Professional Documents

Culture Documents

Swimming Pool Plumbing Systems

Uploaded by

championaquaticOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Swimming Pool Plumbing Systems

Uploaded by

championaquaticCopyright:

Available Formats

SECTION 22 51 00

SWIMMING POOL PLUMBING SYSTEMS

PART 1 GENERAL

1.1 DESCRIPTION OF THE WORK:

A. Work Included: Design and complete installation of swimming pool, complete as

shown and as specified, including, but not necessarily limited to the following:

1. Design, engineering and layout drawings, coordinated with the Contractor's

drawings and work as required to complete the swimming pool per local codes

and ordinances. Show supply needs and stub-out locations.

2. All equipment and accessories for pool above or below finish grade levels.

3. All excavation, and backfill, trenching, concrete, mechanical, and plumbing work

for swimming pool.

4. Backfill and compaction for trench work.

5. Pool and spa coping and operating equipment required for proper water

treatment changes, chemical testing and electrical bonding work.

6. Time clock as required for pump(s) and filter.

1.2 QUALITY ASSURANCE:

A. Requirements of Regulatory Agencies: All work and materials shall be in full

accordance with all applicable local and state laws and regulations.

B. Fees and Permits: Secured and paid for by Contractor.

C. Conformance to Local Codes: Approved by Soils Engineer and Enforcing Agent

relative to project soils condition for conformance to local codes.

D. Applicable Standards: All references to the standards listed below shall mean the

current editions.

ASTM - American Society for Testing and Materials.

ACI - American Concrete Institute, Manual of Concrete Practice.

NEC - National Electric Code.

ANSI - American National Standards Institute, Inc. Specifications for Installation

of Ceramic Tile.

E. Contractor's Pre-Qualifications: Pool and spa installation shall be executed by a firm

currently specializing in the type of construction described and having a minimum of

five (5) years experience in the area location to the project site.

Westdale Euless SWIMMING POOL PLUMBING SYSTEMS

HEDK Project No. 22194 22 51 00 - 1 30 October 2023

1.3 JOB CONDITIONS:

A. Protection of Existing Plants to Remain: See Section 02120 - Existing Planting to

Remain.

1.4 COORDINATION:

A. Items of Other Trades: Furnish and set in place. Execute in ample time, such

portions of their work as are all or in part embedded, built-in, attached to, or

supported by the work.

B. Accessories: Properly install all accessories embedded in the pool and for the

provision of holes, openings, etc., necessary to the execution of the work of the

trades.

1.5 SUBMITTALS:

A. Pre-Qualification Data: Two (2) copies each of a reference list with a minimum of

three (3) references, and a project list of installations in the local area in the last five

(5) years.

B. Samples and Product Data:

1. Plaster Finish Coat: Two (2) color samples for each type.

2. Pool Tile: Four (4) for each type and color.

C. Test Data: Copies of all laboratory test data and reports of all pool materials.

D. Shop Drawings:

1. Layout plan(s).

2. Mechanical and Electrical plan.

3. Longitudinal and cross sections.

4. Coping detail(s).

1.6 ANALYSES OF SAMPLES AND TESTS:

A. Testing Laboratory: Selected and paid for by Owner.

B. Notification: Cooperate in making tests and be responsible for notifying the

designated laboratory in sufficient time to allow taking samples at time of pour.

C. Rejected Work: Full costs of removal of rejected material, its replacement with

material of specified strength and conformation, and retesting shall be borne by

Contractor. Remove all such construction work off the site.

1.7 FINAL ACCEPTANCE:

A. Review: When work is substantially complete, Sub-contractor shall inform Contractor

of same for purposes of review. Defects shall be corrected at no cost to the Owner.

Westdale Euless SWIMMING POOL PLUMBING SYSTEMS

HEDK Project No. 22194 22 51 00 - 2 30 October 2023

B. Final Acceptance Date: The date on which the Owner's representative accepts

satisfactory completion and operation of all work. Upon Final Acceptance, Contractor

shall give the Owner the complete pool operating instructions.

