Professional Documents

Culture Documents

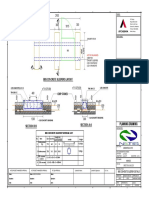

CE048 Rev2

Uploaded by

Jonas MwatangeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CE048 Rev2

Uploaded by

Jonas MwatangeCopyright:

Available Formats

1 2 3 4 5 6 7

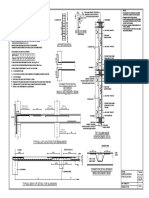

NOTES:

1. The thrust blocks are preliminarily designed for certain soil conditions.

Stopcock Box Type 11A, 4.5kg IV Marker Block Prior to construction the soil conditions and the design require

150x150x100mm Besaans-Du confirmation and finalisation by the Engineer.

Red Road Marking Paint all around

Plessis Product No. 2650 or

90

420

approved equivalent Identification Plate screwed 2. The trench bottom and all backfill under and around the thrust block to be

A onto side of Concrete Marker 90mm Chamfer on A compacted to minimum 95% mod. AASHTO maximum dry density.

160mm Ø uPVC Sleeve Pipe at each corner of I.D. Plate all three edges

C C 3. All DCI fittings, steel pipe specials and valves are to be completely

ND100 PN16 RSV 110mm Ø uPVC Sleeve Pipe resting wrapped with Denso Tape, as specified, prior to casting of the concrete

on Valve, length cut to fit on site thrust block.

110mm Ø ND100 PN16 Flange Adaptor 4. All concrete to be 25 MPa/19 mm.

420

THRUST BLOCK : BENDING SCHEDULE

1000

110mm Ø uPVC Class 6 Pipe 5. All concrete cover to reinforcement to be strictly 50 mm.

BAR TYPE & BARS PER SHAPE BENDING

LENGTH

ND150/100 Hot-Dipped Galvanised Puddle MARK SIZE UNIT CODE A B 90 6. All concrete surfaces to have rough off-shutter finish.

Pipe Special Flanged All Ends Table 1600/3 01 Y12 72 1570 37 600 1000

800

Reinforced Concrete Thrust Block cast insitu 02 Y12 24 1970 37 1000 1000 Plan View of IV Marker Block 7. All concrete to be cured at least 28 days before filling of pipeline.

1600

B B 8. Identification Plate to be of 1.2mm thick, black anodised aluminium sheet

Detail of Isolating Valve Installation: Section A-A 01 01 01 01 01 01 01 01 01 with engraved letters to the sizes specified.

Stopcock Box Type 11A, 4.5kg

20

02 02

02 02 150x150x100mm Besaans-Du

min 400 Plessis Product No. 2650 or

02 02

A

1000

approved equivalent

ND150/100 Hot-Dipped Galvanised 02 4x9Y12-01 02

ND150/125 Flanged Reducer

330

Puddle Pipe Special 02 02 Red Road Marking Paint all around

Item 2 on Drawing ME/005

Flanged All Ends Table 1600/3 and connected to Item 3 02 02

600

1600

01 01 01 01 01 01 01 01 01

160mm Ø ND150

1600

250

SG Iron Flange Adaptor 160 mm Ø uPVC Sleeve Pipe

750

Item 1 on Drawing ME/005

Reinforcement Details Viewed in Section A-A & B-B

1600

160mm Ø uPVC Class 16 Pipe 110 mm Ø uPVC Sleeve Pipe

C C

B B

Reinforced Concrete Thrust Block cast insitu

Section C-C

Flanged ND100 PN16 RSV

110mm Ø ND100 SG Iron Flange Adaptor

110mm Ø uPVC Class 6 Pipe

Text for Identification Plate:

1. Chainage in kilometre decimal

A

2. Type of Installation

425 750 425 3. Diameter, Type & Class of Pipe

CLIENT

Plan View of Isolating Valve Thrust Block 380 Kunene

D D

Regional

20

20

Council

30

1600 km 0.000

40

425 800

SCOUR IV

240

40

APPROVED DATE

60

COPYRIGHT RESERVED

Invert level of Pipe Special

110 uPVC/6

30

determined by Pump Station ND150/100 Concentric Reducer CONSULTANTS

100

Pipework

1000

500

20

Detail of I.D. Plate for IV Installation PCE POWERCONSULT ENGINEERS

E E

300

1000

ND150 Puddle Flange

Section B-B

KUCHLING CONSULTING ENGINEERS

ND150 Puddle Flange

PROJECT

500 500 500 500

F F

2000

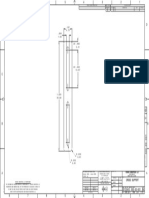

Details of ND150/100 Hot-Dipped Galvanised Puddle Pipe Special

FAE SANS 1123 Table 1600/3

1 2 3 4 5 6 7

You might also like

- CE048 Rev2Document1 pageCE048 Rev2Jonas MwatangeNo ratings yet

- A 3Document1 pageA 3ajNo ratings yet

- 1 ST - Generral NotesDocument1 page1 ST - Generral Notesmandeep gautamNo ratings yet

