Professional Documents

Culture Documents

F-14 Park Jet (Assembly Drawing Non-Tiled)

Uploaded by

pedrods141Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F-14 Park Jet (Assembly Drawing Non-Tiled)

Uploaded by

pedrods141Copyright:

Available Formats

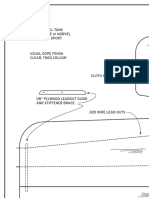

NOTES: Wing Sweep Mechanism Detail

* All parts are made from 6mm Depron or BlueCore foam unless

otherwise indicated 1/16" threaded rod with

Hitec HS-81 MG servo steel clevises on each end

* If using BlueCore, peel the plastic covering off both sides with 1/8" lite-ply servo arm

of all fuselage parts (leave the skin on all wing and Drill 1/4" holes to accept

empennage parts for strength) 1/4-20 nylon bolts

* Recommended control deflections (all dimensions

measured at root trailing edge): 0.157" dia. x 5.12" carbon tube

pivoting inside two short pieces

Tailerons (pitch): +/- 1.5" (-40% expo) of 3/16" dia. aluminum tubing

Tailerons (roll): +/- 1.75" (-40% expo)

Rudder: +/- 7/8" (-30% expo)

* Wing sweep to stabilator mixing is required to keep the

airplane trimmed as the wing sweeps. Set it up so Laminated 1/8" lite-ply tongue Cover wing root and inside

that swinging from full forward to full aft sweep provides 1/8" lite-ply spar box top, of wing slot with packing

Laminated 1/8" lite-ply spacer bottom, and doublers tape to reduce friction

1/4" trailing edge up stabilator (about 5% mix rate)

* Rudder control is optional and provides better control

for aerobatics and low-speed high alpha flight

* Use a heat gun to gently form the foam in the fuselage 3/8" balsa spacer 1/4" balsa shear webs 3/8" balsa triangle

to the shapes shown spar box supports

1/8" lite-ply servo tray

(4 places)

RECOMMENDED POWER SYSTEM:

* For best results choose a power system that provides

20-25 oz static thrust and 45-50 mph pitch speed.

* Prototype used Himax 2015-4100 with 4.4:1 gearing, 9x6 APC

Slowflyer prop, 1320 mAh 11.1V lithium-polymer battery, and

Castle Creations Phoenix 10 speed control

If you enjoy these plans, please consider sending a small contribution

to the designer to show your appreciation for all the work that went

into developing them. Suggested contribution is $10 U.S., and can

be sent via PayPal to jetset44@verizon.net. Thanks for your support! 3 temporary bulkheads installed

in inlets to aid assembly

Cut hatch for access to

receiver and rudder servo

Wing pin is a 1/4-20 nylon

Vertical tails canted bolt retained by a nylon nut

5 deg outboard

.21" dia x 13.0" carbon tube spar

Cover stabilator root on both sides

with 3M Satin tape for strengthening

8

6

Sand wing and empennage leading edges round and Sand wing and empennage trailing

apply a piece of 3M Satin tape around the leading edges to a tapered shape

4 edge to add smoothness and durability

Scale in inches

2

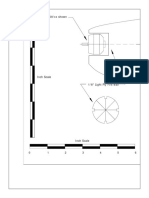

Fuselage Cross Section Detail

Removable canopy mounted

with two bamboo skewers

forward and two Velcro strips aft

0 2 4 6 8

Cut hatch for access

to wing swing servo

Nosecone and canopy made

from laminated foam sheets

or foam block carved to shape

Span: 40.7"/24.7"

Wing area: 220 sq in

Weight: 20 - 23 oz RTF CG location

Sand forward fuselage/canopy Battery mounted to fuselage Rudder servo (optional)

Wing loading: 14 oz/sq ft to contours shown 4.7"

floor with a strip of Velcro Receiver

(or 0.5" forward 3/8" sq x 4.25"

Designed and drawn by Steve Shumate of wing pivots hardwood motor mount

Copyright © 2005 All Rights Reserved

You might also like

- How To Make DIY Aircrete For Ligthweight ConcreteDocument2 pagesHow To Make DIY Aircrete For Ligthweight Concretealvin lumawag100% (3)

- The Science of FlightDocument12 pagesThe Science of FlightBikash ThapaNo ratings yet

