Professional Documents

Culture Documents

LT AX100 03 Aluminum Landing Gear Installation Guide

Uploaded by

BRIJITHOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LT AX100 03 Aluminum Landing Gear Installation Guide

Uploaded by

BRIJITHCopyright:

Available Formats

ALUMINUM LANDING GEAR

INSTALLATION GUIDE

7 1/2"

1. Use Grade 5 bolts minimum – properly torqued. 3 3/4"

1 1/2" 2 1/4"

Typical

1 15/16"

1” Radius

1 15/16" Typical

Grade 5 Grade 8

Ø21/32" 2 1/4"

(10) Holes 2 1/4"

2. Mounting surface should provide clearance around TTMA

bushings and shafts. See TTMA recommended cutout. Recommended Cutout

OK NOT

OK

3. Adequate provisions should be made to prevent galvanic corrosion between aluminum

and steel components (such as the use of Alumilastic or other appropriate material).

4. Mounted square side-to-side and front-to-back.

Trailer Trailer

End View Side View

Square Square

The right to alter specifications is reserved. Page 1 of 4

1770 Hayes Street Ph. (616) 846-7700 (800) 253-5105

Grand Haven, MI 49417 Fax (616) 846-0310

www.jostinternational.com LT AX100-03 RevC

ALUMINUM LANDING GEAR

INSTALLATION GUIDE

5. Bracing as shown on upper leg.

Cross Bracing

Fore - Aft Bracing

“K” Bracing

Individual

Bracing

Separate as

far as possible

Horizontal cross member to keep

legs parallel

“X” Bracing

Wing Plate Bracing

“A” Bracing

Note on the Fore and Aft Bracing:

Jost recommends using the holes provided for the reinforcing strap to attach

the fore and aft braces. If this is not possible additional holes may be added as

required on the tube flange.

6. Bottom reinforcing strap installation.

a. Hardware required:

- 5/8-11 Hex Head Screw (Grade 5 minimum)

- 5/8 Hardened Flat Washer

- 5/8-11 Prevailing Torque Lock Nut

b. Additional washers may be required between the

reinforcing strap and tube flange to maintain a tight fit

without distorting the tube.

The right to alter specifications is reserved. Page 2 of 4

1770 Hayes Street Ph. (616) 846-7700 (800) 253-5105

Grand Haven, MI 49417 Fax (616) 846-0310

www.jostinternational.com LT AX100-03 RevC

ALUMINUM LANDING GEAR

INSTALLATION GUIDE

7. Brace lug design and attachment.

a. Upper brace lugs should be one of the following designs:

4” 4” 2”

6” 6” 6”

4”

2” 2” 2”

Double Angles Tee Double Offset Angle

2x6 x 3/8 thick 4x6 x 3/8 thick 2x6 x 3/8 thick

2x4 x 3/8 thick

b. Lower brace lugs should be one of the following designs:

4” 4”

4” 4”

2” 2”

6”

Double Angles Tee

2x4 x 3/8 thick 4x4 x 3/8 thick

Spread

8. Brace Lug Welding Procedure. apart as

far as

Step 1) Clean all surfaces prior to welding possible 4”

a. Prior to welding, clean all surfaces to be welded Tube

with abrasive soap and water.

b. Rinse with clean water and allow to dry. 2ND Weld

c. Once dry, use a dedicated stainless steel brush Initial Weld Figure 1

to remove the oxide layer.

3RD Weld

Step 2) Preheat the brace lugs to approximately 200ºF

before welding.

Brace Lug

Note: A 200ºF heat crayon works well in this application Figure 2

available at most welding supply stores No starts or stops

in this area

Step 3) Tack the lugs into position (see figure 1).

Step 4) Place an initial weld around both brace lugs Finish all welds here

as shown in figure 2, starting as shown in

figure 3. Use a 1/4"x1/4” fillet weld to attach

the brace lugs to the upper tube.

Step 5) Add the 2nd weld around both brace lugs, as

shown in figure 2. Again use a 1/4"x 1/4" fillet

weld and start as shown in figure 3.

Step 6) Finally, add a 3rd weld around both brace lugs,

starting as shown in figure 3, between the brace Figure 3

lug and weld added in step 5, shown in figure 2. Start all welds here

The right to alter specifications is reserved. Page 3 of 4

1770 Hayes Street Ph. (616) 846-7700 (800) 253-5105

Grand Haven, MI 49417 Fax (616) 846-0310

www.jostinternational.com LT AX100-03 RevC

ALUMINUM LANDING GEAR

INSTALLATION GUIDE

9. Cross shaft bolts tight, but free to move side-to-side and radially.

10. Mount crank hardware.

Washers used

on both sides

11. Check handle for free operation.

- Crank handle bolt must be loose enough to allow free engagement.

