Professional Documents

Culture Documents

Water Distribution System - 2

Uploaded by

kkkhattabbbOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Water Distribution System - 2

Uploaded by

kkkhattabbbCopyright:

Available Formats

Montgomery County Public Schools Facilities Guide

DIVISION 2 - SITE WORK

Conditions of Use/ Responsibility of Data

These “guideline” specifications are to be used by the A/E as a base document in the development

of project/site-specific Division 2 – SITE WORK specifications for Montgomery County Public

Schools Construction Projects. They may or may not be complete, correct and/or appropriate for

use for any given project. It is the responsibility of the A/E to review these “guideline” specifications

and to edit and/or supplement them as required to ensure that they represent the full, complete,

correct and code-compliant specifications required for all construction of the project to which they

apply. The use of these “guideline” specifications, and/or any information herein, in no way

releases the A/E from their Contractual responsibility to prepare and provide the full, complete and

correct code-compliant Contract documents, plans and/or specifications required for construction.

Review and editing of these “guideline” specifications shall be performed by appropriately licensed

Maryland professional engineer. Specifications are to be prepared in Microsoft Word, edited using

the “Track Changes” feature of that software and submitted to MCPS electronically on a compact

Disk for review.

SECTION 02226 – WATER DISTRIBUTION SYSTEM

PART 1 - GENERAL:

1.1 RELATED DOCUMENTS:

A. Drawings and general provisions of Contract, including General and Supplementary

Conditions, and Division 1, Specification Sections apply to work in this section.

1.2 DESCRIPTION OF WORK:

A. This section specifies materials and work required to construct water distribution system.

1.3 RELATED SECTIONS:

A. Refer to Section 02000 “Clearing”, Section 02100 “Earthwork and Grading” and Section

02200 "Utility Standards".

1.4 STANDARDS:

A. Washington Suburban Sanitary Commission's (WSSC) current "General Conditions and

Standard Specifications" and "Standard Details".

B. Washington Suburban Sanitary Commission's current "Regulations Governing Installation of

Plumbing and Sewer Cleaning in Washington Suburban Sanitary District".

C. Washington Suburban Sanitary Commission's current Plumbing and Gasfitting Regulation.

D. American Water Works Association (AWWA).

1.5 SUBMITTALS:

MCPS REV. 02.01.09 WATER DISTRIBUTION SYSTEM 02226 -1

A. Refer to Section 02200 "Utility Standards" and as noted.

B. Products: Submit product manufacturer's specifications and installation instructions and

certificates of compliance signed by Manufacturer and Contractor stating that products

comply with this specification to Architect. Certificates of compliance must be notarized,

signed by an officer of Manufacturer, and shall include WSSC Contract Number or On-site

number, job location, Contractor’s name, types, classes and strengths of pipe and fittings,

and Manufacturer’s name.

C. Submit As-built drawings to Architect.

D. Service Connection Permit: Contractor shall submit to Architect all items required by WSSC

to obtain a Service Connection Permit, including but not limited to: All required WSSC Bonds,

Letter indicating Utility Contractor, and Certificate of Insurance. Architect will obtain Service

Connection Permit once these items are received.

1.6 PRODUCT DELIVERY, STORAGE AND HANDLING:

A. Refer to Section 02200 "Utility Standards", and as noted.

1.7 PROJECT CONDITIONS:

A. Refer to Section 02200 "Utility Standards", and as noted.

B. Jurisdiction Standards: Site is located within WSSC jurisdiction. On-site fire hydrants shall be

"Supervised Fire Hydrants".

C. On-site construction and materials shall be in accordance with latest edition of WSSC

General Conditions and Standard Specifications, Design Manual, Standard Details and

Plumbing and Gasfitting Regulations.

1.8 CONSTRUCTION SURVEYS:

A. Provide survey equipment and qualified personnel for construction surveys. Provide

combined horizontal and vertical alignment stakes for system construction. Horizontal stake

interval to be 50 feet and at appurtenances (e.g. fittings, valves, etc.). Provide construction

cut sheet preparation as required.

