Professional Documents

Culture Documents

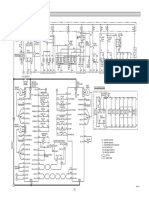

Section B-B Section A-A Detail Z Section C-C: Glued Push Rod D1,2mm

Uploaded by

fer freeOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section B-B Section A-A Detail Z Section C-C: Glued Push Rod D1,2mm

Uploaded by

fer freeCopyright:

Available Formats

36 54 ITEM NAME CATEGORY

18 20 1 Spinner1 C

2 Spinner2 C

54 36

53 16

9 3 Canopy1 A / A-LW

14 9 4 Canopy2 A / A-LW

5 Fus1 A / A-LW

52 15 26

6 Fus2 A / A-LW

17 24

22

7 Fus3 A / A-LW

28

30

8 Fus4 A / A-LW

19

9 Fus5 A / A-LW

21 27

23

10 VTP_1 A / A-LW

32

25 54 36 11 9

11 VTP_2 A / A-LW

29

54 36 31 11 9

11 10 12 Rudder_2 A / A-LW

13 Rudder_1 A / A-LW

11

11 9

14 WingC A / A-LW

10

7 8

3

15 Wing1L A / A-LW

2 4 C 12

B B

16 Wing1R A / A-LW

56 1

17 Wing2L A / A-LW

A 13

9 18 Wing2R A / A-LW

19 Wing3L A / A-LW

5 A C

6 55

20 Wing3R A / A-LW

11 9 21 Aileron1L A / A-LW

11 9 22 Aileron1R A / A-LW

23 Aileron2L A / A-LW

Nut M3 Glued push rod

11 10

24 Aileron2R A / A-LW

D1,2mm

Z 11 10

25 Aileron3L A / A-LW

x3 33

11 9

34

11 9 26 Aileron3R A / A-LW

27 HTP1L A / A-LW

Washer Bolt M3X25

Section B-B

11 9

Section A-A

28 HTP1R A / A-LW

Detail Z

11 9

29 HTP2L A / A-LW

(Concept valid also for join

Section C-C

11 9

30 HTP2R A / A-LW

(Typical detail for intarface between WingC and Wing1R

11 9

between fuselage and wing)

11 9 31 Elev1L A / A-LW

11 9 32 Elev1R A / A-LW

33 Anchor_nut C

Steel rod D2mm 34 Guide C

35 Rudder_fitting C

36 Axis_w_hole C

18 18

41 42

40 39 8 37 Tyre_D20 C

38 RimD20 C

43 44 39 Wheel_fairing_1L C / C-LW

40 Wheel_fairing_1R C / C-LW

92

36

41 Wheel_fairing_2L C / C-LW

92

45

42 Wheel_fairing_2R C / C-LW

46

43 Wheel_fairing_3L C / C-LW

44 Wheel_fairing_3R C / C-LW

45 RimD40 C

37 35 26 26

Push rod D1.2

47

38 RIGHT ROD 8 46 TyreD40 C

47 Motor_holder C

LEFT ROD

51 x2 5

48 Cover_horn C

TAIL SECTION MAIN LANDING GEAR

49 Servo_holder_wing C

15

50 Servo_holder_fus C

15

x2 50

51 Root_LG C

Elevator 52 Wing1L_woLG A / A-LW

Aileron

53 Wing1R_woLG A / A-LW

15

54 Hinge_wing C

15

55 Elevator_fitting C

48 X2

Rudder

x2 49

57 56 Spinner1_short C

57 ESC_iso_plate C

15

Recommended throw

6

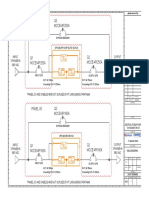

PRINTING PARAMETER CATEGORY

A-LW A C-LW C

11 Add 6 top layers Layer height (mm) 0.25 0,2 0,15 0,13

Bottom layers 0 0 4 4

10 Add 8 bottom layers Top layers 0 0 6 6

Wall lines / perimeter 1 1 2 2

Add 2 bottom layers (parts marked with this flag note)

Nozzle diameter (mm) 0,4 0,4 0,4 0,4

9

Material LW-PLA PLA/ LW-PLA PLA/PETG

Print "tyres" with flexible material.