Engaged Disengaged

12. Check footware for proper attachment.

Check for

bolt in axle Check fasteners

or welds

13. After installation is complete check leg for proper operation and shifting.

The right to alter specifications is reserved. Page 4 of 4

1770 Hayes Street Ph. (616) 846-7700 (800) 253-5105

Grand Haven, MI 49417 Fax (616) 846-0310

www.jostinternational.com LT AX100-03 RevC

You might also like

- The Recumbent Bicycle and Human Powered Vehicle Information Center15Document1 pageThe Recumbent Bicycle and Human Powered Vehicle Information Center15Marcel PiersonNo ratings yet

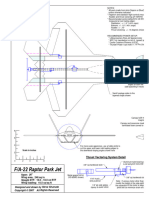

- F-14 Park Jet (Assembly Drawing)Document2 pagesF-14 Park Jet (Assembly Drawing)John MondoNo ratings yet

- EN SS 1025 4 - VariGripDocument4 pagesEN SS 1025 4 - VariGripDemir KarahanNo ratings yet

- Assembly Drawing TiledDocument2 pagesAssembly Drawing Tiled조한준No ratings yet

- F-14 Park Jet (Assembly Drawing Non-Tiled)Document1 pageF-14 Park Jet (Assembly Drawing Non-Tiled)pedrods141No ratings yet

- Draw Off Sump PDFDocument2 pagesDraw Off Sump PDFpradeep4545No ratings yet

- Mini 3dx Plans TiledDocument15 pagesMini 3dx Plans TiledAero LagosNo ratings yet

- Cavalinho de MadeiraDocument11 pagesCavalinho de Madeiraaaff66100% (1)

- Shoe ID ChartDocument6 pagesShoe ID Chartmalcolm healNo ratings yet

- Haldex - Brake Shoe Identification Chart PDFDocument6 pagesHaldex - Brake Shoe Identification Chart PDFYunfan ZhangNo ratings yet

- Series 8000Document20 pagesSeries 8000Bugs MartínezNo ratings yet

- Ft-Seccionador Sin Carga-CoracoraDocument4 pagesFt-Seccionador Sin Carga-CoracoraJorge Muñoz SilvaNo ratings yet

- Gravity Conveyor CatalogDocument20 pagesGravity Conveyor CatalogAriston ForghanjayaNo ratings yet

- Grating Install ClearanceDocument1 pageGrating Install ClearancenalzackNo ratings yet

- Motor Shaft Arbor Small Type A - Stamped Washer PDFDocument2 pagesMotor Shaft Arbor Small Type A - Stamped Washer PDFGladys Anne ZubiriNo ratings yet

- الخطأ والصواب في تسليح العناصر الانشائيهDocument47 pagesالخطأ والصواب في تسليح العناصر الانشائيهSwift WardNo ratings yet

- Composite Blow Out Peventor: Technical FeaturesDocument1 pageComposite Blow Out Peventor: Technical FeaturesVenus DobosNo ratings yet

- All Metal Lock Nuts: Earnest Technical Bulletin Stover StyleDocument3 pagesAll Metal Lock Nuts: Earnest Technical Bulletin Stover StyleDavid Lay IINo ratings yet

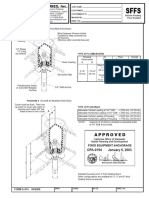

- SFFSDocument1 pageSFFSFede AccorintiNo ratings yet

- Andsaw For The Lathe: by Dennis HorlerDocument6 pagesAndsaw For The Lathe: by Dennis HorlerJohn BrittonNo ratings yet

- Spec Sheet 17 - Cs Combo 86ff9fe0Document2 pagesSpec Sheet 17 - Cs Combo 86ff9fe0Eduardo QuiñonesNo ratings yet

- Catalogo Dixon Swivels 2007Document48 pagesCatalogo Dixon Swivels 2007victor barreraNo ratings yet

- Guppy 2 Paper Plan-1-2Document1 pageGuppy 2 Paper Plan-1-2Pablo D. RigoNo ratings yet

- Reinforcement DetailingDocument47 pagesReinforcement DetailingMuhammad Saqib Abrar94% (16)