- 31 36 00002Document16 pages31 36 00002ryan liaoNo ratings yet

- Morris Mustang P 51Document2 pagesMorris Mustang P 51Emerson URNo ratings yet

- Eawm Middle EastDocument658 pagesEawm Middle EastferNo ratings yet

- EK QRH B777 Systems & ExpandedDocument135 pagesEK QRH B777 Systems & ExpandedNabil KhurshidNo ratings yet

- Router Table - SledDocument6 pagesRouter Table - SledBen Gerez100% (3)

- T-38 Park Jet Plans (Assembly Drawing)Document2 pagesT-38 Park Jet Plans (Assembly Drawing)souheil_souNo ratings yet

- Aerobatic Speed 400 Electric PlaneDocument14 pagesAerobatic Speed 400 Electric PlaneScott Burel100% (1)

- FE 1400 V Belt Drive Selection For FansDocument6 pagesFE 1400 V Belt Drive Selection For FansAvery OppegardNo ratings yet

- Vibro King TL Screen 1Document3 pagesVibro King TL Screen 1RAUL PEREZ NEGREIROSNo ratings yet

- ATR-Be Prepared For X-Wind LandingDocument2 pagesATR-Be Prepared For X-Wind LandingKike CT100% (1)

- Landing Gear LM 2Document18 pagesLanding Gear LM 2Devdatt SondeNo ratings yet

- Hydrodynamic Design of Planing Hulls SavitskyDocument25 pagesHydrodynamic Design of Planing Hulls SavitskyMarcelo CaliNo ratings yet

- F-14 Park Jet (Assembly Drawing)Document2 pagesF-14 Park Jet (Assembly Drawing)John MondoNo ratings yet

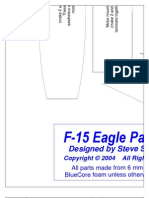

- F-15 Park Jet Plans Assembly Drawing Tiled PDFDocument2 pagesF-15 Park Jet Plans Assembly Drawing Tiled PDFoambesiNo ratings yet

- F-15 Park Jet Plans (Assembly Drawing) Rev CDocument2 pagesF-15 Park Jet Plans (Assembly Drawing) Rev CMAIG ElectricosNo ratings yet

- Fokker DR1 Assembly DrawingDocument1 pageFokker DR1 Assembly Drawingfranco muñozNo ratings yet

- Assembly Drawing TiledDocument2 pagesAssembly Drawing Tiled조한준No ratings yet

- Virgil-Indy500-1915 Studebaker 1Document1 pageVirgil-Indy500-1915 Studebaker 1RianiNo ratings yet

- F-18 Parkflyer (Assembly Drawing) Rev ADocument2 pagesF-18 Parkflyer (Assembly Drawing) Rev AvscribNo ratings yet

- F-18 Parkflyer (Assembly Drawing) Rev ADocument2 pagesF-18 Parkflyer (Assembly Drawing) Rev AvscribNo ratings yet

- Ugly Stick 60 Plans SH2Document1 pageUgly Stick 60 Plans SH2Ria JiotNo ratings yet

- Aluminum landing gear installationDocument4 pagesAluminum landing gear installationBRIJITHNo ratings yet

- F-14 Park JDocument49 pagesF-14 Park Jpedrods141No ratings yet

- Mini 3dx Plans TiledDocument15 pagesMini 3dx Plans TiledAero LagosNo ratings yet

- material list chiltronDocument2 pagesmaterial list chiltronPepe GuaraNo ratings yet

- F-15 Park Jet Plans Assembly Drawing TiledDocument2 pagesF-15 Park Jet Plans Assembly Drawing TiledNestor Omar AmbesiNo ratings yet

- X-29 PlansDocument1 pageX-29 PlansvscribNo ratings yet

- F-14 Park Jet (Parts Templates Tiled)Document25 pagesF-14 Park Jet (Parts Templates Tiled)John MondoNo ratings yet

- INSTALLATION INSTRUCTIONS FOR HIGH OUTPUT 2 SPEED RAD FAN ASSEMBLYDocument3 pagesINSTALLATION INSTRUCTIONS FOR HIGH OUTPUT 2 SPEED RAD FAN ASSEMBLYthe enverNo ratings yet

- Prototype Setup/Specs: X-29 Park JetDocument2 pagesPrototype Setup/Specs: X-29 Park Jetmohamed sidkyNo ratings yet

- 26 B Mount Blocks 04222020Document15 pages26 B Mount Blocks 04222020CarlosAgustoPinedaSanchezNo ratings yet

