP FilmDocument2 pagesB-TVL-M: Standard Barrier Metallized BOPP FilmSayed FathyNo ratings yet

- GP100ORXP enUS ASTMDocument1 pageGP100ORXP enUS ASTMRaul ArmendarizNo ratings yet

- Sikadur - 42 MP Normal HC: 3-Part, Multi Purpose Epoxy Grouting SystemDocument5 pagesSikadur - 42 MP Normal HC: 3-Part, Multi Purpose Epoxy Grouting SystemJay PadamaNo ratings yet

- Torayca Carbon T1100G-Technical-Data-Sheet-1 PDFDocument2 pagesTorayca Carbon T1100G-Technical-Data-Sheet-1 PDFd25932373No ratings yet

- Sabic Chile Ptfe Hoja TecnicaDocument1 pageSabic Chile Ptfe Hoja Tecnicae.vicente.caballeroNo ratings yet

- Concrete Canvas Material Data Post Set CC Properties: StrengthDocument1 pageConcrete Canvas Material Data Post Set CC Properties: StrengthAnriansyah DwitamaNo ratings yet

- TPG Acsr As 450Document1 pageTPG Acsr As 450donlot onliNo ratings yet

- Heat Exchanger Specification SheetDocument1 pageHeat Exchanger Specification SheetRizal NajibNo ratings yet

- DTM Acrylic Pimer Finish B66W1Document4 pagesDTM Acrylic Pimer Finish B66W1Vernon Jiménez FonsecaNo ratings yet

- Heat Exchanger Specification Sheet SI UnitsDocument1 pageHeat Exchanger Specification Sheet SI UnitsIdil Fitri100% (1)

- 4622 Monolec® Multiplex Lubricant - TDSDocument4 pages4622 Monolec® Multiplex Lubricant - TDSEngineering MP CikupaNo ratings yet

- TECASINT 2011 Natural 14Document1 pageTECASINT 2011 Natural 14e.montgomeryNo ratings yet

- Lupox Gp1000H: Description ApplicationDocument2 pagesLupox Gp1000H: Description ApplicationPhuoc Thinh TruongNo ratings yet

- C 4243 Data Sheet PDFDocument3 pagesC 4243 Data Sheet PDFPavlo Fabres SierraltaNo ratings yet

- 2010 Datasheet DMV 22.5Document4 pages2010 Datasheet DMV 22.5Roman BorovkovNo ratings yet

- PP Compound - PP15T1020Document2 pagesPP Compound - PP15T1020Chaimae HanynyNo ratings yet

- Sample Design Calculation Earthing Systems Design As Per IEEE 80 - 2000Document3 pagesSample Design Calculation Earthing Systems Design As Per IEEE 80 - 2000nikkoelbao96No ratings yet

- Guide To All-Ceramic BondingDocument12 pagesGuide To All-Ceramic BondingDan CosteaNo ratings yet

- GeoTree SolutionsT RenewWrap® FRP Installation ManualDocument30 pagesGeoTree SolutionsT RenewWrap® FRP Installation ManualHéctor Yamill López AmpiéNo ratings yet

- PM Blasting and Painting ActivitiesDocument2 pagesPM Blasting and Painting ActivitiesNaveed Ahmed Get-InfoNo ratings yet

- Roofing Solutions IsomatDocument36 pagesRoofing Solutions IsomatBragarin DanNo ratings yet

- Trimdek Optima1Document1 pageTrimdek Optima1Malith MadushanNo ratings yet

- Distribution CatalogDocument41 pagesDistribution Cataloga7mosNo ratings yet

- DIET Srinagar PurneaDocument84 pagesDIET Srinagar PurneaAsif BabuNo ratings yet

- Capoxy Prime - SPL: DescriptionDocument2 pagesCapoxy Prime - SPL: DescriptionEng-Medrar AlkateryNo ratings yet

- Ciclo Di Verniciatura: Painting CycleDocument5 pagesCiclo Di Verniciatura: Painting CycleMaffone NumerounoNo ratings yet

- Stock Availability ReportDocument1 pageStock Availability ReportNova ImperialNo ratings yet

- Miscellaneous Construction Materials: 6.1. Steel BarsDocument6 pagesMiscellaneous Construction Materials: 6.1. Steel BarsGabriel VergaraNo ratings yet

- Substructure WaterproofDocument2 pagesSubstructure Waterproofiade2010e1No ratings yet

- PDS - Ultraguard EP 52Document1 pagePDS - Ultraguard EP 52Maurice DavisNo ratings yet

- Intergard 2511 TdsDocument4 pagesIntergard 2511 TdsFerhat KahveciNo ratings yet

- Installation of Fire Hydrant SystemDocument19 pagesInstallation of Fire Hydrant SystemBinod Davis100% (2)

- Carboxane 2000: Selection & Specification Data Substrates & Surface PreparationDocument2 pagesCarboxane 2000: Selection & Specification Data Substrates & Surface PreparationPurwanto ritzaNo ratings yet

- Preparing HDG For Paint - American Galvanizers AssociationDocument5 pagesPreparing HDG For Paint - American Galvanizers AssociationNsidibe EtimNo ratings yet

- The Basics of CorrosionDocument11 pagesThe Basics of CorrosionTaniaCarpioNo ratings yet

- 145 Pro-Grip Aluminium Systems: Installation GuideDocument10 pages145 Pro-Grip Aluminium Systems: Installation GuideGonzalo Agulló FernándezNo ratings yet

- Weber Firm - Datasheet - Small SizeDocument6 pagesWeber Firm - Datasheet - Small SizeAbxNo ratings yet

- Paint Insp ICorr Level 2 Notes PDFDocument133 pagesPaint Insp ICorr Level 2 Notes PDFravi00098100% (1)

- Question Bank - 1: ApixamsDocument24 pagesQuestion Bank - 1: ApixamsChabdi EssenzNo ratings yet

- Change in Function of ISO12944: Jcoe May 2017Document39 pagesChange in Function of ISO12944: Jcoe May 2017Alex AlexNo ratings yet

- BOQ-CIVIL Sample LucknowDocument25 pagesBOQ-CIVIL Sample LucknowSantosh Thakur100% (1)

- Method of StatementDocument38 pagesMethod of StatementrayNo ratings yet

- Wood Restoration Application InstructionsDocument2 pagesWood Restoration Application InstructionsJuanNo ratings yet

- Primer enDocument2 pagesPrimer enSalih HASNo ratings yet

- Penguard Tie Coat 100Document3 pagesPenguard Tie Coat 100Mohamed FarhanNo ratings yet

- TDS 3M Scotch-Weld Epoxy Adhesive DP190 Gray - 30000376Document7 pagesTDS 3M Scotch-Weld Epoxy Adhesive DP190 Gray - 30000376Akbar Perwira UtamaNo ratings yet

- CombinepdfDocument68 pagesCombinepdfMatthew Dilan ArroyoNo ratings yet