- Reinforcement DetailingDocument47 pagesReinforcement DetailingSun Rise100% (1)

- Dynamic Cone Penetrometer: 105 Harrison Street, American Falls, Idaho 83211 U.S.ADocument2 pagesDynamic Cone Penetrometer: 105 Harrison Street, American Falls, Idaho 83211 U.S.AGeillyn CastroNo ratings yet

- Sprockets: Guide TypeDocument1 pageSprockets: Guide TypeAnonymous yxWIryXNo ratings yet

- Hex Rod CouplingDocument1 pageHex Rod CouplingvirajNo ratings yet

- F-15 Park Jet Plans Assembly Drawing Tiled PDFDocument2 pagesF-15 Park Jet Plans Assembly Drawing Tiled PDFoambesiNo ratings yet

- Reinforcement DetailingDocument47 pagesReinforcement DetailingLimar SetstraNo ratings yet

- Spelter SocketDocument1 pageSpelter SocketarslanahmedkhawajaNo ratings yet

- Build The Ison Race KartDocument8 pagesBuild The Ison Race KartJim100% (2)

- Bootz Bath Spec Sheet Aloha Plus AfrDocument2 pagesBootz Bath Spec Sheet Aloha Plus AfrJMNo ratings yet

- Drawoff SumpDocument1 pageDrawoff SumpmabtesoreroNo ratings yet

- VCTDS 03384 enDocument8 pagesVCTDS 03384 enKrishnamoorthyNo ratings yet

- Virgil-Indy500-1915 Studebaker 1Document1 pageVirgil-Indy500-1915 Studebaker 1RianiNo ratings yet

- الخطأ والصواب في تسليح العناصر الانشائيهDocument47 pagesالخطأ والصواب في تسليح العناصر الانشائيهBen ÂmarNo ratings yet

- Brochure de Guía de CablesDocument3 pagesBrochure de Guía de CablesFernando TamayoNo ratings yet

- Brochure de Guía de CablesDocument3 pagesBrochure de Guía de CablesChristian Javier Lopez DuranNo ratings yet

- Shop Crane ManualDocument16 pagesShop Crane ManualRagu RamsinghNo ratings yet

- Casing SpoolDocument10 pagesCasing SpoolAli mohammadNo ratings yet

- Z Purlin Sample CalculationDocument2 pagesZ Purlin Sample CalculationRodolfo ZazuetaNo ratings yet

- Gas Service Head Adaptor: Flexible TypeDocument2 pagesGas Service Head Adaptor: Flexible TypeRafael GranadoNo ratings yet

- 011 StabilizersDocument2 pages011 StabilizersGonzalo Guzman Jaimes100% (1)

- 33 Roof Curb - Backpan DetailDocument1 page33 Roof Curb - Backpan DetailAhmed Saber NassarNo ratings yet

- Front Suspension Installation Instructions: 1953-1956 Ford Truck Custom IFSDocument10 pagesFront Suspension Installation Instructions: 1953-1956 Ford Truck Custom IFSmickabd2002No ratings yet

- An Introduction to Metal-Working (Illustrated)From EverandAn Introduction to Metal-Working (Illustrated)Rating: 2.5 out of 5 stars2.5/5 (2)

- Tractor Ploughing Manual, The, 2nd Edition: The Society of Ploughman Official HandbookFrom EverandTractor Ploughing Manual, The, 2nd Edition: The Society of Ploughman Official HandbookRating: 5 out of 5 stars5/5 (2)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideFrom EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideNo ratings yet

- A Guide to Making Your Own Fishing-Rod and TackleFrom EverandA Guide to Making Your Own Fishing-Rod and TackleRating: 5 out of 5 stars5/5 (1)

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

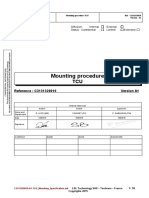

- Mounting Procedure: Reference: C3131320010 A1Document16 pagesMounting Procedure: Reference: C3131320010 A1BRIJITHNo ratings yet

- Corner PostDocument14 pagesCorner PostTeguh Nugraha Kusnan100% (1)

- Intermodal 53ft Container enDocument1 pageIntermodal 53ft Container enBRIJITHNo ratings yet

- Safe Load Securing 8 THDocument76 pagesSafe Load Securing 8 THdsn_sarmaNo ratings yet

- Finite Element Analysis of Automotive Truck ChassiDocument12 pagesFinite Element Analysis of Automotive Truck ChassiBRIJITHNo ratings yet

