Professional Documents

Culture Documents

Emat Pipeline Inspection.5205126

Uploaded by

Ramadhan Prakoso0 ratings0% found this document useful (0 votes)

7 views1 pageOriginal Title

Emat_Pipeline_Inspection.5205126

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views1 pageEmat Pipeline Inspection.5205126

Uploaded by

Ramadhan PrakosoCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

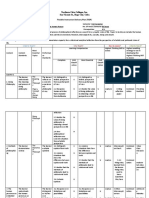

Emat Pipeline Inspection

Electro-Magnetic Acoustic Transducer

• EMAT requires no couplant and uses guided

waves to perform rapid, volumetric inspection Ideally suited for

for detection of pitting and wall loss. Under Support

• This system is set up for piping 6”–42” O.D. Corrosion detection.

and .150”-.750” wall.

• Supports Axial and Circ. scanning modes using

either Pulsed or Permanent magnets.

• Provides A, B & C Scan displays with real time

analysis Determination….EMAT Screening Tool

• At 6” per second, the EMAT pipe scanner will A very reliable method for:

cover 360° of the pipe, identifying internal and • High Speed and linear footage coverage (1000’ – 2000’ per/d)

external corrosion as well as other conditions • Evaluation of corrosion under supports

• Ability to scan through diamond wrap coating • Immediate AUT and / or MUT prove up

making it possible to inspect for damage • Producing ONSITE final report to client

under the coating. • Data is archived for comparison and repeat exams

• Focus on un-insulated piping for best applications

• Long runs for Full-Body scans

• Promote as a screening tool…but have the prove up tools

EMAT Versus Other Methods

• Greater detection capability for internal conditions that could be

missed with conventional UT including ‘under deposit corrosion’

• A bit more sensitive to corrosion under support than most other

guided wave applications.

• Another opnion for “soil-to-air” interface areas rather than

digging them up.

• Enhanced Screening Productivity combined with immediate

follow up.

You might also like

- EMAT Inspection Services PDFDocument1 pageEMAT Inspection Services PDFCepi Sindang KamulanNo ratings yet

- Andt Thank AlgerieDocument28 pagesAndt Thank AlgerieChristian BarNo ratings yet

- CorrosionDocument5 pagesCorrosionTHIRU.SNo ratings yet

- 2021-02-23 ICorr Aberdeen Event - Robert Hardy of Tracerco - Delivering Real Time Monitoring of Subsea PipelinesDocument37 pages2021-02-23 ICorr Aberdeen Event - Robert Hardy of Tracerco - Delivering Real Time Monitoring of Subsea PipelineshamidrezaettelaieNo ratings yet

- TSC - Product, AmigoDocument4 pagesTSC - Product, AmigoHUGO COLORADONo ratings yet

- Applus+K2 - CHIME and CUPSDocument1 pageApplus+K2 - CHIME and CUPSGistek MarcoNo ratings yet

- Applus+K2 - Phased Array UT (PAUT)Document3 pagesApplus+K2 - Phased Array UT (PAUT)Gistek MarcoNo ratings yet

- Automated Ultrasonic InspectionDocument2 pagesAutomated Ultrasonic InspectionSatya Rao100% (1)

- 2020-11-10 Sensorlink Topside v2Document18 pages2020-11-10 Sensorlink Topside v2Paresh TadasNo ratings yet

- Nondestructive Examination - 2013Document97 pagesNondestructive Examination - 2013Armadi Putra100% (1)

- LORUS (Onstream)Document2 pagesLORUS (Onstream)ichwanNo ratings yet

- Non Destructive TestingDocument19 pagesNon Destructive TestingMustafa YıldızNo ratings yet

- QSonic Brochure 209Document12 pagesQSonic Brochure 209Anish DonaldNo ratings yet

- Family of Tofd Products: CEN/TS 14751:2004 Compliant EN 5836:2000 CompliantDocument11 pagesFamily of Tofd Products: CEN/TS 14751:2004 Compliant EN 5836:2000 CompliantHermann LeonardoNo ratings yet

- Application NoteHow To Better Detect Corrosion in Pipe ElbowsDocument2 pagesApplication NoteHow To Better Detect Corrosion in Pipe ElbowsMarciel AmorimNo ratings yet

