Professional Documents

Culture Documents

HAU450V2RTF1 Version1s

HAU450V2RTF1 Version1s

Uploaded by

vscrib0 ratings0% found this document useful (0 votes)

6 views20 pagesOriginal Title

HAU450V2RTF1_version1s[1]

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views20 pagesHAU450V2RTF1 Version1s

HAU450V2RTF1 Version1s

Uploaded by

vscribCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 20

C&msicn

450 SEW2

Electric Helicopter Instruction Manual

Version 4

Specification:

Fuselage length: 650mm 256m

Fuselage height: 230mm 20m

Main biade length: 225mm

Main rotor diameter: 700mm 280

Tail rotor diameter: 150mm 560 ‘actual canopy may ba different

Motor pinion gear: 12/13T

Main drive gear: 1807

Tall drive gear: 1067 -

Tail wing drive gear: 25T

Drive gear ratio: 1:12.5:4,2511:11.6:4.24

Unladen weight: 4009

Weight: 700g

Landing gear wide distance: 123mm.

Radio FunetionInstcton 4

‘Contl System Connsctionintucon == === = === 5

Fight Adjustment 8 Seting .

Pitch & Toot Seting 9-10

Min Rotor Adjustment t

All pilots must abide by regional flying rules Cchargra &Atentens seanoce ttt

and regulations. Stores, distributors and. ea aaron bee a

mig are not responsible for pilot errors. Re-

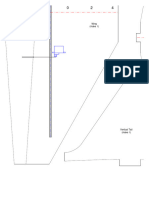

Instation Diagram === += == + vet8

(+ meaner: the Ie ek toy: Please respect ‘Gener! Mainonance Metiod me

WARNING! your fellow pilots and your surrounding. an a

distributed by CERMARK

Please read this manual carefully before assembling and flying to ensure safety and

pleasure. Please keep and refer to this manual for maintenance and replacing parts.

RIC helicopter is not a toy, It utilizes various high techs design and technologies to provide:

‘superior performance. It is a complex and recreational sport product which is only

recommended to the users by ages 14 and above. Users must master relevant handling

technique and safety regulations. It may cause dangers in various degrees during

‘operation. When operating, please pay attention to personal and other people's safety as well as the property safely.

‘The caution andlor attention symbols wil wam you about steps that can be dangerous. Please read the instructions

@ trevovaniycaretty tore proceeding, This 450SE mode requres a certain degree of skiltooporata and is a consumer

item, Any damage or dissatisfaction a8 a result of accidents or modifications are not covered by and warrantee and cannot

be retured for repair or replacement. Please contact our distributors for free technical consultation and parts at discounted

rates when you experience problems during operation or maintenance.

A Keep Away From People

This model can be high risk during ying and operating. Please keep away from people

‘Any improper assembly, damaged parts and electronic control equipment, end unskilul

handling would probably result in out of contol and cause accident. Please pay altention

ta fight safety and know sel-bom liability due to any accident. This Helicopter madel can

achieve high speeds and cause dangers, Site selection is quite important. Do nt operate

your model near people, building high-voltage line and trees, ete. improper handling will

lead to personal damage and cther people's property loss. Piease do no operate during

severe weather such as rainy and thundery day to ensure personal and model safety

Obtain the Assistance of an Experienced Pilot

Before tuming on your model and transmitter, check to make sure no one else is operating

‘on the same frequency, Frequency interference can cause your model or cther models to

‘crash. The guidance provided by an experience pilot will be invaluable for the assembly,

tuning, trimming and actual frst fight. (Recommend you to practice with computer-based

flight simulator.)

Always Be Aware of the Rotating Blades

During the operation of the helicopter, the main rotor and tail rotor will be spinning at a high

rate of speed. The blades are capable of inflicting serious bodlly injury and damage to the

‘environment, Be conscious of your actions, and careful lo Keep your face, eyes, hands,

and loose clothing away from the blades. Always fly the model a safe distance from

yourself and others, as well as surrounding objects. Never take your eyes off the model or leave it unattended while itis

turned on. Immediately tum off the mode! and transmitter when you have landed the model.