- 1 Ounce Fuel Tank .049 Tee Dee or Norvel .061 Big Mig SportDocument8 pages1 Ounce Fuel Tank .049 Tee Dee or Norvel .061 Big Mig SportCarlos Manuel GonzálezNo ratings yet

- Sensus 143 PDFDocument2 pagesSensus 143 PDFVel MuruganNo ratings yet

- PDF Notes and Tips: A-7 Corsair JetDocument20 pagesPDF Notes and Tips: A-7 Corsair JetAlexandra SpătăreluNo ratings yet

- The Recumbent Bicycle and Human Powered Vehicle Information Center15Document1 pageThe Recumbent Bicycle and Human Powered Vehicle Information Center15Marcel PiersonNo ratings yet

- T&S Brass and Bronze Works, Inc.: B-0113-ADF12-BDocument2 pagesT&S Brass and Bronze Works, Inc.: B-0113-ADF12-BSheik Abdul NazeerNo ratings yet

- Fan Belt Drives ED1400Document6 pagesFan Belt Drives ED1400arielNo ratings yet

- V Belt Drive Selection For Fans FE 1400Document6 pagesV Belt Drive Selection For Fans FE 1400Parag ThakkarNo ratings yet

- Cavalinho de MadeiraDocument11 pagesCavalinho de Madeiraaaff66100% (1)

- Extract Pages From TeknoDocument1 pageExtract Pages From TeknohereisamitNo ratings yet

- 30 1185 Ford Explorer4dr Instal CaridDocument2 pages30 1185 Ford Explorer4dr Instal CaridenthonytopmakNo ratings yet

- Designed and Drawn by Michael Ramsey: Cessna MaterialsDocument1 pageDesigned and Drawn by Michael Ramsey: Cessna MaterialsVeras limaNo ratings yet

- Mini 3dx Plans Tiled A4Document20 pagesMini 3dx Plans Tiled A4andrequalNo ratings yet

- 25 Vented Ridge DetailDocument1 page25 Vented Ridge DetailAhmed Saber NassarNo ratings yet

- 33 Roof Curb - Backpan DetailDocument1 page33 Roof Curb - Backpan DetailAhmed Saber NassarNo ratings yet

- Hexadrain Brickslot OverviewDocument2 pagesHexadrain Brickslot Overviewloren4_rengifo3044No ratings yet

- 25 0575 Toyota Pickup Installation Instructions CaridDocument2 pages25 0575 Toyota Pickup Installation Instructions CaridenthonytopmakNo ratings yet

- wl400 InstallDocument1 pagewl400 InstallliengsamsonNo ratings yet

- Bandit Park Jet EDF (Assembly Drawing Tiled)Document2 pagesBandit Park Jet EDF (Assembly Drawing Tiled)roman golianNo ratings yet

- T-38 Park Jet Plans (Parts Templates Tiled 60 Scaled)Document6 pagesT-38 Park Jet Plans (Parts Templates Tiled 60 Scaled)vscribNo ratings yet

- F-15 Park Jet Plans (Parts Templates Tiled)Document18 pagesF-15 Park Jet Plans (Parts Templates Tiled)EricsonNo ratings yet

- 30 1165 Mazda Bseries Instal CaridDocument2 pages30 1165 Mazda Bseries Instal CaridenthonytopmakNo ratings yet

- Hex Rod CouplingDocument1 pageHex Rod CouplingvirajNo ratings yet

- CPR1617 30Document16 pagesCPR1617 30Jamie MiddletonNo ratings yet

- VDG Instruction PagesDocument12 pagesVDG Instruction PagesMarty cNo ratings yet

- Half Lite Stunter Building InstructionsDocument37 pagesHalf Lite Stunter Building InstructionsCarlos Manuel GonzálezNo ratings yet

- By Graham Smith: Top View RudderDocument1 pageBy Graham Smith: Top View RudderSergio De Manuel GálvezNo ratings yet

- Tools, Installation, Operation and MaintenanceDocument20 pagesTools, Installation, Operation and MaintenanceAymeeenNo ratings yet

- Composite Blow Out Peventor: Technical FeaturesDocument1 pageComposite Blow Out Peventor: Technical FeaturesVenus DobosNo ratings yet

- FP3349 Max Hi Flow - Techsheet ENDocument1 pageFP3349 Max Hi Flow - Techsheet ENClaudiu PopicaNo ratings yet

- Top fwd fuselage assemblyDocument19 pagesTop fwd fuselage assemblyDan Stefan DanNo ratings yet

