Professional Documents

Culture Documents

B-268 & C-268 Variable Spring Hanger Submittal

Uploaded by

angelramosCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B-268 & C-268 Variable Spring Hanger Submittal

Uploaded by

angelramosCopyright:

Available Formats

Spring Hangers

Spring Hangers

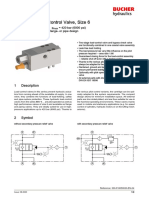

Fig. B-268 Standard Spring Hangers Type: A, B, C, D, E, F, G

Fig. C-268 Corrosion Resistant Spring Hangers Type: A, B, C, D, E, F, G

Design Features: Travel Stop: The functional design of the

• Precompression. pre-compressed variable spring hanger

permits the incorporation of a two-piece

Precompressing the spring into the hanger casing provides the travel stop that locks the hanger spring

following advantages: against upward or downward movement

1. Saves up to 50% in headroom by reducing the length of for temporary conditions of underload or

the hanger. overload. The complete travel stop, the

up travel stop only for cold set purposes

2. Reduces the installed height of the overall hanger assembly.

or the down travel stop only which may

3. Prevents the spring supporting force from exceeding the normal be employed during erection, hydrostatic

safe limits of variations. test (ASC permits a hydrostatic test load of

4. Saves valuable erection time because spring is precompressed 2 times the normal operating load for the

close to ¾ of the working range. spring hanger) or chemical clean out will be

furnished only when specified. The travel stop is painted red and is

Calibration: All ASC Engineered Solutions™ Variable Spring Hangers installed at the factory with a caution tag attached calling attention

and supports are calibrated for accurate loading conditions. that the device must be removed before the pipe line is put in

• Load indicator is clearly seen in the slot, simplifying reading service. Permanently attached travel stops available upon request.

of the scale plate. Load is read from bottom of indicator.

• Cold set at the factory upon request.

• Spring and casing are fabricated of steel and are rugged

UP TRAVEL

and compact. STOP

• Piston cap serves as a centering device or guide maintaining INDICATOR

(Load is read from METAL

spring alignment. bottom of indicator) STRAPS

• Casing protects the spring from damage and weather conditions.

CA

U

T IO

DOWN TRAVEL

N

Standard Finish: Painted with semi-gloss primer. STOP

CAUTION

Corrosion Resistant: ASC offers corrosion-resistant and weather- TAG

resistant (either galvanized or zinc based primer) Variable Spring

Hangers to fill vital needs in the chemical and refinery industries as

well as in modern outdoor power plant construction. For protection

against severe weather conditions or moderate corrosive conditions,

the parts of the hanger are galvanized per ASTM A-153 or painted Approvals:

with zinc based primer, except for the spring which has a protective WW-H-171E (Types 51, 56 and 57), ANSI/MSS SP-69 and MSS SP-58

coating and the load column for Type F which is electro-galvanized. (Types 51, 52 and 53).

Advantages of a Protective Coating: Specifications:

• Protects from a wide range of corrosives. ASC Variable Spring Hangers are welded in strict accordance with

ASME Section IX.

• Does not affect the flex life of the spring.

• Recommended for ambient temperatures up to 200° F.

PROJECT INFORMATION APPROVAL STAMP

Project: Approved

Address: Approved as noted

Contractor: Not approved

Engineer: Remarks:

Submittal Date:

Notes 1:

Notes 2:

PP-11.11 page 1 PP-SUB-B268-C268-v01 20220209

Spring Hangers

Fig. B-268 Standard Spring Hangers

Fig. C-268 Corrosion Resistant Spring Hangers

Size Range:

The ASC Engineered Solutions™ Variable Spring Hanger in five series and seven types

is offered in twenty-three sizes (Fig. B-268 only is offered in twenty-five sizes). The

hanger can be furnished to take loads 10 lbs. to 50,000 lbs.

Ordering:

1. Size

2. Type

3. Figure number

4. Product name

LIFTING 5. Desired supporting force in operating position

Hole LUGS 6. Calculated amount and direction of pipe movement from installed to

operating position.

7. Customer’s identification number (if any)

8. When ordering Type F spring specify if roller or guided load column is to

be furnished.

9. When ordering Type G, specify total load and load per spring plus center to

center rod dimensions.

10. If required, specify with travel stop

11. When ordering corrosion resistant, specify C-268, C-82, C-98, Triple-CR, or

Triple-CR, either painted with zinc based primer or completely galvanized,

except for coated spring coil.

Note:

To help alleviate the problem of lifting large size spring hangers into position for

installation, this product is available with lifting lugs (if required) on sizes weighing

one hundred pounds or more.