PETG FLEX/ABS

8

6 Print the Item 57 with ABS and place it between Infill density (%) 0 0 10 10

the ESC and fuselage to avoid melting the PLA Printing temp (°C) 235 220 235 205 to 240

5 If your motor reach temperatures Bed temp (°C) 60 60 60 60

over 50 °C use ABS or PETG for "Motor_holder" Flow (%) 53 100 53 100

4-Center of gravity marking under the wing. Retraction (mm) 0,5 to 3 0,5 to 3 0,5 to 3 3

3-Do not print LW-PLA parts at the same time with Retraction extra prime amount (mm) 0 to 0,7 0 to 0,7 0 0

others to avoid stringing in the outer surface. Speed (mm/s) 55 50 35 25 to 50

2-Stringing can not be eliminated for LW-PLA material. Fan YES YES YES YES

1- Red parameters are mandatory to ensure airplane Brim (mm) 3 to 5 3 to 5 0 to 3 0 to 3

functionality, assembly or weight target. Minimun layer time (s) 5 5 5 5

Support NO NO NO NO

You might also like

- Ajuda Per A Imprimir AvioDocument1 pageAjuda Per A Imprimir AvioEduard Bauza CollNo ratings yet

- Printing Parameters EMADocument1 pagePrinting Parameters EMA10ahmad yusuf maulanaNo ratings yet

- AvionDocument1 pageAvionADRIAN MARQUEZNo ratings yet

- ALC Hydraulic GMV 3010 Electrical DiagramDocument20 pagesALC Hydraulic GMV 3010 Electrical Diagramمحمد حسينNo ratings yet

- Express Svmanc AppendixaDocument22 pagesExpress Svmanc Appendixaomar lucioNo ratings yet

- 2011 Ford F650 6.7 Turning Stop and Hazard Wiring DiagramDocument1 page2011 Ford F650 6.7 Turning Stop and Hazard Wiring DiagramDenton RohrerNo ratings yet

- 7-2. 전기 회로 PDFDocument1 page7-2. 전기 회로 PDFHuu Cuong NguyenNo ratings yet

- AW55-50SN Parts Catalougue PDFDocument6 pagesAW55-50SN Parts Catalougue PDFStephen BonnettNo ratings yet

- Solar Power Plant SLD - 15KWDocument1 pageSolar Power Plant SLD - 15KWSHIVI ARORA0% (1)

- Mapping Kabel Area ProduksiDocument3 pagesMapping Kabel Area ProduksiHarmawan SaranaprimaNo ratings yet

- Refine S2 Service Manual: MotorsDocument200 pagesRefine S2 Service Manual: MotorsJaime Eduardo Alvarez Baron100% (1)

- Coesex 2013-Geral PDFDocument1 pageCoesex 2013-Geral PDFJacqueline SatikoNo ratings yet

- 330B and 330B L Excavators Hydraulic System: 330B: 8SR1-UP 330B L: 8TR1-UP 1JS1-UP 1KS1-UPDocument2 pages330B and 330B L Excavators Hydraulic System: 330B: 8SR1-UP 330B L: 8TR1-UP 1JS1-UP 1KS1-UPsandrayaniNo ratings yet

- 245 Wiring Diagram For Electronic Ignition Switch (EIS) Control UnitDocument5 pages245 Wiring Diagram For Electronic Ignition Switch (EIS) Control UnitRosli YaacobNo ratings yet

- W36LB CompletoDocument8 pagesW36LB Completoeliot martinezNo ratings yet

- Hydraulic AR1681Document2 pagesHydraulic AR1681Chokchai JitmonmanaNo ratings yet