- Overcoming Heavy Bore Restrictions Case Study LTR Rev.05 15 WebDocument2 pagesOvercoming Heavy Bore Restrictions Case Study LTR Rev.05 15 WebtugrulNo ratings yet

- Mentor 245086489Document5 pagesMentor 245086489Paris KokNo ratings yet

- Non Destructive Testing: Principal Features of The Main NDT MethodsDocument48 pagesNon Destructive Testing: Principal Features of The Main NDT MethodsdayalramNo ratings yet

- Ect, Eca, NFT, RFT, Iris: ApplicationsDocument2 pagesEct, Eca, NFT, RFT, Iris: ApplicationsGistek MarcoNo ratings yet

- FM5178R6 TBM Series EnglishDocument2 pagesFM5178R6 TBM Series EnglishalejgonzNo ratings yet

- TSC - Technical Info, ACFM and Tank Floor Weld InspectionDocument2 pagesTSC - Technical Info, ACFM and Tank Floor Weld InspectionhcmcrlhoNo ratings yet

- Tube Inspection A4Document2 pagesTube Inspection A4Cepi Sindang KamulanNo ratings yet

- Brochure Ceta S 1Document2 pagesBrochure Ceta S 1Enrique AntonioNo ratings yet

- Reformer Care Solutions Brochure A4 Rev.05 15 WebDocument4 pagesReformer Care Solutions Brochure A4 Rev.05 15 WebtugrulNo ratings yet

- Catalogo - Hamerlinevalve (Óculos)Document12 pagesCatalogo - Hamerlinevalve (Óculos)pedroNo ratings yet

- White Paper Automated Ultrasonic Inspection of Tube To Tube Sheet WeldsDocument7 pagesWhite Paper Automated Ultrasonic Inspection of Tube To Tube Sheet WeldsdanemsalNo ratings yet

- Datasheet Codeline OCTA 80S Series PDFDocument4 pagesDatasheet Codeline OCTA 80S Series PDFlordsethdarknessNo ratings yet

- Asd 640Document2 pagesAsd 640RICHI100% (1)

- SEN5226 A4 EnviroSCAN ProductBrochure 4LR FINALDocument2 pagesSEN5226 A4 EnviroSCAN ProductBrochure 4LR FINALDaniel SloczynskiNo ratings yet

- E03f PDFDocument62 pagesE03f PDFYuniar SyahadhatinNo ratings yet

- Fired Heater Solutions A4 Rev.05 15 WebDocument6 pagesFired Heater Solutions A4 Rev.05 15 WebtugrulNo ratings yet

- Ultrasonic Flaw Detectors (Ufds)Document8 pagesUltrasonic Flaw Detectors (Ufds)api-26788960No ratings yet

- Ultrasonic Testing of 125Mm Apfsds/T PenetratorDocument11 pagesUltrasonic Testing of 125Mm Apfsds/T PenetratorBilal AhmedNo ratings yet

- SmartPlugIsolationTechnology Brochure LTR 052014 Web OptDocument5 pagesSmartPlugIsolationTechnology Brochure LTR 052014 Web OptMORELLI silvioNo ratings yet

- Process Piping Solutions Brochure A4 Rev.07 15 WebDocument4 pagesProcess Piping Solutions Brochure A4 Rev.07 15 WebtugrulNo ratings yet

- Brochure Adv NDT - ProminentDocument3 pagesBrochure Adv NDT - ProminentRizki YudaNo ratings yet

- 3000 GroundingDocument36 pages3000 GroundingHenwi Adi CahyoNo ratings yet

- SmartPlug Isolation Tool BrochureDocument6 pagesSmartPlug Isolation Tool BrochureFaisal AwanNo ratings yet

- Honeywell SensePoint XCDDocument8 pagesHoneywell SensePoint XCDAhmed Ayman HassaneenNo ratings yet

- N116 Tank Inspection 208 PDFDocument2 pagesN116 Tank Inspection 208 PDFAylin Salgado AvilaNo ratings yet

- Soil Research Equipment BrochureDocument9 pagesSoil Research Equipment Brochureluis norabuenaNo ratings yet