PP-12.19 page 2 PP-SUB-B268-C268-v01 20220209

Spring Hangers

Fig. B-268 Standard Spring Hangers

Fig. C-268 Corrosion Resistant Spring Hangers

Spring Hangers (Type B & Type C)

Spring Hangers (Type B & C)

D D

T

S

R

R

H H

T

DEFL. (IN.) LOAD (LB.)

DEFL. (IN.) LOAD (LB.) 0

0

1/4

1/4

1/2

1/2

3/4

3/4

1

1

1 1/4 1 1/4

1 1/2

LOAD 1 1/2 LOAD

J 1 3/4 INDICATOR 1 3/4

INDICATOR

2 J 2

2 1/4 B 2 1/4

B

2 1/2 2 1/2

SPG.RATE LB./IN. SPG.RATE LB./IN .

FIG. B-26 8 FIG. B-26 8

SIZE TYPE SIZE TYPE

MARKNO. MARKNO.

LOAD SCALE LOAD SCALE &

& NAME PLATE NAME PLATE

MIN.=Z MIN.=Z

F MAX.=Z+3¾" F MAX.=Z+3¾"

ROD SIZE "A"

C ROD NOT FURNISHED ROD SIZE "A"

LENGTH OF R.H. TH'D. C ROD NOT FURNISHED

SEE TABLE BELOW LENGTH OF R.H. TH'D.

SEE TABLE BELOW

Fig. B-268 Type B Fig. B-268 Type B Fig. B-268 Type

Fig.CB-268 Type C

Type B is furnished with a single lug for attachment to the building Type C is furnished with two lugs for attachment to the building

structure. The lug permits use of a clevis, welded beam attachment or structure. These two lugs permit the use of an eye rod, Fig. 55L or

a pair of angles for attachment where headroom is limited. a single plate for attachment where headroom is limited.

Fig. B-268, Fig. C-268 Type B , C: Weight (Lbs) • Dimensions (In)

R.H. Min. Thread Clevis

Hanger Rod Lug Hole Casing Casing Flange Height Rod Take Thickness

Weight Thread Engagement R Opening Z

Size Size A Size Length B Diam. C Diam. D of Pin H Out J T

Length F S

000 5 55/8 7 13/16

½ 5 11/16 4 51/8 15/16 1½ 1¼ 7/8 ¼

00 6 715/16 9½ 13/16

0 8 611/16 8

¾

1 9 ½ 5 11/16 79/16 4 51/8 15/16 1½ 87/8 1¼ 7/8 ¼

2 10 85/16 97/8 1

3 14 9½ 1

715/16

4 16 ½ 5 11/16 59/16 615/16 15/16 1½ 1¼ 7/8 ¼ 13/8

97/8

5 17 85/8 11/16

6 27 813/16 915/16 9/16

7 30 5/8 5 13/16 65/8 83/8 15/16 1½ 1¼ 11/16 ¼

10 113/16 5/8

8 32

9 66 107/16 117/16 ¾

10 72 ¾ 6 15/16 121/8 85/8 10¾ 1¼ 1½ 137/8 1¼ 1¼ 3/8 1½

11 66 107/16 123/8 111/16

12 71 6 107/16 12½ 11/16

1 1¼ 2 1½ 15/8

13 89 131/8 85/8 10¾ 1¼ 143/8 ½ ½

14 94 1¼ 7 1½ 13¼ 3 153/8 2 2 3/8

15 114 1¼ 1½ 13¼ 10¾ 153/8 2 2 5/8 3/8

16 138 1½ 1¾ 161/16 85/8 115/16 3 193/16 23/8 21/16

8 113/8 2½ ¾

17 168 1¾ 2 181/8 211/8 25/8 115/16

18 331 2 23/8 18¼ 4 221/8 27/8 29/16

9 3 ¾

19 378 2¼ 25/8 20½ 12¾ 157/8 2¾ 25 31/8

4½ 211/16

20 486 2½ 10 27/8 23¾ 28¼ 4 33/8 1

21 568 2¾ 10 31/8 275/16 4½ 311/8 35/8 311/16

12¾ 167/8 35/8 4 1

3¾

22 714 3 11 33/8 333/8 5 37¾ 37/8

PP-11.11 page 4 PP-SUB-B268-C268-v01 20220209

You might also like

- Fig. 82 Standard Short Spring Hangers Type: A, B, C, D, E, F, G Fig. C-82 Corrosion Resistant Short Spring Hangers Type: A, B, C, D, E, F, GDocument7 pagesFig. 82 Standard Short Spring Hangers Type: A, B, C, D, E, F, G Fig. C-82 Corrosion Resistant Short Spring Hangers Type: A, B, C, D, E, F, GsazehpaidarelahieNo ratings yet