1.9 SPECIAL INSPECTIONS, TESTING OBSERVATION AND CERTIFICATIONS:

A. Special utility inspections, testing observation and certifications are those services specifically

required by government agencies and/or utility purveyors, and that must be performed by

Engineer of Record.

B. WSSC ON-SITE WATER SYSTEM: In accordance with requirements and regulations of

Washington Suburban Sanitary Commission (WSSC), Owner has retained services of

Engineer of Record to provide following special inspection, testing observation and

certification services in connection with construction of WSSC On-Site water lines and

appurtenances.

1. Three (3) Three (3) hour inspection visits for on-site water line construction

2. One (1) Four (4) hour visit to observe mandatory 2- hour pressure test

3. Two (2) Three (3) hour inspection visits to observe construction of thrust blocking

4. One (1) time preparation of As-Built Drawings and Certifications, based-upon as-built

information and test result documentation provided by Contractor, to be performed upon

completion of construction and successful testing of WSSC On-Site Water and Sewer

lines and appurtenances.

MCPS REV. 02.01.09 WATER DISTRIBUTION SYSTEM 02226 -2

C. ADDITIONAL INSPECTIONS, OBSERVATIONS AND CERTIFICATIONS: It shall be

responsibility of Contractor to hire Engineer-of-Record to perform additional special

inspections, testing observations and certifications required beyond those specific services

identified herein as being provided by Owner.

PART 2 - PRODUCTS:

2.1 MATERIALS:

A. Materials shall be WSSC Standards and shall meet WSSC requirements indicated.

B. Valve Boxes: Cast iron two-piece valve boxes, screw type box, bell base section, 5-1/4 inch

shaft, round drop cover with "W" marking.

2.2 FIRE HYDRANTS:

A. WSSC Standard. Fire Hydrants shall be Supervised type hydrants. Provide all coordination,

materials and equipment necessary for the supervision system.

2.3 CONCRETE PADS: Class 'A' Portland cement.

2.4 CONCRETE ANCHORS: WSSC Standards indicated and specified. Class 'A' Portland cement

concrete, Section 02200 "Utility Standards".

2.5 STRAPS AND RODS:

A. Clamps, Straps and Washers: Steel, ASTM A 506.

B. Rods: Steel, ASTM A 575.

C. Rod Couplings: Malleable-Iron, ASTM A 197

D. Bolts: Steel, ASTM A 307

E. Cast-Iron Washers: Gray-iron, ASTM A 126

2.6 MISCELLANEOUS PRODUCTS:

A. Underground Identification Tape: Manufactured by Allen Systems, Houston, Texas.

1. Type: “Markline”.

2. Color: Precaution Blue.

3. Legend: Caution water line buried below.

4. Tape Width: Three inches.

B. Disinfection Products: W.S.S.C. standards indicated and specified. For continuous feed

disinfection method, use Calcium Hypochlorite: AWWA B 300, granular form.

1. Contractor's Option: AWWA B 301 Liquid Chlorine.

2. Contractor's Option: AWWA B 303 Sodium Chloride.

3. Water: Potable.

PART 3 - EXECUTION:

3.1 PROTECTION AND RESTORATION:

MCPS REV. 02.01.09 WATER DISTRIBUTION SYSTEM 02226 -3

A. Refer to Section 02200 "Utility Standards".

3.2 DEWATERING, EXCAVATION, OVER-EXCAVATION AND UNSUITABLE EARTH:

A. Refer to Section 02200 "Utility Standards".

3.3 PIPE:

A. General:

1. Install in accordance with pipe manufacturer's installation instructions, WSSC

standards and requirements and as noted.

2. Inspect each pipe laying length, pipe joint materials and fittings for defects. Remove

defective products from project site. Install pipe to horizontal and vertical alignment

indicated. Place fittings at changes in horizontal and vertical alignment as indicated.

