Professional Documents

Culture Documents

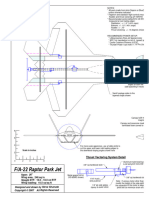

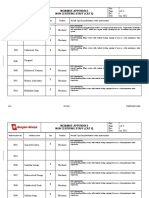

F-18 Parkflyer (Assembly Drawing) Rev A

Uploaded by

vscrib0 ratings0% found this document useful (0 votes)

9 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views2 pagesF-18 Parkflyer (Assembly Drawing) Rev A

Uploaded by

vscribCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

NOTES:

* All parts made from 6mm Depron unless otherwise indicated

* Sand all wing and empennage leading edges round and

apply a piece of 3M Satin tape around the leading edge to

add smoothness and durability

* Recommended control deflections (all dimensions

measured at root trailing edge):

Stabilators: +/- 1.0"

Ailerons: +/- 1.25"

Flaps: 0 up, 1.25" down

* Use -40% exponential rates on elevator and ailerons

* Use a heat gun to gently bend the foam in the aft fuselage

to pre-form it to the shapes shown

RECOMMENDED POWER SYSTEMS:

* Brushed: GWS EPS-350C with C gearing (5.3:1), 8x6 GWS

Slowflyer prop, 1200 mAh 11.1V lithium-polymer battery,

10 Amp speed control

* Brushless: Himaxx 2015-4100 with B gearing (4.4:1), 9x7

GWS Slowflyer prop, 1320 mAh 11.1V lithium-polymer battery,

15 Amp speed control

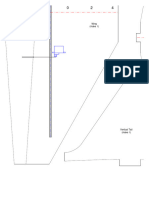

Sand fuselage corners

round as shown below

(not to scale)

Sand strake to the cross

section shown below

(not to scale)

Outboa

Bottom

Aft canopy mount

(1/4" balsa triangle

Removable canopy mounted with Velcro on top)

0 1 2 3 4 5 6 7 8 with two bamboo skewers forward

and two Velcro strips aft

Scale in inches

Canopy and nosecone

made from laminated foam

sheets and carved to shape

Span: 28.4 in

Wing area: 254 sq in

Weight: 15.0 - 18.0 oz Battery mounted to

Wing loading: 8.5 - 10.2 oz/sq ft fuselage floor with Velcro

Designed and drawn by Steve Shumate

Copyright © 2004 All Rights Reserved

Cut 45 deg bevel in flaperon

leading edges and use tape

0.21" dia x 25.5" carbon tube spar hinges on top and bottom

Trim flaperons to clear

vertical tails with

up deflection

5.25"

Flaperon servos

(with 1/32" music

wire pushrods)

0.157" dia. x 9" carbon tube

pivoting inside three short pieces

of 3/16" dia. aluminum tubing

Outboard

1/4" x 5/16" balsa

missle rails

Cut hatch for access

to radio equipment 1/32" ply vertical

tail supports

Cut pocket in fuslelage side (two per side)

to mount flaperon servo 3/8" sq. x 4"

hardwood

motor mount GWS EPS-350

motor shown

(no right or

down thrust)

Stabilator servo .75" x .75" 1/64" ply

Dashed lines indicate foam 6 channel (with 1/32" music bearing supports

strip doublers at corners (see micro receiver wire pushrod) (4 total)

parts templates for details)

Use servo arm for control horn and

end stop (drill out to fit carbon tube)

You might also like

- The Private Pilot BlueprintDocument41 pagesThe Private Pilot BlueprintTankful75% (8)

- FH03JAu GardenShed PDFDocument17 pagesFH03JAu GardenShed PDFMax Popp80% (5)

- Mini 3dx Plans Tiled A4Document20 pagesMini 3dx Plans Tiled A4andrequalNo ratings yet

- Instructions For Continued Airworthiness 03 2019Document10 pagesInstructions For Continued Airworthiness 03 2019Santiago GuzmanNo ratings yet

- F-18 Parkflyer (Assembly Drawing) Rev ADocument2 pagesF-18 Parkflyer (Assembly Drawing) Rev AvscribNo ratings yet

- F-15 Park Jet Plans (Assembly Drawing) Rev CDocument2 pagesF-15 Park Jet Plans (Assembly Drawing) Rev CMAIG ElectricosNo ratings yet

- F-14 Park Jet (Assembly Drawing)Document2 pagesF-14 Park Jet (Assembly Drawing)John MondoNo ratings yet

- F-15 Park Jet Plans Assembly Drawing Tiled PDFDocument2 pagesF-15 Park Jet Plans Assembly Drawing Tiled PDFoambesiNo ratings yet

- F-14 Park Jet (Assembly Drawing Non-Tiled)Document1 pageF-14 Park Jet (Assembly Drawing Non-Tiled)pedrods141No ratings yet