1.8 GUARANTEE:

A. Subcontractor shall supply a written guarantee dated from the date of Final

Acceptance by the Owner , that all work executed under this section is free of defects

of material and workmanship, and shall further guarantee that he shall, at his own

expense, repair and replace all such defective work, and all other work damaged

thereby, which becomes defective during the term of the guarantee.

B. Terms of the Guarantee shall be as follows:

1. One (1) year for all other equipment, materials and labor including, but not limited

to, automatic controls and valves.

PART 2 PRODUCTS

2.1 ACCEPTABLE MANUFACTURERS:

A. Pool Equipment

Swimquip

A Division of Wylain, Inc.

El Monte, CA 91732

(213) 443-4211

Atlanta, GA 30318

(404) 355-0480

Dallas, TX 75229

(214) 357-3801

Hydrel Corporation

Sun Valley, CA 91352

(213) 875-0131

Imperial Bronzelite

A Division of Wide Lite Corporation

San Marcos, TX 78666

(512) 392-8957

Bryan Steam Corporation

Peru, IN 46970

(317) 473-6651

Pool-Tech, Inc.

Lafayette, CA 94549

(415) 284-1400

Sta-Rite

Westdale Euless SWIMMING POOL PLUMBING SYSTEMS

HEDK Project No. 22194 22 51 00 - 3 30 October 2023

Richards-Wilcox, Inc.

San Francisco, CA 94125

(415) 468-0600

B. Tile:

Villeroy and Boch

American Tile

Noble Tile

C. Handrails and Railings:

Pine Ironworks

Oakland, CA 94607

(415) 465-0988

2.2 PORTLAND CEMENT AND AGGREGATES: See Site Concrete - Section 03335.

2.3 STEEL REINFORCEMENT:

A. Reinforcing Steel: Standard sizes of deformed bars equal to the requirements of the

Standard Specifications for Billet Steel, Concrete Reinforcement; Intermediate Grade,

Serial Designation A15-39.

B. Electrical Bonding: Per NEC code.

2.4 PLASTER FOR INTERIOR SURFACES OF POOL (AND SPA):

A. Application: All exposed interior surfaces of the pool.

B. Coat Thickness: 1/4 in. to 3/8 in. thick, troweled into the truing coat of the rough

gunite, floated to a uniform plane, and troweled to smooth, dense surface.

C. Type: "Marcite" plaster finish

D. Color: White

2.5 UNDERWATER LIGHT NICHE AT POOL:

A. Type: Wet niche type 500 watt underwater light.

B. Manufacturer: Hydrel or accepted alternate.

2.6 UNDERWATER LIGHT NICHE AT SPA:

A. Location: Recess and flush mounting rung for light shall be as shown on the

Drawings.

B. Type: Wet niche type 200 watt underwater light.

C. Surface Finish: Recess finish shall match other pool surface.

2.7 COPING: Coping as detailed on the Drawings.

Westdale Euless SWIMMING POOL PLUMBING SYSTEMS

HEDK Project No. 22194 22 51 00 - 4 30 October 2023

2.8 PIPES:

A. Lateral Piping: PVC Schedule 40.

B. Face Piping: Copper Type "L".

2.9 POOL RAILINGS AND LADDERS:

A. Type: Stainless steel pipe Schedule 40 with standard mill finish.

B. Flange Plates and All Appurtenances: 1/8 in. thick stainless steel with standard mill

finish, as manufactured by Pine Iron Works, or accepted equal.