- Spring Hangers - AnvilDocument7 pagesSpring Hangers - AnvilRicardo De JesusNo ratings yet

- Danuhm Bush Air Cooled Split PACUDocument16 pagesDanuhm Bush Air Cooled Split PACUFalak KhanNo ratings yet

- Millennium: Air Cooled Screw Liquid ChillersDocument64 pagesMillennium: Air Cooled Screw Liquid ChillersJulian Andres VillarrealNo ratings yet

- Passoni PNO BushingsDocument12 pagesPassoni PNO BushingsDimitar MarkovNo ratings yet

- WH Brady Electric Hoist PDFDocument4 pagesWH Brady Electric Hoist PDFSuresh NathNo ratings yet

- 10 Tension Collapse Buoyancy KeyseatingDocument56 pages10 Tension Collapse Buoyancy KeyseatingCarlos Antonio Fontalvo CarrascalNo ratings yet

- (Gsa-Oa) 1zse 2750-111 en Rev 6 NBDocument16 pages(Gsa-Oa) 1zse 2750-111 en Rev 6 NBUmar ChNo ratings yet

- Easy-E Cryogenic Sliding-Stem Control ValvesDocument22 pagesEasy-E Cryogenic Sliding-Stem Control ValvesArman MominNo ratings yet

- P6SD Series: Technical Specifications Features and BenefitsDocument8 pagesP6SD Series: Technical Specifications Features and BenefitsEduardo Rogelio Prado LevanoNo ratings yet

- Reaction VesselDocument4 pagesReaction VesselArunkumar MyakalaNo ratings yet

- Product Bulletin: Model Osd Ansi ProcessDocument6 pagesProduct Bulletin: Model Osd Ansi ProcessZainal MuzidNo ratings yet

- Variable Spring SupportsDocument12 pagesVariable Spring SupportsMadhan RajNo ratings yet

- WACT Hydraulic ActuatorDocument12 pagesWACT Hydraulic Actuatorjhonyblaze1984No ratings yet

- Series 65-72 Ball Valve 2019 - v4 - FinalDocument8 pagesSeries 65-72 Ball Valve 2019 - v4 - FinalPrathamesh Pradeep MashilkarNo ratings yet

- ET and EZ DifferenceDocument12 pagesET and EZ DifferenceAshish GargNo ratings yet

- LIEEMAN Variable Spring SupportsDocument13 pagesLIEEMAN Variable Spring SupportsAimiNo ratings yet

- CFS CatalogDocument18 pagesCFS CatalogperezismaelNo ratings yet

- Variable Spring SupportsDocument13 pagesVariable Spring SupportsJOSEPH ESCOBARNo ratings yet

- Pressure Regulators - ICSDocument6 pagesPressure Regulators - ICSMul YadiNo ratings yet

- 40-300REOZJ - G6099 Enclosure Specification SheetDocument8 pages40-300REOZJ - G6099 Enclosure Specification SheetĐoàn Trung HậuNo ratings yet

- Single Stage Inline Fire Pumps: Fairbanks NijhuisDocument4 pagesSingle Stage Inline Fire Pumps: Fairbanks NijhuisDiego MorenoNo ratings yet

- Submittal Sheet Kennedy Guardian k81d K81a and K81am 89dfbd8f PDFDocument18 pagesSubmittal Sheet Kennedy Guardian k81d K81a and K81am 89dfbd8f PDFvicvic34No ratings yet

- KennedyDocument18 pagesKennedyHimat KhimaniNo ratings yet

- Injection Pressure Operated BarrierDocument1 pageInjection Pressure Operated Barrierafzal7No ratings yet

- 5000 Series Cryogenic Valve: Bulletin 86.1:5000 CryoDocument8 pages5000 Series Cryogenic Valve: Bulletin 86.1:5000 CryoDatt NguyenNo ratings yet

- Screw Pumps Series SPF: Application Shaft SealingDocument16 pagesScrew Pumps Series SPF: Application Shaft Sealingmsh16000No ratings yet

- Spring - Hanger - Basic PSA Inc PDFDocument26 pagesSpring - Hanger - Basic PSA Inc PDFViji SvrNo ratings yet

- Compact SubstationDocument6 pagesCompact SubstationHafiza Sulaiman100% (1)