- Jost Landing Gear ManualDocument8 pagesJost Landing Gear ManualBRIJITHNo ratings yet

- Iso 3874Document34 pagesIso 3874BRIJITHNo ratings yet

- SF 0654Document4 pagesSF 0654QA LAB ISMNo ratings yet

- Chapter 26-Nontraditional MachiningDocument67 pagesChapter 26-Nontraditional MachiningHassan AliNo ratings yet

- 3D Printing Technology: Under The Guidance of Subhra Chakraborty Submitted by AYUSHI (1MV16TE007)Document15 pages3D Printing Technology: Under The Guidance of Subhra Chakraborty Submitted by AYUSHI (1MV16TE007)Ayushi SharmaNo ratings yet

- PG-Grafmax SPDocument1 pagePG-Grafmax SPazeem bilalNo ratings yet

- Investment CastingDocument16 pagesInvestment CastingDENNY JACOBNo ratings yet

- PQR Al 6xxxDocument7 pagesPQR Al 6xxxAmin ThabetNo ratings yet

- Material & Specification: Chemical CompositionDocument1 pageMaterial & Specification: Chemical CompositionTommy CamposNo ratings yet

- MC 780Document2 pagesMC 780Maurício LopesNo ratings yet

- CSWIP 3.1 Course Note 2016 With Question & AnswersDocument3 pagesCSWIP 3.1 Course Note 2016 With Question & AnswersSakthi Pk100% (1)

- Friction Stir WeldingDocument26 pagesFriction Stir WeldingMahaManthra0% (1)

- Hot Cracking in Incoloy 825Document2 pagesHot Cracking in Incoloy 825navasNo ratings yet

- Centrifugal Shroud Tundish SteelmakingDocument12 pagesCentrifugal Shroud Tundish Steelmakingdebasish chatterjeeNo ratings yet

- Waste Water Treatment Plants Data SheetDocument2 pagesWaste Water Treatment Plants Data SheetbpjindiaNo ratings yet

- Plastic SyllabusDocument11 pagesPlastic SyllabusrajatNo ratings yet

- Material Product Data Sheet Amdry 100 Series Braze Filler MetalsDocument4 pagesMaterial Product Data Sheet Amdry 100 Series Braze Filler MetalsJ. BangjakNo ratings yet

- New Low-Cost Manufacturing Methods To Produce SiliDocument9 pagesNew Low-Cost Manufacturing Methods To Produce Sililyxuannam lyNo ratings yet

- Wood Assembly Without Nails or ScrewsDocument4 pagesWood Assembly Without Nails or Screwsadamj123No ratings yet

- Anna University ME 9301 Design of Jigs. Fixtures and Press Tools Question PaperDocument5 pagesAnna University ME 9301 Design of Jigs. Fixtures and Press Tools Question PaperMuruga AnanthNo ratings yet

- Pressure Vessels Lectures 94Document1 pagePressure Vessels Lectures 94Adeel NizamiNo ratings yet

- 112 PlanerstandDocument9 pages112 Planerstandmochitvb100% (2)

- Denstone 99Document2 pagesDenstone 99Mohamad ZarghampoorNo ratings yet

- Raw Sugar ProcessingDocument6 pagesRaw Sugar ProcessingJan April MahinayNo ratings yet

- Antic Invetions Vs Modern Investions: Lopazov Timur cl.6 'B''Document4 pagesAntic Invetions Vs Modern Investions: Lopazov Timur cl.6 'B''Timur LopazovNo ratings yet

- General Specification For Pipeline Field Welding & NDTDocument77 pagesGeneral Specification For Pipeline Field Welding & NDTRanjan KumarNo ratings yet

- Section 8. QuestionaryDocument20 pagesSection 8. QuestionaryferyNo ratings yet

- Technical Presentation On Engine ValvesDocument32 pagesTechnical Presentation On Engine ValvesRockey RahulNo ratings yet

- Special Casting ProcessesDocument31 pagesSpecial Casting Processesdarshan_rudraNo ratings yet

- Edison Welding Institute Hot Tap WeldingDocument19 pagesEdison Welding Institute Hot Tap WeldingShikhar JainNo ratings yet

- Donner CompanyDocument1 pageDonner CompanyAsri Marwa UmniatiNo ratings yet

- Foundry Shop ManualDocument9 pagesFoundry Shop ManualRanjit Singh67% (3)