2.10 TILE AT WATERLINE:

A. Tile:

1. Manufacturer: Villeroy and Boch, American Tile or Noble Tile.

2. Tile Size: 6 in. x 6 in.

3. Color: LEA-RK 053, SVR-55 or GIADA.

B. Setting Bed:

1. Mortar, Grout and Expansion Joint Materials: See Section 09310 - Site Tile.

2. Joint Sealant Color: Match Grout.

2.11 POOL EQUIPMENT:

A. D.E. Filter with pressure gauges.

B. Filter pump, 3 HP, single phase, 230 V.

C. Flow meter with Hydrostatic Relief Valve.

D. Chlorinator with Solution Tank.

E. Skimmers, valved separately with Deck Frame and Cover.

F. Pool vacuum with forty (40) feet of hose.

G. Fill line with vacuum breaker.

H. Return fittings (cycolac).

2.12 MISCELLANEOUS EQUIPMENT:

A. Water test kits.

B. Shepherd’s Hook with sixteen-foot (16') pole.

C. Wall brush with sixteen-foot (16') pole.

Westdale Euless SWIMMING POOL PLUMBING SYSTEMS

HEDK Project No. 22194 22 51 00 - 5 30 October 2023

D. Leaf skimmer with sixteen-foot (16') pole.

E. Life line.

F. Thermometers.

2.13 SAFETY SIGNS: Per State and Federal Codes.

PART 3 EXECUTION

3.1 GENERAL:

A. Comply with Local and State Code and the Soils Report for all pool construction.

Consult the soil report for conditions regarding ground water.

B. Provide written notification of all discrepancies or omissions on Drawings and

conditions on the site which would prevent proper drainage of water away from pool.

3.2 EXCAVATION, BACKFILLING AND COMPACTING:

A. Pool Excavations: Continuously shore or excavate and backfill in accordance with

the Soils Report and as approved by the Soils Engineer. Be responsible for all costs

incurred as a result of encountered underground water including, but not limited to,

pumping, shoring and drain rock.

B. Rough Excavation and Hand Trim: Execute as one operation to aid in eliminating

over-excavation. Dispose of excavated earth off-site or to a location on site as

instructed by the General Contractor.

C. Templates: Use templates to form the vertical and curved excavation of the pool

structure.

D. Voids: Fill with gunite all voids which may occur from over-excavation.

E. Gravel Backfill: Place clean, crushed rock backfill in the excavation beneath the pool

and up the sides as specified in the Soil and Geologic Investigation.

F. Drainage Conduit: Provide for subsurface drainage to storm system.

3.3 TILE AT WATER LINE: Install with latex Portland cement mortar per ANSI 108.5.

3.4 PLASTER FOR INTERIOR SURFACES OF POOL: Trowel into the truing coat of the

rough gunite, float to a uniform plante, and trowel to a smooth, dense surface.

3.5 CLEAN-UP:

A. Keep all areas of work clean, neat and orderly at all times.

B. Upon completion of work, remove off the site all surplus materials, tools, equipment,

rubbish and debris resulting from the work area.

END OF SECTION 22 51 00

Westdale Euless SWIMMING POOL PLUMBING SYSTEMS

HEDK Project No. 22194 22 51 00 - 6 30 October 2023

You might also like

- Water Distribution System - 2Document6 pagesWater Distribution System - 2kkkhattabbbNo ratings yet

- Plan 1124 A 13205 Welded Steel TDocument7 pagesPlan 1124 A 13205 Welded Steel TneoNo ratings yet

- 2688 Water MainDocument10 pages2688 Water MainAnonymous NR3qZ30No ratings yet

- Domestic Water Filtration EquipmentDocument10 pagesDomestic Water Filtration EquipmentElie HajjNo ratings yet

- SECTION 13121 Fountains Part 1 - General 1.1Document6 pagesSECTION 13121 Fountains Part 1 - General 1.1garych72No ratings yet

- Plumbing Specs SampleDocument7 pagesPlumbing Specs SampleRichmond SyNo ratings yet

- SECTION 15061 Steel Pipe Specification - Transmission MainDocument9 pagesSECTION 15061 Steel Pipe Specification - Transmission MainMohammad AlizadehNo ratings yet

- Plumbing - Technical Specifications PDFDocument18 pagesPlumbing - Technical Specifications PDFEdzon LacayNo ratings yet

- Domestic Water SystemsDocument20 pagesDomestic Water Systemsabdullah sahibNo ratings yet

- Duct Silencers and Acoustic TreatmentDocument8 pagesDuct Silencers and Acoustic TreatmentShabbir WahabNo ratings yet

- Bolted Tank Specifications Final 11-5-15Document6 pagesBolted Tank Specifications Final 11-5-15Rodrigo ZapataNo ratings yet