Z\ Prevent Moisture

RIC models are composed of many precision electrical components. It is eical to keep the

model and associated equipment away from moisture and other contaminants, The

introduction or exposure fo water or moisture in any form can cause the model to

‘malfunction resulting in loss of use or a erash. Do not operate or expose to rain or moisture,

Keep Away From Heat

RIC models are made up of various forms of plastic. Plastic Is very susceptible to damage

or deformation due to extreme heat and could climate, Make sure nat to store the model

near any source of heat such as an oven, or heater. Itis best to store the model indoors,

ina dimate-controlled and room temperature environment.

450 SE

A) BF version helicopter includes parts as follows, please check when purchasing

Please contact local hobby shop for replacing parts in case of defect.

ah,

Charger Gyro

Battery Motor 28g Servo * tpe

8g Servo * pcs

Pitch Shift Button

Flight Mode Switch

Throttle/Rudder Stiok | ~~

Throttle Lack Switch|

—— Elevator Trim]

Rudder Trim]

[Power Switeh|

Details setting of the radio as per attached

Transmitter: Puta trims at center. The left knob is a fine adjustment for pitch and throttle, the right knob is for

your ‘pro rate", or how quickly the tail responds, Put both so they are at the 12 o'clock position. The top switches are to

be in their rear positions. As you become familiar with your 450, move the knobs to find your preference.

The First Flight: If you are new to RC helis, we recommend “training wheels", which you can make using 24°

dowels and 4 ping pong balls, or are available through your dealer.

Your firs fight be over short grass. Plug in the battery and wait for the ESC to initialize (the beeps). Slowly advance

the throttle. Vibration is normal as the blades settle to place. Your HAUSLER 450 SE V2 will slowly stat to lif. Keep

Your first few fights very close to the ground to identify any needed trim changes. When you are comfortable, let the

heli climb to two or three feet and it will stabilize in ‘clean air.

Keep the heli in front of you. Make trim adjustments as needed. For example: If the heli wants to wander to right,

move the aileron trim 2 ~ 3 clicks to the lef. Ifthe heli wants to wander backwards, move the trim forward.

When you crash: DO NOT PANIC! Most crashes result in only minor damage and can be fixed with new parts

and a few minutes. We carry a complete selection of replacements parts.

Loading the Transmitter T6 Software: CDis PC compatible (not Mac). You can fine tune your set up

from scale fight to full 3D capability using the software. Your transmitter must be connected to your PC using the USB

cord for the changes to be made in the transmitter. Different models can be created and stored using the "Save" func-

tion in the software.

450 SE

Instruction

Receiver Connection Instruction

“The diagrams below are for your reference only. They are different on throttle and elevator between Mode 1 and Mode 2,

JR and Futaba. Therefore, their functions are cifferent accordingly. For example, CH1 of JR Mode 2 is elevator while its

‘Has tt

esa Futaba

(RFE fp fee | Ht ae Rudder

HBX emer Bower

i cit Throte ‘Aeron

Gyro Connection Instruction

‘Stroke Adjustment Danae

LED indicator for detail reference.

sala T

wo Te

2

Digital Mode Option Switch

GYRO 7 AvcS

ZD720

‘Servo Direction Switch

Connect to receiver sensitivity

(a ‘channel (connect CHS)

= ‘Connect to receiver rudder channel

i (connect cH4)

re Connect receiver tai udder

Gyro Installation Steps

Make sure all the remote device and servos are in good condition and the servo suspensions are back to the neutral position.

The gyro should be installed near the gravity position

Connect CH4 and CHS signal nes respectively to the recever and tail rudder.

Tum on the transmitter, set the tudder stick and trim to the neutral position, power on and begin to receive signal. The

gyro indicator will be flashing. The ayra is testing signals from receiver and helicopter. After 11 seconds or so, the indicator

will ight stably, and the gyro begins fo work. This moment, you can statt to operate the mode! to ly. Butif the indicator is

continuously twinkling, it needs to test the receiver and other parts.

5, Reverse switch setting: Sway the helicopter nose to the left and push tal rotor to the back, ifthe tal wing also sways to

the left, then the direction is the same,

6, Sensitivity adjustment: Please notice that whether the tal wll sway continuously or not when adjusting and testing the

helicopter. Fit sways slowly by vast scale, this suggests that the sensitivity is on the low side while quickly by small scale

shows the sensitivity is on the high side.