- F-15 Park Jet Plans (Parts Templates Tiled)Document18 pagesF-15 Park Jet Plans (Parts Templates Tiled)EricsonNo ratings yet

- Assembly Drawing TiledDocument2 pagesAssembly Drawing Tiled조한준No ratings yet

- F-14 Park JDocument49 pagesF-14 Park Jpedrods141No ratings yet

- Fokker DR1 Assembly DrawingDocument1 pageFokker DR1 Assembly Drawingfranco muñozNo ratings yet

- Atmospheric Sounding Projectile: 13mm Carded Scale ModelDocument1 pageAtmospheric Sounding Projectile: 13mm Carded Scale ModelStevenNo ratings yet

- T-38 Park Jet Plans (Parts Templates Tiled 60 Scaled)Document6 pagesT-38 Park Jet Plans (Parts Templates Tiled 60 Scaled)vscribNo ratings yet

- Arched Aurora NightstandDocument7 pagesArched Aurora NightstandRoberto LandaNo ratings yet

- 28Chap2-Lower WingDocument17 pages28Chap2-Lower Wingmohamed sidkyNo ratings yet

- F-18 Park Jet (Part Templates Tiled) Rev ADocument16 pagesF-18 Park Jet (Part Templates Tiled) Rev ApapacoolNo ratings yet

- Accuride Full Extension Drawer Slides for Heavy LoadsDocument2 pagesAccuride Full Extension Drawer Slides for Heavy LoadsKissa DolautaNo ratings yet

- Guia Cola de MilanoDocument7 pagesGuia Cola de MilanoFrancisco SanchezNo ratings yet

- Claridge Leather Rolltop Rucksack PatternDocument5 pagesClaridge Leather Rolltop Rucksack Patternrampante1100% (2)

- T-38 Park Jet Plans (Parts Templates Tiled)Document15 pagesT-38 Park Jet Plans (Parts Templates Tiled)Iruel Street NewNo ratings yet

- Counterbalanced Backdraft Damper PerformanceDocument2 pagesCounterbalanced Backdraft Damper PerformancePat AuffretNo ratings yet

- Mini 3dx Plans TiledDocument15 pagesMini 3dx Plans TiledAero LagosNo ratings yet

- 42inch Sbach Legal - PDF Versión 1Document16 pages42inch Sbach Legal - PDF Versión 1capp1264No ratings yet

- Router JigsDocument2 pagesRouter JigsIlberto Fortuna100% (1)

- 25 0575 Toyota Pickup Installation Instructions CaridDocument2 pages25 0575 Toyota Pickup Installation Instructions CaridenthonytopmakNo ratings yet

- AwningDocument18 pagesAwninghot.moose.soupNo ratings yet

- Boat Scarf JigDocument1 pageBoat Scarf JigFrancois VaaltynNo ratings yet

- Morris Mustang P 51Document2 pagesMorris Mustang P 51Emerson URNo ratings yet

- 96-0012 - N Haas Automatic Pallet Changer Operator AddendumDocument26 pages96-0012 - N Haas Automatic Pallet Changer Operator AddendumTuanNo ratings yet

- Top fwd fuselage assemblyDocument1 pageTop fwd fuselage assemblymohamed sidkyNo ratings yet

- Top fwd fuselage assemblyDocument19 pagesTop fwd fuselage assemblyDan Stefan DanNo ratings yet

- F-14 Park Jet (Parts Templates Tiled)Document25 pagesF-14 Park Jet (Parts Templates Tiled)John MondoNo ratings yet

- Guppy 2 Paper Plan-1-2Document1 pageGuppy 2 Paper Plan-1-2Pablo D. RigoNo ratings yet

- SuspensionDocument4 pagesSuspensionatlanticblue98No ratings yet

- Ugly Stick 60 Plans SH2Document1 pageUgly Stick 60 Plans SH2Ria JiotNo ratings yet

- Subwoofer Box Accuton P - Ported Box - PipeDocument3 pagesSubwoofer Box Accuton P - Ported Box - Pipefajarfura123No ratings yet

- Fokker d7 ElectricDocument2 pagesFokker d7 ElectricEmerson URNo ratings yet

- Installation Guidelines EngDocument24 pagesInstallation Guidelines EngAlejandraSánchezMiresNo ratings yet

- Sukhoi Su 26Document4 pagesSukhoi Su 26Jesùs AlfaroNo ratings yet

- Ing Swin Gar M 1/8" Lite-PlyDocument1 pageIng Swin Gar M 1/8" Lite-Plymam73100% (1)

- Dutchman Build Spec SheetDocument8 pagesDutchman Build Spec SheetthemerijengNo ratings yet