Construct concrete anchors at each fitting as indicated. Place concrete to permit

access to joints for inspection and maintenance. Apply liberal coat of coal tar pitch to

exposed steel and hardware. Field cut pipe only where required to complete

closures or to install fittings, valves or fire protection equipment. Cut pipe to smooth

square end with equipment designed for cutting pipe.

B. Ductile Iron Pipe:

1. Install pipe in accordance with AWWA C 600 and as noted.

2. Install with bell ends facing in direction of laying operations. Begin installation of

pipe, with vertical gradient exceeding 10 percent, at lowest elevation and proceed

upgrade. Place identifying mark on pipe not provided with spigot depth mark. Clean

interior and exterior surfaces of bell and spigot removing oil, grit, excess coating and

foreign matter. Lubricate pipe ends and gasket in accordance with pipe

manufacturer's instruction.

C. Ductile Iron Push-On Pipe: Position each laying length in previously installed pipe and push

or pull joint tightly together with mechanical device designed for pipe jointing. Grind or file

spigot end of field cut pipe to resemble manufactured spigot end. Place spigot identifying

depth mark as specified. Pipe joint deflection not to exceed the limits specified in Table 2,

AWWA C 655.

3.4 BURIED VALVES:

A. Install valves in accordance with valve manufacturer's installation instructions, and WSSC

requirements.

3.5 FIRE HYDRANTS:

A. General: Install fire hydrants at locations indicated, in accordance with AWWA M17

"Installation, Operation and Maintenance of Fire Hydrants", manufacturer's installation

instructions, and WSSC standards and requirements.

B. On-site fire hydrants installed within WSSC jurisdiction shall be "Supervised Fire Hydrants".

Contractor shall be responsible for coordinating fire hydrant acquisition and installation with a

WSSC approved monitoring company. Contractor shall also coordinate installation with

mechanical and electrical Contractors for required connections, panels or power supplies.

Required monitoring equipment, connections, power supplies, testing and incidentals shall be

provided, at no increase to the Contract Sum, for a completed and approved monitoring

system.

MCPS REV. 02.01.09 WATER DISTRIBUTION SYSTEM 02226 -4

3.6 BACKFILL:

A. Refer to Section 02200 "Utility Standards" and as noted.

B. Water mains 4-inches and larger must be inspected by Engineer of Record prior to

completion of backfill operations. Contractor shall provide a minimum of 48 hours notice to

Engineer of Record before completion of backfill operations.

C. Valve Box Installation: Install valve box for each buried gate valve during backfill operations.

Install boxes to prevent shock or stress transmission to valves or pipe and center over valve

operating nut plumb to 1/4 inch in five feet. Adjust box cover flush to finished grade.

D. Underground Identification Tape: Install tape during backfill operations. Tape shall be

centered over pipe, located 24 inches below finished grade.

3.7 SYSTEM TESTING:

A. General: Provide materials, equipment (e.g. pumps, gauges, etc.) and labor required to test

system. Do not conduct tests until concrete anchors cure and set seven calendar days.

Provide a minimum of 48 hours notification of planned testing. Test observation by Architect

and local governing water authority personnel. Test system in accordance with AWWA C 600

and as noted.

B. Hydrostatic Pressure Tests: Conduct hydrostatic pressure tests, upon completion of Phase I

backfill operations. Fill systems or valved section of system with water. Expel air from pipe.

Slowly apply test pressure. Test pressure as shown on the approved drawings. Test

duration to be two hours. Test pressure shall not vary more than +5 psi for the duration of the

test. Examine system joints. Correct defective products or improper system installation as

directed by Architect and local governing water authority personnel.

C. Hydrostatic Leakage Tests: Conduct hydrostatic leakage tests upon completion of Phase II

backfill operations. Test procedure as specified for hydrostatic pressure tests, except as

noted. Test pressure @ 110 PSI. Test duration 24 hours. Allowable leakage for ductile iron

pipe is not to exceed the limits specified in Table 3, AWWA C 600. Correct system installation

exceeding allowable leakage specified as directed by Architect and local governing water

authority personnel.