Aen

0720 Is a gyto with function of dual rate and head lock,which designed for helicopters specially 20720 adopts AVCS

(Angular Vector Control System),which makes the function of head lock more outstanding and steady. AVCS system:Since

rudder tim changes caused by wind and other meteorological changes and varieties of helicopter attitude changes are

automaticaly cancelled, tall rudder operation becomes easy making it perfect for 3D flight.

[Specification:

Digital proportional RIC system

Operating volatage:4.8V~6V(common for receiver)

Operating temperature:0 C°~ +40 C°

Dimensions:28%28*20 mm

Operating current:80mA

Functions:

Minimizes changes in an aircrat's atituce by wind ete

Angular acceleration commands used

‘Sensor vibration proofing

‘Simple sensitivity adjustment

(Fiinctions Expianation

Gyro Operation Direction Switch

z: LeD

Paps te.

Wee ee Control Delay Trimmer Limit Trimmer

sot

Ds mode switch

s

GYRO Te AVES

PA COROHET SHRRL TE Ruscer input Connector

_ZD720_—

Rey Sensitivity Switching Connector

Rudder Servo Connector

DS mode switch: Digital servo mode switch When using a digital servo,please set the switch the ON postion. While using the

normal one,ect it to the OFF position, tit is set to the ON position.the servo will be destroyed

Gyro Operation Direction Switeh:Switch control direction of the gyro.!t must be switched correctly according to the rotation

direction of the main rotor on the helicopter and the direction of the rudder linkage.

Control Delay Trimmer:Adjust operation speed of rudder control signal. if using slower speed rudder. please turn the knob

clockwise to increase delay time, then you can stop tracing, If using high-speed digital servo,please turn the knob anticlockwise

to the position of “0°

Rudder Input Connestor:Conneet to the receiver rudder channel(CHA).

‘Sensitivity Switching Connector:Connect to the receiver sensitivity switching channel(normally CHS), This connector can be

simultaneously used to switch the sensitivity of gyro between the AVCS and normal modes.Since the connector is a single wire

signal line do not pull it forcefully

Rudder Servo Connector:Connect to the tudder servo.

(LED Display:

Rep flash ncicate that data fs Being iniaized after you tum onthe power.

‘Steady light: Indicate that the gyro is operating in the AVCS mode,

OFF:indicate that the poner is OFF.or the gyro Is operating in the normal rode

450 SE

‘Slow flash:indicate that gyro has not received any signal of rudder operation from the transmitter. the rudder servo cannot

operate at this tine

Intermittent flash:|ncicate that open power in the normal mode, but gyto can't inliaize the data correctly at that time. Plesae

witch the gyro sensitivity switch to the AVCS mode and close the power of transmitter,hen open it again, When in AVCS

‘mode, rudder control signs! currently received is different from neutral sigral in the gyro

Double ftash:lt hapens in the following circumstances. The rudder stick is operating, The meutral positon of tall rudder is

‘moving.and you have to readjust and set i

(825720 instatiation on Helicopter

When installing the ZD720 on helicoper,please use the double-sided sponge tape included, 90°

‘Make sure the bottom of gyro is perpendicular to the main shaft of helicopter. Otherwise it

will effect the direction is roll and pitch, When installing ZD720 to electric helicopter, —

please make the distance to motor nat less than 10cm to avoid interference,

at [SS] connect to receiver

ic, anc sensitivity channel

— pa connect roster

2 1@L

cemecttonstersre.

[Servo Selection:

Head lock function of gyro has close relations with the function of tal servo you use,the effect can be more

Prominent to use digital servos recommended ta! you use futaba 9257 9650 digital servo et. When Using au

€ digital servo as the tail servo, such as 59253 S9250 S9450, please set the DS mode switch to the ON a

position While using @ normal one,please set it to the OFF position. NOTE:If using a normal servo, set the DS

switch to the ON position instead, the rudder may be destroyed

eReck Gyro Operation Direction:

Lift the helicopter, vibrate its head to the left.f the tal servo moves to the left when the tall servo linkage rod jg

of the transmitter moves to the same direction the gyro direction is correct.) the direction is nat correct, sh

please switch the direction switch

lf operation direction of gyro is designed wrong danger of high-speed rotation will arise while helicopter begins to fly Please

‘make sure gyro operation diraction is eorrect again and again

(QAajast MaximumTravel of Tail Rudder Servo:

Moe the rsr sk othe lft ang and acs te mit rmmer so thatthe sen operating anc2 aye,

cher rc ste te trkage Dung High the ero wil net operat beyond fs eit and te kage il

be pretectef the sting ito on he gro perormance wil be aleced

[EAVES Mode Adjustment: e

a

IF using digital servo please set delay time trimmer to the position of 0", while using normal servo,please

adjust the delay volume according to the detailed fact. ea

ae DELAY

De

Mode 1

Mode 2

NONE

THROTTLE

fm oot

_

fromm

Fie

Move left Move right

“—_— oe

woo wiadage

even

General Flight

a4?

