Professional Documents

Culture Documents

FABIG TM79 FactorsInfluencingtheExplosionDALandQuantificationoftheirImportance GNalvarte

Uploaded by

AbabOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FABIG TM79 FactorsInfluencingtheExplosionDALandQuantificationoftheirImportance GNalvarte

Uploaded by

AbabCopyright:

Available Formats

FACTORS INFLUENCING

THE EXPLOSION DAL AND

QUANTIFICATION OF THEIR

IMPORTANCE

Gladys Nalvarte

DNV GL

E: Gladys.nalvarte@dnvgl.com

T: +47 9060 2309

Technical meeting proceedings - JUNE 2014 www.fabig.com 3

OIL & GAS

Factors Influencing the Explosion

Dimensioning Accidental Loads (DAL)

and quantification of their importance

Safety Risk Management

25 & 26 June 2014

Confidential

1 DNV GL © 2014 16 June 2014 SAFER, SMARTER, GREENER

Content

Introduction

Objective

What is done

Influence of design parameters on DAL

– Ventilation

– Dispersion

– Explosion

Influence of process parameters on DAL

– ESD and Shutdown

– Ignition Control

Conclusions

Confidential

DNV GL © 2014 16 June 2014

2

Technical meeting proceedings - JUNE 2014 www.fabig.com 4

Introduction

Risk based approach

Provides loads that accounts for both the severity of events and the likelihood of those events

– Impracticality or economic viability of designing only against worst case events (WCEs)

– Significantly high loads can be experienced for WCE

Identification of key risk drivers and important physical effects

– Particularly beneficial for complex facilities

1.E-02

Target 1_Small

1.E-03 Process area

Exceedence frequency (1/year)

1.E-04

1.E-05

1.E-06

1.E-07

1.E-08

Confidential

0 0.5 1 1.5 2 2.5 3 3.5 4

Pressure (barg)

3 DNV GL © 2014 16 June 2014

DAL at 1.E-4

Objective

Identification of the relevant parameters that influences the DAL

Define the influence of each parameter in different type of installations

Where we will have the best effect for reducing Explosion DAL

In this context we can provide a decision support where the Key question

is: “how we can reduce the explosion DAL in a more effective manner”

Confidential

4 DNV GL © 2014 16 June 2014

Technical meeting proceedings - JUNE 2014 www.fabig.com 5

What was done

DNVGL has run ERA tool that can efficiently be used to perform parameter

studies

A sensitivity analysis was performed to quantify the variation in DAL when

each input to the probabilistic analyses was changed at the time.

Two types of areas were analysed : one large process area and one small area

in a floating unit.

ERA performed 112 times

Confidential

5 DNV GL © 2014 16 June 2014

Explosion Risk Analysis (ERA) approach normal areas

FREQUENCY AND SAFETY SYSTEM ANALYSIS

CONSEQUENCE

ANALYSIS WITH FLACS

CFD

Converting

geometry

CFD

Ventilation

CFD

Dispersion

Risk analysis:

CFD DNV program EXPRESS

Explosion Response surfaces

JIP Ignition model

Monte Carlo simulations

Improve

design

Explosion DAL

Design effects and

recommendations

Confidential

DNV GL © 2014 16 June 2014

6

Technical meeting proceedings - JUNE 2014 www.fabig.com 6

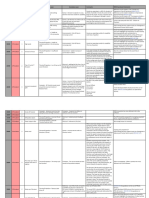

Summary of the cases run for the sensitivity analysis –

Small process area (14 parameters x 4 values)

Base case Average

V= 3515 min value max value

DAL DAL

P3 Cloud growth - 0.01 0.03 0.09 0.12 0.69

Filling fraction

C1 - 3 10 30 90 0.46

steepness coefficient

Dispersion Filling fraction decay

param. P2 - 0.5 1 2 4 0.59

coefficient

A+B Max filling fraction - 0.1 0.2 0.3 0.5 0.76

Normalized ventilation

Q/uref (m2) 0.25 0.5 1 2 0.50

rate

small Pressure exponential

P1 0.9 1 1.07 1.2 0.54

process Explo growth

area param.

