Professional Documents

Culture Documents

Revisions:: PE Project: 230647

Uploaded by

Karthik NOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Revisions:: PE Project: 230647

Uploaded by

Karthik NCopyright:

Available Formats

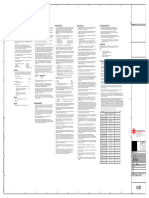

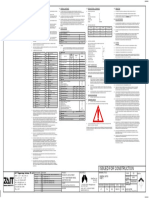

GENERAL NOTES: CAST IN PLACE REINFORCED CONCRETE (CONTINUED): STEEL JOIST: DELEGATED DESIGN NOTES:

1. ALL MATERIALS, CONSTRUCTION, AND DETAILS SHALL CONFORM WITH THE FOLLOWING: 18. OWNER SHALL HIRE A MATERIALS TESTING LABORATORY TO CAST AND TEST CONCRETE CYLINDERS. ALL TESTING SHALL BE IN ACCORDANCE 1. DESIGN, FABRICATION, AND ERECTION SHALL CONFORM TO THE CURRENT EDITION OF ''STEEL JOIST INSTITUTE SPECIFICATIONS''. 1. ENGINEERING DESIGN, DETAILING, AND COORDINATION OF DELEGATED DESIGN ITEMS ARE DELEGATED TO THE CONTRACTOR PER THE

PLANS AND SPECIFICATIONS WITH ACI 318. RESULTS OF CYLINDER TESTS SHALL BE SUBMITTED TO THE ARCHITECT AND ENGINEER. CONCRETE TEST REPORTS SHALL SPECIFICATIONS AND CRITERIA INDICATED ON THE DRAWINGS. THE PRIMARY BASE BUILDING STRUCTURE HAS BEEN DESIGNED AS INDICATED

CODE AS SPECIFIED IN DESIGN DATA STATE THE FOLLOWING INFORMATION: 2. JOIST MANUFACTURER SHALL BE A MEMBER OF THE SJI (STEEL JOIST INSTITUTE). HEREIN TO ACCEPT THE DELEGATED DESIGN ITEMS. THE CONTRACTOR SHALL COORDINATE THE WORK OF THE DELEGATED DESIGNERS WITH

A. LOCATION ON PROJECT WHERE THE CONCRETE IS USED EACH OTHER AND THE PRIMARY BASE BUILDING STRUCTURE. IT IS SUGGESTED THAT DESIGN CRITERIA, LOAD PATHS, AND ATTACHMENT

2. THE GENERAL CONTRACTOR AND SUBCONTRACTORS SHALL BE FAMILIAR WITH THE ENTIRE SET OF CONSTRUCTION DOCUMENTS B. 7 DAY COMPRESSIVE STRENGTH 3. CONTRACTOR SHALL ELECTRONICALLY SUBMIT STEEL JOIST SHOP DRAWINGS FOR APPROVAL PRIOR TO FABRICATION. CONTRACTOR SHALL SCHEMES PROPOSED BY THE DELEGATED DESIGNER BE SUBMITTED FOR REVIEW BY THE ARCHITECT FOR COMPATIBILITY OF THE BASE

(ARCHITECTURAL, CIVIL, MECHANICAL, ELECTRICAL, PLUMBING, STRUCTURAL, ETC.) IN ORDER TO PROVIDE ALL CONSTRUCTION AND MATERIALS C. 28 DAY COMPRESSIVE STRENGTH REVIEW AND STAMP ALL SHOP DRAWINGS BEFORE SUBMITTING TO THE ARCHITECT. BUILDING DESIGN PRIOR TO FINAL DESIGN AND DETAILING OF THE DELEGATED DESIGN PACKAGE.

FOR THIS PROJECT. D. AIR CONTENT

E. SLUMP 4. PROVIDE SJI STANDARD BRIDGING AS REQUIRED BY DESIGN. JOIST BRIDGING IS A REPRESENTATION FOR GENERAL INFORMATION PURPOSES 2. STRUCTURAL SYSTEMS SHALL BE DESIGNED FOR THE DELEGATED DESIGN PERFORMANCE CRITERIA DEFLECTION LIMITS NOTED ON THIS SHEET 181 N. Broadway Ave

3. THE CONTRACTOR SHALL REFER TO OTHER DRAWINGS CONTAINED IN THE CONSTRUCTION DOCUMENTS FOR ADDITIONAL SPECIFIED MEMBERS, F. AMOUNT OF WATER ADDED ON JOB SITE ONLY. JOIST SUPPLIER SHALL BE RESPONSIBLE FOR DESIGNING BRIDGING. AND TO LIMIT BUILDING MOVEMENTS TO LESS THAN THE VALUES INDICATED IN THE COORDINATION WITH OTHER TRADES AND BUILDING Milwaukee, WI 53202

DIMENSIONS, ELEVATIONS, DETAILS, OPENINGS, INSERTS, SLEEVES, DEPRESSIONS, ETC. NOT SHOWN ON THE STRUCTURAL DRAWINGS, G. MIX USED SYSTEMS NOTES ON S002. 414.278.6060

REQUIRED TO CONSTRUCT THIS PROJECT. 5. DO NOT CUT OR DRILL THROUGH ANY JOIST. www.pierceengineers.com

19. CONCRETE TEST REPORTS SHALL DIRECTLY STATE WHETHER OR NOT THE TEST RESULT COMPLIES WITH THE CONSTRUCTION DOCUMENTS 3. DOCUMENTS FOR DELEGATED DESIGN ITEMS SHALL BE STAMPED BY A QUALIFIED, PROFESSIONAL ENGINEER LICENSED IN THE STATE IN WHICH PE Project: 230647

4. DETAILS SHOWN ON STRUCTURAL DRAWINGS SHALL BE APPLICABLE TO ALL PORTIONS OF THE CONTRACT DOCUMENTS UNLESS NOTED AND SPECIFICATIONS. 6. ALL CONCENTRATED LOADS SHALL BE APPLIED AT A JOIST PANEL POINT UNLESS SPECIFICALLY NOTED OTHERWISE. PROVIDE ANGLE TO PANEL THE PROJECT IS LOCATED. THE CONTRACTOR SHALL FORWARD THE REVIEWED DOCUMENTS TO THE ARCHITECT AND/OR ENGINEER OF RECORD

OTHERWISE. POINT PER DETAILS WHERE CONCENTRATED LOADS DO NOT OCCUR AT PANEL POINT. WITH A NOTATION INDICATING THAT THE DELEGATED DESIGN DOCUMENTS HAVE BEEN REVIEWED AND BEEN FOUND TO BE IN GENERAL

20. CONTRACTOR SHALL BE RESPONSIBLE FOR REPAIR OF ANY IRREGULARITIES OR DEFECTS IN CONCRETE SLABS (CRACKS, BUMPS, FLOOR CONFORMANCE TO THE DESIGN OF THE BUILDING.

5. NOTES AND DETAILS ON DRAWINGS SHALL TAKE PRECEDENCE OVER GENERAL STRUCTURAL NOTES AND TYPICAL DETAILS. CURLING, ETC.) BEFORE ANY FLOOR FINISHES ARE APPLIED. 7. JOIST MANUFACTURER SHALL VERIFY ALL MEPF EQUIPMENT, DISTRIBUTION SYSTEMS, AND BUILDING EQUIPMENT WEIGHTS, SIZES, AND

LOCATIONS PRIOR TO PREPARING SHOP DRAWINGS AND FABRICATING MATERIALS. CONTRACTOR TO COORDINATE ANY CHANGES w/ JOIST 4. DELEGATED DESIGN ITEMS INCLUDE ANY ITEMS NOT EXPLICITLY NOTED ON THE STRUCTURAL DRAWINGS, INCLUDING BUT NOT LIMITED TO:

6. DO NOT SCALE PLANS. 21. CONFORM TO ACI 117 FOR CONCRETE TOLERANCES. SUPPLIER AND STRUCTURAL ENGINEER.

PRIMARY BASE BUILDING STRUCTURAL ELEMENTS

7. IN NO CASE SHALL STRUCTURAL ALTERATIONS OR WORK AFFECTING A STRUCTURAL MEMBER BE MADE UNLESS APPROVED BY THE 22. CONFORM TO ACI 306.1 FOR COLD WEATHER CONCRETE PLACEMENT. 8. DESIGN JOIST AND BRIDGING TO RESIST A NET WIND UPLIFT LOAD COMBINATION 0.6DL+0.6WL. "WL" AS INDICATED IN THE GENERAL NOTES • SHORING AND/OR UNDERPINNING OF EXISTING STRUCTURES

STRUCTURAL ENGINEER. DESIGN DATA. USE "DL" = 7 PSF. • LOAD-BEARING COLD FORMED METAL FRAMING AND CONNECTIONS

8. IT IS SOLELY THE CONTRACTOR'S RESPONSIBILITY TO DETERMINE AND PROVIDE FOR THE CONSTRUCTION MEANS, METHODS, TECHNIQUES,

23. CONFORM TO ACI 305.1 FOR HOT WEATHER CONCRETE PLACEMENT.

9. PROVIDE CAMBER IN JOIST AS RECOMMENDED BY SJI SPECIFICATIONS.

•

•

OPEN WEB STEEL JOISTS AND JOISTS GIRDERS

PRE-ENGINEERED ROOF/FLOOR OPENING FRAMES REVISIONS:

SEQUENCES, AND PROCEDURES REQUIRED TO COMPLETE THE STRUCTURE IN ACCORDANCE WITH THE CONTRACT DOCUMENTS. THIS POST-INSTALLED ANCHORS TO CONCRETE AND MASONRY: OTHER ITEMS SUPPORTED BY PRIMARY STRUCTURE (SECONDARY MEMBERS)

DATE ISSUE

INCLUDES, BUT IS NOT LIMITED TO: SHORING, UNDERPINNING, TEMPORARY BRACING, ETC. SAFETY PRECAUTIONS AND PROGRAMS IN 1. POST INSTALLED ANCHORS SHALL BE: EXPANSION, ADHESIVE, OR SCREW ANCHORS AS SPECIFIED, UNLESS NOTED OTHERWISE. 10. JOIST MANUFACTURER SHALL PROVIDE SPECIAL SEATS IN ACCORDANCE WITH SJI FOR JOISTS SLOPING MORE THAN 1/4" PER FOOT. • NON-LOAD-BEARING COLD FORMED METAL FRAMING AND CONNECTIONS

CONNECTION WITH THE WORK AS REQUIRED TO ENSURE THE SAFETY OF THE BUILDING AND WORKMEN ARE THE SOLE RESPONSIBILITY OF THE • STAIRS, RAILINGS, HANDRAILS, GUARDRAIL, LADDERS, ETC. – REFER TO STAIR DELEGATE DESIGN NOTES

CONTRACTOR. THE BASE BUILDING PRIMARY STRUCTURAL FRAME IS DESIGNED FOR THE FINAL, COMPLETED CONDITION AS INDICATED 2. EXPANSION ANCHORS (SEE NOTES BELOW FOR SUBSTITUTIONS): 11. JOIST SUPPLIER SHALL COORDINATE THEIR WORK WITH THE STEEL SUPPLIER ON THE PROJECT. • BOLLARDS, GUARDRAILS, TRAFFIC CONTROL DEVICES

HEREIN. LOADS IMPOSED ON THE BUILDING STRUCTURE DURING THE COURSE OF CONSTRUCTION SHALL BE CONFIRMED BY THE CONTRACTOR A. FOR CONCRETE: • CLADDING SYSTEMS AND COMPONENTS, INCLUDING SUPPLEMENTAL SUPPORT, WHERE REQUIRED

AND THE CONTRACTOR’S ENGINEER AS PART OF THE MEANS AND METHODS OF CONSTRUCTION. CARE SHALL BE GIVEN BY THE CONTRACTOR a. HILTI KWIK BOLT TZ. 12. DO NOT RUN JOIST BRIDGING THROUGH ANY DECK OPENINGS. JOIST SUPPLIER SHALL REVIEW AND PROVIDE ALTERNATE LOCATION FOR • FURNITURE, FIXTURES, AND OTHER MISCELLANEOUS ARCHITECTURAL FABRICATIONS

AND THE CONTRACTOR’S ENGINEER TO CONSIDER THE PRESENT STATE OF THE STRUCTURE AT THE TIME OF LOADING, INCLUDING AGE- B. FOR SOLID GROUTED CONCRETE MASONRY: BRIDGING ALONG JOIST SPAN AS REQUIRED. • SITE, UTILITY, PLAZA, AND LANDSCAPE ITEMS

DEPENDENT STRENGTH OF THE STRUCTURAL ELEMENTS AND THE NATURE OF ALL LOADS IMPOSED. a. HILTI KWIK BOLT TZ. • SUPPORTS, BRACING, ATTACHMENTS, AND SUBFRAMING FOR SUPPORT OF OTHER TRADES AND BUILDING COMPONENTS. REFER TO

13. JOIST SHALL BE FIELD ATTACHED w/ A MINIMUM OF LISTED VALUES, UNLESS NOTED OTHERWISE ON PLAN DETAILS: MODIFICATIONS FOR COORDINATION WITH OTHER TRADES NOTES.

9. CONSTRUCTION DOCUMENTS SHOW DIMENSIONS AND ELEVATIONS TO SIGNIFICANT WORKING POINTS (COLUMN CENTERLINES, OUTSIDE FACE 3. ADHESIVE ANCHORS (SEE NOTES BELOW FOR SUBSTITUTIONS): A. K-SERIES JOISTS - (2)-1/8" FILLET WELDS x 2 1/2" LONG EACH SIDE OF JOIST SEAT,OR BOLTED w/ (2)-1/2" DIA BOLTS IN SLOTTED HOLES

OF WALLS, TOP OF FRAMING MEMBERS, ETC.) MATERIAL SUPPLIERS AND DESIGNERS ARE RESPONSIBLE FOR ALL OTHER INFORMATION IN A. FOR CONCRETE: PARALLEL TO JOIST AT COLUMNS. 5. DELEGATED DESIGN SUBMITTALS PERTAINING TO FOUNDATIONS AND OTHER GEOTECHNICAL ELEMENTS SHALL BE REVIEWED BY THE

ORDER TO DETAIL/FABRICATE THEIR WORK. CONTACT THE ARCHITECT WITH ANY DISCREPANCIES. a. HILTI HIT RE 500 V3 EPOXY ADHESIVE ANCHOR SYSTEM WITH HAS THREADED ROD, THREADED ROD OR REBAR WHERE GEOTECHNICAL ENGINEER OF RECORD.

SPECIFIED METAL DECK:

10. IN THE EVENT OF ANY DISCREPANCIES BETWEEN THE STRUCTURAL DRAWINGS AND ANY OTHER PLANS, THE CONTRACTOR SHALL BRING THE b. HILTI HIT-HY 200 ADHESIVE ANCHOR SYSTEM WITH HAS THREADED ROD, THREADED ROD OR REBAR WHERE SPECIFIED. 1. DECK, ACCESSORIES, AND ATTACHMENTS SHALL CONFORM WITH THE CURRENT EDITION OF ''STEEL DECK INSTITUTE SPECIFICATIONS''. 6. ENGINEERING AND SYSTEMS REQUIRED BY THE CONTRACTOR TO SUPPORT CONSTRUCTION REMAIN THE PREROGATIVE AND RESPONSIBILITY

DISCREPANCY TO THE ARCHITECT'S ATTENTION IMMEDIATELY, IN WRITING. B. SOLID GROUTED CONCRETE MASONRY: OF THE CONTRACTOR. REFER TO GENERAL NOTES.

a. HILTI HIT-HY 270 ADHESIVE ANCHOR SYSTEM WITH HAS THREADED ROD, THREADED ROD OR REBAR WHERE SPECIFIED. 2. ALL ROOF DECK SHALL BE PAINTED, EXCEPT DECK EXPOSED TO WEATHER WHICH SHALL BE GALVANIZED. ALL FLOOR DECK SHALL BE GALVANIZED.

11. NO PROVISIONS HAVE BEEN MADE IN THE DESIGN OF THIS STRUCTURE FOR FUTURE EXPANSION, UNLESS SPECIFICALLY NOTED ON PLAN. C. HOLLOW OR MULTI-WYTHE MASONRY: COORDINATION WITH OTHER TRADES:

a. HILTI HIT-HY 70 ADHESIVE ANCHOR SYSTEM WITH HAS THREADED ROD OR THREADED ROD WITH SCREEN TUBES. 3. AT CHANGE IN DECK DIRECTION, PROVIDE A 20 GAUGE x 9'' WIDE CONTINUOUS PLATE. PROVIDE SAME PLATE AT ALL RIDGES, VALLEYS, AND HIPS BENT TO 1. SUPPORT, SUBFRAMING, BRACING, AND ATTACHMENTS TO PRIMARY BASE BUILDING STRUCTURE FOR ALL NONSTRUCTURAL BUILDING

12. ALL EXISTING STRUCTURES, INCLUDING EXISTING FOUNDATION SYSTEMS AND UNDERGROUND ELEMENTS, SHALL BE COMPLETELY REMOVED. MATCH PROFILE OF ROOF. COMPONENTS, INCLUDING ARCHITECTURAL, MECHANICAL, ELECTRICAL, PLUMBING, AND FIRE PROTECTION ELEMENTS SHALL BE DESIGNED AND NOTICE TO BIDDERS

EXISTING SUBSURFACE ELEMENTS MAY REMAIN IF APPROVED BY THE GEOTECHNICAL ENGINEER IN CONSULTATION WITH THE STRUCTURAL 4. SCREW ANCHORS (SEE NOTES BELOW FOR SUBSTITUTIONS): DETAILED BY THE MANUFACTURER, SUPPLIER, OR CONTRACTOR FURNISHING THOSE COMPONENTS. CONNECTIONS AND SUPPORTED LOADS TO BIDDERS SHALL REVIEW ALL DRAWINGS AND

ENGINEER AND THE EXISTING MATERIALS ARE PREPARED AS DIRECTED BY THE GEOTECHNICAL ENGINEER TO ACHIEVE THE PERFORMANCE A. FOR CONCRETE: COLD FORMED METAL FRAMING: STRUCTURAL MEMBERS SHALL BE SUBMITTED TO THE ARCHITECT FOR REVIEW. RESPONSIBILITY FOR THE PERFORMANCE OF THE SUPPLIED SPECIFICATION SECTIONS TO DETERMINE THE IMPACT OF

CHARACTERISTICS INDICATED IN THE GEOTECHNICAL REPORT. a. HILTI KWIK HUS EZ 1. CONTRACTOR SHALL ELECTRONICALLY SUBMIT COLD-FORMED SHOP DRAWINGS WITH STRUCTURAL CALCULATIONS STAMPED BY A SYSTEM AND ASSOCIATED CONNECTIONS SHALL REMAIN THAT OF THE PARTY FURNISHING THE DESIGN AND DETAILING. OTHER SECTIONS OF WORK ON THEIR OWN WORK

B. SOLID GROUTED CONCRETE MASONRY: PROFESSIONAL ENGINEER REGISTERED IN THE STATE IN WHICH THE PROJECT IS LOCATED TO THE ARCHITECT AND ENGINEER FOR APPROVAL.

