Professional Documents

Culture Documents

Pi Oks 200 110579 en

Uploaded by

Starlord PlazaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pi Oks 200 110579 en

Uploaded by

Starlord PlazaCopyright:

Available Formats

PRODUCT INFORMATION

OKS 200

MoS₂ Assembly Paste

Description

OKS 200 is a MoS₂-paste for assembly lubrication for press-on processes.

Applications Advantages and benefits

Mounting paste for press-fitting wheels, shafts, tires or Against seizing, wear and stick-slip

bearings to prevent galling Highly effective due to the strong affinity of the MoS₂ for

Non-stick primer coat for moving threads, supports, guides metals

and slideways to prevent stick-slip effect Extremely low friction at highest loading capability

Wearing-in lubrication of highly stressed sliding surfaces such Increased operational reliability of moving parts due to anti-

as plain bearings, gearwheels, crankshafts with provision of seizing properties

anti-seizing properties

Resistant to water, oil, grease, chemicals and hydraulic media

In non-cutting shaping of the difficult type, such as doming,

Improved performance due to organic molybdenum complex

pressing, embossing while avoiding critical metal contacts

compounds

and welding

Branches

Plant and machine (tool) engineering

Iron and steel industry

Chemical industry

Glass and foundry industry

Rail vehicle technology

Municipal services

Logistics

Rubber and plastic processing

Shipbuilding and marine technology

Paper and packaging industry

Application tips

For best adhesion, clean the surfaces from dirt and other lubricants. Best way is to clean mechanically first and then with OKS

2610 or OKS 2611 universal cleaner. Apply paste evenly thin with brush, spatula, etc. Remove excessing paste. Do not use paste

instead of grease and only mix with appropriate lubricants.

Packaging

40 ml Tube 1 kg Can 25 kg Hobbock

250 g Can 5 kg Hobbock

29.10.2023, En Page 1/2

© OKS Spezialschmierstoffe GmbH

PRODUCT INFORMATION

OKS 200

MoS₂ Assembly Paste

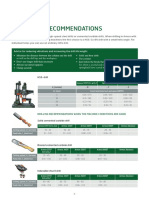

Technical data

Standard Conditions Unit Value

Main components

base oil synthetic oil

thickener lithium soap

solid lubricants white solid lubricants

solid lubricants MoS₂

solid lubricants graphite

additives Moₓ-Active

Application related technical data

unworked penetration DIN ISO 2137 no shear stress 0.1 mm 220-250

lower operating temperature °C -35

upper operating temperature separation °C 450

colour black

density (at 20°C) DIN EN ISO 3838 g/cm³ 1.2

four-ball test rig welding load DIN 51 350-4 N 2,400

screw ISO 4017 M10x55-8.8 black-oxide,

thread friction coefficient (μ total) DIN EN ISO 16 047 0.07

nut ISO 4032 M10-10 black-oxide

breakaway torque DIN 267-27 M10 A2, 40 Nm, 400 °C, 100 h Nm < 2,0 x tightening torque

press-fit test (μ) draft DIN 51 833 0,09, no chatter

OKS Spezialschmierstoffe GmbH The information in this publication reflects state-of-the-art technology, as well as extensive testing and

experience. Due to the diversity of possible applications and technical realities, they can only serve as

Ganghoferstraße 47 recommendations and are not arbitrarily transferable. Therefore, no obligations, liability or warranty

82216 Maisach claims can be derived from them. We only accept liability for the suitability of our products for particular

purposes, and for certain properties of our products, in the event that we have accepted such liability in

+49 8142 3051 - 500 writing in the individual case. Any case of justified warranty claims shall be limited to the delivery of

info@oks-germany.com replacement goods free of defects, in the event that this subsequent improvement fails, to reimbursement

of the purchase price. Any and all further claims, in particular the liability for consequential injuries or

www.oks-germany.com damage, shall always be excluded. Prior to use, the customer must conduct its own testing to prove

suitability. The data are subject to change for the sake of progress. ® = Registered trademark

Product restricted to professional users. Safety data sheet available for download at www.oks-germany.com

Our Customer and Technical service will be pleased to help should you have any further questions.