3.8 INSPECTION AND CERTIFICATION:

A. Retain services of a Maryland-Registered Professional Engineer for inspection of system

construction and certification that system complies with standards specified. In accordance

with the requirements on the approved WSSC drawings, inspecting engineer must be

engineer of record for approved WSSC drawings.

3.9 SYSTEM DISINFECTION:

A. Disinfect system in accordance with AWWA C 651, W.S.S.C. standards specified, and as

noted. Provide materials, equipment (e.g. pumps, etc.) and labor required to disinfect

system.

B. Disinfection Method: Continuous feed.

1. Preliminary and final flushing velocity to be 2.5 fps. Solution concentration as

specified. Maintain 50 MG/L available chlorine during 24-hour disinfection period.

Bacteriologic test interval every six hours. Flushing and drainage locations where

directed by Owner's Representative.

MCPS REV. 02.01.09 WATER DISTRIBUTION SYSTEM 02226 -5

3.10 DISINFECTION TESTING:

A. Conduct chlorine residual tests upon completion of final flushing operations. Repeat

disinfection operation until satisfactory chlorine residual quality tests are obtained.

3.11 WATER BACTERIOLOGIC QUALITY TESTING:

A. Retain services of an independent testing laboratory to conduct water bacteriologic quality

testing.

B. Provide test on main waterline, if branch from the mainline is greater than 50’ long, provide

additional testing on said line.

3.12 CERTIFICATIONS, INSPECTIONS AND AS-BUILT DOCUMENTS: Contractor shall provide "as-built"

plans of on-site water system by a State of Maryland Licensed Surveyor, or Professional Engineer.

Contractor shall notify Architect within 15 calendar days of Contract signature, the name of Licensed

Surveyor or Registered P.E. who will certify as-built water plan. Show any changes and include ties

for location of valves, bends, manholes, fire hydrants, and laterals accompanied by qualifying test

date and certification of compliance. See Division One “Project Record Documents” for format of “as-

built” drawings.

END OF SECTION

MCPS REV. 02.01.09 WATER DISTRIBUTION SYSTEM 02226 -6

You might also like

- SECTION 15061 Steel Pipe Specification - Transmission MainDocument9 pagesSECTION 15061 Steel Pipe Specification - Transmission MainMohammad AlizadehNo ratings yet

- Swimming Pool Plumbing SystemsDocument6 pagesSwimming Pool Plumbing SystemschampionaquaticNo ratings yet

- Steel Pipe, CMLC - Rev 3-17Document18 pagesSteel Pipe, CMLC - Rev 3-17A T AlhershNo ratings yet

- (0018) 2.3 - SteelWaterPipe - Aug2011Document14 pages(0018) 2.3 - SteelWaterPipe - Aug2011Sixto Gerardo Oña AnaguanoNo ratings yet

- Ductile Iron Pipe For Sewers 012221Document9 pagesDuctile Iron Pipe For Sewers 012221สุภรัตน์ จันทร์คุณาภาสNo ratings yet

- 33 330000 CFRST UtilitiesDocument11 pages33 330000 CFRST UtilitiesYueying LINo ratings yet

- CS Tec 2004 336321 Direct Buried Steam and Condensate Utility DistributionDocument9 pagesCS Tec 2004 336321 Direct Buried Steam and Condensate Utility DistributionOsamah AlzubadiNo ratings yet

- 07-Division 2-Section 02206 VC Pipelines-Version 2.0Document9 pages07-Division 2-Section 02206 VC Pipelines-Version 2.0Avaan IvaanNo ratings yet

- Domestic Water SystemsDocument20 pagesDomestic Water Systemsabdullah sahibNo ratings yet