+5°~

< ———

Stick position at low/Throttle 0%/Pitch 0°

General Flight Throttle Curve(Hovering Fight)

100% = ae

Throttle Pitch 1

: 26% | _ }

5 | 100% High specs | 49~ 417° mn

65%} ~ ‘ '

4 | 05% me te Hy

2 | 65% ~70% Hovenng a hor

2 | 40% +548? me

4 0% Low speed Y pee ogee | tied | byl ee

‘When the general fight mode is switched to 3D mode, the stick position should be at throttle,

70%, otherwise it will cause the gear stuck. When the mode is switched from 3D to general

flight, the stick position also should be at high position; otherwise it may cause instability of the

helicopter. Under 3D mode, it can obtain maximum power with the stick at the lowest position,

Warning} [tan make inverted fight and other stunt actions when the mode is Switched to 3D,

Chusicn

3D Flight

+9°~ 417°

— =

Stick position at low/Throttle 100%/Pitch-9°~11°

Throttle Curve(3D Flight)

3D Flight

100% fF:

Throttle Curve Pitch

5 100% +9~411°

Hg 50%

3 50% Middle o

1 100% Low. 9~-11°

+ Pitch range:Approx.23 degrees.

© * If the pitch is set too high, it will result in shorter fight duration and

CAUTION! poor motor performance.

% Setting the throttle to provide a higher speed is preferable to

increasing the pitch too high

LL,

Adjustment Mark

When replacing the main rotor, it is necessary to balance

the blades first. Screw the rotor blades together as in the

illustration. The rotor blades are properly balanced when

they are suspended exactly horizontally. If not, the blades

are not in equilibrium. This is corrected by applying tape

to lighter blade.

Adjustment Mark

Ps

Apply a red piece of tape on one blade, or paint a rod stripe with a marker or paint to identity one blade. Operate the

helicopter at 2 safe distance and have someone jook at the spinning blades at the reference angle shown in the photo

I the blade tracking is not set correctly, you will be able to identify the blade with the red identifying mark rotating higher or

lower than the other blade. Adjust the linkage rod length shorter or longer to make both blades track level.

A When adjusting and testing, please keep a certain distance

Warning! _ Tome fotary-surtace:to peevant.accident,

Check the battery if it is correct specification for the helicopter and fully charged

2. Check if the pitch setting is too high. If the pitch setting is too high, it will affect the power

efficiency and flight time

3. Check the tightness of the main rotor blades. Blades should be tightened so that they do

not move freely, but can be moved by applying slight pressure by hand

4, Check for vibration on the main and tail rotors.(Vibration can be caused by main

shaft/feathering shaft wear, damage, or looseness, check all linkages and bearings for

excess play or wear. )

5. Check for interference caused by improper gear mesh or belt tension

1"

Charging: please follow the MFG instruction

41 Connect the battery and charger connector firstly, then connect the charger

plug to the AC socket,

2 Disconnect the battery and charger when charging campleted.

3. To protect the battery life and performance, please charge when the

battery get cooled after using,

optional

4 Connect the battery with charger

4 =

OD saa

3 Remove the battery

after a full charge

Attentions

41, Please charge the battery in strict accordance with the manual

2, When charging.the charger and battery must be put on a fire-resistant table-board or the ground and far aveay from

combustibles

3. Do not leave the LiPo charging process unattended,

4. f any abnormality such as swelling of the battery pack, STOP (DISENGAGE) IMMEDIATELY and contact the MFG

for additional instructions. (Bur, leak and fire can occur if continue).

Please do not charge non-rechargeable battery. Otherwise it may cause accident! Users of

Li-Po battery (Li-Polymer) require to learn more knowledge on how to use Li-Po battery,

and know the potential danger due to wrong use. It is recommended that users are at the

ages of 16 and above or to handle the battery accompanied by an adult with experienced

knowledge of Li-Po battery.