CONTRACTOR SHALL REVIEW AND STAMP ALL SHOP DRAWINGS BEFORE SUBMITTING TO THE ARCHITECT. 2. THE CONTRACTOR SHALL COORDINATE THE WORK OF ALL TRADES CONNECTING TO, REQUESTING OPENINGS IN, PENETRATIONS THROUGH, OR © 2023 ABACUS ARCHITECTS, INC.

FOUNDATION AND EARTHWORK: a. HILTI KWIK HUS EZ

1. FOUNDATION DESIGN IS BASED ON THE SUBSURFACE EXPLORATION AND RECOMMENDATIONS OF THE BORINGS PERFORMED BY: ITEMS EMBEDDED WITHIN STRUCTURAL ELEMENTS, OR OTHERWISE IMPACTING THE BASE BUILDING STRUCTURE. UPON COMPLETION OF

5. WHEN INSTALLING POST INSTALLED ANCHORS: 2. SHOP DRAWING SUBMISSIONS SHALL INCLUDE THE FOLLOWING INFORMATION: COORDINATION AND DESIGN, FULLY COORDINATED PLANS SHALL BE SUBMITTED FOR REVIEW AND APPROVAL BY THE STRUCTURAL ENGINEER

MILLER ENGINEERS & SCIENTISTS A. THE MANUFACTURER'S PRINTED INSTALLATION INSTRUCTIONS AND CURRENT ICC-ES REPORT SHALL BE FOLLOWED. A. THE NAME, ADDRESS, PHONE NUMBER, AND FAX NUMBER OF THE SUPPLIER OF RECORD PRIOR TO FABRICATION AND INSTALLATION. THIS INCLUDES BUT IS NOT LIMITED TO SLEEVES, CONDUITS, CABLES, PIPES,

5308 SOUTH 12th STREET B. DO NOT DAMAGE EXISTING REINFORCING, POST TENSIONED CABLES OR OTHER EMBEDDED ITEMS. B. ALL DESIGN LOADS ELECTRICAL BOXES, CAST-IN ATTACHMENTS, POST-INSTALLED ANCHORS, ETC. REFER TO TYPICAL DETAILS CONTAINED HEREIN FOR

SHEBOYGAN, WI 53081 C. WHEN INSTALLING IN CONCRETE: C. PLANS AND ELEVATIONS KEYING IN ALL SECTION REINFORCEMENT REQUIRED TO ACCOMMODATE REQUESTED MODIFICATIONS TO THE PRIMARY BASE BUILDING STRUCTURE. UPON REVIEW,

JOB NO. 20689-001 a. THE MINIMUM CONCRETE DESIGN COMPRESSIVE STRENGTH SHALL MATCH THE COMPRESSIVE STRENGTHS NOTED IN THE D. CONNECTION DETAILS SPECIFYING ALL FASTENER TYPES, QUANTITY, AND LOCATIONS ADDITIONAL OR ALTERNATIVE MODIFICATIONS MAY BE REQUIRED AT THE DISCRETION AND DIRECTION OF THE STRUCTURAL ENGINEERING OF

1135A MICHIGAN AVE. SHEBOYGAN, WI 53081 (920) 452-4444 │ 640 N VEL R. PHILIPS AVE, SUITE 210, MILWAUKEE, WI 53203

DATED MAY 23, 2023 CONCRETE NOTES SECTION. E. ALL REQUIRED BRIDGING, BRACING, AND OTHER COLD FORMED COMPONENTS RECORD.

b. FOR POST INSTALLED ADHESIVE ANCHORS, THE CONCRETE SHALL HAVE A MINIMUM AGE OF 21 DAYS AT THE TIME OF

2. THE CONTRACTOR AND THE OWNER'S TESTING AGENT SHALL CONFIRM INSTALLATION AND CONSTRUCTION OF FOUNDATIONS IS COMPLETED IN INSTALLATION. ANCHORS INSTALLED IN CONCRETE LESS THAN 21 DAYS OLD SHALL BE TESTED IN ACCORDANCE WITH ACI 355.4 3. ALL COLD-FORMED MEMBERS SPECIFIED ON THE CONSTRUCTION DOCUMENTS ARE MINIMUM SIZES. COLD-FORMED DESIGNER TO VERIFY ALL 3. PENETRATIONS THROUGH, CONNECTIONS TO, AND ITEMS EMBEDDED WITHIN STRUCTURAL MEMBERS SHALL NOT NEGATIVELY IMPACT THE

CONFORMANCE WITH THE RECOMMENDATIONS OF THE GEOTECHNICAL REPORT. TO VERIFY PERFORMANCE. SIZES. PERFORMANCE OF THE BASE BUILDING STRUCTURE.

c. FOR POST INSTALLED ADHESIVE ANCHORS, THE CONCRETE TEMPERATURE AT THE TIME OF INSTALLATION SHALL BE AT LEAST

3. CENTER PIERS AND FOUNDATIONS UNDER COLUMN / WALL CENTERLINES UNLESS NOTED OTHERWISE. 50-DEGREES FAHRENHEIT. 4. REFER TO MATERIAL STRENGTHS FOR COLD-FORMED METAL FRAMING YIELD STRESS (Fy). 4. CONTRACTOR SHALL COORDINATE THE WORK OF ALL TRADES, INCLUDING AS-BUILT CONDITIONS IMPACTING DESIGN AND COORDINATION.

D. ADHESIVE USED IN AN ADHESIVE ANCHOR SYSTEM SHALL BE STORED AT THE SERVICE TEMPERATURE RANGE RECOMMENDED BY THE ADJACENCIES OF ITEMS PLANNED OR INSTALLED IN OR ON STRUCTURE SHALL BE IDENTIFIED AND CONSIDERED BY EACH TRADE FOR THE

4. BACKFILL AT WALLS SHALL BE PROVIDED PER THE RECOMMENDATIONS OF THE GEOTECH. BACKFILL SIMULTANEOUSLY ON BOTH SIDE OF MANUFACTURER. 5. ALL COLD-FORMED MEMBERS SHALL BE GALVANIZED. IMPACT OF SUCH ADJACENCIES TO THEIR SYSTEMS. VERIFY ALL MECHANICAL EQUIPMENT, WEIGHTS, SIZES, AND LOCATIONS PRIOR TO

FOUNDATION AND STEM WALLS. E. ANCHORS TO BE INSTALLED IN ADHESIVE SHALL BE CLEAN, OIL FREE AND FREE OF RUST, PAINT OR OTHER COATINGS. PREPARING SHOP DRAWINGS AND FABRICATING MATERIALS. COORDINATE ANY REQUIRED REVISIONS TO THE BASE BUILDING STRUCTURE WITH

F. ADHESIVE ANCHORS SHALL BE SECURELY PLACED TO PREVENT DISPLACEMENT OR DISTURBANCE WHILE THE ADHESIVE CURES. IF AN 6. DESIGN, SUPPLY, AND INSTALL ANY HOT-ROLLED OR COLD-ROLLED SECTION NEEDED TO PROVIDE A COMPLETE EXTERIOR CLADDING SYSTEM. THE STRUCTURAL ENGINEER.