Kp Pressure linear growth 0.5 1 3 6 0.55 0.24

Vs inventory m3 18 36 100 300 0.56

tESD time to ESD closure s 15 30 45 120 0.56

Process tBD time to BD open s 15 30 45 300 0.56

param.

BD def time BD duration to 7 barg min 2.5 5 15 30 0.60

Max m Max initial leak rate kg/s 50 100 300 900 0.54

No. of ign.sources, 3 increase

Ignition Ns 0.5 1 2 3 0.56

places factor

sources

param Increase of T1

Tsd Time to ign.sd. 0.5 1 2 3 0.57

and T2

Confidential

7 DNV GL © 2014 16 June 2014

Summary of the cases run for the sensitivity analysis –

Large process area (14 parameters x 4 values)

Base case Average

V= 819731 min value max value

DAL DAL

P3 Cloud growth 0.01 0.03 0.09 0.12 1.12

Filling fraction steepness

C1 2 5 15 60 0.89

coefficient

Dispersion Filling fraction decay

param. P2 0.5 0.8 2 4 1.12

coefficient

A+B Max filling fraction 0.02 0.04 0.06 0.1 1.07

Normalized ventilation

Q/uref (m2) 0.1 0.25 0.5 1 1.26

rate

large P1

Pressure exponential

0.6 0.7 1 1.2 0.90

Explo growth

process

param.

area Kp Pressure linear growth 0.5 1.8 5 10 1.05 2.48

Vs inventory m3 43 86 150 300 1.09

tESD time to ESD closure s 15 30 45 120 0.98

Process tBD time to BD open s 15 30 45 300 0.86

param.

BD def time BD duration to 7 barg min 2.5 5 15 30 1.05

Max m Max initial leak rate kg/s 182.5 365 730 1500 1.12

No. of ign.sources, 3

Ignition Ns increase factor 0.5 1 2 3 1.06

places

sources

param Increase of T1

Tsd Time to ign.sd. 0.5 1 2 3 0.83

and T2

Confidential

8 DNV GL © 2014 16 June 2014

Technical meeting proceedings - JUNE 2014 www.fabig.com 7

Average

C1 DAL Variation

DAL

Main result and selection of 90

30

0.85

0.55

0.395

parameters to pay most attention : 10 0.29

0.455

0.325

3 0.13

Confidential

9 DNV GL © 2014 16 June 2014

Ventilation and Dispersion are recognized to be

the key topics for control of explosion and fire

on offshore installations.

Confidential

10 DNV GL © 2014 16 June 2014

Technical meeting proceedings - JUNE 2014 www.fabig.com 8

Complex problem

Example for dispersion: find the largest cloud size within the flammable limits

Real problem CFD analysis

Q9 – Volume of

Fuel the gas cloud

within the

Air flammable limits

Complexity: Physics & Geometry

Confinement,

Congestion,

Leak (Location, Direction, etc.)

Wind (Direction, Speed, etc.)

Mathematical Parameters that are used to

model fit the mathematical models

Response to the CFD results

curves Example:

Confidential

Filling fraction steepness

11 DNV GL © 2014 16 June 2014 coefficient C1

C1 - Filling faction steepness coefficient (local effect)

Poor local

ventilation Good local

ventilation

Confidential

12 DNV GL © 2014 16 June 2014

Technical meeting proceedings - JUNE 2014 www.fabig.com 9

C1 - Dispersion local effects: how good or bad is the local

ventilation for small leak rates

Confidential

13 DNV GL © 2014 16 June 2014

Effect

Influence of of the

the filling C1 parameter

faction steepness in the 1.E-4

coefficient onDAL

the DAL at 1.E-

comparison

4/year for

for the small

small process

process area area

Poor local

ventilation

Good local

ventilation

Total Variation

0.7 barg

Confidential

14 DNV GL © 2014 16 June 2014

Technical meeting proceedings - JUNE 2014 www.fabig.com 10

Effect of C1 on the overpressure exceedence curve

1.E-02

C1=3

C1=10

1.E-03 Good local C1=30

Exceedence frequency (1/year)

ventilation C1=90

Poor local

1.E-04 ventilation

1.E-05

1.E-06

1.E-07

0 0.5 1 1.5 2 2.5 3 3.5 4

Overpressure (barg)