Please do not charge the battery with Ni-MH or NiCd charger! This may cause damage of

the battery. Please use appropriative charger which is special for Li-Po battery to charge

Caution {discharge battery.

4

16

‘Statement: In order ta improve product performance

and quailty, individual parts of this product may be

improved and changed. Appearance and parameters}

are subject fo change without notice. Please consult

ur company’s website for relevant and further

information.

Front

Back

Warning! )

1. When assembling, please make sure the strap

veer 90 degrees,

2. Strap Tighiness: Itis recommended that after the

‘assembly of tail boom, tension of the strap be

increased a litle to prevent strap shock and skid

‘of rotation from friction injury.

450 SE

450 SE style electric remote control helicopter is a detailed model products which is made

up of precision parts, Players must make sure high performance of each control assembly and

mechanism so that it can unleash excellent and stable flight characteristic. The helicopter may

cause accident or loss in case of inadequate maintenance. We recommend that you develop

the habit of regular inspection to ensure your favorite aircraft and maintain the best performance

at any time.

Structural Inspection Focused of the Main Rotor

1.Main rotor housing : When the operation of main rotor exception occurs, it will have unobvious

shock during flight. Please check the main rotor and shaft to find if they are out of shape or the

balance is inadequate. Replace the defective parts if necessary.

2. Main rotor oil seal: It will have elastic fatigue by long use and will affect the flight stability. It is

recommended to replace it right now.

3. Main rotor holder: Generally speaking, the thread pitch is confirmed before flight, however

the thread pitch stoke still needs to be adjusted before operating, If you fly often for continuous

movements such as dramatic action, etc., you should focus on checking plastic parts, bearings

and ball bearings. It needs to replace new parts in case there is obvious clearance between

plastic parts and ball bearing or in case the steel ball of bearing drops off.

@ Before flying, the main rotor must be checked if it is in bad condition of deformation

and damage, etc. The balance is very important. If it is not well balanced, more loss

Attention! of parts, airframe and getloose will occur due to the flying shock.

4. Control arm assembly: Checking each control arm and locking screws regularly to find whether

the arms work smoothly or have less sway can ensure the stable performance of hovering and

control precision.

5. Control pane! assembly: When the control panel assembly has serious virtual spaces, it will

lead to bad stability and control performance, and maybe appear unexplained phenomena of

the main rotor blades. It must be replaced when it is in serious condition

Inspection Focus of the Fuselage Assembly

1. Main bearing: The functional status of each bearing must be examined after about 50 times

take-off and landing under long time normal load operation. And it is recommended to replace

new parts in order to maintain smooth action and reliability. If fierce 3D flying or serious

crashes are needed frequently, it is suggested that the main shaft bearings be checked

frequently. In case the main bearing has obvious clearance or obvious barrier during rotation,

it must be replaced to a new one.

2. Unilateral bearing set: It is not easy to be damaged, but it is recommended that you remove

it after 50 times take-off and landing period, clean and apply oil to it. Ifthe main gear has

obvious unusual movement, please replace the unilateral bearing set.

7

Chosen

Inspection Focus of Control Rod Set

When assembling control rod, control arm connection mount and tail servo, please pay more

attention to keep each connection part smooth and make the shaft have less swaying

clearance. This is very important because it will affect the flight performance. Natural wear or

bad site also may cause abrasion and loose situation. In case any clearance of the rod

occurs or the rod is easy to loose, please replace a new part to ensure flight performance

and safety.

Inspection Focus of the Main Rotor System

4. Tail Gear assembly: Please pay attention to the inspection of tail rotor bearings. When you

find the bearing has obvious clearance, please replace a new one to avoid biting deadly.

And do not lack the tail servo so tight. The operation must work well and avoid meltdown

of plastic parts

2. Tail rotor control sliding seat: When flying the helicopter over the lawn, please pay attention

to check if there is grass involved into the sliding seat when it is landing. If so, the grass

must be cleared away before flying again. Otherwise, it may block the movement and make

the tail rotor lose control as a result. In ordinary maintenance, please try to avoid using

lubricating oil to the outside mechanism. This will help to protect the parts from dust or

other sundries. If not, it will wear away other parts’ bearings and the sliding seat won't work

3. Tail rotor holder: Please remove the tail rotor holder for cleaning and maintenance after it

finishes 50 times take-off and landing. Make sure the bearing clearance is correct. If the

rotation doesn't work smoothly or the clearance is large, please replace the bearing to

ensure that the control system is perfect

4. Tail Rotor: When flying, if the tail rotor contacts to earth, please have them checked

immediately. If it has obvious appearance damage, please replace them right away to

avoid shocking and damaging other parts.