- WTSPECSDocument6 pagesWTSPECSFawwaz KhanNo ratings yet

- SECTION 26 05 41 Underground Electrical ConstructionDocument11 pagesSECTION 26 05 41 Underground Electrical ConstructionEzana EzanaNo ratings yet

- 11 HazopDocument7 pages11 Hazopeladio30No ratings yet

- SECTION 15175 Swimming Pool Piping and Equipment General 1.1Document14 pagesSECTION 15175 Swimming Pool Piping and Equipment General 1.1fatREVITNo ratings yet

- 23 21 14 Hydronic SpecialtiesDocument7 pages23 21 14 Hydronic SpecialtiesSoumojit SamantaNo ratings yet

- SECTION 03300 Concrete: Hilltown Township Water and Sewer AuthorityDocument9 pagesSECTION 03300 Concrete: Hilltown Township Water and Sewer AuthoritybrentosjNo ratings yet

- Domestic Water PipingDocument13 pagesDomestic Water PipingEN LeedNo ratings yet

- Ccad-Aed-Sp - G-224000 - 0 - Plumbing FixturesDocument13 pagesCcad-Aed-Sp - G-224000 - 0 - Plumbing FixturesArun UdayabhanuNo ratings yet

- 34 REHAB OF LVP WATER TREATMENT - ContractorsDocument2 pages34 REHAB OF LVP WATER TREATMENT - ContractorsVianne MagsinoNo ratings yet

- UtilitiesDocument31 pagesUtilitiesjia wangNo ratings yet

- Section 21 13 00Document4 pagesSection 21 13 00Ismail MohammadNo ratings yet

- Technical Specification For PlumbingDocument4 pagesTechnical Specification For PlumbingJoeven JagocoyNo ratings yet

- Division 22: PlumbingDocument6 pagesDivision 22: PlumbingRaya VillafloresNo ratings yet

- 334100Document5 pages334100jia wangNo ratings yet

- PlumbingDocument10 pagesPlumbingAngemar Roquero Mirasol100% (2)

- Section 23 21 14 - Underground Pre-Insulated Hydronic PipingDocument7 pagesSection 23 21 14 - Underground Pre-Insulated Hydronic PipingaadsamudNo ratings yet

- Ductile Iron Pipe For Sewers 012221Document9 pagesDuctile Iron Pipe For Sewers 012221สุภรัตน์ จันทร์คุณาภาสNo ratings yet

- Plumbing SpecsDocument3 pagesPlumbing SpecsAngel NuevoNo ratings yet

- Public Water Well SpecificationsDocument5 pagesPublic Water Well SpecificationsSilvioCarrilloNo ratings yet

- Cable Trays For Electrical Systems-Rev05Document8 pagesCable Trays For Electrical Systems-Rev05Mohamed Hamed100% (1)

- 22 11 13 - Facility Water Distribution Piping PDFDocument11 pages22 11 13 - Facility Water Distribution Piping PDFmasoodaeNo ratings yet

- DLSUL ER - Specs - Plumbing - SanitaryDocument20 pagesDLSUL ER - Specs - Plumbing - SanitaryRyan BacalaNo ratings yet

- Specification Plumbing SystemDocument16 pagesSpecification Plumbing SystemGhiovani DayananNo ratings yet

- Division 22 - Plumbing Section 22 13 16 - Sanitary Waste and Vent PipingDocument8 pagesDivision 22 - Plumbing Section 22 13 16 - Sanitary Waste and Vent PipingAlexander MasongsongNo ratings yet

- QC911000-SLC-TEC-MTS-MEC-11A-Z00-00013 - uPVC Storm Water Drainage PipesDocument74 pagesQC911000-SLC-TEC-MTS-MEC-11A-Z00-00013 - uPVC Storm Water Drainage PipesriyasudheenmhNo ratings yet

- DLSUL UH - Specs - Plumbing - SanitaryDocument20 pagesDLSUL UH - Specs - Plumbing - SanitaryRyan BacalaNo ratings yet