29.10.2023, En Page 2/2

© OKS Spezialschmierstoffe GmbH

You might also like

- Fabrication, Inspection, and Testing of Pressure VesselsDocument75 pagesFabrication, Inspection, and Testing of Pressure VesselsAsad Iqbal Siddiqui71% (7)

- ATA51Document213 pagesATA51Challa AmarsrinuNo ratings yet

- Pi Oks 250 110589 enDocument2 pagesPi Oks 250 110589 enStarlord PlazaNo ratings yet

- Pi Oks 252 113701 enDocument2 pagesPi Oks 252 113701 enGokulNo ratings yet

- OKS 252 - Product Information: White High Temperature Paste For The Food IndustryDocument2 pagesOKS 252 - Product Information: White High Temperature Paste For The Food IndustryIván ChávezNo ratings yet

- Product Information: High Temperature Oil, Light-Coloured, SyntheticDocument2 pagesProduct Information: High Temperature Oil, Light-Coloured, SyntheticKevin Daniel Casta?O CorreaNo ratings yet

- PI OKS 450 OKS 451 Rev01 ENDocument2 pagesPI OKS 450 OKS 451 Rev01 ENSujay NahaldeNo ratings yet

- Product Information: High-Temperature Oil, Light-Coloured, SyntheticDocument2 pagesProduct Information: High-Temperature Oil, Light-Coloured, SyntheticIván ChávezNo ratings yet

- Pi Oks 476 113678 enDocument2 pagesPi Oks 476 113678 enSophia RoseNo ratings yet

- Copper Paste 9006611 (GB)Document1 pageCopper Paste 9006611 (GB)Erick CallejasNo ratings yet

- Product Information: High-Temperature Grease For Food Processing TechnologyDocument2 pagesProduct Information: High-Temperature Grease For Food Processing TechnologyFelipe OsorioNo ratings yet

- Technical Data Sheet For Bechem GreaseDocument1 pageTechnical Data Sheet For Bechem GreaseSandeepNo ratings yet

- BERULUB FR 16 TdsDocument1 pageBERULUB FR 16 TdsVishal AmleNo ratings yet

- Molykote G-2003Document2 pagesMolykote G-2003Luz Angela GuerreroNo ratings yet

- Addinol Gear Oil 100 F, 150 F, 220 F, 320 F, 460 F, 680 F: Industrial Special Gear OilsDocument2 pagesAddinol Gear Oil 100 F, 150 F, 220 F, 320 F, 460 F, 680 F: Industrial Special Gear OilsMateo RincónNo ratings yet

- Addinol Gear Oil 100 F, 150 F, 220 F, 320 F, 460 F, 680 F: Industrial Special Gear OilsDocument2 pagesAddinol Gear Oil 100 F, 150 F, 220 F, 320 F, 460 F, 680 F: Industrial Special Gear OilsdanililloNo ratings yet

- Additex SW 22, SW 32, SW 46: Textile Machine OilDocument2 pagesAdditex SW 22, SW 32, SW 46: Textile Machine OilRonald Mario Kupa AnticonaNo ratings yet

- Berutox FB 22: Technical Product InformationDocument1 pageBerutox FB 22: Technical Product InformationMauricio SánchezNo ratings yet

- Sinopec EP Golden GreaseDocument2 pagesSinopec EP Golden GreaseYoong TanNo ratings yet

- BECHEM High Lub LFB 2000 TDS enDocument1 pageBECHEM High Lub LFB 2000 TDS enluisvictorbariteNo ratings yet

- ADV - Bearing GreaseDocument2 pagesADV - Bearing GreasePaulo BaltorNo ratings yet

- Eni Grease MSX 2-460Document2 pagesEni Grease MSX 2-460ranjanguptNo ratings yet

- Poly Gear PG en PDFDocument2 pagesPoly Gear PG en PDFAlfredo CarlosNo ratings yet

- MOLYKOTE G-Rapid Plus Paste 71-0084F-01Document2 pagesMOLYKOTE G-Rapid Plus Paste 71-0084F-01sungkarsNo ratings yet

- MOLYKOTE® G-Rapid Plus Solid Lubricant PasteDocument2 pagesMOLYKOTE® G-Rapid Plus Solid Lubricant PasteBart AertsNo ratings yet

- 528hoja-tecnica-MOLYKOTE® TP-42Document2 pages528hoja-tecnica-MOLYKOTE® TP-42Diego MarroneNo ratings yet

- 4.4.molykote TP 42 Grease Paste Data SheetDocument2 pages4.4.molykote TP 42 Grease Paste Data SheetAhmed Hamdy WorkNo ratings yet

- Rope Dressing 9255101 (GB)Document1 pageRope Dressing 9255101 (GB)SandeepNo ratings yet

- Berutox FE 18 EP: Technical Product InformationDocument1 pageBerutox FE 18 EP: Technical Product InformationMauricio SánchezNo ratings yet

- Gleitmo 700 Pi CP1000310 enDocument2 pagesGleitmo 700 Pi CP1000310 enJORGE VELAZQUEZNo ratings yet

- Px3 Lubrication: Wire Rope GreaseDocument1 pagePx3 Lubrication: Wire Rope GreaseEhsan AhmadiNo ratings yet