- 26 2413 Main Distribution Board PDFDocument18 pages26 2413 Main Distribution Board PDFMena Amir KhairyNo ratings yet

- This Product Masterspec Section Modifies The Original Masterspec Text, and Does Not Include The Full Content of The Original Masterspec SectionDocument32 pagesThis Product Masterspec Section Modifies The Original Masterspec Text, and Does Not Include The Full Content of The Original Masterspec Sectionabdullah sahibNo ratings yet

- SECTION 13121 Fountains Part 1 - General 1.1Document6 pagesSECTION 13121 Fountains Part 1 - General 1.1garych72No ratings yet

- Central Business District CBD EAST - Phase 1 of The New Administrative CapitalDocument20 pagesCentral Business District CBD EAST - Phase 1 of The New Administrative CapitalLi LiuNo ratings yet

- 315000Document4 pages315000Raul AtencioNo ratings yet

- Plumbing Specs SampleDocument7 pagesPlumbing Specs SampleRichmond SyNo ratings yet

- 2.1. Concrete Mix For StormwaterDocument11 pages2.1. Concrete Mix For StormwaterKrishna SankarNo ratings yet

- Section - Multi-Column Elevated Water Storage TankDocument6 pagesSection - Multi-Column Elevated Water Storage Tankali gholiaNo ratings yet

- Pipeline Testing and DisinfectionDocument10 pagesPipeline Testing and DisinfectionWayjantha Sunethra Bandara JayawardhanaNo ratings yet

- Section 02815 FountainsDocument8 pagesSection 02815 FountainsMØhãmmed ØwięsNo ratings yet

- Plan 1124 A 13205 Welded Steel TDocument7 pagesPlan 1124 A 13205 Welded Steel TneoNo ratings yet

- Ccad-Aed-Sp - G-224000 - 0 - Plumbing FixturesDocument13 pagesCcad-Aed-Sp - G-224000 - 0 - Plumbing FixturesArun UdayabhanuNo ratings yet

- Seismic Requirements - MSTDocument4 pagesSeismic Requirements - MSTwafikmh4No ratings yet

- Pipeline-Testing-and-Disinfection AWWA B300Document10 pagesPipeline-Testing-and-Disinfection AWWA B300Jason Angel BuñagNo ratings yet

- AWWA C 204 Mortar Lined MS PipeDocument19 pagesAWWA C 204 Mortar Lined MS PipeAnonymous D66WHl100% (1)

- Busway Specs Section 16450Document10 pagesBusway Specs Section 16450ehteshamNo ratings yet

- 334100Document5 pages334100jia wangNo ratings yet

- 02450-Final 06 01 2017Document14 pages02450-Final 06 01 2017Y.EbadiNo ratings yet

- Precast Post Tentioned TanksDocument20 pagesPrecast Post Tentioned TanksMarcel SteoleaNo ratings yet

- 57 - Water Lines Sewage and ChannelingDocument24 pages57 - Water Lines Sewage and ChannelingTemur LomidzeNo ratings yet

- 05 - 12 - 00 - 00 (05120) - Steel FramingDocument12 pages05 - 12 - 00 - 00 (05120) - Steel FramingMatthew Ho Choon LimNo ratings yet

- Section 02651 - Steel Pipe, Lined and Coated City of San Diego, CWP GuidelinesDocument23 pagesSection 02651 - Steel Pipe, Lined and Coated City of San Diego, CWP GuidelinesMohammed HarrisNo ratings yet

- 05450-Pre Engineered Metal TrussesDocument4 pages05450-Pre Engineered Metal TrussesRamsey RasmeyNo ratings yet

- Pipe and Tube RailingsDocument10 pagesPipe and Tube RailingssobhiNo ratings yet

- (Expansion Fittings and Loops For Hvac Piping)Document2 pages(Expansion Fittings and Loops For Hvac Piping)Mostafa SalemNo ratings yet