- Specialty ConnectorsDocument62 pagesSpecialty ConnectorsLuis David Concha CastilloNo ratings yet

- Specialty ConnectorsDocument62 pagesSpecialty ConnectorsjdmacbookNo ratings yet

- Alternating Current Field Measurement Level 1 Course (ACFM L1)Document357 pagesAlternating Current Field Measurement Level 1 Course (ACFM L1)susheel100% (2)

- Lyft - Pulsed Eddy CurrentDocument8 pagesLyft - Pulsed Eddy CurrentRicardoNo ratings yet

- Sensepoint XCD BrochureDocument4 pagesSensepoint XCD BrochureHSE btlpgarsrNo ratings yet

- Teletest Focus Case StudiesDocument55 pagesTeletest Focus Case StudiesPradeepNo ratings yet

- Lasair III 110 - ManualDocument2 pagesLasair III 110 - ManualCaleb SpiderNo ratings yet

- Vestera Mini ROV 2019Document36 pagesVestera Mini ROV 2019Ahmad ImranNo ratings yet

- Non - Destructive TestingDocument28 pagesNon - Destructive TestingPhilip PanaNo ratings yet

- 20200302roof Leak Detectors BrochureDocument2 pages20200302roof Leak Detectors BrochureFabian Vasquez PadillaNo ratings yet

- 2A1 - CMS Capabilites - Daryl Hickey - 14 June 2021Document16 pages2A1 - CMS Capabilites - Daryl Hickey - 14 June 2021dileepaNo ratings yet

- Dry Cross-Cut Sampling Solutions: Your Specialist in Process EquipmentDocument6 pagesDry Cross-Cut Sampling Solutions: Your Specialist in Process EquipmenttounsiNo ratings yet

- GREENLEE OTDR - DatasheetDocument4 pagesGREENLEE OTDR - DatasheetCovei GabrielNo ratings yet

- Phased Array Ultrasonic Testing: Inspection ServicesDocument19 pagesPhased Array Ultrasonic Testing: Inspection ServicesAnkur desaiNo ratings yet

- Piping Vibration Screening - WoodDocument2 pagesPiping Vibration Screening - WoodAbbas Al MisbahNo ratings yet

- Dacon PAUT PresentationDocument20 pagesDacon PAUT Presentationbacabacabaca100% (1)

- MEC-Floorscanners: Storage Tank InspectionDocument3 pagesMEC-Floorscanners: Storage Tank InspectionReadersmoNo ratings yet

- Eddy Current White PaperDocument25 pagesEddy Current White PapervrapciudorianNo ratings yet

- Incotest 12365927Document5 pagesIncotest 12365927Ramadhan PrakosoNo ratings yet

- Magnaglo Fluorescent Particle Inspection MaterialsDocument1 pageMagnaglo Fluorescent Particle Inspection MaterialsRamadhan PrakosoNo ratings yet

- Ix-Film BrochuresDocument4 pagesIx-Film BrochuresRyanto KurniawanNo ratings yet

- Jadwal Pasien Feb 2022Document1 pageJadwal Pasien Feb 2022Ramadhan PrakosoNo ratings yet

- Sony DVR-VX2000 ManualDocument92 pagesSony DVR-VX2000 ManualHenryNo ratings yet

- Pathways 4 Listening & Speaking Unit 4 TestDocument8 pagesPathways 4 Listening & Speaking Unit 4 TestaLeKs GaRcíA100% (1)

- Directorate General of Drug Administration: SL Name of The Pharmaceutical Address Location Licence No. Present StatusDocument2 pagesDirectorate General of Drug Administration: SL Name of The Pharmaceutical Address Location Licence No. Present StatusAnamika SahaNo ratings yet

- PINOYBIX1Document5 pagesPINOYBIX1andreareyesmalinao7No ratings yet

- China Domestic Style Test ProcessDocument2 pagesChina Domestic Style Test ProcessPopper JohnNo ratings yet

- Sika Anchorfix®-3030: Product Data SheetDocument5 pagesSika Anchorfix®-3030: Product Data SheetReab SimanthNo ratings yet

- Exercise Phase 4 - Team LeadershipDocument13 pagesExercise Phase 4 - Team LeadershipLUZ AMPARO MARTINEZNo ratings yet