- Gear Oil CLP 220-11-En - GBDocument1 pageGear Oil CLP 220-11-En - GBputel_ajaNo ratings yet

- Bechem CoolantsDocument1 pageBechem CoolantsChung LeNo ratings yet

- Molylub GoldTex T 46 KnittingDocument1 pageMolylub GoldTex T 46 KnittingismoyoNo ratings yet

- TDB ENG Bechem Ecorail 2009 6002039 en UsDocument3 pagesTDB ENG Bechem Ecorail 2009 6002039 en UsSami Ben LazregNo ratings yet

- Molylub GoldTex T 32 KnittingDocument1 pageMolylub GoldTex T 32 KnittingismoyoNo ratings yet

- MOLYKOTE Longterm 2 Plus Grease 71-0076F-01Document2 pagesMOLYKOTE Longterm 2 Plus Grease 71-0076F-01Dicky PratamaNo ratings yet

- MOLYKOTE BR-2 Plus High Performance Grease 71-0241D-01Document2 pagesMOLYKOTE BR-2 Plus High Performance Grease 71-0241D-01Syed Noman AhmedNo ratings yet

- Molylub GoldTex T 22 KnittingDocument1 pageMolylub GoldTex T 22 KnittingismoyoNo ratings yet

- Molykote BR-2 Plus High Performance GreaseDocument2 pagesMolykote BR-2 Plus High Performance GreaseRamonNo ratings yet

- MOLYKOTE P-74 Assembly Paste 10-929B-01Document2 pagesMOLYKOTE P-74 Assembly Paste 10-929B-01ko htetNo ratings yet

- MOLYKOTE HSC Plus Paste 71-0212H-01Document2 pagesMOLYKOTE HSC Plus Paste 71-0212H-01Vendy KurniawanNo ratings yet

- Meisseltrennpaste-183 1016104 enDocument1 pageMeisseltrennpaste-183 1016104 enStefan UngurNo ratings yet

- 503hoja-tecnica-MOLYKOTE® 44 MediumDocument2 pages503hoja-tecnica-MOLYKOTE® 44 MediumeariesilvapcNo ratings yet

- High Performance Lubricants Molykote: G-2001 High Speed Bearing GreaseDocument2 pagesHigh Performance Lubricants Molykote: G-2001 High Speed Bearing GreaseRildo CarvalhoNo ratings yet

- TDS - Motul VIS 46 - ENDocument2 pagesTDS - Motul VIS 46 - ENnghiaNo ratings yet

- Berulit IKP: Technical Product InformationDocument1 pageBerulit IKP: Technical Product InformationMauricio SánchezNo ratings yet

- Ravenol Awd-H Fluid: Click Here For The Oil Test AnalysisDocument2 pagesRavenol Awd-H Fluid: Click Here For The Oil Test AnalysisTudor RatiuNo ratings yet

- BECHEM - Lubricantes Especiales en AerosolDocument16 pagesBECHEM - Lubricantes Especiales en AerosolAlfonso Florez MartinezNo ratings yet

- MOLYKOTE 44 - MediumDocument2 pagesMOLYKOTE 44 - MediumCesar AlejandroNo ratings yet

- Weicon Anti SeizeDocument8 pagesWeicon Anti SeizeummanNo ratings yet

- Sinopec Extreme Pressure Lithium GreaseDocument3 pagesSinopec Extreme Pressure Lithium GreaseYoong TanNo ratings yet

- MOLYKOTE 1000 Solid Lubricant 71-0218G-01Document2 pagesMOLYKOTE 1000 Solid Lubricant 71-0218G-01Budi HandokoNo ratings yet

- GL XX Mobilgrease SpecialDocument2 pagesGL XX Mobilgrease SpecialTiago PaivaNo ratings yet

- PDS - Addinol Gear Oil CLP 10, 68, 100, 150, 220, 320, 460, 680Document2 pagesPDS - Addinol Gear Oil CLP 10, 68, 100, 150, 220, 320, 460, 680LeoNo ratings yet

- Molykote® Longterm 2 Plus Datasheet EngDocument2 pagesMolykote® Longterm 2 Plus Datasheet EngAlaa HassanNo ratings yet

- Tds Renolit Cxi 2 enDocument3 pagesTds Renolit Cxi 2 enAldair MezaNo ratings yet

- P004547 Top Tec 6300 0W 20 11 en - GBDocument1 pageP004547 Top Tec 6300 0W 20 11 en - GBHaja_01No ratings yet

- P004087 Leichtlauf Energy 0W 40 17 en - GBDocument1 pageP004087 Leichtlauf Energy 0W 40 17 en - GBHalil Marcelo SejkicNo ratings yet