Confidential

15 DNV GL © 2014 16 June 2014

AB – Maximum filling fraction at the worst combination of leak

rate and wind speed for a given jet direction considering all

wind directions

Semi obstructed jet

Jet zone

Passive zone

Confidential

16 DNV GL © 2014 16 June 2014

Technical meeting proceedings - JUNE 2014 www.fabig.com 11

Example of the effect of different wind direction for one leak

direction (jet direction towards west)

N

E

Vfmax/V

=

0.13 Vfmax/V=

0.06

Vfmax/V=

NW 0.15

Vfmax/V=

W 0.16

Confidential

10 DNV GL © 2014 16 June 2014

Nove

Slide 17

mber Version

Example of the effect on the Maximum filling fraction for different

wind direction and one leak direction

Wind dir: N Wind dir: E

Jet dir: N Jet dir: N

Confidential

18 DNV GL © 2014 16 June 2014

Technical meeting proceedings - JUNE 2014 www.fabig.com 12

AB – Maximum filling fraction

More global effect that will produce the biggest gas cloud

1.6

Poor

1.4

ventilation

Good

1.2

ventilation

1

DAL (barg)

0.8

0.6 High

variation ~ 1

0.4

barg

0.2

0

0.1 0.2 0.3 0.5

Average A+B

Confidential

19 DNV GL © 2014 16 June 2014

Effect of Maximum filling fraction (AB) on the exceedence curve

Good Poor

ventilation ventilation

Confidential

20 DNV GL © 2014 16 June 2014

Technical meeting proceedings - JUNE 2014 www.fabig.com 13

Influence of explosion on the DAL

Confidential

21 DNV GL © 2014 16 June 2014

Effects that decides the overpressure

Congestion – Amount of Plot 2, l/V (m/m3) is parameter

l/V = 3.0 m/m3

turbulence generating obstacles 3

l/V = 2.0 m/m3

2.5

– l/V, congestion parameter, l/V = 1.0 m/m3

length of all obstacles per 2

Pressure (barg)

volume (m/m3) 1.5

0.5

Confinement – Amount of walls

0

and decks 0 200 400 600 800 1000

Cloud size, Vf (m3)

– Av/A, confinement parameter,

Open area per total surface 3

Plot 1, Av/A is parameter

area 2.5

Av/A = 0.10

Av/A = 0.12

2

Pressure (barg)

Av/A = 0.20

Distance - cloud size 1.5

1

Gas type and concentration

0.5

0

Confidential 0 200 400 600 800 1000

Cloud size, Vf (m3)

DNV GL © 2014 16 June 2014

22

Technical meeting proceedings - JUNE 2014 www.fabig.com 14

Effect of different congestion and confinement

East side Explosion pressure – 1600 m3 cloud

Confidential

DNV GL © 2014 16 June 2014

23

Effect of different congestion and confinement

West side Explosion pressure - 1600 m3 cloud

Confidential

DNV GL © 2014 16 June 2014

24

Technical meeting proceedings - JUNE 2014 www.fabig.com 15

Explosion theory and background

P0 ( E ) P K P f1 ( E )ril ( E ) 0 E Ec

P0 ( E ) P (aE b) ril ( E ) Ec E Emax

12 FLACS results

11

Response surface, f1

10

9 Linear part, f1 Pmax

7

P (barg)

3

6 E p1

5

f1 e

4

3

0

0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4

Confidential

Ec/Emax Filling

10 DNV GL © 2014 16 June 2014

Nove

Slide 25

mber Version

Effect of congestion and confinement

Pressure linear

increase

Kp

Pressure

exponential

increase

P1

Confidential

DNV GL © 2014 16 June 2014

26

Technical meeting proceedings - JUNE 2014 www.fabig.com 16

Effect of the exponential

increase of the

overpressure vs gas

cloud volume

Lower

congestion

and

Higher

confinement

congestion

and

confinement

Confidential

27 DNV GL © 2014 16 June 2014

Effect of P1 in the overpressure exceedence curve

Higher

Low congestion/ congestion/

confinement confinement

Confidential

28 DNV GL © 2014 16 June 2014

Technical meeting proceedings - JUNE 2014 www.fabig.com 17

Effect of the process parameters on the

Dimensioning accidental load

Confidential

29 DNV GL © 2014 16 June 2014

ESD and blowdown

Settings that will influence the risk:

Example from hild

– Gas detection time (number of gas

detectors)

– ESD valve closing time

– Reduction of the inventory, better

segmentation

– Time to start blowdown

– automatic at ESD

– manual 5 min

– Blowdown duration

Why

– Gas is building up very quickly,

within 30s

– Most ignitions occurs during gas

buildup phase due to exposure of

Confidential

continuous ignition sources

DNV GL © 2014 16 June 2014

30

Technical meeting proceedings - JUNE 2014 www.fabig.com 18

Ignition probability

Leak profiles

Confidential

DNV GL © 2014 16 June 2014

31

Shutdown of ignition sources, ignition control

Ignition sources:

Static electricity, hot work, manning, How long time does it take to shut

electric, pumps, compressors, other down?

sources

– Hot work, need to cool down

External ignition: Flare, turbine air

inlets and exhausts, furnaces, – Compressors, has shutdown cycle

cranes – Manning must leave area

Immediate ignition (no explosion) – Pumps and others need to wind

What can be shut down? down and cool down

– Hot work, manning, electric, pumps, Significant ignition sources are still hot

compressors during first 30 s.

How much is shut down?

– Electric 50-90%

– Hot work 90%

– Pumps 50%

– Compressors100%

Confidential

DNV GL © 2014 16 June 2014

32

Technical meeting proceedings - JUNE 2014 www.fabig.com 19

Main result and selection of process parameters to pay most attention:

Confidential

33 DNV GL © 2014 16 June 2014

Main result and selection of

parameters to pay most attention :

Confidential

34 DNV GL © 2014 16 June 2014

Technical meeting proceedings - JUNE 2014 www.fabig.com 20

Conclusions

Designers can reduce DAL pressures by up to an order of magnitude by

building inherent safe designs whereas after the design is fixed, the process

control mitigating measures can only reduce the DAL with typically less than

50%

The largest effects on reducing DAL pressures are found on the congestion

and confinement parameters. For the large process area, DAL varies from 0.1

to 2 barg for a well and poorly designed process area

Effects that improve ventilation and gas dispersion can influence the DAL

pressures significantly, e.g. for small process areas, from 1.4 to 0.25 barg by

having a better ventilation with less re-circulation zones

Reduced time to ESD closure can reduce the DAL from 1.5 to 0.5 barg for the

large process area when closure time is reduced from 2 min to 15 s.

Confidential

35 DNV GL © 2014 16 June 2014

Conclusion (continuation)

It is evident that many parameters influences the explosion risk hence

detailed DAL analyses are recommended

Results from this study gives an indication of how much improvement in

DAL can be expected when changing the input parameters – useful in the

concept stage

It gives the opportunity to run more CFD simulations considering sensitivity

cases in parallel with the base case and quantify the reduction on DAL at

early stages and contribute actively to improve the design.

DNVGL - JIP FLNG REVDesign

Confidential

36 DNV GL © 2014 16 June 2014

Technical meeting proceedings - JUNE 2014 www.fabig.com 21

Thank You

Gladys Nalvarte

Gladys.nalvarte@dnvgl.com

+47 9060 2309

www.dnvgl.com

SAFER, SMARTER, GREENER

Confidential

37 DNV GL © 2014 16 June 2014

Technical meeting proceedings - JUNE 2014 www.fabig.com 22

Questions and answers

Q: You seem to have characterised explosions via their peak pressures. Did you also

consider their durations in your analysis?

A: No. We only considered the overpressures on the target area in the presented study.

However, it is possible to establish a correlation between overpressure and duration

in the analysis.

Q: I understand that the presented sensitivity study was carried out by changing one

parameter at the time whilst keeping the others unchanged. Is it correct to assume

that the parameters described in your presentation are independent from each other

and that changing one does not affect others?

A: We do know that this is not entirely the case and that some parameters are not

independent. The type of analysis described in my presentation is however very

efficient at the preliminary design stage for identifying the parameters which influence

the risk the most.