5. EARTH RETENTION AND UNDERPINNING SYSTEMS, TEMPORARY OR PERMANENT, SHALL BE PROVIDED BY THE CONTRACTOR AND THE ANCHOR IS DISPLACED OR DISTURBED BEFORE A FULL ADHESIVE CURE IT SHALL BE CONSIDERED DAMAGED AND REPLACED AT THE

CONTRACTOR'S ENGINEER AS AN ELEMENT OF THE MEANS AND METHODS OF CONSTRUCTION. CONTRACTOR'S EXPENSE. 7. REFER TO DEFLECTION LIMIT CRITERIA FOR ALL COLD-FORMED FRAMING DEFLECTION REQUIREMENTS. 5. MISCELLANEOUS ELEMENTS SUCH AS SHELF ANGLES, LINTELS, SUPPORTS FOR CURTAIN WALLS OR MASONRY, AND EDGE ANGLES AT OPENINGS

G. UNLESS NOTED OTHERWISE, ANCHORS SHALL BE INSTALLED PERPENDICULAR TO THE SUPPORTING SURFACE. AND PERIMETER CONDITIONS ARE INTENDED TO SUPPORT AND BE COORDINATED WITH MATERIALS FURNISHED BY OTHER TRADES. THESE

HAPPY LANE, SHEBOYGAN FALLS, WI 53085

6. SUBGRADES SHALL BE PREPARED PER THE GEOTECHNICAL RECOMMENDATIONS. TOP OF FOOTING ELEVATIONS SHOWN ON THESE H. INSTALL ANCHORS TO ACCOMMODATE THE STANDARD HOLE SIZE IN THE SUPPORTED STEEL MEMBER. THE HOLE DIAMETER THROUGH 8. ALL WELDING SHALL BE AWS D1.3. WELDERS SHALL BE CERTIFIED FOR THE THICKNESS OF MATERIAL BEING WELDED. MATERIALS ARE INTENDED TO BE FIELD ATTACHED TO MEET THE TOLERANCES REQUIRED BY OTHER TRADES, WHICH MAY BE MORE STRINGENT

OOSTBURG STATE BANK

CONSTRUCTION DOCUMENTS REPRESENT MINIMUM FOOTING DEPTHS FOR FROST PROTECTION AND ESTIMATES OF REQUIRED BEARING DEPTH THE SUPPORTED STEEL MEMBER SHALL BE 1/16" LARGER THAN THE ANCHOR UNLESS NOTED OTHERWISE. USE PLATE WASHERS WITH A THAN THE TOLERANCES SPECIFIED BY THE RELEVANT CODE OF STANDARD PRACTICE FOR THE SUPPORTING ELEMENTS. THE CONTRACTOR

BASED ON THE RECOMMENDATIONS OF THE GEOTECHNICAL REPORT. THE ON-SITE GEOTECHNICAL ENGINEER SHALL ENSURE FOUNDATION STANDARD SIZE HOLE WELDED TO STEEL MEMBERS WHERE OVERSIZED HOLES MUST BE USED THROUGH THE STEEL MEMBER, UNO. 9. SCREW PENETRATION THROUGH JOINED MATERIALS SHALL NOT BE LESS THAN THREE EXPOSED SCREW THREADS. REFER TO INSTALLATION SHALL COORDINATE THE WORK OF ALL TRADES AND COORDINATE THE INSTALLATION OF SUPPORTING ELEMENTS TO COMPLY WITH THE

AND SLAB-ON-GROUND SYSTEMS ARE FOUNDED ON COMPETENT MATERIAL TO ACHIEVE THE DESIGN VALUES INDICATED ON THESE I. HOLES SHALL BE DRILLED AND INSTALLED PER THE MANUFACTURER'S PRINTED INSTALLATION INSTRUCTIONS AS OUTLINED IN THE ICC- INSTRUCTIONS OF THE SCREW MANUFACTURER AND/OR ASTM C-954 FOR MINIMUM SPACING AND EDGE DISTANCE AND TORQUE REQUIREMENTS. TOLERANCE CRITERIA REQUIRED FOR INSTALLATION OF MATERIALS BY OTHER TRADES.

CONSTRUCTION DOCUMENTS AND IN THE GEOTECHNICAL REPORT. AT THE GEOTECHNICAL ENGINEER'S DIRECTION, EXCAVATIONS MAY BE ES REPORT. WHERE APPLICABLE, INSTALLATION SHALL ALSO FOLLOW PROPER CLEANING PROCEDURE AS INDICATED IN THE

NEED TO BE EXTENDED TO FIND COMPETENT MATERIALS OR ADDITIONAL SUBGRADE PREPARATIONS MAY BE REQUIRED. MANUFACTURER'S PRINTED INSTALLATION INSTRUCTION AS OUTLINED IN THE ICC-ES REPORT. HOLES SHALL BE DRILLED WITH A 10. INSTALL CONTINUOUS TRACKS SIZED TO MATCH STUDS. ALIGN TRACKS ACCURATELY TO LAYOUT AT BASE AND TOPS OF STUDS. SECURE 6. UNDERGROUND

ROTARY IMPACT HAMMER DRILL OR ROCK DRILL, DO NOT CORE DRILL HOLES. TRACKS AS RECOMMENDED BY STUD MANUFACTURER FOR TYPE OF CONSTRUCTION INVOLVED, EXCEPT DO NOT EXCEED 24'' o/c SPACING FOR A. THE INFLUENCE AREA OF A FOOTING OR MAT SHALL BE DEFINED AS THE FRUSTUM OF SOIL LOCATED BELOW THE FOOTING OR MAT

POWDER-DRIVEN FASTENERS, OR 16'' o/c FOR OTHER TYPES OF ATTACHMENT. PROVIDE FASTENERS AT CORNERS AND END OF TRACKS. HAVING A 1:1 (HORIZONTAL:VERTICAL) SLOPE EMANATING FROM THE FOOTING OR MAT EDGE, OR AS DEFINED BY THE GEOTECHNICAL

NEW BUILDING FOR:

7. ALL EXTERIOR FOUNDATIONS SHALL BE CAST AT LEAST FROST DEPTH BELOW ADJACENT FINISH EXTERIOR GRADE. FOOTINGS SHALL BE CAST

AT LEAST MINIMUM BEARING DEPTH BELOW ADJACENT FINAL GRADE OR FINISHED FLOOR ELEVATION. REFER TO SOIL DESIGN VALUES. 6. ALL PERSONNEL INSTALLING ANCHORS SHALL BE TRAINED AND CERTIFIED BY THE ANCHORING SYSTEM MANUFACTURER. CONTRACTOR SHALL ENGINEER OF RECORD.

ISSUE DATE: 11/13/2023

SUBMIT VALID CERTIFICATION FROM THE MANUFACTURER ON ALL PERSONNEL. ALL PERSONNEL INSTALLING ADHESIVE ANCHORS IN A 11. WHERE SPLICING OF TRACK IS NECESSARY BETWEEN STUD SPACINGS, PROVIDE A PIECE OF STUD PLACED BETWEEN ADJACENT TRACKS AND

FASTENED BY WELD OR SCREW TO EACH SIDE OF THE TRACK EACH END.

BID SET

8. REFER TO GEOTECHNICAL AND/OR ENVIRONMENTAL REPORT FOR REMEDIATION OF SOILS THAT ARE NOT SUITABLE FOR BEARING BELOW HORIZONTAL, OVERHEAD OR UPWARDLY INCLINED CONDITION SHALL BE TRAINED AND CERTIFIED BY THE ACI/CRSI ADHESIVE ANCHOR B. PIPES, CONDUITS, AND BURIED ITEMS SHALL NOT BE PLACED WITHIN THE INFLUENCE AREA OF ADJACENT FOOTINGS OR MATS.

FOOTINGS OR SLABS, OR SOILS THAT REQUIRE REMOVAL DUE TO CONTAMINATION. INSTALLER CERTIFICATION PROGRAM FOR SUCH APPLICATIONS.

12. AT NON-LOAD BEARING WALLS, PROVIDE A SLIP TRACK AT TOP OF WALL. C. ALL STRUCTURES (eg. TRIPLE BASINS, GREASE TRAPS, ETC.) SHALL NOT BE INSTALLED WITHIN THE INFLUENCE AREA OF ADJACENT

9. ENGINEERED FILL MATERIALS OR LEAN CONCRETE SHALL BE PROVIDED AND INSTALLED PER THE GEOTECHNICAL ENGINEER'S 7. POST INSTALLED ANCHORS SHALL ONLY BE USED WHERE SPECIFIED ON THE DRAWINGS. CONTRACTOR SHALL OBTAIN APPROVAL FROM FOOTINGS OR MATS UNLESS THE STRUCTURE IS DESIGNED BY THE MANUFACTURER FOR INCREASED SURCHARGE LOAD APPLIED BY

RECOMMENDATIONS. STRUCTURAL ENGINEER OF RECORD PRIOR TO USING POST INSTALLED ANCHORS FOR MISSING OR MISPLACED CAST IN PLACE ANCHORS. ONLY 13. FASTENING OF COMPONENTS SHALL BE WITH SELF-DRILLING SCREWS OR BY WELDING. SCREWS AND WELDS SHALL BE SUFFICIENT SIZE TO THE ADJACENT FOUNDATION AND HAS BEEN REVIEWED AND APPROVED BY THE STRUCTURAL ENGINEER OF RECORD OR THE

USE SPECIFIC TYPE OF ANCHOR (EXPANSION, ADHESIVE, SCREW) WHERE INDICATED. DO NOT SUBSTITUTE ANCHOR TYPES WITHOUT WRITTEN ENSURE THE STRENGTH OF THE CONNECTION. GEOTECHNICAL ENGINEER OF RECORD.