- MOLYKOTE 165 LT Gearwheel Grease 71-0179D-01Document2 pagesMOLYKOTE 165 LT Gearwheel Grease 71-0179D-01bravindranath5768No ratings yet

- UntitledDocument28 pagesUntitledStarlord PlazaNo ratings yet

- Plant Based Eco-Friendly Air PurifierDocument4 pagesPlant Based Eco-Friendly Air PurifierStarlord PlazaNo ratings yet

- Revised Assignment-1 Mechanical VibrationsDocument2 pagesRevised Assignment-1 Mechanical VibrationsStarlord PlazaNo ratings yet

- Simplex MethodDocument12 pagesSimplex MethodStarlord PlazaNo ratings yet

- Mechanical Bone ImplantsDocument3 pagesMechanical Bone ImplantsStarlord PlazaNo ratings yet

- Touchwood NC Thinner: Architectural CoatingsDocument2 pagesTouchwood NC Thinner: Architectural CoatingsmuthukumarNo ratings yet

- Wood CarvingDocument2 pagesWood CarvingAsif HussainNo ratings yet

- Flange Insulation PresentationDocument10 pagesFlange Insulation PresentationA N MadhavanNo ratings yet

- Abrasives Selection Guide: Choose From Our Extensive Range of Discs, Wheels, Burrs and Sanding ProductsDocument27 pagesAbrasives Selection Guide: Choose From Our Extensive Range of Discs, Wheels, Burrs and Sanding Productsagniva dattaNo ratings yet

- British and ISO Standards Related ToDocument14 pagesBritish and ISO Standards Related Tocao thanh quocNo ratings yet

- DH31-EX Heat TreatDocument4 pagesDH31-EX Heat TreatMichael KrummNo ratings yet

- Lathe and VMC Cycle Time CalculatorDocument3 pagesLathe and VMC Cycle Time Calculatorchandra shekarNo ratings yet

- Boschert Compact EDocument5 pagesBoschert Compact ETin NecNo ratings yet

- EKK ProductsDocument3 pagesEKK ProductsOscar SalazarNo ratings yet

- Machining Recommendations: Advice For Reducing Vibrations and Increasing The Drill Life LengthDocument3 pagesMachining Recommendations: Advice For Reducing Vibrations and Increasing The Drill Life LengthbasaricaNo ratings yet

- Sanweld Electrodes Catalog Vol 4Document24 pagesSanweld Electrodes Catalog Vol 4prashant mishra100% (4)

- Work Permit FormatDocument12 pagesWork Permit FormatAejaz Mujawar0% (1)

- Galvanizing and Mechanical Preparation of Steel - 1Document4 pagesGalvanizing and Mechanical Preparation of Steel - 1Saurabh SinghNo ratings yet

- Tratamente Termice F4Document6 pagesTratamente Termice F4andreeaoana45No ratings yet

- ALBERDINGK Technology - Info - Corrosion - ProtectionDocument30 pagesALBERDINGK Technology - Info - Corrosion - ProtectionmassimodinelliNo ratings yet

- Cat Bpe PDFDocument57 pagesCat Bpe PDFJohnNo ratings yet

- Precision Steel Tube Handbook Third Edition PDFDocument218 pagesPrecision Steel Tube Handbook Third Edition PDFRohan KulkarniNo ratings yet

- A389 CuNiDocument1 pageA389 CuNiPrathamesh OmtechNo ratings yet

- Cutting Tool - 0Document45 pagesCutting Tool - 0Sam SadaNo ratings yet

- Steel Formwork BrochureDocument9 pagesSteel Formwork BrochurehectorNo ratings yet

- Concrete Material and MixtureDocument51 pagesConcrete Material and MixtureAina Aqilah100% (1)

- Landing ValveDocument3 pagesLanding ValveMd. Asrafujjaman (Livon)No ratings yet

- Ips C Pi 410Document13 pagesIps C Pi 410ali1860No ratings yet

- Epoxy HR PDFDocument5 pagesEpoxy HR PDFJayaraman KamarajNo ratings yet

- Sierra DNA75 DNA133 DNA167 - Build InstructionsDocument14 pagesSierra DNA75 DNA133 DNA167 - Build InstructionsGuido CatelloNo ratings yet

- Product Data Sheet Powernics 9701 Black Lead Free: Berger Nippon Paint Automotive Coatings Private LimitedDocument2 pagesProduct Data Sheet Powernics 9701 Black Lead Free: Berger Nippon Paint Automotive Coatings Private LimitedSamNo ratings yet

- Ceramic Turning InsertsDocument39 pagesCeramic Turning InsertsR AksathNo ratings yet

- Cámara de Espuma - Instalación y Mantenimiento PDFDocument5 pagesCámara de Espuma - Instalación y Mantenimiento PDFvivicastedoNo ratings yet