- Duct Silencers and Acoustic TreatmentDocument8 pagesDuct Silencers and Acoustic TreatmentShabbir WahabNo ratings yet

- Pre-Fabricated Bridge - MSTDocument12 pagesPre-Fabricated Bridge - MSTwafikmh4No ratings yet

- Civil - Technical SpecificationsDocument28 pagesCivil - Technical SpecificationskhalidNo ratings yet

- Swimming Pool SystemDocument22 pagesSwimming Pool Systemanaseid977No ratings yet

- 10-Division 2-Section 02230 DI Pipelines-Version 2.0Document10 pages10-Division 2-Section 02230 DI Pipelines-Version 2.0Avaan IvaanNo ratings yet

- Fire-Suppression StandpipesDocument11 pagesFire-Suppression StandpipesAlaa FouaniNo ratings yet

- Irrigation System Specs - Rev.0.1Document26 pagesIrrigation System Specs - Rev.0.1muhammad.civilNo ratings yet

- Ccad-Aed-Sp - G-223229 - 0 - Limestone Contactor Treatment SystemDocument17 pagesCcad-Aed-Sp - G-223229 - 0 - Limestone Contactor Treatment SystemArun UdayabhanuNo ratings yet

- Domestic Water PipingDocument13 pagesDomestic Water PipingEN LeedNo ratings yet

- 05120-Structural SteelDocument10 pages05120-Structural SteelHusen ZahranNo ratings yet

- E16406Document11 pagesE16406HOFFERNo ratings yet

- 857 Fiberglass Reinforced Pipe For Gravity Sanitary SewerDocument13 pages857 Fiberglass Reinforced Pipe For Gravity Sanitary Sewershahidy9211No ratings yet

- Division 22 - Plumbing Section 22 13 16 - Sanitary Waste and Vent PipingDocument8 pagesDivision 22 - Plumbing Section 22 13 16 - Sanitary Waste and Vent PipingAlexander MasongsongNo ratings yet

- Specification For The Use of Steel Tanks in The Water Industry PDFDocument15 pagesSpecification For The Use of Steel Tanks in The Water Industry PDFJorge Alberto Martinez OrtizNo ratings yet

- Plumbing - Technical Specifications PDFDocument18 pagesPlumbing - Technical Specifications PDFEdzon LacayNo ratings yet

- Cable Trays For Electrical Systems-Rev05Document8 pagesCable Trays For Electrical Systems-Rev05Mohamed Hamed100% (1)

- 06-Division 2-Section 02205 uPVC Pipelines-Version 2.0Document16 pages06-Division 2-Section 02205 uPVC Pipelines-Version 2.0Avaan Ivaan100% (1)

- W C Ss 011Document15 pagesW C Ss 011VasatoreNo ratings yet

- Rubber Gasket TypesDocument92 pagesRubber Gasket Typessushant_moreyNo ratings yet

- Page 2 From 33 01 10.54 - CLEANING WATER UTILITY PIPING - Rev00Document1 pagePage 2 From 33 01 10.54 - CLEANING WATER UTILITY PIPING - Rev00Riaz AhmadNo ratings yet

- 12-Division 2-Section 02400 Pipeline by NDM-V 2.0Document26 pages12-Division 2-Section 02400 Pipeline by NDM-V 2.0Avaan IvaanNo ratings yet

- Secondary IrrigationDocument49 pagesSecondary IrrigationNijasNo ratings yet

- SPEC 262416 PanelboardsDocument7 pagesSPEC 262416 Panelboardsabdulbasit88No ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- Process Calculation-Rev0Document15 pagesProcess Calculation-Rev0kkkhattabbbNo ratings yet

- Civil Sheet3Document1 pageCivil Sheet3kkkhattabbbNo ratings yet

- BP Comatrol-137oct2020Document1 pageBP Comatrol-137oct2020kkkhattabbbNo ratings yet