Q: What leak durations do you typically use in such analyses?

A: The leak durations to be considered will depend on type of installation. The values

shown in my presentation corresponded to the small and large process areas

investigated in this case.

Q: How do you account for the non-uniform mixing of the gas cloud with air in your

explosion analysis?

A: For the type of analysis described in my presentation, we use the equivalent

stoichiometric gas cloud (Q9) approach with FLACS.

Q: You showed average values in your presentation. How was this “averaging”

carried out?

A: For the purpose of this presentation, I simply considered an arithmetic mean of

the results.

Technical meeting proceedings - JUNE 2014 www.fabig.com 23

You might also like

- Intelligent Digital Oil and Gas Fields: Concepts, Collaboration, and Right-Time DecisionsFrom EverandIntelligent Digital Oil and Gas Fields: Concepts, Collaboration, and Right-Time DecisionsRating: 4.5 out of 5 stars4.5/5 (5)

- Reliability, Maintainability and Risk: Practical Methods for Engineers including Reliability Centred Maintenance and Safety-Related SystemsFrom EverandReliability, Maintainability and Risk: Practical Methods for Engineers including Reliability Centred Maintenance and Safety-Related SystemsRating: 4.5 out of 5 stars4.5/5 (5)

- Optimizing Fire and Gas SystemDocument27 pagesOptimizing Fire and Gas SystemShakeel AhmedNo ratings yet

- SCW PQSDocument67 pagesSCW PQStabathadennis100% (1)

- UC 2018 Introduction To Computational Fluid Dynamics (CFD)Document26 pagesUC 2018 Introduction To Computational Fluid Dynamics (CFD)anub0025No ratings yet

- How Can Remote Sensing Measurements Add Value To Your Wind Farm ProjectDocument4 pagesHow Can Remote Sensing Measurements Add Value To Your Wind Farm ProjectjesusNo ratings yet

- Safeti 3D Explosions - The Delta - MexicoDocument20 pagesSafeti 3D Explosions - The Delta - MexicolopezmoramiguelNo ratings yet

- Extending The Life of Your LNG Assets: March 2016Document24 pagesExtending The Life of Your LNG Assets: March 2016aleNo ratings yet

- DNV Free Spaning Pipeline RP F105 PDFDocument46 pagesDNV Free Spaning Pipeline RP F105 PDFrachedNo ratings yet

- Performance - Pivano - PaperDocument9 pagesPerformance - Pivano - PaperGiovanni Aiosa do AmaralNo ratings yet

- DNV PSMDocument1 pageDNV PSMDharfan ApriantoNo ratings yet

- 19 Elliott CASTAnalysisOfTheBuncefieldIncidentDocument13 pages19 Elliott CASTAnalysisOfTheBuncefieldIncidentСергей МазеинNo ratings yet

- Introduction FreeSpanningPipelinesDNV RP F105Document13 pagesIntroduction FreeSpanningPipelinesDNV RP F105Nabil37No ratings yet

- DNV GL EEXI - What You Need To Know WebDocument31 pagesDNV GL EEXI - What You Need To Know WebPrabhu Deva100% (1)

- Operator's ManualDocument270 pagesOperator's ManualmNo ratings yet

- Risk-Based Techniques For LV/MV Cable Prioritization and Aging ManagementDocument27 pagesRisk-Based Techniques For LV/MV Cable Prioritization and Aging ManagementOsama SharafNo ratings yet

- MMH Dan StoringDocument13 pagesMMH Dan Storingfilza100% (1)

- EPWS13Document23 pagesEPWS13dagualtieriNo ratings yet

- Fracture Control For Pipeline Installation Methods Introducing Cyclic Plastic StrainDocument24 pagesFracture Control For Pipeline Installation Methods Introducing Cyclic Plastic StrainManohar SeetharamNo ratings yet

- New Generation RBI Methodology and Software - COMADEM2011Document10 pagesNew Generation RBI Methodology and Software - COMADEM2011ManeeshSinghNo ratings yet

- F&G Mapping Using Detect 3D: A Study On Software Working, Advantages & ComparisonDocument24 pagesF&G Mapping Using Detect 3D: A Study On Software Working, Advantages & ComparisonTania NoorNo ratings yet