- 30 1165 Mazda Bseries Instal CaridDocument2 pages30 1165 Mazda Bseries Instal CaridenthonytopmakNo ratings yet

- Aluminum landing gear installationDocument4 pagesAluminum landing gear installationBRIJITHNo ratings yet

- New Gen D44 Comparison ChartDocument1 pageNew Gen D44 Comparison ChartSeth_Gibbons_8837No ratings yet

- Feed TableDocument3 pagesFeed Table- yAy3e -No ratings yet

- EXTRA 300L - 1,2m 3d/aerobatic EPP Model: Building InstructionsDocument6 pagesEXTRA 300L - 1,2m 3d/aerobatic EPP Model: Building InstructionsCarlos NakagawaNo ratings yet

- The Recumbent Bicycle and Human Powered Vehicle Information Center15Document1 pageThe Recumbent Bicycle and Human Powered Vehicle Information Center15Marcel PiersonNo ratings yet

- Tuf-Lite III Fans 3000K Series Hub: Installation ManualDocument9 pagesTuf-Lite III Fans 3000K Series Hub: Installation ManualVíctor Hugo Morales CurayNo ratings yet

- F-15 Park Jet Plans Assembly Drawing TiledDocument2 pagesF-15 Park Jet Plans Assembly Drawing TiledNestor Omar AmbesiNo ratings yet

- T-38 Park Jet Plans (Assembly Drawing)Document2 pagesT-38 Park Jet Plans (Assembly Drawing)souheil_souNo ratings yet

- Woodworking Plans - Childs RockerDocument16 pagesWoodworking Plans - Childs RockerBob Kowalski100% (1)

- Critical Factors Installing A DH Antenna: YOUR STARTING POINT! Pilot Hole Is Located On The 2Document15 pagesCritical Factors Installing A DH Antenna: YOUR STARTING POINT! Pilot Hole Is Located On The 2CarlosAgustoPinedaSanchezNo ratings yet

- Super Bandit Park Jet (Parts Templates Scaled 75 Tiled)Document9 pagesSuper Bandit Park Jet (Parts Templates Scaled 75 Tiled)Ahmad Khanif FikriNo ratings yet

- Nanofalcon Glider: Parts ListDocument1 pageNanofalcon Glider: Parts Listshashi1810No ratings yet

- Shovel Hoist Drum Gear Alignment Procedure SummaryDocument13 pagesShovel Hoist Drum Gear Alignment Procedure SummaryFreud CutireNo ratings yet

- Salt & Pepper ShakersDocument5 pagesSalt & Pepper ShakersDGNo ratings yet

- Sigrc 74 Kadetlt 25Document34 pagesSigrc 74 Kadetlt 25carlosulloa100% (1)

- Arts and Crafts ChairDocument9 pagesArts and Crafts Chairlight darkNo ratings yet

- Auto Exhaust Damper MODEL 611: Ratings Features FrameDocument1 pageAuto Exhaust Damper MODEL 611: Ratings Features FrameMiguel OrhlNo ratings yet

- g2 Mounting Instructions T 420 Nissan 2004 PresentDocument10 pagesg2 Mounting Instructions T 420 Nissan 2004 PresentLisette HowardNo ratings yet

- Aermacchi M.B 339 Plan With PartsDocument2 pagesAermacchi M.B 339 Plan With PartsAlejandro LabléeNo ratings yet

- Mig 29Document4 pagesMig 29vscribNo ratings yet

- Me 262Document3 pagesMe 262mam73100% (2)

- PittsS 1sredDocument1 pagePittsS 1sredvscribNo ratings yet

- Gripen Park Jet (Parts Templates Scaled 120 Tiled)Document25 pagesGripen Park Jet (Parts Templates Scaled 120 Tiled)Randi tyaNo ratings yet

- T-38 Park Jet Plans (Parts Templates Tiled 60 Scaled)Document6 pagesT-38 Park Jet Plans (Parts Templates Tiled 60 Scaled)vscribNo ratings yet

- T-38 Park Jet Plans (Parts Templates 120 Scaled)Document25 pagesT-38 Park Jet Plans (Parts Templates 120 Scaled)vscribNo ratings yet

- T-38 Park Jet Plans (Parts Templates Non-Tiled) BETA2Document1 pageT-38 Park Jet Plans (Parts Templates Non-Tiled) BETA2vscribNo ratings yet

- Mobius ManualDocument19 pagesMobius ManualHowardgfNo ratings yet

- X-29 Plan Parts TiledDocument25 pagesX-29 Plan Parts TiledvscribNo ratings yet

- X-29 PlansDocument1 pageX-29 PlansvscribNo ratings yet

- BF Sentient Weapons r4Document4 pagesBF Sentient Weapons r4vscribNo ratings yet