- Cat 320CDocument2 pagesCat 320CДмитрий100% (1)

- Ilovepdf MergedDocument10 pagesIlovepdf MergeddgplazaNo ratings yet

- Transmision RTLO 14618ADocument2 pagesTransmision RTLO 14618ATractopartes IntertipNo ratings yet

- 1) 7500kVA Drawing SGS MY PT-09-0112Document1 page1) 7500kVA Drawing SGS MY PT-09-0112Mark Roger II HuberitNo ratings yet

- Dept. Technical Reference Created by Approved byDocument1 pageDept. Technical Reference Created by Approved bymadmanmikeNo ratings yet

- Mid-Section: Clamp/Swivel Brackets and Drive Shaft HousingDocument9 pagesMid-Section: Clamp/Swivel Brackets and Drive Shaft HousingRich UrbanNo ratings yet

- Single Line Ibs ApcdbDocument1 pageSingle Line Ibs ApcdbM Arifur RahmanNo ratings yet

- Senr 8972 A 00001Document2 pagesSenr 8972 A 00001alsief1951No ratings yet

- Digital inDocument1 pageDigital inRafałSzewcNo ratings yet

- 3 PoleDocument3 pages3 PoleSejahtra AbadiNo ratings yet

- LW 110 B - 130 B - DiagrammDocument6 pagesLW 110 B - 130 B - DiagrammsvkeenNo ratings yet

- Hyundai HBF25C Electric ShematicDocument63 pagesHyundai HBF25C Electric ShematicmartinNo ratings yet

- Concerto No.9 in D Major (RV 230) : Allegro A. VivaldiDocument8 pagesConcerto No.9 in D Major (RV 230) : Allegro A. VivaldiVanessa Ortega VallejoNo ratings yet

- Current Revision Approved: Anti-Spin, 68H/SbsDocument2 pagesCurrent Revision Approved: Anti-Spin, 68H/Sbscapslive_001No ratings yet

- Section 4 Electrical SystemDocument3 pagesSection 4 Electrical SystemTaha RdmanNo ratings yet

- F4A-El / 4Eat-F / If4E / F4Eiii: FWD 4 Speed (1 Pan)Document5 pagesF4A-El / 4Eat-F / If4E / F4Eiii: FWD 4 Speed (1 Pan)andres guerraNo ratings yet

- v6 Engine Complete Assembly-ExplodedDocument1 pagev6 Engine Complete Assembly-Explodedmarouane najaheNo ratings yet

- Adm-16 Ring-42Document1 pageAdm-16 Ring-42Saikat SarkarNo ratings yet

- EBLA Wiring Diagram PDFDocument1 pageEBLA Wiring Diagram PDFJoão VazNo ratings yet

- Diagrama Chevrolet Sail NewDocument16 pagesDiagrama Chevrolet Sail NewHildemar Javier Liscano100% (1)

- Exc Wheel 200Document52 pagesExc Wheel 200Husin Umardani100% (1)

- Section 4 Electrical SystemDocument3 pagesSection 4 Electrical SystemAlexis BodronNo ratings yet

- U150E / U151E / U250E: FWD 5 SpeedDocument6 pagesU150E / U151E / U250E: FWD 5 SpeedJD Dionisio100% (2)

- Toyota U140 / U240: FWD 4 SpeedDocument6 pagesToyota U140 / U240: FWD 4 Speedjuan carlos garcia100% (1)

- U140Document6 pagesU140HectorNo ratings yet

- 12H, 140H & 160H NA Versions Hydraulic Systems Motor GradersDocument2 pages12H, 140H & 160H NA Versions Hydraulic Systems Motor Gradersyasser eljabaliNo ratings yet

- QM5 Series Parts - AirToolProDocument8 pagesQM5 Series Parts - AirToolProCLAUDIO MELLANo ratings yet