10. FOUNDATIONS SHALL NOT BE INSTALLED ON FROZEN SUBGRADE. APPROVAL FROM SEOR.

14. ALL WELDS SHALL BE TOUCHED UP WITH ZINC-RICH PAINT. D. ITEMS TO BE BURIED IN IMPROVED SOILS SHALL BE REVIEWED AND APPROVED BY THE GROUND IMPROVEMENT DELEGATED DESIGN

8. SUBSTITUTION REQUESTS FOR PRODUCTS OTHER THAN THOSE LISTED ABOVE SHALL BE SUBMITTED TO THE ENGINEER WITH CALCULATIONS ENGINEER AND THE GEOTECHNICAL ENGINEER OF RECORD

CAST IN PLACE REINFORCED CONCRETE: THAT ARE PREPARED AND SEALED BY A STRUCTURAL ENGINEER REGISTERED IN THE STATE WHERE THE PROJECT IS LOCATED (PER THE 15. INSTALL COLD-FORMED FRAMING MEMBERS IN ACCORDANCE WITH MANUFACTURERS PRINTED OR WRITTEN INSTRUCTIONS AND

1. CONCRETE WORK SHALL CONFORM TO REFERENCED EDITION OF ACI 318 "BUILDING CODE REQUIREMENTS FOR STRUCTURAL CONCRETE" AND DELEGATED DESIGN NOTES) SHOWING THAT THE SUBSTITUTED PRODUCT WILL ACHIEVE AN EQUIVALENT CAPACITY USING THE APPROPRIATE RECOMMENDATIONS UNLESS NOTED OTHERWISE. 7. CONCRETE ELEMENTS

ACI 302 "GUIDE FOR CONCRETE FLOOR AND SLAB CONSTRUCTION". DESIGN PROCEDURE REQUIRED BY THE BUILDING CODE. PRODUCT ICC-ES CODE REPORTS SHALL BE INCLUDED WITH THE SUBMITTAL PACKAGE. A. REFER TO TYPICAL CONCRETE SLAB PENETRATION AND CONDUIT PLACEMENT CRITERIA DETAIL.

THE PROPOSED SUBSTITUTION(S) SHALL MEET THE MOST RECENTLY PUBLISHED ACI 355.2 OR ACI 355.4. 16. FIELD CUTTING OF COLD-FORMED MEMBERS SHALL BE BY SAW OR SHEAR. TORCH CUTTING IS NOT PERMITTED.

2. CONTRACTOR SHALL ELECTRONICALLY SUBMIT STEEL REBAR SHOP DRAWINGS FOR APPROVAL PRIOR TO CONSTRUCTION. CONTRACTOR B. GROUPS OF ADJACENT OPENINGS REQUIRE SPECIAL CONSIDERATION AND MAY BE IMPERMISSIBLE. EARLY COORDINATION OF

SHALL REVIEW AND STAMP ALL SHOP DRAWINGS BEFORE SUBMITTING TO THE ARCHITECT. 17. TEMPORARY BRACING OF COLD-FORMED MEMBERS SHALL BE PROVIDED AND REMAIN IN PLACE UNTIL WORK IS PERMANENTLY STABILIZED. ALL CLUSTERED PENETRATIONS WITH THE STRUCTURAL ENGINEER OF RECORD IS HIGHLY RECOMMENDED.

STRUCTURAL STEEL:

BRACING REQUIRED SHALL BE DESIGNED AND SUPPLIED BY THE COLD-FORMED CONTRACTOR.

1. DESIGN, FABRICATION, AND ERECTION SHALL CONFORM TO AISC (AMERICAN INSTITUTE OF STEEL CONSTRUCTION) ''STEEL CONSTRUCTION

3. REFER TO REINFORCEMENT DEVELOPMENT AND LAP SPLICE SCHEDULE FOR LAP SPLICES (Lst) AND DEVELOPMENT LENGTH (Ld) IN 8. STEEL ELEMENTS

MANUAL''. EDITION AS SPECIFIED BY CODE.

REINFORCING STEEL. 18. AT LOCATIONS REQUIRING WELDING OF OR TO METAL STUDS, MINIMUM STUD THICKNESS SHALL BE 16 GA. A. ALL PENETRATIONS INDICATED HEREIN SHALL BE CONFIRMED BY THE CONTRACTOR THROUGH COORDINATION WITH THE

SUBCONTRACTORS AND DELEGATED DESIGN ENGINEERS. SUBMIT ALL REQUIRED PENETRATIONS FOR REVIEW AND APPROVAL

2. STEEL DETAILING AND CONNECTIONS SHALL CONFORM TO THE REQUIREMENTS OF AISC 360 ''SPECIFICATIONS FOR STRUCTURAL STEEL

4. ALL LAPS IN REINFORCING STEEL SHALL BE CLASS ''B'' LAP SPLICES UNLESS OTHERWISE NOTED. AT CONSTRUCTION JOINTS, CONTINUOUS SUBSEQUENT TO FINAL COORDINATION OF BUILDING SYSTEMS.

BUILDINGS". EDITION AS SPECIFIED BY CODE, ALLOWABLE STRESS DESIGN. DELEGATED DESIGN STAIR NOTES:

BARS SHALL BE LAP SPLICED WITH A CLASS "B" LAP. ALL OTHER BARS EXTENDING THRU THE JOINT SHALL BE FULLY DEVELOPED (Ld OR Ldh AS 1. STAIRS NOT DETAILED ON THE DRAWINGS ARE DELEGATED TO THE CONTRACTOR FOR DESIGN. REFER TO THE ARCHITECTURAL DRAWINGS AND

ILLUSTRATED OR NOTED) EACH SIDE OF JOINT, UNO. B. FIELD-CUTTING SHALL NOT BE PERMITTED WITHOUT PRIOR APPROVAL BY THE STRUCTURAL ENGINEER OF RECORD.

3. BEAM AND GIRDER CONNECTIONS SHALL BE DETAILED AS NOTED ON PLANS AND DETAILS. PROJECT SPECIFICATIONS FOR ADDITIONAL PERFORMANCE CRITERIA AND FINISHING REQUIREMENTS. THE BASE BUILDING STRUCTURE HAS

BEEN DESIGNED FOR SUPPORT OF STAIRS AS INDICATED HEREIN.

5. ALL HOOKS IN REINFORCING STEEL SHALL BE STANDARD HOOKS, UNO. 9. METAL DECK

4. SUBSTITUTION REQUESTS FOR CONNECTIONS SHALL BE SUBMITTED TO THE STRUCTURAL ENGINEER WITH CALCULATIONS THAT ARE PREPARED

A. ATTACHING OR HANGING ANY LOADS FROM METAL ROOF DECK WILL NOT BE ACCEPTED WITHOUT WRITTEN APPROVAL FROM THE

AND SEALED BY A REGISTERED STRUCTURAL ENGINEER SHOWING THAT THE SUBSTITUTED CONNECTION WILL ACHIEVE AN EQUIVALENT 2. STAIRS, HANDRAILS, AND GUARDRAILS SHALL BE DELEGATED DESIGN BY THE STEEL SUPPLIER. CONNECTIONS INTO SURROUNDING STRUCTURE

6. PROVIDE THE FOLLOWING CLEAR COVER DISTANCES FOR REINFORCEMENT IN CONCRETE UNLESS NOTED OTHERWISE: STRUCTURAL ENGINEER.

CAPACITY USING THE APPROPRIATE DESIGN PROCEDURE REQUIRED BY THE BUILDING CODE. SHALL BE APPROVED BY STRUCTURAL ENGINEER. CALCULATIONS OF ALL STAIR COMPONENTS MUST BE SUPPLIED WITH STAIR SHOP DRAWINGS

AND STAMPED BY THE PROFESSIONAL ENGINEER IN RESPONSIBLE CHARGE, IN THE STATE IN WHICH THE PROJECT IS LOCATED.

CONCRETE CAST AGAINST AND PERMANENTLY EXPOSED TO EARTH: 3" B. COMPOSITE FLOOR DECK HANGER LOADS SHALL NOT EXCEED 60 POUNDS PER HANGER. IN ADDITION, LOADS ON HANGERS SHALL BE

5. STRUCTURAL STEEL AND CONNECTIONS EXPOSED TO WEATHER OR CORROSIVE ENVIRONMENTS SHALL BE GALVANIZED OR COATED PER THE

DISTRIBUTED IN SUCH A MANNER THAT THE TRIBUTARY LOADS FROM EACH HANGER SHALL NOT EXCEED 5 POUNDS PER SQUARE FOOT.

REQUIREMENTS OF AISC 360. 3. REFER TO ARCHITECTURAL DRAWINGS FOR STAIR FRAMING AND CONFIGURATION.

CONCRETE EXPOSED TO EARTH OR WEATHER:

NO. 6 THROUGH NO. 18 BARS 2" C. CONDUIT AND PIPING MAY NOT BE EMBEDDED IN COMPOSITE DECK SLABS.

6. WELDING SHALL BE PERFORMED BY CERTIFIED WELDERS HOLDING CURRENT AWS CERTIFICATES IN THE TYPES OF WELDING SPECIFIED ON THE 4. LANDING BEAMS AND ANY ADDITIONAL SUPPORTS BEYOND WHAT IS SHOWN IN THE CONTRACT DOCUMENTS INCLUDING ADDITIONAL

NO. 5 BAR AND SMALLER 1 1/2" CONSTRUCTION DOCUMENTS. FOUNDATIONS, IF REQUIRED, SHALL BE DESIGNED AND PROVIDED BY THE STAIR SUPPLIER.

