Professional Documents

Culture Documents

Ultrasonic Flow Meter PDF

Uploaded by

sandeep chandranOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ultrasonic Flow Meter PDF

Uploaded by

sandeep chandranCopyright:

Available Formats

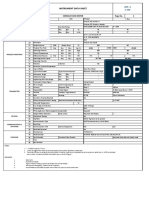

DATASHEET FOR ULTRASONIC METER

1 Meter Type ULTRASONIC FLOW METER REV 43 Others

Flow Piping

2 Quantity 1 Size 6" Flange 46 Special Cable m VTA

5 Services Flow Measurement and Control 47 Strainer VTA

6 Location 6''-RG-002-D1A-80 48

7 Fluid/State HC GAS 49

Flow

8 Min 15 Op. 50 Max 65 50

OPERATING CONDITIONS

MMSCFD

9 Pressure barg Min 18 Op. 26 Max 40 51

10 Temperature ºC Min 10 Op. 36 Max 50 52 ISO 17089 Yes

Density OIML R137-1

Compliance

11 kg/m³ Min 14.10 Op. 20.65 Max 32.40 53 Yes

Specific Gravity/Molec.

12 Weight 0.63 18.34 54 Rules AGA REPORT 9 Yes

13 Dynamic Viscosity cP 0.01213 55 2004/22/CE (MID)

14 Compressibility Factor (z) Cp/Cv 0.9328 1.369667 56

15 H2S/CO2 / Water 0 %. %.1.6867 %.0.25 57 Minimum Flowrate MMSCFD Sm3/day

16 Max Diff Pressure / Velocity Bar m/s 58 Transitional Flowrate MMSCFD Sm3/day

Metrological Characteristics

17 Size 6" 59 Normal Flowrate MMSCFD Sm3/day

Line

18 Class / Schedule 600# / SCH. 80 60 Maximum Flowrate MMSCFD Sm3/day

19 Material ASTM A333 GR.6 / LT Carbon Steel 61 Overload Flowrate kg/h Sm3/day

20 DN - 62 Density Min Max

MECHANICAL CHARACTERISTICS

Primary Instrument

21 Design Temperature ºC Min 0 Norm. Max 80 63 Accuracy Class MID OIML Yes

22 Design Code ASME B31.3/B16.5/B16.47 64 Flow Direction Unidirectional

23 Wet parts/Body Material 316 SS LT-CS 65 Systematic Uncertainty Qmin - Qt Qt - Qmax

Uncertainty

Min. No. of

24 Body connection Flange 4 66 Volume mᵌ/h - %

Path

25 Face to Face dimension/weight mm VTA kg VTA 67 Random Uncertainty Qmin - Qt Qt - Qmax

26 Connection Type/Class/Rating Flange 150# RF 68 Volume mᵌ/h - %

Connection

Ambient Cond.

27 Flange Mat./Sealing surf. Finish. ASTM A105 RF 69 Ambient Temperature ºC Min 16 oC Max 36 oC

28 70 Relative Humidity - % Normal 90% to 95% (Max 99%)

29 Up/Downstream straight pipe (min) 10 D 3D 71 Tropicalization Yes

Installation

30 Flow Conditioner / Type 72 Nº of Calibration point VTA

Calibration

31 Mounting In-Line 73 Calibration range m³/h VTA

32 Model/Type VTA VTA 74 Reference rule VTA

33 Mounting On Meter Tube 75 Allowable limits VTA

34 Supply/Power Consumption 230Vac from UPS VTA

35 Power Feed UPS

TRANSMITTER

36 Electric Area Classification Zone 1 Gas Group IIB T3

37 Eletr. Connect. Supply/Signal VTA 1/2" NPT (F)

38 Box Mater./Ingress Protection Aluminium (AlSi12(Fe)) IP65

39 4-20mA Yes

40 Output (Type/Q.ty/ Function) RS485 Yes

41 Impulse

File Name:NGIC-CTM-005-ICS-DTS-0028_R01_Technical datasheet for Ultrasonic Meter

This document is CONFIDENTIAL and the sole property of the Company. It shall neither be shown to third parties nor used for other purposes than those for which it has been issued/sent. Any unauthorized

attempt to reproduce it, in any form, is strictly prohibited.