- Reserves DefinitionsDocument49 pagesReserves Definitionsslackfamily100% (2)

- X DF Two Stroke Engines Operational Efficiency and Future DevelopmentsDocument52 pagesX DF Two Stroke Engines Operational Efficiency and Future Developmentsthememeph12345No ratings yet

- Tutorial DNV - AUTOPIPEDocument25 pagesTutorial DNV - AUTOPIPESulist N WahyudieNo ratings yet

- Fraser Hardie Rev. 2 Sbpaut For Kint Issue 2Document28 pagesFraser Hardie Rev. 2 Sbpaut For Kint Issue 2Tony TheFatoneNo ratings yet

- Sdmyers Fluid Testing EbookDocument18 pagesSdmyers Fluid Testing EbookJesus TzianNo ratings yet

- DA NUT2013 B4 Rune Frederiksen PDFDocument56 pagesDA NUT2013 B4 Rune Frederiksen PDFMaheshNo ratings yet

- PLAN 10 N No. 37538919: Declaration of PerformanceDocument4 pagesPLAN 10 N No. 37538919: Declaration of PerformanceAndreea MunteanuNo ratings yet

- Powerfailure Investigation Brochure 1606291667895Document4 pagesPowerfailure Investigation Brochure 1606291667895Supriya RaiNo ratings yet

- Kelman Transport X : GE Grid SolutionsDocument2 pagesKelman Transport X : GE Grid SolutionsUmer KhanNo ratings yet

- Last Update - 11 - 2020Document30,702 pagesLast Update - 11 - 2020ahmed sobhyNo ratings yet

- 2018 05 04 - Session 3.1 OREDA JIP - ISOTC67 WG4 Seminar May 2018 PDFDocument23 pages2018 05 04 - Session 3.1 OREDA JIP - ISOTC67 WG4 Seminar May 2018 PDFRatheesh VidyadharanNo ratings yet

- I For ST Oc CosDocument25 pagesI For ST Oc CosMohammad MussadaqNo ratings yet

- Elixir Engineering - Process Safety ConsultantDocument14 pagesElixir Engineering - Process Safety ConsultantSathishNo ratings yet

- 22a Proj QADocument15 pages22a Proj QAIrsyad RosyidiNo ratings yet

- RYALL Peter Lessons From Decommissioning Planning in The UKCSDocument12 pagesRYALL Peter Lessons From Decommissioning Planning in The UKCSOlusegun OyebanjiNo ratings yet

- Module16 - Incident SpecDocument10 pagesModule16 - Incident SpecMinh ThưNo ratings yet

- Fire and Explosion Assessment On Oil and Gas Oating Production Storage of Oading (FPSO) : An Effective Screening and Comparison ToolDocument14 pagesFire and Explosion Assessment On Oil and Gas Oating Production Storage of Oading (FPSO) : An Effective Screening and Comparison ToolKonstantinKotNo ratings yet

- Middha Release and Dispersion Perspectives From GexConDocument26 pagesMiddha Release and Dispersion Perspectives From GexConmehranlnjdNo ratings yet

- SBM ReportDocument12 pagesSBM ReportWaiNo ratings yet

- Webinar Presentation Subsea Manifold InstallationDocument55 pagesWebinar Presentation Subsea Manifold InstallationTeck Tiong HuanNo ratings yet

- FAU S PSG 0221 Capability CalculationDocument24 pagesFAU S PSG 0221 Capability CalculationHammamiSalahNo ratings yet

- Project Standards and Specifications Fesibiliy Studies Rev01.1Document13 pagesProject Standards and Specifications Fesibiliy Studies Rev01.1sirengeniusNo ratings yet

- Schneider Electric - R&D Job Description - 2024 BatchDocument32 pagesSchneider Electric - R&D Job Description - 2024 BatchTejeswini KrishnanNo ratings yet

- Dokumen - Tips - Handbook of Failure FrequenciesDocument33 pagesDokumen - Tips - Handbook of Failure FrequenciesJorge A.No ratings yet