- J10 To J14 2-Pin Male Headers - J10, J11 Shorted by Jumper When Programming - J12, J13, J14 Shorted During Board TestingDocument1 pageJ10 To J14 2-Pin Male Headers - J10, J11 Shorted by Jumper When Programming - J12, J13, J14 Shorted During Board TestingRenzoNo ratings yet

- Section 7 Electrical System: Group 1 Component LocationDocument83 pagesSection 7 Electrical System: Group 1 Component Locationdaniela100% (1)

- Parmac L.L.C. V-80 Hydromatic Brake End Inlets (Old Style) C.C.W. Rotation REPAIR KIT 1-U632348-XDocument1 pageParmac L.L.C. V-80 Hydromatic Brake End Inlets (Old Style) C.C.W. Rotation REPAIR KIT 1-U632348-XingcalderonNo ratings yet

- Panel I/O Q3 MCCB 4P/250A: Input 3 Phase+N 380 VAC Output 3 Phase+N 380 VACDocument4 pagesPanel I/O Q3 MCCB 4P/250A: Input 3 Phase+N 380 VAC Output 3 Phase+N 380 VACefitNo ratings yet

- Structure Drawing-1Document6 pagesStructure Drawing-1Abenether Bekele75% (4)

- MHAWK LHD Manual Electrico PDFDocument52 pagesMHAWK LHD Manual Electrico PDFAlex BravoNo ratings yet

- HPU Pump Part Numbers ParkerDocument7 pagesHPU Pump Part Numbers Parkerahmedwinner119No ratings yet

- 011023.GA Drg.2500 33 SPL Tap - BilaspurDocument1 page011023.GA Drg.2500 33 SPL Tap - BilaspurYogesh GuptaNo ratings yet

- Dsa-6000, Fsa-Dlhi1217 (Sarita Vihar)Document1 pageDsa-6000, Fsa-Dlhi1217 (Sarita Vihar)Print WorksNo ratings yet

- Control Loop 9Document19 pagesControl Loop 9nmulyonoNo ratings yet

- RMQLP-4120-H10 (Assembly)Document3 pagesRMQLP-4120-H10 (Assembly)Debabrata SahaNo ratings yet

- KXF1 - SC02 - 400KV Tie Protection - Rev-Z - 09.04.2018Document84 pagesKXF1 - SC02 - 400KV Tie Protection - Rev-Z - 09.04.2018Saipavan kumar ravikantiNo ratings yet

- One-Line Diagram - OLV1 (Load Flow Analysis) : Scheme-1Document1 pageOne-Line Diagram - OLV1 (Load Flow Analysis) : Scheme-1EILA545 QAQCNo ratings yet

- VW Sharan 1997 WD EngDocument745 pagesVW Sharan 1997 WD Engkolea13579No ratings yet

- ABS (TMMMS Made), Brake Assist (TMMMS Made)Document12 pagesABS (TMMMS Made), Brake Assist (TMMMS Made)Albert BriceñoNo ratings yet

- P.38 F Lightning. Plan. Scale Rubber Twin. Aeromodeller December 1985Document1 pageP.38 F Lightning. Plan. Scale Rubber Twin. Aeromodeller December 1985fer freeNo ratings yet

- Plan Trotteldecker A1Document1 pagePlan Trotteldecker A1fer freeNo ratings yet

- Build Instructions:: Download Extra 300 - 900 MM Plans Download Extra 300 - 900 MM Mazda DecalsDocument16 pagesBuild Instructions:: Download Extra 300 - 900 MM Plans Download Extra 300 - 900 MM Mazda Decalsfer freeNo ratings yet

- Super Decathlon Plan DecGp02Document2 pagesSuper Decathlon Plan DecGp02fer freeNo ratings yet

- Avionic Gulfstream IV-3Document657 pagesAvionic Gulfstream IV-3Henry Blandon100% (2)

- Clutch Manual 2013 PDFDocument16 pagesClutch Manual 2013 PDFArnaldo BenitezNo ratings yet