- 002-RTK-A-005-03-XX-001 - Leasing Plan - RoofDocument1 page002-RTK-A-005-03-XX-001 - Leasing Plan - RoofkkkhattabbbNo ratings yet

- Comatrol Distributor Letter 2020Document1 pageComatrol Distributor Letter 2020kkkhattabbbNo ratings yet

- Civil Sheet3Document1 pageCivil Sheet3kkkhattabbbNo ratings yet

- STD 15144Document4 pagesSTD 15144kkkhattabbbNo ratings yet

- Types of CCTV Cameras - The Complete Guide - BusinessWatchDocument12 pagesTypes of CCTV Cameras - The Complete Guide - BusinessWatchkkkhattabbbNo ratings yet

- Football Fields 2002mar12Document3 pagesFootball Fields 2002mar12kkkhattabbbNo ratings yet

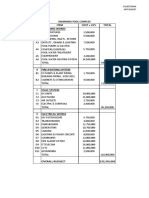

- Complex Swimming Pool - Mep Estimated Budget BoqDocument1 pageComplex Swimming Pool - Mep Estimated Budget BoqkkkhattabbbNo ratings yet

- Ismaeilia BattleDocument1 pageIsmaeilia BattlekkkhattabbbNo ratings yet

- Individual Room Control Applications IntroductionDocument12 pagesIndividual Room Control Applications IntroductionkkkhattabbbNo ratings yet

- POWER CONSUMPTION Young1991Document9 pagesPOWER CONSUMPTION Young1991kkkhattabbbNo ratings yet

- Pricing CriteriaDocument6 pagesPricing CriteriakkkhattabbbNo ratings yet

- Admin Pricing CriteriaDocument1 pageAdmin Pricing CriteriakkkhattabbbNo ratings yet

- MCCB PricingDocument15 pagesMCCB PricingkkkhattabbbNo ratings yet

- Pricing#6 6 11Document1 pagePricing#6 6 11kkkhattabbbNo ratings yet

- Fuller Factory#PricingDocument39 pagesFuller Factory#PricingkkkhattabbbNo ratings yet

- RES To GENSET Material Submittal-KDocument35 pagesRES To GENSET Material Submittal-KkkkhattabbbNo ratings yet

- Oasis PricingDocument1 pageOasis PricingkkkhattabbbNo ratings yet

- BIC Infra Package Pricing Rev.1Document10 pagesBIC Infra Package Pricing Rev.1kkkhattabbbNo ratings yet

- Cable List Buyer Scope# QTY Is 120KDocument191 pagesCable List Buyer Scope# QTY Is 120KkkkhattabbbNo ratings yet

- General Warehouses Pricing CriteriaDocument1 pageGeneral Warehouses Pricing CriteriakkkhattabbbNo ratings yet

- Eni - Iraq Zubair Oil Field Development ProjectDocument4 pagesEni - Iraq Zubair Oil Field Development ProjectkkkhattabbbNo ratings yet

- Pool GuttersDocument1 pagePool GutterskkkhattabbbNo ratings yet

- Humidity ControlDocument22 pagesHumidity ControlkkkhattabbbNo ratings yet

- Filter Mounting Bank: For Particulate or Activated Carbon FiltersDocument6 pagesFilter Mounting Bank: For Particulate or Activated Carbon FilterskkkhattabbbNo ratings yet

- Readme For Launching Pipe2020Document1 pageReadme For Launching Pipe2020kkkhattabbbNo ratings yet

- Pool Design Requirements 25m by 6 LanesDocument5 pagesPool Design Requirements 25m by 6 LanesMarkClancyNo ratings yet

- RS485, RS232, RS422, RS423, Quick Reference GuideDocument3 pagesRS485, RS232, RS422, RS423, Quick Reference GuideTito HassanNo ratings yet

- PendahuluanDocument25 pagesPendahuluanLand RoamNo ratings yet

- Biology - Pond Water LabDocument4 pagesBiology - Pond Water LabAngela CuiNo ratings yet