- NFPA 13 Sprinkler System Design Density Curves - Where Did They Come From?Document7 pagesNFPA 13 Sprinkler System Design Density Curves - Where Did They Come From?ChandaKundaNo ratings yet

- Sil4s en Silence FullDocument23 pagesSil4s en Silence FullAshish PawarNo ratings yet

- FABIG TM83 2 MActonMJohnsonDocument23 pagesFABIG TM83 2 MActonMJohnsonGion67No ratings yet

- Resolve: Advanced Integration A Vendor Neutral Solution Formulation PlatformDocument4 pagesResolve: Advanced Integration A Vendor Neutral Solution Formulation PlatformFranck Duprey MvogoNo ratings yet

- Dokumen - Tips DNV Os c105Document29 pagesDokumen - Tips DNV Os c105Gabriella LacerdaNo ratings yet

- SAFEDOR D 04.05.02 2005 10 21 DNV RiskEvaluationCriteria Rev 3Document117 pagesSAFEDOR D 04.05.02 2005 10 21 DNV RiskEvaluationCriteria Rev 3SriKakarlapudiNo ratings yet

- Casing System Risk Analysis Using Structural Reliability PDFDocument10 pagesCasing System Risk Analysis Using Structural Reliability PDFsabilco13No ratings yet

- DNV-RP-F203 Riser Interference April 2009Document22 pagesDNV-RP-F203 Riser Interference April 2009TroyNo ratings yet

- Business Case FREP Handheld PDFDocument32 pagesBusiness Case FREP Handheld PDFHardeep KaurNo ratings yet

- SS 555 1st May 2019 UpdateDocument106 pagesSS 555 1st May 2019 UpdateThet ThetNo ratings yet

- Portable Offshore UnitDocument24 pagesPortable Offshore UnitshonialamNo ratings yet

- Jobs Safety Plan - TemplateDocument16 pagesJobs Safety Plan - TemplateFairus Md Yusof100% (1)

- Introduction To Quantitative RisK Assessment Webinar - Slides - tcm8-99019Document38 pagesIntroduction To Quantitative RisK Assessment Webinar - Slides - tcm8-99019Kazehaya AliNo ratings yet

- Evaluating Hedge Fund and CTA Performance: Data Envelopment Analysis ApproachFrom EverandEvaluating Hedge Fund and CTA Performance: Data Envelopment Analysis ApproachNo ratings yet

- Fire Protection Engineering in Building DesignFrom EverandFire Protection Engineering in Building DesignRating: 4.5 out of 5 stars4.5/5 (5)

- Computer Performance Optimization: Systems - Applications - ProcessesFrom EverandComputer Performance Optimization: Systems - Applications - ProcessesNo ratings yet

- Fairplay-14-Datenblatt-1 - HTDocument1 pageFairplay-14-Datenblatt-1 - HTAbabNo ratings yet

- Jacking SystemsDocument19 pagesJacking SystemsAbabNo ratings yet

- IMCAM261 DP Station Keeping Events Summary 2022 nj3zf0Document17 pagesIMCAM261 DP Station Keeping Events Summary 2022 nj3zf0AbabNo ratings yet

- Part FVol 02Document160 pagesPart FVol 02AbabNo ratings yet

- Incertezza Con D 85mm (P86 - T-15 - DP125)Document2 pagesIncertezza Con D 85mm (P86 - T-15 - DP125)AbabNo ratings yet

- Standard Detail X-BT - FCMDocument1 pageStandard Detail X-BT - FCMAbabNo ratings yet

- Grating FixingsDocument17 pagesGrating FixingsAbabNo ratings yet

- FABIG TM79 ExplosionRiskAssessmentforanFPSOandDALSpecificationforNLFEA CAzzi RBrewertonDocument30 pagesFABIG TM79 ExplosionRiskAssessmentforanFPSOandDALSpecificationforNLFEA CAzzi RBrewertonAbabNo ratings yet

- FABIG TM79 DesignExplosionLoadSpecificationforLargeFloatingFacilities LParisDocument17 pagesFABIG TM79 DesignExplosionLoadSpecificationforLargeFloatingFacilities LParisAbabNo ratings yet

