Professional Documents

Culture Documents

Calculatin For Baggasse Pol Loss and Moisture

Calculatin For Baggasse Pol Loss and Moisture

Uploaded by

dgmOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calculatin For Baggasse Pol Loss and Moisture

Calculatin For Baggasse Pol Loss and Moisture

Uploaded by

dgmCopyright:

Available Formats

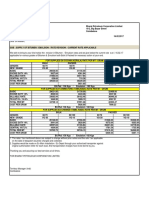

Standard

Bagasse Input

For Mill

Moisture % 51 50 51

Pol % 2 1.8 2.1

GCV Kcal/Kg 2230 2278.4 2228.8

GCV=4600*(1-moisture/100)-((1200)*pol/100))

Standard Baggasse pol for Mill is =2

Season 2023-24 Season 2023-24

Crushing in MT 525000 Crushing in MT 525000

GCV of Baggasse in

Baggasse % Cane 27 Kcal/kg 2230

Standard GCV of

Baggasse pol as per RT(8)C 2.4 baggasse 2278.4

Standard Baggasse Pol for

Mill 1.8 GCV difference 48.4

Pol Difference 0.6 Baggasse%Cane 27

Baggasse Production

Actual sugar loss/MT 0.0162 in MT 141750

Total Sugar Loss 8505 Baggasse loss 1% 1417.5

Rate of Sugar @Rs.3100 26365500 Available Baggasse 140332.5

Loss in energy due to

baggasse pol and

Total Loss for four season 26365500 Moisture 6792093

Saving of bagagsse in

MT 2981.080144

Total Baggasse lost 2981.080144

Baggasse

cost@RS.2200/MT 6260268.302

Generation due to

saved baggsse

@1MW/5.6MT steam

in MW 917.2554289

Cost of Generation in

Rs. 4136821.984

You might also like

- Cameroon KoleDocument1 pageCameroon KoleSamNo ratings yet

- Engine Control (7A-Fe A/T)Document8 pagesEngine Control (7A-Fe A/T)tonze10% (1)

- Executive Summary: NACES 2015 - Plant DesignDocument2 pagesExecutive Summary: NACES 2015 - Plant DesignVentrue LeongNo ratings yet

- Chapter 2 - Literature ReviewDocument11 pagesChapter 2 - Literature ReviewAK4780% (5)

- Ethanol PlantDocument15 pagesEthanol PlantRizvanVavanNo ratings yet

- Activity Plan Antisipasi Surcharge Natural GasDocument17 pagesActivity Plan Antisipasi Surcharge Natural GasHafidz FahmiNo ratings yet

- Weight Calculation Sn-5845-B01: Item Estimated Obtained Savings (KG) Unit NO TOTAL (KG) Unit NO TOTAL (KG) - 354 191 191Document1 pageWeight Calculation Sn-5845-B01: Item Estimated Obtained Savings (KG) Unit NO TOTAL (KG) Unit NO TOTAL (KG) - 354 191 191SanjithRNairNo ratings yet

- Concrete Mix Design Using IS Code Method: Input DataDocument6 pagesConcrete Mix Design Using IS Code Method: Input DataCANAL VERMELHONo ratings yet

- Opgs Power Gujarat PVT LTD: 2 X 150 MW TPPDocument2 pagesOpgs Power Gujarat PVT LTD: 2 X 150 MW TPPDharansamNo ratings yet

- Qubic BriketDocument13 pagesQubic BriketFebri Ardyanto putraNo ratings yet

- Annexure C: Rate Analysis For Major ItemsDocument11 pagesAnnexure C: Rate Analysis For Major Itemshemasundar7675No ratings yet

- Gacl-Dahej Captive Co-Generation Power Plant Corrected Gas Turbines Output Calculation On Site ConditionDocument6 pagesGacl-Dahej Captive Co-Generation Power Plant Corrected Gas Turbines Output Calculation On Site ConditionDurga PrasadNo ratings yet

- BP Daily Report 07 APRIL 2023Document1 pageBP Daily Report 07 APRIL 2023bpbua292No ratings yet

- Bitumen Rates 16.2.2017Document1 pageBitumen Rates 16.2.2017aearunkarthick2012No ratings yet