D. VERIFY ALL MECHANICAL EQUIPMENT WEIGHTS, SIZES, & LOCATIONS PRIOR TO PREPARING SHOP DRAWINGS & FABRICATING

CONCRETE NOT EXPOSED TO WEATHER OR IN CONTACT WITH GROUND: MATERIALS. CONTRACTOR TO COORDINATE ANY CHANGES w/ STRUCTURAL ENGINEER..

7. ALL STEEL BEAMS SHALL BE FABRICATED WITH THE NATURAL CAMBER (WITHIN MILL TOLERANCE) IN THE UPWARD VERTICAL DIRECTION. 5. DESIGN LOADS:

WALLS, JOISTS: NO. 11 BAR AND SMALLER 1"

BEAMS AND COLUMNS 1 1/2" E. REFER TO TYPICAL DETAILS FOR FRAMING AROUND FLOOR AND ROOF OPENINGS. COORDINATE SIZE, LOCATION, & QUANTITY OF STEEL

8. PROVIDE 3/16'' CAP PLATE AT THE ENDS OF ALL EXPOSED TUBE AND PIPE MEMBERS, UNLESS NOTED OTHERWISE. A. STAIR LIVE LOAD SHALL BE 100 PSF, NON-REDUCIBLE.

FRAMES WITH MECHANICAL CONTRACTOR ON PROJECT.

7. CALCIUM CHLORIDE OR ADMIXTURES CONTAINING CALCIUM CHLORIDE ARE NOT PERMITTED IN ANY CONCRETE MIX. 9. PROVIDE STIFFENER PLATES ON BOTH SIDES OF BEAM WEBS AT ALL CONCENTRATED LOADS ABOVE AND BELOW A BEAM. UNLESS NOTED B. STAIR CONSTRUCTION SHALL BE:

F. NO METAL ROOF DECK OPENINGS SHALL BE CUT UNLESS AUTHORIZED AND/OR DIRECTED BY THE STRUCTURAL ENGINEER. WHEN

OTHERWISE, FRAME THE LARGEST BEAM OVER COLUMNS AT BEAM TO BEAM INTERSECTIONS.

8. CONTRACTOR SHALL USE SMOOTH FORMS FOR EXPOSED CONCRETE SURFACES. ANY CONCRETE SURFACE REPAIRS SHALL BE PERFORMED a. METAL PAN WITH 2” NORMAL WEIGHT CONCRETE FILL ON TREADS AND INTERMEDIATE LANDINGS, HAVING A TOTAL AVERAGE DEAD

OPENINGS ARE REQUIRED, THE FOLLOWING RECOMMENDATIONS APPLY: DRAWN BY: PE

BY THE CONTRACTOR AS REQUIRED. REPAIR AND PATCH DEFECTIVE AREAS WITH PROPRIETARY PATCHING COMPOUND IMMEDIATELY AFTER 6" OPENING OR LESS (ONE RIB REMOVED) - NO REINFORCING REQUIRED

10. SPLICES SHALL BE ALLOWED ONLY AT LOCATIONS INDICATED ON THE STRUCTURAL DRAWINGS, UNLESS APPROVED BY THE STRUCTURAL LOAD OF NOT MORE THAN 50 PSF.

REMOVAL OF FORMS. 6" TO 8" OPENING (ONE RIB REMOVED) - 18 GA. REINFORCING PLATE, SCREWED TO ADJACENT RIBS,

ENGINEER. UNLESS NOTED OTHERWISE, FRAME THE LARGEST BEAM OVER COLUMNS AT BEAM TO BEAM INTERSECTIONS.

6. CONNECTIONS TO BASE BUILDING STRUCTURE

PROVIDED BY STEEL SUPPLIER. CHECKED BY: PE

9. PROVIDE A 3/4'' CHAMFER ON EXPOSED CORNERS OF CONCRETE UNLESS NOTED OTHERWISE. TOP SURFACE OF WALLS SHALL BE FINISHED 8" TO 12" OPENING (TWO RIBS REMOVED) - 16 GA. REINFORCING PLATE, SCREWED TO ADJACENT RIBS,

11. CONTRACTOR SHALL ELECTRONICALLY SUBMIT STEEL SHOP DRAWINGS FOR APPROVAL PRIOR TO FABRICATION. CONTRACTOR SHALL REVIEW

SMOOTH, UNLESS NOTED OTHERWISE. PROVIDED BY STEEL SUPPLIER.

AND STAMP ALL SHOP DRAWINGS BEFORE SUBMITTING TO THE ARCHITECT. A. CONNECTION OF STAIRS TO THE BASE BUILDING STRUCTURE SHALL BE DESIGNED AND SUPPLIED BY THE STAIR SUPPLIER SUBJECT TO THE

OPENINGS OVER 12" STEEL ANGLE FRAME, AS SHOWN ON THE STEEL DETAIL DRAWINGS

CONDITIONS INDICATED HEREIN AND COORDINATED WITH ALL OTHER TRADES AND SUBCONSULTANTS. SIGNED AND SEALED STAIR

10. CONTRACTOR SHALL PROVIDE SUITABLE WIRE SPACERS, CHAIRS, TIES, ETC FOR SUPPORTING REINFORCING STEEL IN THE PROPER POSITION - ARE REQUIRED, PROVIDED BY STEEL SUPPLIER.

12. THE STRUCTURE IS STABLE ONLY IN ITS COMPLETED FORM. CONTRACTOR SHALL DETERMINE, FURNISH AND INSTALL ANY TEMPORARY BRACING DESIGNS, INCLUDING CONNECTION LOCATIONS AND LOADS, SHALL BE PROVIDED PRIOR TO OR CONCURRENT WITH THE REVIEW OF SHOP

WHILE PLACING CONCRETE. OR GUYS REQUIRED TO ERECT STEEL MEMBERS. TEMPORARY BRACING SHALL BE LEFT IN PLACE UNTIL THE PERMANENT STRUCTURE IS IN

PLACE AND SECURE.

DRAWINGS FOR THE SUPPORTING BASE BUILDINGS STRUCTURAL ELEMENTS. CONNECTION CALCULATIONS SHALL INCLUDE CONSIDERATION

OF ALL LOCAL EFFECTS IMPOSED ON THE SUPPORTING MEMBERS.

10. MOVEMENT ACCOMMODATION BY BUILDING COMPONENTS. GENERAL NOTES

11. PROVIDE 1/2'' EXPANSION JOINT MATERIAL AT INTERIOR LOCATIONS WHERE SLABS ABUT WALLS, COLUMNS, AND OTHER VERTICAL SURFACES A. BUILDING COMPONENTS SUPPORTED ON THE BASE BUILDING STRUCTURE, SUCH AS CLADDING SYSTEMS, PARTITIONS WALLS,

UNLESS NOTED OTHERWISE. OPERABLE PARTITIONS, ETC., SHALL BE DESIGNED AND DETAILED TO ACCOMMODATE STRUCTURAL MOVEMENTS INDICATED BELOW:

13. STRUCTURAL STEEL FRAMING SHALL BE TRUE AND PLUMB BEFORE CONNECTIONS ARE FINALLY BOLTED OR WELDED. B. CONNECTIONS FOR INTERMEDIATE LANDINGS ARE ASSUMED TO BE MADE AT THE FAR END OF THE STAIR STRINGER OPPOSITE THE

CONNECTION AT THE FLOOR LEVELS, UNLESS NOTED OTHERWISE. IT IS SUGGESTED THAT ALTERNATE SUPPORT LOCATIONS BE

12. TIME BETWEEN CONCRETE BATCHING AND PLACEMENT SHALL BE IN ACCORDANCE WITH ASTM C94. B. VERTICAL MOVEMENTS

14. ANY HOLES, CUTS, OR COPING FIELD CUT INTO STEEL MUST BE VERIFIED WITH THE STRUCTURAL ENGINEER PRIOR TO WORK. CONTRACTOR SUBMITTED FOR REVIEW PRIOR TO COMPLETION OF THE STAIR SHOP DRAWINGS.

a. FLEXIBLE CLADDING SYSTEMS: 1/2"

S

SHALL COORDINATE ALL HOLES REQUIRED BY OTHERS WITH THE STRUCTURAL ENGINEER.

13. ADDITION OF JOBSITE WATER TO CONCRETE SHALL BE PER ASTM C94. b. BRITTLE CLADDING SYSTEMS: 3/8”

C. ALL LOADS APPLIED TO BASE BUILDING SHALL BE ATTACHED SUCH THAT ROTATION OF THE BASE BUILDING STEEL FRAMING IS RESTRAINED,

c. INTERIOR PARTITION DIFFERENTIAL MOVEMENT BETWEEN FLOORS: 1 1/2"

15. THE STEEL SUPPLIER SHALL COORDINATE HIS WORK WITH OTHER DELEGATED DESIGN COMPONENTS (i.e. STEEL JOISTS, PRECAST CONCRETE, UNLESS NOTED OTHERWISE. PROVIDE CONCENTRIC CONNECTIONS WHERE POSSIBLE, OR DESIGN AND PROVIDE KICKERS OR OTHER

14. ALL CONCRETE SLABS SHALL BE CURED PER ACI 308.1 RECOMMENDATIONS. d. OPERABLE PARTITIONS HUNG FROM ABOVE: 2 1/2”

STEEL STAIR COMPONENTS, ETC.). MEANS OF RESTRAINT IF NECESSARY.