- Top fwd fuselage assemblyDocument1 pageTop fwd fuselage assemblymohamed sidkyNo ratings yet

- Quick Release Couplings: HT-Series ISO16028 Flushface InterchangeDocument3 pagesQuick Release Couplings: HT-Series ISO16028 Flushface InterchangerweidlingNo ratings yet

- RC Shark User Manual v1.1Document6 pagesRC Shark User Manual v1.1Zulqarnain sabirNo ratings yet

- MR Eriadi EriadiDocument2 pagesMR Eriadi EriadiPT Jihan Sentosa AbadiNo ratings yet

- Airbus Helicopters: Coloring Book Fun & GamesDocument12 pagesAirbus Helicopters: Coloring Book Fun & GamesLuis RomeroNo ratings yet

- Airside Capacity-Volume3Document18 pagesAirside Capacity-Volume3kkrajcekNo ratings yet

- Ad 93-14-12Document1 pageAd 93-14-12Mohamad Hazwan Mohamad JanaiNo ratings yet

- IJSET V9 Issue5 471Document5 pagesIJSET V9 Issue5 471Israe El AmriNo ratings yet

- 003 The Boeing 7E7 Case Solution and Analysis, HBR Case Study Solution & Analysis of Harvard Case StudiesDocument5 pages003 The Boeing 7E7 Case Solution and Analysis, HBR Case Study Solution & Analysis of Harvard Case StudiesdmNo ratings yet

- SBGR - Sid Rnav Ukbev 1a Rwy 27r - Sid - 20171012Document1 pageSBGR - Sid Rnav Ukbev 1a Rwy 27r - Sid - 20171012Eduardo AlmeidaNo ratings yet

- DA40 AMM Rev5Document2,035 pagesDA40 AMM Rev5dtickner92100% (6)

- Travel Reservation March 13 For MR OUSMANE TRAOREDocument2 pagesTravel Reservation March 13 For MR OUSMANE TRAORECHRISTIAN FORGESNo ratings yet

- Drone Training Syllabus for Remote PilotsDocument28 pagesDrone Training Syllabus for Remote PilotsVenkata NS DhulipalaNo ratings yet

- Eglllfpg PDF 1708877328Document50 pagesEglllfpg PDF 1708877328shiaviation1No ratings yet

- Type-Certificate Data Sheet: An Agency of The European UnionDocument44 pagesType-Certificate Data Sheet: An Agency of The European UnionfuckNo ratings yet

- UG - CAO.00121 Foreing Part 145 - Aircraft Certifying StaffDocument30 pagesUG - CAO.00121 Foreing Part 145 - Aircraft Certifying StaffMeriem BouzerzourNo ratings yet

- Waterjet Versus Propeller Engine Matching Characteristics: Is SoDocument11 pagesWaterjet Versus Propeller Engine Matching Characteristics: Is SoKarina AnggeliaNo ratings yet

- Application For: Civil Aviation Authority, BangladeshDocument2 pagesApplication For: Civil Aviation Authority, BangladeshShariful Mamun RanimNo ratings yet

- Ae 17412 - Aerodynamics Lab - I (Manual)Document50 pagesAe 17412 - Aerodynamics Lab - I (Manual)EZHILMARANNo ratings yet

- New Microsoft Word DocumentDocument3 pagesNew Microsoft Word DocumentGAMES OF BATTELSNo ratings yet

- Civil Aviation RegulationsDocument16 pagesCivil Aviation RegulationsNguyen Ngoc BinhNo ratings yet

- Air Tractor, Inc.: Air Tractor Achieves High Flying Productivity With VERNON ToolDocument4 pagesAir Tractor, Inc.: Air Tractor Achieves High Flying Productivity With VERNON ToolemanuelNo ratings yet

- Flyer UAV LauncherDocument1 pageFlyer UAV LauncherShehryar AwanNo ratings yet

- Far 23Document25 pagesFar 23Quispe Inga Americo GiuseppeNo ratings yet

- Catania, Italy Licc/Cta: 1.1. Atis 1.2. Procedures in Reduced Visibility Conditions 1. GeneralDocument49 pagesCatania, Italy Licc/Cta: 1.1. Atis 1.2. Procedures in Reduced Visibility Conditions 1. GeneralTweed3ANo ratings yet

- Dokumen - Tips Atpl Pof Principles of Flight Questions BankDocument32 pagesDokumen - Tips Atpl Pof Principles of Flight Questions BankfedeNo ratings yet