- Sanitery Items Comparision SheetDocument2 pagesSanitery Items Comparision SheetpkrjprNo ratings yet

- Read VlogDocument1 pageRead VlogLord GrimNo ratings yet

- Power and Energy Report DatabaseDocument8 pagesPower and Energy Report DatabaseImran HossainNo ratings yet

- Description Cement Sand 20Mm 10Mm Design Mix Water in Ltrs. Plasticiser Inltrs. (Sp-430)Document2 pagesDescription Cement Sand 20Mm 10Mm Design Mix Water in Ltrs. Plasticiser Inltrs. (Sp-430)Teja KopalleNo ratings yet

- Process Parameter Value UnitDocument6 pagesProcess Parameter Value UnitYota PentawanNo ratings yet

- Tentative Calculations of Fuel Consumption To Generate 1MW Power With Cost. A) RequirementDocument2 pagesTentative Calculations of Fuel Consumption To Generate 1MW Power With Cost. A) RequirementhsemarkNo ratings yet

- Imported RM Damage Report - Updated 16th Sept. 2022Document3 pagesImported RM Damage Report - Updated 16th Sept. 2022FATIMA BINTA ABDULLAHINo ratings yet

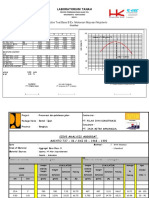

- Laboratorium Tanah: Compaction Test Base B Ex. Mekarsari Mojosari MojokertoDocument13 pagesLaboratorium Tanah: Compaction Test Base B Ex. Mekarsari Mojosari MojokertoIndra Avian RahmanNo ratings yet

- Harshal IndDocument1 pageHarshal Indkawalas12No ratings yet

- CH 18Document72 pagesCH 18harshNo ratings yet

- Gasbill 3622988824 202301 20230204025720Document1 pageGasbill 3622988824 202301 20230204025720gdrive.r859abNo ratings yet

- Digester SizingDocument11 pagesDigester SizingRAJNo ratings yet

- Bitumen Emulsion Rates 16.07.2016Document9 pagesBitumen Emulsion Rates 16.07.2016CKICPNo ratings yet

- Col Lapsk: Abstract of Concrete Mix Design of M30 GradeDocument3 pagesCol Lapsk: Abstract of Concrete Mix Design of M30 GradeLeelaKrishna QNo ratings yet

- Age HomeDocument2 pagesAge HomeMugees AhamadNo ratings yet

- A A A - Rate Anlysis (16.01.2018)Document1 pageA A A - Rate Anlysis (16.01.2018)sunilkumar1988No ratings yet

- SP 06 02 26Document1 pageSP 06 02 26Utpal MondalNo ratings yet

- A New Sugar Complex Designed To Provide Maximum Raw Material To A Paper IndustryDocument36 pagesA New Sugar Complex Designed To Provide Maximum Raw Material To A Paper IndustryTriyono S. SiNo ratings yet

- Coal - OptionsDocument2 pagesCoal - OptionsgmsangeethNo ratings yet

- Steel & Concrete Summary FOR OLD AGE HOMEDocument4 pagesSteel & Concrete Summary FOR OLD AGE HOMEMugees AhamadNo ratings yet

- M-25 Design MixDocument9 pagesM-25 Design MixakNo ratings yet

- RAW CASHEW COST - DocxfinalDocument4 pagesRAW CASHEW COST - DocxfinalBrijesh Panchal100% (1)

- Presentation - MEE - Spray Dryer - Drum De-Contamination - Dahej - July 2021Document28 pagesPresentation - MEE - Spray Dryer - Drum De-Contamination - Dahej - July 2021sai muraliNo ratings yet

- Talcher IB Secl: Date 03.06.2022 DD - Mm.yyyyDocument6 pagesTalcher IB Secl: Date 03.06.2022 DD - Mm.yyyyNaresh Kumar MeenaNo ratings yet

- Sibanye Stillwater Q32020 Operating Update 29oct2020Document14 pagesSibanye Stillwater Q32020 Operating Update 29oct2020Mashudu MbulayeniNo ratings yet