15. CONTROL JOINTS SHALL BE PLACED IN CONVENTIONAL SLAB ON GROUND WITHIN 24 HOURS OF INITIAL POUR. REFER TO PLAN NOTES FOR C. HORIZONTAL MOVEMENTS

001

16. ALL BEAMS TO BE PLACED WITH POSITIVE CAMBER (INCLUDING NATURAL BEAM CAMBER) UPWARD. STRUCTURAL ENGINEER RECOMMENDS

ADDITIONAL INFO. a. CLADDING SYSTEMS – IN-PLANE: H/400

CONTRACTOR PERFORM A PRE-POUR SURVEY OF THE FRAMING TO ENSURE CAMBERS ARE WITHIN TOLERANCE. COORDINATE ALL INFORMATION

b. CLADDING SYSTEMS – OUT-OF-PLANE: L/240

PRIOR TO CONCRETE POUR WITH STRUCTURAL ENGINEER.

16. WELDING OF REINFORCING STEEL SHALL NOT BE PERMITTED FOR NONWELDABLE REBAR NOR WITHOUT THE CONSENT OF THE STRUCTURAL

ENGINEER 17. STEEL SUPPLIER SHALL VERIFY ALL MEPF EQUIPMENT, DISTRIBUTION SYSTEMS, AND BUILDING EQUIPMENT WEIGHTS, SIZES, AND LOCATIONS

PRIOR TO PREPARING SHOP DRAWINGS AND FABRICATING MATERIALS. CONTRACTOR TO COORDINATE ANY CHANGES w/ STEEL SUPPLIER AND

17. DOWELS FOR SUCCESSIVE WORK SHALL BE SECURELY FASTENED IN CORRECT POSITION BEFORE PLACING CONCRETE. THE STICKING OF STRUCTURAL ENGINEER.

DOWELS AFTER PLACING CONCRETE SHALL NOT BE PERMITTED.

18. PROVIDE SUPPORT AT COLUMNS AS REQUIRED FOR DECK SUPPORT. PROVIDE L2x2x3/16 MINIMUM.

PROJ. NO. 2023-50

You might also like

- STRUCTURALDocument12 pagesSTRUCTURALKevin NamayaNo ratings yet

- The Architect's Guide to Design-Build ServicesFrom EverandThe Architect's Guide to Design-Build ServicesG. William Quatman, IINo ratings yet

- سوبرDocument7 pagesسوبرmahmoudbargouthi4No ratings yet

- Structural Notes: Virginia Department of TransportationDocument26 pagesStructural Notes: Virginia Department of TransportationRal GLNo ratings yet

- General Notes: Submittal For ApprovalDocument6 pagesGeneral Notes: Submittal For ApprovalMyo AungNo ratings yet

- Metro Proj - 12 MTR Span-1Document3 pagesMetro Proj - 12 MTR Span-1kukadiya127_48673372No ratings yet

- Ground Water Tank Structural DrawingDocument8 pagesGround Water Tank Structural DrawingMonish Lakhey ShresthaNo ratings yet

- Bound Brook 300 - Structural PackageDocument25 pagesBound Brook 300 - Structural PackageGuillermo Romero HuertasNo ratings yet

- 2021-12-1 - 1605 QA Review SetDocument12 pages2021-12-1 - 1605 QA Review SetDung AnhNo ratings yet

- Schedule OpeningsDocument1 pageSchedule OpeningsArun S DasNo ratings yet

- Proposed 2 Storey Warehouse Structure Steel Design Project:: Group MemberDocument13 pagesProposed 2 Storey Warehouse Structure Steel Design Project:: Group MemberDominic Robiso DatuinNo ratings yet

- Steel Design Project PublishDocument48 pagesSteel Design Project PublishCzelsi Carlos NavarroNo ratings yet

- MC HNK FC1 301 PDFDocument1 pageMC HNK FC1 301 PDFRASULKHALEJ CENTERNo ratings yet

- C1 - Design Criteria For Civil and Structural WorkDocument33 pagesC1 - Design Criteria For Civil and Structural WorkNicoleta cristianNo ratings yet

- A1.0 General NotesDocument1 pageA1.0 General NotesNguyen DuongNo ratings yet

- Mcpherson Design GROUP P.CDocument26 pagesMcpherson Design GROUP P.CdeviationzNo ratings yet

- Proposed 2 Story Warehouse Structure Steel Design Project:: Group MemberDocument5 pagesProposed 2 Story Warehouse Structure Steel Design Project:: Group MemberDominic Robiso Datuin100% (1)

- KFC Solano - Strucl - 041217 PDFDocument31 pagesKFC Solano - Strucl - 041217 PDFFroilan EspinosaNo ratings yet

- Final Construction PlansDocument12 pagesFinal Construction Plansapi-597427971No ratings yet

- General Note SampleDocument13 pagesGeneral Note SampleShyam AwalNo ratings yet

- General NotesDocument1 pageGeneral NotesWee RenNo ratings yet

- Structural DrawingsDocument28 pagesStructural DrawingsJason Cuison100% (1)

- DriveUp Expansion Site Lighting-ElectricalDocument3 pagesDriveUp Expansion Site Lighting-ElectricalNathaniel KwekNo ratings yet

- Design Criteria: GeneralDocument1 pageDesign Criteria: GeneralRolly Marc G. SoteloNo ratings yet

- Kumaran Sir BniDocument1 pageKumaran Sir BniKARANSAMYNo ratings yet

- Production MergedDocument26 pagesProduction MergedMIHAEL CRUZNo ratings yet

- D Eugp1 TPT G 000 Gen FWG 001 R01Document1 pageD Eugp1 TPT G 000 Gen FWG 001 R01debapriyoNo ratings yet

- Issued For Construction: ZAIT Engineering Solutions Pty LTDDocument1 pageIssued For Construction: ZAIT Engineering Solutions Pty LTDAhmedBoutlyNo ratings yet

- Plan For CID No. 21ID0029-2Document10 pagesPlan For CID No. 21ID0029-2Lara FloresNo ratings yet

- Gelan Coffee Processing - 200620Document33 pagesGelan Coffee Processing - 200620abrhamNo ratings yet

- ST 009Document1 pageST 009MahMoudAbdEl-KaderNo ratings yet

- Quiruben M. Mera Engr. Landrito R. Pilao: S-1 Highline Builders CompanyDocument1 pageQuiruben M. Mera Engr. Landrito R. Pilao: S-1 Highline Builders CompanyHighline BuildersNo ratings yet

- Structural Drawings g+2 1Document34 pagesStructural Drawings g+2 1Syed Arman AlamNo ratings yet

- Alshihabi For Steel Structure: Eng: Safwan Alhaj AbdoDocument10 pagesAlshihabi For Steel Structure: Eng: Safwan Alhaj AbdosafwanNo ratings yet

- General Construction Notes:: Two Story Residential Building Jerg Sunogan S-1Document6 pagesGeneral Construction Notes:: Two Story Residential Building Jerg Sunogan S-1clemennikki29No ratings yet

- DR - 1.majid Albana Structural 13 Floor BUILDING 23Document1 pageDR - 1.majid Albana Structural 13 Floor BUILDING 23Mohamad RammelNo ratings yet

- Polytechnic University of The Philippines Santa Maria BulacanDocument1 pagePolytechnic University of The Philippines Santa Maria BulacanCharleneMendozaEspirituNo ratings yet

- ST 003Document1 pageST 003MahMoudAbdEl-KaderNo ratings yet

- 994 Structural PDF BookletDocument20 pages994 Structural PDF BookletRommel Abenoja100% (2)

- STRUCDocument5 pagesSTRUCEdward D. SarcoNo ratings yet

- Define Abbrev: Issue Date: Drawn By: Checked By: Issue Date Author CheckerDocument2 pagesDefine Abbrev: Issue Date: Drawn By: Checked By: Issue Date Author Checkerdnl_vicarsNo ratings yet

- P20199-Pr-A-Cs-Stc-6007 - Tech STR Design Calculation NativeDocument67 pagesP20199-Pr-A-Cs-Stc-6007 - Tech STR Design Calculation NativeNitin SakpalNo ratings yet

- Issued For Construction: ZAIT Engineering Solutions Pty LTDDocument1 pageIssued For Construction: ZAIT Engineering Solutions Pty LTDAhmedBoutlyNo ratings yet

- Flowchart 2Document24 pagesFlowchart 2pooja apteNo ratings yet

- FlowchartDocument22 pagesFlowchartpooja apteNo ratings yet

- Pile NotesDocument16 pagesPile NotesSatya kaliprasad vangara100% (1)

- Pineda, Khian, M. - Comed PlumbingDocument6 pagesPineda, Khian, M. - Comed PlumbingKhian PinedaNo ratings yet

- ST 007Document1 pageST 007MahMoudAbdEl-KaderNo ratings yet

- General Notes: General Design and Detailing Criteria For Suppliers Structural SteelDocument2 pagesGeneral Notes: General Design and Detailing Criteria For Suppliers Structural SteelNguyen SonNo ratings yet

- 11705-Struct-Rev-A 200226 PDFDocument18 pages11705-Struct-Rev-A 200226 PDFcathyNo ratings yet