- Awwa Swing Check Valve: Make The Change To Quality! SpecifyDocument12 pagesAwwa Swing Check Valve: Make The Change To Quality! SpecifySouvik DaluiNo ratings yet

- 7-Ottawa County Farms CP 7-Vi Pipe-Stress-Calculations 530131 7Document91 pages7-Ottawa County Farms CP 7-Vi Pipe-Stress-Calculations 530131 7Juan Carlos RiveraNo ratings yet

- Fire HydrantsDocument22 pagesFire HydrantsRaduNo ratings yet

- Cash Valve B Series: Pressure RegulatorsDocument8 pagesCash Valve B Series: Pressure Regulatorsjose arangoitiaNo ratings yet

- Saudi Aramco: Drilling Technical Department September 2013 2 Workover Practices B CasingDocument5 pagesSaudi Aramco: Drilling Technical Department September 2013 2 Workover Practices B CasingMahrouz MadoNo ratings yet

- Bushings PDFDocument6 pagesBushings PDFeider yovannis payares davilaNo ratings yet

- Leak-Free Load-Control Valve, Size 6Document9 pagesLeak-Free Load-Control Valve, Size 6Yazad DoctorrNo ratings yet

- 2 VAG EKO Plus F4Document3 pages2 VAG EKO Plus F4Baris BoskanNo ratings yet

- Ductile Iron/Stainless Steel Cylinders Quarter-Turn Spring Return and Double Acting Actuators Output Torques To 238,000 LB - inDocument12 pagesDuctile Iron/Stainless Steel Cylinders Quarter-Turn Spring Return and Double Acting Actuators Output Torques To 238,000 LB - inCapacitacion TodocatNo ratings yet

- Medium Velocity Water Spray NozzleDocument6 pagesMedium Velocity Water Spray NozzlePhua Shang YangNo ratings yet

- Intermediate PDFDocument6 pagesIntermediate PDFRIGOBERTO PONCENo ratings yet

- FCS/BCS Series - Centrifugal Fans: Description DataDocument7 pagesFCS/BCS Series - Centrifugal Fans: Description DataHuyNo ratings yet

- AVX A R134a 50 60Hz - MS04102B 0416 - Cs - Lo PDFDocument40 pagesAVX A R134a 50 60Hz - MS04102B 0416 - Cs - Lo PDFEnrique EndoNo ratings yet

- KSB Sicca HP Cast Gate Valve PDFDocument4 pagesKSB Sicca HP Cast Gate Valve PDFJamalNo ratings yet

- Valvulas Mariposa WSVDocument19 pagesValvulas Mariposa WSVGuillermo ArandaNo ratings yet

- Luz de Navegacion Marca Peter and Bay CompletaDocument4 pagesLuz de Navegacion Marca Peter and Bay CompletaVENTAS PROINMARNo ratings yet

- Resin Impregnated Paper Bushing ABBDocument20 pagesResin Impregnated Paper Bushing ABBjtcool74No ratings yet

- CC Awwa c561 en r3Document17 pagesCC Awwa c561 en r3SoeiroMarinaNo ratings yet

- PM PRO Non-AdjustableDocument26 pagesPM PRO Non-AdjustableKarimZianiNo ratings yet

- ABB Padmount Switchgear Brochure Rev BDocument12 pagesABB Padmount Switchgear Brochure Rev BbertovalenNo ratings yet

- RN - Transformer Spec.Document21 pagesRN - Transformer Spec.ddhar633No ratings yet

- Клапан Регулирующий Поворотный Finetrol Fc Fg 5ft20 EnDocument12 pagesКлапан Регулирующий Поворотный Finetrol Fc Fg 5ft20 EnAli KianersiNo ratings yet

- PowerFulLiterature1 8smaDocument8 pagesPowerFulLiterature1 8smaGeorge Kwamina Anaman100% (1)

- R Series Valves PDFDocument3 pagesR Series Valves PDFRonald LlerenaNo ratings yet

- Semi-Internal "Pop-Action" Pressure Relief Valves For ASME ContainersDocument1 pageSemi-Internal "Pop-Action" Pressure Relief Valves For ASME ContainersshuzaoNo ratings yet

- KTM Actuator CatalogueDocument12 pagesKTM Actuator CatalogueRahimNo ratings yet

- "Pop-Action" Pressure Relief Valves: A8434 and A8436 SeriesDocument1 page"Pop-Action" Pressure Relief Valves: A8434 and A8436 SeriesshuzaoNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Olofsson 2015 IOP Conf. Ser.: Mater. Sci. Eng. 84 012026Document9 pagesOlofsson 2015 IOP Conf. Ser.: Mater. Sci. Eng. 84 012026Parag NaikNo ratings yet