- Bhaluka Project Capacity With Estimated Costing of All MC & Others For OperationDocument2 pagesBhaluka Project Capacity With Estimated Costing of All MC & Others For OperationHabibur RahmanNo ratings yet

- 2018 Mecs Petroleum Refining Energy Carbon FootprintDocument3 pages2018 Mecs Petroleum Refining Energy Carbon FootprintanajjarNo ratings yet

- Gasbill 3622988824Document1 pageGasbill 3622988824gdrive.r859abNo ratings yet

- Costing FormatDocument1 pageCosting Formatnathansta61No ratings yet

- Book 1Document1 pageBook 1Ardian Wahyu RNo ratings yet

- Construction of Girls Hostel at Sub Campus Mianwali, University of SargodhaDocument5 pagesConstruction of Girls Hostel at Sub Campus Mianwali, University of Sargodhaassad aawanNo ratings yet

- Estimate Whole WorksDocument41 pagesEstimate Whole WorksRooking Ewondo SfuutNo ratings yet

- Costcard 20212022Document43 pagesCostcard 20212022विशाल कुमारNo ratings yet

- Flow Line and Well Hook-Up Authorisation (GD) : (Well SRS - V48A)Document1 pageFlow Line and Well Hook-Up Authorisation (GD) : (Well SRS - V48A)Qayyum KhanNo ratings yet

- Laporan Produksi Harian Lapangan Semberah: Comp Vibration Low FeedDocument1 pageLaporan Produksi Harian Lapangan Semberah: Comp Vibration Low Feedadi SaputraNo ratings yet

- Minimum Support Prices (MSP) For Kharif Crops For Marketing Season 2020-21Document4 pagesMinimum Support Prices (MSP) For Kharif Crops For Marketing Season 2020-21P DNo ratings yet

- KomariyahDocument11 pagesKomariyahtotomusto03No ratings yet

- May-23Document2 pagesMay-23bawakcNo ratings yet

- BP Daily Report 18 June 2023Document1 pageBP Daily Report 18 June 2023bpbua292No ratings yet

- Cameroon / Kole: WT% PPM Mgkoh/G °C PPM PPM KpaDocument1 pageCameroon / Kole: WT% PPM Mgkoh/G °C PPM PPM KpaSamNo ratings yet

- Cameroon KoleDocument1 pageCameroon KoleSamNo ratings yet

- Sales and Purchases 2021-22Document15 pagesSales and Purchases 2021-22Vamsi ShettyNo ratings yet

- TTU2-20-DWG-10-0031-A3 P - ID - Propane Transfer Pump Rev1Document1 pageTTU2-20-DWG-10-0031-A3 P - ID - Propane Transfer Pump Rev1nika prasetioNo ratings yet

- Case I PDFDocument1 pageCase I PDFvinod kumarNo ratings yet

- 16.04.2022 POL Price ListDocument1 page16.04.2022 POL Price ListTri LokNo ratings yet

- Mix Proportions EdDocument2 pagesMix Proportions EdEngr Uzor K UzorNo ratings yet

- Afghan Hing ChartDocument2 pagesAfghan Hing Chartmacklincoln653No ratings yet

- Kamakshi DrawingDocument1 pageKamakshi DrawingdgmNo ratings yet

- Wet ScrubberDocument2 pagesWet ScrubberdgmNo ratings yet

- Final PRDSDocument7 pagesFinal PRDSdgmNo ratings yet

- Steam CostingDocument5 pagesSteam CostingdgmNo ratings yet

- Mill VFD PanelDocument16 pagesMill VFD PaneldgmNo ratings yet

- Steam Saving DataDocument2 pagesSteam Saving DatadgmNo ratings yet

- Steam Required To Batch MachineDocument5 pagesSteam Required To Batch MachinedgmNo ratings yet

- SHWWDocument2 pagesSHWWdgmNo ratings yet

- Carrier Calculation For ReferenceDocument1 pageCarrier Calculation For ReferencedgmNo ratings yet

- Auto Fuel Vision Policy - 2025Document293 pagesAuto Fuel Vision Policy - 2025Rushi vedeNo ratings yet