- Specification For Structural Steelworks PDFDocument58 pagesSpecification For Structural Steelworks PDFfarahazura80% (5)

- General Note Sample 3Document8 pagesGeneral Note Sample 3Shyam AwalNo ratings yet

- V07 (Signage)Document20 pagesV07 (Signage)Cyril J PadiyathNo ratings yet

- Architectural Precast Guide Specifications 03 01 16Document40 pagesArchitectural Precast Guide Specifications 03 01 16Julia AndengNo ratings yet

- 1 Exterior Scheme: Ar. Andrew Dg. Gozar, UapDocument1 page1 Exterior Scheme: Ar. Andrew Dg. Gozar, UapDrew GozarNo ratings yet

- Niagara Frontier Transportation Authority Serving The Niagara RegionDocument1 pageNiagara Frontier Transportation Authority Serving The Niagara RegionHamid EhsanNo ratings yet

- Placing DrawingsDocument4 pagesPlacing DrawingsXavi FlorezNo ratings yet

- 1 Reflected Ceiling Plan: Doha Festival City Hotel (DHFC)Document1 page1 Reflected Ceiling Plan: Doha Festival City Hotel (DHFC)eromax1No ratings yet

- Combined Bulletin 9 and 10 - StructuralDocument50 pagesCombined Bulletin 9 and 10 - StructuralDimitrios VoulgarisNo ratings yet

- Word Invoice Template For US Template 11Document1 pageWord Invoice Template For US Template 11Karthik NNo ratings yet

- Word Invoice Template For US Template 11Document1 pageWord Invoice Template For US Template 11Karthik NNo ratings yet

- Bill of Material: Raft Detail 5 3025 MR-4 Top Flange Plate 125 X 5 3235 5 Bottom Flange Plate 125 X 5 5 2598Document1 pageBill of Material: Raft Detail 5 3025 MR-4 Top Flange Plate 125 X 5 3235 5 Bottom Flange Plate 125 X 5 5 2598Karthik NNo ratings yet

- #Arch BinderDocument21 pages#Arch BinderKarthik NNo ratings yet

- Word Invoice Template For US Template 08Document1 pageWord Invoice Template For US Template 08Karthik NNo ratings yet

- Automated InvoiceDocument3 pagesAutomated InvoiceKarthik NNo ratings yet

- Bill of Material: Raft Detail 5 3025 MR-4 Top Flange Plate 125 X 5 3235 5 Bottom Flange Plate 125 X 5 5 2598Document1 pageBill of Material: Raft Detail 5 3025 MR-4 Top Flange Plate 125 X 5 3235 5 Bottom Flange Plate 125 X 5 5 2598Karthik NNo ratings yet

- Bill of Material: Raft Detail 2 3023 MR-5 Top Flange Plate 125 X 5 2985 2 Bottom Flange Plate 125 X 5 2 2959Document1 pageBill of Material: Raft Detail 2 3023 MR-5 Top Flange Plate 125 X 5 2985 2 Bottom Flange Plate 125 X 5 2 2959Karthik NNo ratings yet

- Bill of Material: Raft Detail 2 3023 MR-5 Top Flange Plate 125 X 5 2985 2 Bottom Flange Plate 125 X 5 2 2959Document1 pageBill of Material: Raft Detail 2 3023 MR-5 Top Flange Plate 125 X 5 2985 2 Bottom Flange Plate 125 X 5 2 2959Karthik NNo ratings yet

- WC 1Document1 pageWC 1Karthik NNo ratings yet

- MR 8 PDFDocument1 pageMR 8 PDFKarthik NNo ratings yet

- Peb DetailingDocument1 pagePeb DetailingKarthik NNo ratings yet

- Bill of Material: Anchor Rod Detail 1 750 AB1 48Document1 pageBill of Material: Anchor Rod Detail 1 750 AB1 48Karthik NNo ratings yet

- Bill of Material: Raft Detail 5 3251 MR-2 Top Flange Plate 125 X 5 3234 5 Bottom Flange Plate 125 X 5 5 2598Document1 pageBill of Material: Raft Detail 5 3251 MR-2 Top Flange Plate 125 X 5 3234 5 Bottom Flange Plate 125 X 5 5 2598Karthik NNo ratings yet

- GC 1Document1 pageGC 1Karthik NNo ratings yet

- Guidance Note Site Welding No. 7.01: ScopeDocument6 pagesGuidance Note Site Welding No. 7.01: ScopeKarthik NNo ratings yet

- Bio Botany 11thDocument301 pagesBio Botany 11thPradeep Chandar100% (3)

- ErectionDocument55 pagesErectionAjay Sastry100% (7)

- Yamaha Rx100 Part CatalogDocument53 pagesYamaha Rx100 Part CatalogKoh Kheng Boon70% (20)

- ErectionDocument55 pagesErectionAjay Sastry100% (7)

- OU600456153R0Document1 pageOU600456153R0anton.olennikovNo ratings yet

- 07 42 13 Mcelroy Metal MCPDocument15 pages07 42 13 Mcelroy Metal MCPMelvin SanchezNo ratings yet

- Horizontal Shaftwall Duct and Ceiling Assemblies: Description DetailsDocument2 pagesHorizontal Shaftwall Duct and Ceiling Assemblies: Description DetailsVan LLiNo ratings yet

- CV Rajamohan P - Project Manager MEPDocument4 pagesCV Rajamohan P - Project Manager MEPDheeraj Chowdary DhanekulaNo ratings yet

- Project Execution PlanDocument60 pagesProject Execution PlanJohn MichaelNo ratings yet

- Structured Method Statement For Concrete Repair - 3Document5 pagesStructured Method Statement For Concrete Repair - 3m.umarNo ratings yet

- Method Statement For Bored PilesDocument18 pagesMethod Statement For Bored PilesKaushalye Mahanama Dissanayake100% (3)

- Mep Spec 3Document80 pagesMep Spec 3loc khaNo ratings yet

- Fidic (Cy) Red - Construction Contract 2nd Ed 2017Document225 pagesFidic (Cy) Red - Construction Contract 2nd Ed 2017Javaid Piracha100% (1)

- 0.1 - RFQ - Utility Boiler PacakgeDocument8 pages0.1 - RFQ - Utility Boiler Pacakgeabdelkader benabdallahNo ratings yet

- Architect'S Perspective: Architectural A-1 1 6 2 6 A-3 3 6Document1 pageArchitect'S Perspective: Architectural A-1 1 6 2 6 A-3 3 6Roseanne CarsolaNo ratings yet

- BCITO Carp Specs Oct 2018Document36 pagesBCITO Carp Specs Oct 2018CharlyAcostaNo ratings yet

- Full Download Contemporary Strategy Analysis Text and Cases 9th Edition Grant Test BankDocument35 pagesFull Download Contemporary Strategy Analysis Text and Cases 9th Edition Grant Test Bankmirthafoucault100% (29)

- Exeed Premium Dry Mortar Project ReferencesDocument11 pagesExeed Premium Dry Mortar Project ReferencesFaris AlwanNo ratings yet

- Prada TransformerDocument23 pagesPrada TransformerPablo García PettersNo ratings yet

- Civil Engineer Road and BridgeDocument4 pagesCivil Engineer Road and BridgeeauzamanNo ratings yet

- What Is CarpentryDocument1 pageWhat Is Carpentryjan yeabukiNo ratings yet

- Restaurant in UAE (Page 3)Document4 pagesRestaurant in UAE (Page 3)jeevafoodstufftradingNo ratings yet

- OMNIPRESS 800 - User Manual - ENDocument45 pagesOMNIPRESS 800 - User Manual - ENAntonio BagnatoNo ratings yet

- Apollo Contacts ExportDocument36 pagesApollo Contacts Exportanasakram701No ratings yet

- MS -37-Proposal For Diversion of Existing 200Φ D.I. Sewer PiDocument13 pagesMS -37-Proposal For Diversion of Existing 200Φ D.I. Sewer PiSyed Umair HashmiNo ratings yet

- Tank Container Inspection Handbook TankDocument90 pagesTank Container Inspection Handbook TankSergiy Kovernik100% (2)

- BrochureDocument17 pagesBrochureSunilkumar ThimmarayappaNo ratings yet

- Architectural Services 17011aa059Document10 pagesArchitectural Services 17011aa059harshinireddy mandadiNo ratings yet

- Cuplock EngineeringDocument14 pagesCuplock Engineeringkauffmanj09No ratings yet

- Health and Safety Inspection Checklist ConstructionDocument9 pagesHealth and Safety Inspection Checklist Constructionntdduc.ngoNo ratings yet

- (Article) Design and Documentation Quality and Its Impact On The Construction Process (1999)Document9 pages(Article) Design and Documentation Quality and Its Impact On The Construction Process (1999)M YazdkhastiNo ratings yet

- ACI Concrete International Vol44 No3 2022Document68 pagesACI Concrete International Vol44 No3 2022Ing HectorNo ratings yet

- Job Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyDocument9 pagesJob Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyTeodoro Esquillo100% (1)

- 18-ASTM E2174-14bDocument7 pages18-ASTM E2174-14bAli Adnaan RazaNo ratings yet