- SU-47 Parts 6mm Depron A4Document1 pageSU-47 Parts 6mm Depron A4vscribNo ratings yet

- The Bitter Lesson - Rich SuttonDocument2 pagesThe Bitter Lesson - Rich SuttonvscribNo ratings yet

- The Best Lenses For Canon DSLRs in 2021 Digital Photography Review - APS-CDocument13 pagesThe Best Lenses For Canon DSLRs in 2021 Digital Photography Review - APS-CvscribNo ratings yet

- Owners Manual AT-502 Agricultural AirplanesDocument6 pagesOwners Manual AT-502 Agricultural AirplanesVinicius RodriguesNo ratings yet

- APS3200Document2 pagesAPS3200Tc UmtNo ratings yet

- Vol1 AOM Part1Document37 pagesVol1 AOM Part1alexttNo ratings yet

- Mmel-A320-2021 11 22 PDFDocument1,454 pagesMmel-A320-2021 11 22 PDFAmanNo ratings yet

- ATR Upgrade Catalogue (Issue 4 February 2021)Document128 pagesATR Upgrade Catalogue (Issue 4 February 2021)Arefin FerdousNo ratings yet

- 11 Aircraft Systems 747 400 v10Document69 pages11 Aircraft Systems 747 400 v10flightstudent90% (10)

- Emc 3 TTM Level 1 AfDocument194 pagesEmc 3 TTM Level 1 AfPrajwal PatidarNo ratings yet

- Design ReportDocument11 pagesDesign ReportNikhil ThosarNo ratings yet

- Accident IgruaDocument21 pagesAccident IgruaBestin JoseNo ratings yet

- CFM Training Courses Catalog 2019Document22 pagesCFM Training Courses Catalog 2019Олег ОлександровичNo ratings yet

- 240119 Ltr to Whitaker 1Document4 pages240119 Ltr to Whitaker 1Live 5 NewsNo ratings yet

- Working Capital Management in HALDocument112 pagesWorking Capital Management in HALAkshay SrivastavaNo ratings yet

- Ship Hydrodynamics Propeller Dimensional AnalysisDocument27 pagesShip Hydrodynamics Propeller Dimensional AnalysisAbdelrahman Atef ElbashNo ratings yet

- Air Transportation 2Document19 pagesAir Transportation 2Clerk Janly R FacunlaNo ratings yet

- Majestic Dash8 Checklists PDFDocument13 pagesMajestic Dash8 Checklists PDFDanielNo ratings yet

- Appendix 6 Rev 3 Sep 2012Document3 pagesAppendix 6 Rev 3 Sep 2012lucisteauaNo ratings yet

- 1945 Naca-Wr-E-269 Sea-Level Performance Tests of A 22-Inch-Diameter Pulse-Jet Engine at Various Simulated Ram PressuresDocument40 pages1945 Naca-Wr-E-269 Sea-Level Performance Tests of A 22-Inch-Diameter Pulse-Jet Engine at Various Simulated Ram PressuresAviationaddictNo ratings yet

- Landing Gear and Brakes ReviewDocument8 pagesLanding Gear and Brakes ReviewromixrayzenNo ratings yet

- PA 28 161 Warrior IIDocument257 pagesPA 28 161 Warrior II韩超No ratings yet

- Geomac Product UAV (Unmanned Aerial Vihicle) : PT Geomac Survey IndonesiaDocument5 pagesGeomac Product UAV (Unmanned Aerial Vihicle) : PT Geomac Survey IndonesiaAhmad RamdaniNo ratings yet

- WB FCL5Document16 pagesWB FCL5Martin GohNo ratings yet

- Therelek ProfileDocument1 pageTherelek ProfileTherelek EngineersNo ratings yet

- Preliminary CRJ Manual AerosoftDocument48 pagesPreliminary CRJ Manual AerosoftTimNo ratings yet

- B757-767 Series: by Flightfactor and Steptosky For X-Plane 11.35+ (VR Compatable) Produced by VmaxDocument12 pagesB757-767 Series: by Flightfactor and Steptosky For X-Plane 11.35+ (VR Compatable) Produced by VmaxDave91No ratings yet

- Performance-Based Navigation (PBN) : Rnav 2Document1 pagePerformance-Based Navigation (PBN) : Rnav 2BirilloNo ratings yet

- BGA Self-Declared Maintenance Programme GuideDocument19 pagesBGA Self-Declared Maintenance Programme GuideJG DEVETINo ratings yet

- Term I NologiesDocument6 pagesTerm I NologiesHUSSAIN SUMALINGNo ratings yet

- Heathrow Egll Pilot Operations Guide 2 0Document10 pagesHeathrow Egll Pilot Operations Guide 2 0Marcelo CameraNo ratings yet