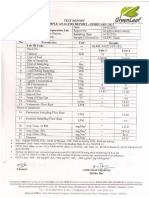

DATASHEET FOR ULTRASONIC METER

1 Meter Type ULTRASONIC FLOW METER REV 43 Others

Flow Piping

2 Quantity 1 Size 6" Flange 46 Special Cable m VTA

5 Services Flow Measurement for Flow Control 47 Strainer VTA

6 Location 6''-RG-003-D1A-80 48

7 Fluid/State HC GAS 49

Flow

8 Min 15 Op. 50 Max 65 50

OPERATING CONDITIONS

MMSCFD

9 Pressure barg Min 18 Op. 26 Max 40 51

10 Temperature ºC Min 10 Op. 36 Max 50 52 ISO 17089 Yes

Density OIML R137-1

Compliance

11 kg/m³ Min 14.10 Op. 20.65 Max 32.40 53 Yes

12 Specific Gravity/Molec. Weight 0.63 18.34 54 Rules AGA REPORT 9 Yes

13 Dynamic Viscosity cP 0.01213 55 2004/22/CE (MID)

14 Compressibility Factor (z) Cp/Cv 0.9328 1.369667 56

15 H2S/CO2 / Water 0 %. %.1.6867 %.0.25 57 Minimum Flowrate MMSCFD Sm3/day

16 Max Diff Pressure / Velocity Bar m/s 58 Transitional Flowrate MMSCFD Sm3/day

Metrological Characteristics

17 Size 6" 59 Normal Flowrate MMSCFD Sm3/day

Line

18 Class / Schedule 600# / SCH. 80 60 Maximum Flowrate MMSCFD Sm3/day

19 Material ASTM A106 Gr. B 61 Overload Flowrate kg/h Sm3/day

20 DN - 62 Density Min Max

MECHANICAL CHARACTERISTICS

Primary Instrument

21 Design Temperature ºC Min 0 Norm. Max 80 63 Accuracy Class MID OIML Yes

22 Design Code ASME B31.3/B16.5/B16.47 64 Flow Direction Unidirectional

23 Wet parts/Body Material 316 SS 316 SS 65 Systematic Uncertainty Qmin - Qt Qt - Qmax

Uncertainty

Min. No. of

24 Body connection Flange 4 66 Volume mᵌ/h - %

Paths

25 Face to Face dimension/weight mm VTA kg VTA 67 Random Uncertainty Qmin - Qt Qt - Qmax

26 Connection Type/Class/Rating Flange 150# RF 68 Volume mᵌ/h - %

Connection

Ambient Cond.

27 Flange Mat./Sealing surf. Finish. ASTM A105 RF 69 Ambient Temperature ºC Min 16 oC Max 36 oC

28 70 Relative Humidity - % Normal 90% to 95% (Max 99%)

29 Up/Downstream straig 10 D 3D 71 Tropicalization Yes

Installation

30 Flow Conditioner / Type 72 Nº of Calibration point VTA

Calibration

31 Mounting In-Line 73 Calibration range m³/h VTA

32 Model/Type VTA VTA 74 Reference rule VTA

33 Mounting On Meter Tube 75 Allowable limits VTA

34 Supply/Power Consumption 24Vdc VTA

35 Power Feed UPS

TRANSMITTER

36 Electric Area Classification Zone 1 Gas Group IIB T3

37 Electr. Connect. Supply/Signal VTA 1/2" NPT (F)

38 Box Meter./Ingress Protection 316 SS IP65

39 4-20mA Yes

40 Output (Type/Q.ty/ Function) RS485 Yes

41 Impulse

File Name:NGIC-CTM-005-ICS-DTS-0028_R01_Technical datasheet for Ultrasonic Meter

This document is CONFIDENTIAL and the sole property of the Company. It shall neither be shown to third parties nor used for other purposes than those for which it has been issued/sent. Any unauthorized

attempt to reproduce it, in any form, is strictly prohibited.