- Companny Tanker 2017Document29 pagesCompanny Tanker 2017Muhamad AriepNo ratings yet

- Fossil Fuel Fact SheetDocument2 pagesFossil Fuel Fact Sheetasoni98No ratings yet

- Natural Gas ProcessingDocument6 pagesNatural Gas ProcessingsgrsthNo ratings yet

- Diesel Injection Pump Test BenchDocument15 pagesDiesel Injection Pump Test BenchedgarjayaNo ratings yet

- List of Companies in Jubail Re-Imbursment Tuv Procedure Qualification Criteria Assessment RaghdaDocument4 pagesList of Companies in Jubail Re-Imbursment Tuv Procedure Qualification Criteria Assessment RaghdaMuhammad ShoaibNo ratings yet

- 8 Minerals in India IDocument11 pages8 Minerals in India Ipratima patelNo ratings yet

- Ecoinvent LCI Modifications For Eco-Costs CalculationDocument5 pagesEcoinvent LCI Modifications For Eco-Costs CalculationMark Niño JavierNo ratings yet

- Biofuel PaperDocument6 pagesBiofuel PaperPradip PatelNo ratings yet

- List of CPCB Approved Waste Oil Re-ProcessorsDocument45 pagesList of CPCB Approved Waste Oil Re-Processorsalive2flirtNo ratings yet

- 07 Hydrogen From SMRDocument6 pages07 Hydrogen From SMRmaheshNo ratings yet

- CHP 7 - Energy Transfer (Multiple Choice) QPDocument6 pagesCHP 7 - Energy Transfer (Multiple Choice) QPDhrumeelNo ratings yet

- Wa 2-2022Document19 pagesWa 2-2022Hayate100% (1)

- INVESTIGACIONDocument343 pagesINVESTIGACIONandres povedaNo ratings yet

- Uop RCD Unionfining Process: Daniel B. GillisDocument10 pagesUop RCD Unionfining Process: Daniel B. GillisBharavi K SNo ratings yet

- QatarDocument97 pagesQataryouss ef100% (1)

- 350 Data Buyer Valid Komoditi ArangDocument18 pages350 Data Buyer Valid Komoditi ArangBintang tujuh UnitetNo ratings yet

- CH414 Petroleum Refinery EngineeringDocument14 pagesCH414 Petroleum Refinery EngineeringHaider AliNo ratings yet

- Oil Gas Conversion Chart FINAL 1Document2 pagesOil Gas Conversion Chart FINAL 1Arief Budiman HermaniNo ratings yet

- Bunker SuppliersDocument17 pagesBunker SuppliersgbhatikarNo ratings yet

- Developing Sour Gas Resources With Controlled Freeze Zone ™ TechnologyDocument8 pagesDeveloping Sour Gas Resources With Controlled Freeze Zone ™ TechnologyWilliam LimNo ratings yet

- Valve Saver Fluid BrochureDocument2 pagesValve Saver Fluid BrochureNina RandjelovicNo ratings yet

- Hydroconversion A Study Case For Minas Residue: Dr. Rachman Subroto Hendro Prawoto NasutionDocument16 pagesHydroconversion A Study Case For Minas Residue: Dr. Rachman Subroto Hendro Prawoto NasutionriansagemilangNo ratings yet

- Case Study Reliance Refinery Uses Emerson S Fiscal Metering System To Monitor Oil Gas Valued at Us 20b Annually Daniel en 44098Document3 pagesCase Study Reliance Refinery Uses Emerson S Fiscal Metering System To Monitor Oil Gas Valued at Us 20b Annually Daniel en 44098ghooestiepNo ratings yet

- Coal (Makarwal) : Approximate Analysis: Ultimate AnalysisDocument3 pagesCoal (Makarwal) : Approximate Analysis: Ultimate AnalysisAli AhsanNo ratings yet

- Cairn India IntroductionDocument7 pagesCairn India IntroductionSunil PeerojiNo ratings yet

- Energy Production From Marine Biomass (Ulva Lactuca) - Annex 6 PDFDocument3 pagesEnergy Production From Marine Biomass (Ulva Lactuca) - Annex 6 PDFRashedul IslamNo ratings yet