- Propositions: A. Learning Outcome Content StandardDocument9 pagesPropositions: A. Learning Outcome Content StandardMarc Joseph NillasNo ratings yet

- Fault Detection System of Underground Power Line (1) (1) (AutoRecovered)Document4 pagesFault Detection System of Underground Power Line (1) (1) (AutoRecovered)Surya RtzNo ratings yet

- Do Global Economic and Political Integrations Bring More Harm To The Philippines and The Filipinos or Not? Articulate Your StanceDocument3 pagesDo Global Economic and Political Integrations Bring More Harm To The Philippines and The Filipinos or Not? Articulate Your StancenonononowayNo ratings yet

- Northern Cebu Colleges, Inc. San Vicente ST., Bogo City, Cebu Flexible Instruction Delivery Plan (FIDP)Document6 pagesNorthern Cebu Colleges, Inc. San Vicente ST., Bogo City, Cebu Flexible Instruction Delivery Plan (FIDP)Jilmore Caseda Cantal100% (1)

- My Side of The Mountain PDFDocument61 pagesMy Side of The Mountain PDF12333% (3)

- PAPER (14) - Puucho PDFDocument21 pagesPAPER (14) - Puucho PDFethan tylerNo ratings yet

- Final Verbal Agression ResearchDocument26 pagesFinal Verbal Agression ResearchLucañas PhilipNo ratings yet

- Tugas Bahasa InggrisDocument3 pagesTugas Bahasa InggrisDesy Lianti EchiNo ratings yet

- MR Right - Case Study Test - Summer 2018Document7 pagesMR Right - Case Study Test - Summer 2018jadenNo ratings yet

- RFQ 10406475 - RWSCM00015F-Rev05-RequestforQuotationSupplyandDelivery - 20230929112300.955 - X 23 October 2023TDocument11 pagesRFQ 10406475 - RWSCM00015F-Rev05-RequestforQuotationSupplyandDelivery - 20230929112300.955 - X 23 October 2023TPfunzo MammbaNo ratings yet

- Declaration KitDocument4 pagesDeclaration KitJITANSHUCHAMPNo ratings yet

- GRC Manual of StyleDocument44 pagesGRC Manual of StyleRSA ArcherNo ratings yet

- Asesor Internal TKRSDocument113 pagesAsesor Internal TKRSNingsih NingsihNo ratings yet

- Đề MINH HỌA Số 11 Luyện Thi Tốt Nghiệp THPT 2023Document7 pagesĐề MINH HỌA Số 11 Luyện Thi Tốt Nghiệp THPT 2023Minh ThưNo ratings yet

- Ma Education-4th-Engl2115-16-16 PDFDocument39 pagesMa Education-4th-Engl2115-16-16 PDFSameera ZahidNo ratings yet

- Vignettes: I. Lesson PlanDocument27 pagesVignettes: I. Lesson PlanAcademic ServicesNo ratings yet

- Dgms AvaDocument3 pagesDgms AvaVinod GuptaNo ratings yet

- Critically Discuss About Major Features of Water Resource Act, 2049 B.SDocument12 pagesCritically Discuss About Major Features of Water Resource Act, 2049 B.SPurple DreamNo ratings yet

- Magic Arrays - Multichannel Microphone Array Design Applied To Microphone Arrays Generating Interformat CompatabilityDocument19 pagesMagic Arrays - Multichannel Microphone Array Design Applied To Microphone Arrays Generating Interformat CompatabilitymewarulesNo ratings yet

- Math g7 m1 Topic A Lesson 6 TeacherDocument8 pagesMath g7 m1 Topic A Lesson 6 TeacherSammy DejliNo ratings yet

- Performance Comparison of Simulated Annealing GA and ACO Applied To TSPDocument8 pagesPerformance Comparison of Simulated Annealing GA and ACO Applied To TSPSaurav AcharyaNo ratings yet

- One-Day Workshop Brochure - KHP - 10.02.2022Document1 pageOne-Day Workshop Brochure - KHP - 10.02.2022Ramya RajeshNo ratings yet

- GRIHA EDS Feasibility ChecklistDocument7 pagesGRIHA EDS Feasibility ChecklistNikunj DwivediNo ratings yet