- Plumbing - Specification 2011.Document8 pagesPlumbing - Specification 2011.Ponz MadianoNo ratings yet

- 857 Fiberglass Reinforced Pipe For Gravity Sanitary SewerDocument13 pages857 Fiberglass Reinforced Pipe For Gravity Sanitary Sewershahidy9211No ratings yet

- Appendix 6A: CSI Specifications For Cathodic ProtectionDocument25 pagesAppendix 6A: CSI Specifications For Cathodic Protectionzaheer ahamedNo ratings yet

- SECTION 26 05 36.26 Wireways For Radiology EquipmentDocument5 pagesSECTION 26 05 36.26 Wireways For Radiology EquipmentEzana EzanaNo ratings yet

- Electrical Surface RacewaysDocument4 pagesElectrical Surface RacewaysMohammed Hussain OMNo ratings yet

- SECTION 02605 Manholes: Part 1. GeneralDocument11 pagesSECTION 02605 Manholes: Part 1. GeneralDaniel KariukiNo ratings yet

- Project Standard Specification: Decorative Fountain 15495 - Page 1/7Document7 pagesProject Standard Specification: Decorative Fountain 15495 - Page 1/7adel rihanaNo ratings yet

- SPC Occ 221423 MeDocument4 pagesSPC Occ 221423 Metarekhisham1234No ratings yet

- 067 S 13200 Elevated Water Storage TankDocument7 pages067 S 13200 Elevated Water Storage TankAsep SuhermanNo ratings yet

- 33 16 13 - Ground Storage TanksDocument5 pages33 16 13 - Ground Storage TanksHizbar ArsjadNo ratings yet

- Precast Post Tentioned TanksDocument20 pagesPrecast Post Tentioned TanksMarcel SteoleaNo ratings yet

- DCS-026 DTD 08.08.10 Method Statement For Water Tank Walls Casting With BlockoutsDocument12 pagesDCS-026 DTD 08.08.10 Method Statement For Water Tank Walls Casting With Blockoutsmirza057No ratings yet

- Steel Pipe, CMLC - Rev 3-17Document18 pagesSteel Pipe, CMLC - Rev 3-17A T AlhershNo ratings yet

- SECTION 02200 EarthworksDocument8 pagesSECTION 02200 EarthworksStraus WaseemNo ratings yet

- Architectural SpecificationsDocument20 pagesArchitectural SpecificationsJulius Noe San PedroNo ratings yet

- 33 75 43.1 TND - 100MVAR ShuntDocument3 pages33 75 43.1 TND - 100MVAR Shuntnimaboat4589No ratings yet

- Plumbing Fixtures StandardDocument12 pagesPlumbing Fixtures StandardPamela Joyce MaddumaNo ratings yet

- (Expansion and Compression Tanks)Document3 pages(Expansion and Compression Tanks)Mostafa SalemNo ratings yet

- Irrigation System Specs - Rev.0.1Document26 pagesIrrigation System Specs - Rev.0.1muhammad.civilNo ratings yet

- Awwa d100 PotableDocument8 pagesAwwa d100 PotableOnatNo ratings yet

- E16050Document39 pagesE16050HOFFERNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Oxford Solutions Intermediate Cumulative Test Answer Keys ADocument5 pagesOxford Solutions Intermediate Cumulative Test Answer Keys AAleks50% (2)

- Internal Audit Checklist StoresDocument2 pagesInternal Audit Checklist Storesdhir.ankurNo ratings yet

- DC Que BankDocument11 pagesDC Que BankGaurav Kumbharde0% (1)

- Mathcad - 04-Loads On Structures (Case of One-Way Slabs)Document3 pagesMathcad - 04-Loads On Structures (Case of One-Way Slabs)MakaraSoyNo ratings yet

- Basics of Networking and RoutingDocument39 pagesBasics of Networking and RoutingSaurabh ShuklaNo ratings yet

- A Quick Tour of UK Census DataDocument22 pagesA Quick Tour of UK Census DataDave RawnsleyNo ratings yet