- DPR - Preparation DataDocument12 pagesDPR - Preparation DataBalakumaran GunasekaranNo ratings yet

- (Compare Report) SAES-A-401Document42 pages(Compare Report) SAES-A-401kartik_harwani43870% (1)

- FloodDocument11 pagesFlooddgNo ratings yet

- State Power 7-3Document138 pagesState Power 7-3gauravee1No ratings yet

- Uncensored Adam and Eve StoryDocument196 pagesUncensored Adam and Eve Storymary6jones-687% (70)

- Module 6 AssignmentDocument2 pagesModule 6 AssignmentdaryllNo ratings yet

- LS 924 eHTX Separator BrochureDocument6 pagesLS 924 eHTX Separator BrochureLucius VorenusNo ratings yet

- Works Manual: Indian RailwaysDocument219 pagesWorks Manual: Indian RailwaysAmitabh SharmaNo ratings yet

- Jomo Kenyatta University of Agriculture and TechnologyDocument19 pagesJomo Kenyatta University of Agriculture and TechnologyMohd Afiq AminNo ratings yet

- Hydro and Geochemical Characteristics of Ground Water Assessment in Puducherry Coastal Stretch, Puducherry RegionDocument11 pagesHydro and Geochemical Characteristics of Ground Water Assessment in Puducherry Coastal Stretch, Puducherry RegionIJRASETPublicationsNo ratings yet

- Safety Data SheetDocument7 pagesSafety Data SheetJivendra KumarNo ratings yet

- Environmental Management Plan Sample2Document9 pagesEnvironmental Management Plan Sample2Besim Ufuk Balcı0% (1)

- Projects - PIDA PAP2 APPROVEDDocument7 pagesProjects - PIDA PAP2 APPROVEDDinesh BabuNo ratings yet

- EA wAnswers-ESDocument2 pagesEA wAnswers-ESchristine bautistaNo ratings yet

- Thesis On Wastewater ManagementDocument7 pagesThesis On Wastewater Managementamybakewellfargo100% (2)

- bd600 PDFDocument4 pagesbd600 PDFkakaNo ratings yet

- Ecological SuccessionDocument14 pagesEcological Successionanjuanjutti03No ratings yet

- Tutorial and Practice ProblemsDocument4 pagesTutorial and Practice ProblemsPranshul SesmaNo ratings yet

- DeChinhThuc AnhChuyenDocument11 pagesDeChinhThuc AnhChuyenSon HoangNo ratings yet

- Analysis of GRIHA Certified BuildingsDocument26 pagesAnalysis of GRIHA Certified BuildingsAnshul Sharma100% (7)

- November 2021 Ce Board Exam Tuzon 6: Eview NnovationsDocument3 pagesNovember 2021 Ce Board Exam Tuzon 6: Eview NnovationsamberNo ratings yet

- HydroDocument16 pagesHydroKemal Al ZaroNo ratings yet

- Asae Surface Irrigation Systems Chapter 14 PDFDocument33 pagesAsae Surface Irrigation Systems Chapter 14 PDFZIGAMENo ratings yet

- Spotcheckskl SP Aerosolenukclpghssds2018!10!31Document7 pagesSpotcheckskl SP Aerosolenukclpghssds2018!10!31Thomas SchotsNo ratings yet

- Fire Flow / Water Supply General Requirements: (In Uncorpiorated Areas of Stanislaus CountyDocument2 pagesFire Flow / Water Supply General Requirements: (In Uncorpiorated Areas of Stanislaus CountyBenouna FertNo ratings yet

- Geography SBA 2Document11 pagesGeography SBA 2Rayanna JeffreyNo ratings yet

- 5 Factors To Consider in Foundation DesignDocument25 pages5 Factors To Consider in Foundation DesignMotamed Ben TaherNo ratings yet

- 6129-206 Sanitation Systems Version ADocument14 pages6129-206 Sanitation Systems Version AP_DaviesNo ratings yet