You might also like

- Pedia Idiot NotesDocument18 pagesPedia Idiot Noteswiljamesclim100% (8)

- African Cookbook 2nd EditionDocument144 pagesAfrican Cookbook 2nd EditionTuğçe Dinçer100% (1)

- Thesis 1-Scope and DelimitationDocument1 pageThesis 1-Scope and DelimitationBryan Bryan87% (31)

- Calculation Note - Pump Rev 2Document4 pagesCalculation Note - Pump Rev 2Steve WanNo ratings yet

- IMO 884 TowingDocument15 pagesIMO 884 TowingPrasanna Kumar Kollala100% (3)

- Rigel Medical A Practical Guide To IEC 60601 1 PDFDocument28 pagesRigel Medical A Practical Guide To IEC 60601 1 PDFV RNo ratings yet

- Chemistry ProjectDocument10 pagesChemistry ProjectVineet Agarwal50% (4)

- Datasheet For Restriction OrificeDocument1 pageDatasheet For Restriction OrificeRajesh Rajesh67% (3)

- FEA-Inlet Separator & Scrubber Process Data Sheet ADA Rev. B0Document14 pagesFEA-Inlet Separator & Scrubber Process Data Sheet ADA Rev. B0ddaalayamoct313024No ratings yet

- (A) Design - Introduction To Transformer DesignDocument16 pages(A) Design - Introduction To Transformer DesignZineddine BENOUADAHNo ratings yet

- Haramase Simulator Achievement GuideDocument3 pagesHaramase Simulator Achievement GuideRisdiansyah 08633% (9)

- PX 95 Service ManualDocument167 pagesPX 95 Service Manualidigiti100% (1)

- EH Coriolis & Ultrasonic DSDocument5 pagesEH Coriolis & Ultrasonic DSsendutdutNo ratings yet

- Coriolis Mass Flow MeterDocument2 pagesCoriolis Mass Flow MeterSreejesh SundaresanNo ratings yet

- DASDocument39 pagesDASchakrapani vagish chandra pandeyNo ratings yet

- Documents For Approval Rev-1 - ApprovedDocument42 pagesDocuments For Approval Rev-1 - ApprovedAbhijeet WayaseNo ratings yet

- Instrument Data For Coriolis Flow TransmitterDocument2 pagesInstrument Data For Coriolis Flow Transmitterdilip matalNo ratings yet

- KSB MIL Controls Limited Valve Specification SheetDocument2 pagesKSB MIL Controls Limited Valve Specification SheetPablo TorresNo ratings yet

- Ultra Filtration: 201485 Mechanical Data Sheet REV 2 201485-Z20212-01 Ammonia-Urea Ii Project Proj NoDocument2 pagesUltra Filtration: 201485 Mechanical Data Sheet REV 2 201485-Z20212-01 Ammonia-Urea Ii Project Proj NoAbu SuraisyNo ratings yet

- M40035 8 Dshe 004Document4 pagesM40035 8 Dshe 004faradioNo ratings yet

- NSDocument1 pageNSXemtintuc Xem TinNo ratings yet

- Extracted Pages From 1.2 P2B-00-52-ABB-273-001 REV.1 INSTRUMENT DATA SHEET AMMONIADocument2 pagesExtracted Pages From 1.2 P2B-00-52-ABB-273-001 REV.1 INSTRUMENT DATA SHEET AMMONIALoolooNo ratings yet

- 150HV003-IFT-Data SheetDocument1 page150HV003-IFT-Data SheetgerardoNo ratings yet

- Data Sheet For Flow TransmitterDocument1 pageData Sheet For Flow TransmitterNilesh ChavanNo ratings yet

- New Project - ExportDocument1 pageNew Project - ExportRadhakrishnan SreerekhaNo ratings yet

- 150FV054-IFT-Data SheetDocument1 page150FV054-IFT-Data SheetgerardoNo ratings yet

- Cam 200-390-110kwDocument4 pagesCam 200-390-110kwbocahjeblogNo ratings yet

- Datasheet For PSVDocument1 pageDatasheet For PSVlãng duNo ratings yet

- 150FV104-IFT-Data SheetDocument1 page150FV104-IFT-Data SheetgerardoNo ratings yet

- Gujarat Electricity Corporation Ltd. Stack Sample AnalysisDocument1 pageGujarat Electricity Corporation Ltd. Stack Sample AnalysisAbhijeet OundhakarNo ratings yet

- K 61 33 PR DTS 20009 - 0001 - 0Document6 pagesK 61 33 PR DTS 20009 - 0001 - 0santhoshkrishnaNo ratings yet

- Kirloskar Systech Limited: NotesDocument1 pageKirloskar Systech Limited: NotesNilesh ChavanNo ratings yet

- Q1Co 3000 Q1Co 3620 3620-FIT - 286Document2 pagesQ1Co 3000 Q1Co 3620 3620-FIT - 286JHONATAN RODRIGUEZ VENTONo ratings yet

- Usonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionDocument3 pagesUsonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionJhonatan RodriguezNo ratings yet

- Q1Co 3000 Q1Co 3620 3620-FIT - 186Document2 pagesQ1Co 3000 Q1Co 3620 3620-FIT - 186JHONATAN RODRIGUEZ VENTONo ratings yet

- Flow Trans DataheetsDocument5 pagesFlow Trans DataheetsAbraham Osarenkhoe PatrickNo ratings yet

- Project Title Metering Unit Process Datasheet: Date: Rev.: Ref. 1 / 4Document4 pagesProject Title Metering Unit Process Datasheet: Date: Rev.: Ref. 1 / 4anghel_florin82No ratings yet

- Datasheet For Control Valve - IfbDocument34 pagesDatasheet For Control Valve - Ifbfathan fathullahNo ratings yet

- Shift LogDocument4 pagesShift LogRohith kumarNo ratings yet

- Cam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetDocument2 pagesCam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetJHONATAN RODRIGUEZ VENTONo ratings yet

- MQ13 02 DS 3510 Inhv142b - R0Document2 pagesMQ13 02 DS 3510 Inhv142b - R0JHONATAN RODRIGUEZ VENTONo ratings yet

- 150FV002-IFT-Data SheetDocument1 page150FV002-IFT-Data SheetgerardoNo ratings yet

- RCCT36 Coriolis Mass MeterDocument20 pagesRCCT36 Coriolis Mass Meterfabio amayaNo ratings yet

- Me Performance Jul - 2020Document1 pageMe Performance Jul - 2020Amit Raj AnandNo ratings yet

- Aspen Zik PDFDocument31 pagesAspen Zik PDFAhmad ZikryNo ratings yet

- Cam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetDocument2 pagesCam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetJHONATAN RODRIGUEZ VENTONo ratings yet

- Fairchild Model 11 Low Pressure Reducing Regulator: Installation, Operation and Maintenance InstructionsDocument4 pagesFairchild Model 11 Low Pressure Reducing Regulator: Installation, Operation and Maintenance Instructionsishtiaque_anwarNo ratings yet

- Desuper-heater Specification Sheet فناورانDocument1 pageDesuper-heater Specification Sheet فناورانMAHDINo ratings yet

- SGPC-GIZ-HD-002 - Hoja de Datos Medidor Masico (Coriolis) - RevADocument1 pageSGPC-GIZ-HD-002 - Hoja de Datos Medidor Masico (Coriolis) - RevAاليخاندرو اغيليراNo ratings yet

- A307 Ius Uv DS 1201Document2 pagesA307 Ius Uv DS 1201smartravi222No ratings yet

- Q1Co 3000 Q1Co 3520 3520-LIT - 381Document3 pagesQ1Co 3000 Q1Co 3520 3520-LIT - 381Jhonatan RodriguezNo ratings yet

- Aximax 2HL 3698SF FanDocument3 pagesAximax 2HL 3698SF FanDhanus KodiNo ratings yet

- Final End User Data Sheets 15 Valves Tor Deshy Rev1Document15 pagesFinal End User Data Sheets 15 Valves Tor Deshy Rev1Ghofrane HNo ratings yet

- A307 Ius FV DS 1311Document2 pagesA307 Ius FV DS 1311Ravi KumarNo ratings yet

- Control Valve Data SheetDocument1 pageControl Valve Data SheetKelly Perez LopezNo ratings yet

- 2FRM 5Document5 pages2FRM 5Romly MechNo ratings yet

- SR - 2012-09 Solenoid ValveDocument2 pagesSR - 2012-09 Solenoid ValveHsein WangNo ratings yet

- CDM 400x300 enDocument5 pagesCDM 400x300 enbocahjeblogNo ratings yet

- Guidline IcpDocument2 pagesGuidline IcpChandra IskandarNo ratings yet

- 417 2016052-Di041-509 - 1Document1 page417 2016052-Di041-509 - 1lamisma09No ratings yet

- 03 Series Stacking Type Port A/B Throttle Valves: NomenclatureDocument2 pages03 Series Stacking Type Port A/B Throttle Valves: NomenclatureAnonymous 3o4Mwew0No ratings yet

- Submersible Pump CatalogueDocument8 pagesSubmersible Pump CatalogueFILID MADNo ratings yet