- Rosemount PT 3051SDocument5 pagesRosemount PT 3051SAbabNo ratings yet

- R109 - p9-11 - Barge Optimisation Leads To Cuts in Fuel ConsumptionDocument2 pagesR109 - p9-11 - Barge Optimisation Leads To Cuts in Fuel ConsumptionAbabNo ratings yet

- 8 PCO Training Invitation Letter December 2018Document2 pages8 PCO Training Invitation Letter December 2018sayo goraNo ratings yet

- LG Mobile CompanyDocument6 pagesLG Mobile Companymallickantonio6559No ratings yet

- Laporan Beton 1Document80 pagesLaporan Beton 1Seulgi BearNo ratings yet

- Powershell Simple and Effective Strategies To Execute Powershell Programming - Daniel JonesDocument53 pagesPowershell Simple and Effective Strategies To Execute Powershell Programming - Daniel JonesdemisitoNo ratings yet

- ContainerDocument12 pagesContainerlakkekepsuNo ratings yet

- Fuel System: Fuel Tank / Fuel Cock 4-1 Fuel Pump 4 - 2 Carburetor 4 - 3Document10 pagesFuel System: Fuel Tank / Fuel Cock 4-1 Fuel Pump 4 - 2 Carburetor 4 - 3Fabrizio FloresNo ratings yet

- Piston and Connecting Rod Assembly TopicsDocument1 pagePiston and Connecting Rod Assembly TopicsgandhiramNo ratings yet

- 820-3740 Technical OverviewDocument238 pages820-3740 Technical Overviewppjim100% (1)

- Yousif Yassin PDFDocument124 pagesYousif Yassin PDFJAVIYAROSNo ratings yet

- Chiller: Asian Paints Khandala PlantDocument19 pagesChiller: Asian Paints Khandala PlantAditiNo ratings yet

- TX IrhsDocument1 pageTX IrhsvelizarkoNo ratings yet

- OPA237Document21 pagesOPA237philprefNo ratings yet

- Advanced Power ElectronicsDocument4 pagesAdvanced Power ElectronicsLinkan PriyadarsiniNo ratings yet

- VM 6083 - 60B1 Data SheetDocument3 pagesVM 6083 - 60B1 Data SheetMinh HoàngNo ratings yet

- NHPC ReportDocument53 pagesNHPC ReportVishal SinghNo ratings yet

- POLYMATH TutorialChemical Reaction Engineering PDFDocument8 pagesPOLYMATH TutorialChemical Reaction Engineering PDFAfifah SabriNo ratings yet

- Auto Chassis NotesDocument90 pagesAuto Chassis Notesanishsukumar000gmailcomNo ratings yet

- Sewa bill-AED 559Document1 pageSewa bill-AED 559muhdazarNo ratings yet

- Cessna 525 LimitationsDocument16 pagesCessna 525 LimitationsCesar BanchoffNo ratings yet

- ANCAP Corporate Design GuidelinesDocument20 pagesANCAP Corporate Design GuidelineshazopmanNo ratings yet

- Otrs Admin BookDocument619 pagesOtrs Admin BookMendoza Carlos100% (1)

- E DPT2020Document37 pagesE DPT2020arjuna naibahoNo ratings yet

- API Valves: A. API Gate Valves B. Mud Gate Valves C. API Plug ValvesDocument15 pagesAPI Valves: A. API Gate Valves B. Mud Gate Valves C. API Plug Valveskaveh-bahiraeeNo ratings yet

- 49 CFR 195Document3 pages49 CFR 195danigna77No ratings yet

- Syntel Mock 2Document18 pagesSyntel Mock 2Ashutosh MauryaNo ratings yet

- True 63Document2 pagesTrue 63stefanygomezNo ratings yet

- Lectut MI 106 PDF MI 106 Sol Tut 5 76vs9e5Document4 pagesLectut MI 106 PDF MI 106 Sol Tut 5 76vs9e5Pritam PaulNo ratings yet

- BTS 84Document4 pagesBTS 84Kiara Ticangan ArgelNo ratings yet

- lTRF+IEC 61215-23A2 Part 1 of 2-Solar PanelDocument42 pageslTRF+IEC 61215-23A2 Part 1 of 2-Solar PanelGrupo CardogalNo ratings yet