- Lecture # 4Document28 pagesLecture # 4Usama ShahidNo ratings yet

- Corrosion Testing D Rossi CathodicDocument63 pagesCorrosion Testing D Rossi CathodicRahmat MohsinNo ratings yet

- PlasticsDocument69 pagesPlasticsMyrna TabernillaNo ratings yet

- Demoulding of Concrete Cubes From Plastic MDocument4 pagesDemoulding of Concrete Cubes From Plastic MangelinemiuNo ratings yet

- Effect of Si, Cu and Processing Parameters On Al-Si-Cu HPDC CastingsDocument24 pagesEffect of Si, Cu and Processing Parameters On Al-Si-Cu HPDC Castingskt rajaNo ratings yet

- A A 2017 Wintech S.R.L. Paper Aplusa2017.2500212 20old9qiRJq69hdzvqJPnw PDFDocument5 pagesA A 2017 Wintech S.R.L. Paper Aplusa2017.2500212 20old9qiRJq69hdzvqJPnw PDFkaleeswaranNo ratings yet

- Structure of SnO2 Nanoparticles by Sol-Gel MethodDocument3 pagesStructure of SnO2 Nanoparticles by Sol-Gel Methodivan benayaNo ratings yet

- Moormann (2012) German Design of Pile GroupsDocument20 pagesMoormann (2012) German Design of Pile GroupsJoeNo ratings yet

- 457 Plus: Physical DescriptionDocument2 pages457 Plus: Physical DescriptionZirve PolimerNo ratings yet

- Mineral and Power Resources of Chhota Nagpur RegionDocument10 pagesMineral and Power Resources of Chhota Nagpur RegionJasvinder Singh0% (1)

- IGCSE Chemistry - States of Matter and Separation TechniquesDocument12 pagesIGCSE Chemistry - States of Matter and Separation TechniquesChemistryKlipz100% (24)

- Norma Astm F794Document7 pagesNorma Astm F794WalterRamosNo ratings yet

- SCCS1624 Eng PH Salinity SodicityDocument39 pagesSCCS1624 Eng PH Salinity SodicityMenzi CekwaneNo ratings yet

- Expansion Joints For Power Stations Kompaflex BrochureDocument8 pagesExpansion Joints For Power Stations Kompaflex Brochuremdt3eNo ratings yet

- Carbon Structural Steel: Standardspecification ForDocument4 pagesCarbon Structural Steel: Standardspecification ForlinaNo ratings yet

- Water Treatment: SolutionsDocument16 pagesWater Treatment: SolutionsrobinNo ratings yet

- Nonrenewable Energy ResourcesDocument54 pagesNonrenewable Energy ResourcesEUNAH LimNo ratings yet

- BEC008 - MemsnemsDocument39 pagesBEC008 - MemsnemsACHIEVER MNo ratings yet

- Applied Catalysis B: EnvironmentalDocument14 pagesApplied Catalysis B: EnvironmentalAnonymous 2g4jKo5a7vNo ratings yet

- Corrosion Project Presentation SlidesDocument20 pagesCorrosion Project Presentation SlidesIsmeth Amir Johari100% (1)

- Detailed Estimates: Construction of Welcome Arch New Little Baguio, Brgy. Magsaysay, Infanta, QuezonDocument8 pagesDetailed Estimates: Construction of Welcome Arch New Little Baguio, Brgy. Magsaysay, Infanta, QuezonAiresh GoNo ratings yet

- iGCSE Chemistry Revision SheetsDocument26 pagesiGCSE Chemistry Revision SheetsPanagiotis ScordisNo ratings yet

- Heat Transfer To Fluids Without Phase ChangeDocument56 pagesHeat Transfer To Fluids Without Phase ChangeJanice Omadto100% (2)

- Saes A 134Document13 pagesSaes A 134Mohamed Soliman100% (1)

- Casting Defect in Slab PDFDocument55 pagesCasting Defect in Slab PDFBhoomaiah SunkenapalliNo ratings yet

- Acid in GiDocument23 pagesAcid in GiAsian Trans PowerNo ratings yet

- Pressure For Different Temperatures For Dimensions of Stainless Steel Welded Pipe and Seamless PipesDocument7 pagesPressure For Different Temperatures For Dimensions of Stainless Steel Welded Pipe and Seamless PipeswenigmaNo ratings yet

- D4206Document4 pagesD4206saifullah629No ratings yet

- Iso 6691 en PDFDocument11 pagesIso 6691 en PDFPAWAN KNo ratings yet