- SRN Raptakos PLANTDocument41 pagesSRN Raptakos PLANTscribd viewerNo ratings yet

- An Overview of LTE PositioningDocument12 pagesAn Overview of LTE PositioningJose Carlos Mendez PenaNo ratings yet

- Implementing Control Flow in An SSIS PackageDocument35 pagesImplementing Control Flow in An SSIS PackageRichie PooNo ratings yet

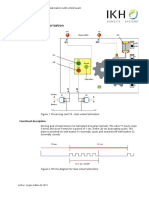

- Crush Knife Attachment - BG46Document19 pagesCrush Knife Attachment - BG46DeniMestiWidiantoNo ratings yet

- Bahan Ajar Genre of TextDocument112 pagesBahan Ajar Genre of Textokta anita pouwNo ratings yet

- Hikaru Nara (Your Lie in April) Sheet Music For Piano (Solo) Musescore - Com 3Document1 pageHikaru Nara (Your Lie in April) Sheet Music For Piano (Solo) Musescore - Com 3Jéssica E DiegoNo ratings yet

- Globalsat Gps Module: Hardware Data Sheet Product No: EM-506Document21 pagesGlobalsat Gps Module: Hardware Data Sheet Product No: EM-506Svaruu SectaNo ratings yet

- Standards For Email SecurityDocument2 pagesStandards For Email SecurityPeng GuinNo ratings yet

- 19 Gear Wheel Lubrication Solutuion ENGDocument3 pages19 Gear Wheel Lubrication Solutuion ENGhaftu gideyNo ratings yet

- LR Mate 100 Ibm ManualDocument144 pagesLR Mate 100 Ibm ManualManuel GutierrezNo ratings yet

- Magazine: Mcneel'S FL Ying CircusDocument36 pagesMagazine: Mcneel'S FL Ying CircusNoureddine SemaraNo ratings yet

- In-Flight Characterization of Image Spatial Quality Using Point Spread FunctionsDocument38 pagesIn-Flight Characterization of Image Spatial Quality Using Point Spread Functionssaritha K MenonNo ratings yet

- Using Digital and Ai To Meet The Energy Sectors Net Zero ChallengeDocument5 pagesUsing Digital and Ai To Meet The Energy Sectors Net Zero ChallengeLuciana BritoNo ratings yet

- DS5300Document4 pagesDS5300kishore kumarNo ratings yet

- Technical Support Engineer - JDDocument2 pagesTechnical Support Engineer - JDKshitiz SagarNo ratings yet

- Abouorban H Et Al GC 52 Delay Analysis PDFDocument11 pagesAbouorban H Et Al GC 52 Delay Analysis PDFvominhhuy100% (1)

- Aplikasi Alat Ukur Indeks Massa Tubuh Untuk Evaluasi Gizi Balita Berbasis AndroidDocument5 pagesAplikasi Alat Ukur Indeks Massa Tubuh Untuk Evaluasi Gizi Balita Berbasis Androidsri lestariNo ratings yet

- Manuale d'uso Direction for use Manuel d'instructions Bedienungsanleitung Manual de istrucciones Pуководство 潜水呼吸调节器使用手册Document54 pagesManuale d'uso Direction for use Manuel d'instructions Bedienungsanleitung Manual de istrucciones Pуководство 潜水呼吸调节器使用手册Алексей ШишкоNo ratings yet

- Excel Black Belt (Answers)Document54 pagesExcel Black Belt (Answers)21Y6C41 SHARMAINE SEET SHIENNo ratings yet

- SDM MCQ BankDocument87 pagesSDM MCQ BankRamkishan ShindeNo ratings yet

- Part A: ListeningDocument7 pagesPart A: ListeningTrần HuyềnNo ratings yet

- Topic 3 Slides - Demand ForecastingDocument28 pagesTopic 3 Slides - Demand ForecastingPetal RemonNo ratings yet

- Simple FM Walkie TalkieDocument4 pagesSimple FM Walkie TalkieNeo Mechatron0% (2)

- Fire Hazard QuizDocument1 pageFire Hazard QuizAna GreorNo ratings yet