© Screw-loose will lead to unexpected accident, be sure to check the

caution: [ck regularly.

18

GERMARK (excusive N American cstrbutor

BFE CE 5

9830 Bell Ranch Dr, #101, Santa Fe Springs, CA, 90670 - United States

Tel: 562-906-0808 | Fax: §62-906-0820 Email: sales@cermark com

wwwwhauslerre.com (available soon) Mee cA

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Aileron Throw ModelDocument1 pageAileron Throw ModelvscribNo ratings yet

- f22 03Document1 pagef22 03vscribNo ratings yet

- F-18 Parkflyer (Assembly Drawing) Rev ADocument2 pagesF-18 Parkflyer (Assembly Drawing) Rev AvscribNo ratings yet

- F-14 Fixed Wing Conversion Parts (Tiled) Rev ADocument12 pagesF-14 Fixed Wing Conversion Parts (Tiled) Rev AvscribNo ratings yet

- Blu 51cd TiledDocument8 pagesBlu 51cd TiledvscribNo ratings yet

- F-18 Park Jet (Part Templates Non-Tiled) Rev ADocument1 pageF-18 Park Jet (Part Templates Non-Tiled) Rev AvscribNo ratings yet

- 2 of 3 Cozy Drgs 16-5-05Document1 page2 of 3 Cozy Drgs 16-5-05vscribNo ratings yet

- 3 of 3 Cozy Drgs 5-8-05 TiledDocument8 pages3 of 3 Cozy Drgs 5-8-05 TiledvscribNo ratings yet

- Me 109Document1 pageMe 109vscribNo ratings yet

- 1 of 3 Cozy Drgs 5-8-05Document1 page1 of 3 Cozy Drgs 5-8-05vscribNo ratings yet

- Canard Throw ModelDocument1 pageCanard Throw ModelvscribNo ratings yet

- InstructionsDocument5 pagesInstructionsvscribNo ratings yet

- Su 25Document1 pageSu 25vscribNo ratings yet

- Mig 29Document4 pagesMig 29vscribNo ratings yet

- PittsS 1sredDocument1 pagePittsS 1sredvscribNo ratings yet

- COLDITZLDocument5 pagesCOLDITZLvscribNo ratings yet

- GB StandDocument1 pageGB StandvscribNo ratings yet

- Kamikaze DDocument1 pageKamikaze DvscribNo ratings yet

- Ju52 LFDocument1 pageJu52 LFvscribNo ratings yet

- Su 29Document3 pagesSu 29vscribNo ratings yet

- T-38 Park Jet Plans (Parts Templates Non-Tiled) BETA2Document1 pageT-38 Park Jet Plans (Parts Templates Non-Tiled) BETA2vscribNo ratings yet

- Gripen Park Jet (Parts Templates 120 Nontiled)Document1 pageGripen Park Jet (Parts Templates 120 Nontiled)vscribNo ratings yet

- X-29 Plan PartsDocument1 pageX-29 Plan PartsvscribNo ratings yet

- F-15 Park Jet Plans (Parts Templates 175 Tiled)Document56 pagesF-15 Park Jet Plans (Parts Templates 175 Tiled)vscribNo ratings yet

- T-38 Park Jet Plans (Parts Templates 150 Tiled)Document36 pagesT-38 Park Jet Plans (Parts Templates 150 Tiled)vscribNo ratings yet

- X-29 PlansDocument1 pageX-29 PlansvscribNo ratings yet

- T-38 Park Jet Plans (Parts Templates 120 Scaled)Document25 pagesT-38 Park Jet Plans (Parts Templates 120 Scaled)vscribNo ratings yet

- T-38 Park Jet Plans (Parts Templates Tiled 60 Scaled)Document6 pagesT-38 Park Jet Plans (Parts Templates Tiled 60 Scaled)vscribNo ratings yet

- X-29 Plan Parts TiledDocument25 pagesX-29 Plan Parts TiledvscribNo ratings yet

- SR 71aDocument24 pagesSR 71avscribNo ratings yet