- ACI-World Business Partner DirectoryDocument104 pagesACI-World Business Partner Directoryhaihien98livly100% (1)

- Vaoz/Isk Ozar, IndiaDocument4 pagesVaoz/Isk Ozar, Indiamehul da aviatorNo ratings yet

- Elastic Stability of ColumnsDocument11 pagesElastic Stability of ColumnsSayantan GhosalNo ratings yet

- ES 15 2SAY1617 SyllabusDocument2 pagesES 15 2SAY1617 SyllabusdewittdalisayNo ratings yet

- AD 2-FAKM-7 AIP South AfricaDocument4 pagesAD 2-FAKM-7 AIP South AfricaKHUSHAL BANSALNo ratings yet

- HSBA MIC Open Source Review 2014Document11 pagesHSBA MIC Open Source Review 2014Aly VerjeeNo ratings yet

- TE255261 TE SensorSolutions - SS TS TE100!09!2016inddDocument100 pagesTE255261 TE SensorSolutions - SS TS TE100!09!2016inddAravind VickyNo ratings yet

- Part 145 Airworthiness Approved OrganisationsDocument145 pagesPart 145 Airworthiness Approved Organisationsflorin constantinNo ratings yet

- Flight LabDocument4 pagesFlight LabGabriela BibiNo ratings yet

- Obogs System Training: Life SupportDocument30 pagesObogs System Training: Life SupportKim GomezNo ratings yet

- ABAP ProjectsDocument10 pagesABAP Projectsprakash_tseNo ratings yet

- AW609 BrochureDocument8 pagesAW609 BrochureSiddiq Naslah0% (1)

- Cleanroom CleaningDocument5 pagesCleanroom Cleaningbmverona100% (1)

- International CanSat Workshop - Program and AbstractsDocument30 pagesInternational CanSat Workshop - Program and AbstractsjjaavvmmNo ratings yet

- 120mm M865 TPCSDS-T: Target Practice Cone Stabilized Discarding Sabot With TracerDocument1 page120mm M865 TPCSDS-T: Target Practice Cone Stabilized Discarding Sabot With TracerOsorio LuisNo ratings yet

- CG TestDocument2 pagesCG TestSanket PujariNo ratings yet

- SP 8001 - Buffeting During Atmospheric AscentDocument22 pagesSP 8001 - Buffeting During Atmospheric AscentElumalai SrinivasanNo ratings yet

- Basic Navigation: His Fuel Management, So That The Flight Could Be Continued in SafetyDocument1 pageBasic Navigation: His Fuel Management, So That The Flight Could Be Continued in SafetyUser123456nameNo ratings yet

- Bro Bspot en r7Document4 pagesBro Bspot en r7Daniel Jimenez MerayoNo ratings yet

- Completing The E Conditions DossierDocument9 pagesCompleting The E Conditions DossieraunbhuttaNo ratings yet

- Indian Logistics Industry Insight-AviationDocument101 pagesIndian Logistics Industry Insight-AviationSmrita Singh Chandra100% (1)

- Aircraft Sealants: Sealant Application Chart & Cross ReferenceDocument1 pageAircraft Sealants: Sealant Application Chart & Cross ReferenceYuda IswantoNo ratings yet

- 9gana18k02 PDFDocument5 pages9gana18k02 PDFFalaq RpNo ratings yet

- Despre Tarom WikipediaDocument8 pagesDespre Tarom WikipediaDenisa BaltariuNo ratings yet

- Ho 51Document68 pagesHo 51Lavern P. SipinNo ratings yet

- Module 17.2 - B1 - Rev 00 PDFDocument13 pagesModule 17.2 - B1 - Rev 00 PDFAhmed Nasir MalikNo ratings yet

- Bonanza 14v Wiring 5891Document255 pagesBonanza 14v Wiring 5891José A. Montiel QuirósNo ratings yet

- HawkDocument6 pagesHawkMarcus Wolf100% (2)