- 14960-000-ME-DAS-003 Data Sheet For Sump PumpsDocument8 pages14960-000-ME-DAS-003 Data Sheet For Sump PumpsAshish TIwariNo ratings yet

- Columna de DestilaciónDocument1 pageColumna de Destilaciónest.sgil899No ratings yet

- KNT-002-TS-IA2-DS-018 - 1 - DATASHEET FOR WATERCUT METER-trang-3-6Document4 pagesKNT-002-TS-IA2-DS-018 - 1 - DATASHEET FOR WATERCUT METER-trang-3-6hoapro537817No ratings yet

- Process Design Conditions: 842-PA-K17-3"-ES32EKFR-NIDocument2 pagesProcess Design Conditions: 842-PA-K17-3"-ES32EKFR-NITHOMASNo ratings yet

- Ds DpsDocument1 pageDs DpsNilesh ChavanNo ratings yet

- Drum Data Sheet: Ctci CorporationDocument4 pagesDrum Data Sheet: Ctci Corporationjdaig17No ratings yet

- Gene Regulation: Made By: Diana Alhazzaa Massah AlhazzaaDocument17 pagesGene Regulation: Made By: Diana Alhazzaa Massah AlhazzaaAmora HZzNo ratings yet

- Day 1 - Introduction To Mobile CommunicationDocument16 pagesDay 1 - Introduction To Mobile CommunicationMichelle NyamupanemundaNo ratings yet

- GEHC Brochure OEC Brivo Plus C Arm The Confident ChoiceDocument8 pagesGEHC Brochure OEC Brivo Plus C Arm The Confident ChoiceGANESHNo ratings yet

- Polish Recipe PDFDocument3 pagesPolish Recipe PDFfoodprinteuNo ratings yet

- Jared Hunter ResignationDocument1 pageJared Hunter ResignationAnna BeahmNo ratings yet

- Drug StudyDocument9 pagesDrug StudyPantaleon PacisNo ratings yet

- Group - 6 Positive PhychologyDocument57 pagesGroup - 6 Positive PhychologyIamLNo ratings yet

- Dwnload Full Anatomy and Physiology 9th Edition Patton Test Bank PDFDocument20 pagesDwnload Full Anatomy and Physiology 9th Edition Patton Test Bank PDFamess.trias.xpuax100% (13)

- Effects of Carbohydrate Crystallization On Stability of Dehydrated Foods and Ingredient FormulationsDocument9 pagesEffects of Carbohydrate Crystallization On Stability of Dehydrated Foods and Ingredient FormulationsIsra CFNo ratings yet

- JHA 12 - Complete - 4 CopiesDocument15 pagesJHA 12 - Complete - 4 CopiesSaravanan krishnanNo ratings yet

- Booking Report 12-20-21Document2 pagesBooking Report 12-20-21WCTV Digital TeamNo ratings yet

- Exp 3 Lab Scale Margarine ProductionDocument11 pagesExp 3 Lab Scale Margarine Productionaffeena100% (2)

- Polybond PVA: PVA Based Bonding Agent and AdmixtureDocument2 pagesPolybond PVA: PVA Based Bonding Agent and AdmixtureHtun ZarniNo ratings yet

- 2 Infectious Disease EpidemiologyDocument62 pages2 Infectious Disease Epidemiologykindness jawoNo ratings yet

- Scarlett Ball - Wicreflecttemp23Document3 pagesScarlett Ball - Wicreflecttemp23api-665569952No ratings yet

- Sympathetic Vs para SympatheticDocument2 pagesSympathetic Vs para SympatheticLesther Alba Dela CruzNo ratings yet

- Fall 08 MC Newsletter Research Microscopy & Histology CoreDocument4 pagesFall 08 MC Newsletter Research Microscopy & Histology CoreslusompedsNo ratings yet

- Dimensions and Terminal (Unit: MM (Inches) )Document2 pagesDimensions and Terminal (Unit: MM (Inches) )cojoncioNo ratings yet

- Freeman Aortic RegurgitationDocument102 pagesFreeman Aortic RegurgitationJose Ignacio Tarton SisimitNo ratings yet

- Form 4. 1 Self-Assessment ChecklistDocument3 pagesForm 4. 1 Self-Assessment ChecklistMay M RodeoNo ratings yet

- P&F NBB3 V3 Z4 BrochureDocument2 pagesP&F NBB3 V3 Z4 BrochureVikrantNo ratings yet