- MOS Duct Sealing & Bentonite Calculation PDFDocument12 pagesMOS Duct Sealing & Bentonite Calculation PDFSenthilnathan NagarajanNo ratings yet

- MOS Duct Sealing & Bentonite CalculationDocument12 pagesMOS Duct Sealing & Bentonite CalculationSenthilnathan NagarajanNo ratings yet

- Gas Fuel Conditionning Skid 1021776 2g0 Ek PFB 0001Document5 pagesGas Fuel Conditionning Skid 1021776 2g0 Ek PFB 0001faisalnadimNo ratings yet

- Boundary Wall DrawingDocument1 pageBoundary Wall Drawingsandip wankhadeNo ratings yet

- Section-B: Fabricated Angle 44x37x5mmDocument4 pagesSection-B: Fabricated Angle 44x37x5mmshoebNo ratings yet

- Foundation Layout LusenkeDocument1 pageFoundation Layout LusenkeMwesigwa DaniNo ratings yet

- BR124-04A Construction Section & SpecificationsDocument1 pageBR124-04A Construction Section & SpecificationsLaurentiu NaeNo ratings yet

- Layout Pig LauncherDocument2 pagesLayout Pig LauncherBang Jeck100% (1)

- Test Project 3Document1 pageTest Project 3Zaenal MutaqinNo ratings yet

- GRP Pipe ClassDocument1 pageGRP Pipe ClassAli RaheemNo ratings yet

- 500-30-001 Cross Support - Sheet - 1Document1 page500-30-001 Cross Support - Sheet - 1Mirza MešanovićNo ratings yet

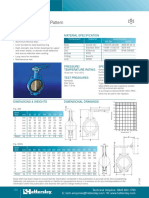

- Brosur Valve Hatersley 2Document1 pageBrosur Valve Hatersley 2Muhamad SuryaNo ratings yet

- Wistron11288 1AcerTravelMateP653 V PDFDocument109 pagesWistron11288 1AcerTravelMateP653 V PDFpedro arthur AlvesNo ratings yet

- GRP Panel Tanks CatalogDocument12 pagesGRP Panel Tanks Catalogpvsreddy2002No ratings yet

- Corken Parts - Sliding - Vane - CP - CD - SeriesDocument9 pagesCorken Parts - Sliding - Vane - CP - CD - Seriesdimas agungNo ratings yet

- RD 245Kv GR POWERDocument10 pagesRD 245Kv GR POWERGanesh VeluNo ratings yet

- A B C D A": Cerramiento CG P-135Document1 pageA B C D A": Cerramiento CG P-135Johann Alexander Caballero BohorquezNo ratings yet

- Conveyorcatalogue nz11Document1 pageConveyorcatalogue nz11vankarpNo ratings yet

- 3 Speed Mining Gearbox OverviewDocument1 page3 Speed Mining Gearbox OverviewAndrew KochNo ratings yet

- MP HNB Insulation MP HNB POLYISO Product Data 658274 PDFDocument2 pagesMP HNB Insulation MP HNB POLYISO Product Data 658274 PDFRafael Ramirez CasateNo ratings yet

- 20119161010380.mech Joint Fittings BRO 007Document21 pages20119161010380.mech Joint Fittings BRO 007vineethNo ratings yet

- ULR CL17sc - TD - 979000087 - RevADocument1 pageULR CL17sc - TD - 979000087 - RevAEmanuel GamboaNo ratings yet

- Last SheetDocument1 pageLast SheetShaun PattersonNo ratings yet

- Heat Burner Inner TubeDocument2 pagesHeat Burner Inner TubemeldinipujasmaraNo ratings yet

- Structural FPD P.sanchezDocument9 pagesStructural FPD P.sanchezHailley DensonNo ratings yet

- Basic CAD 2D FILE With Details-ElevationsDocument1 pageBasic CAD 2D FILE With Details-ElevationsoybzvapNo ratings yet

- Senr1788 03Document2 pagesSenr1788 03jgmanaure3105No ratings yet

- PUHY-P200, 250, 300YNW-A2 (-BS) : 2. External DimensionsDocument2 pagesPUHY-P200, 250, 300YNW-A2 (-BS) : 2. External DimensionsElena BucurașNo ratings yet

- IPS Solvent Cement, Primer & Cleaner Saudi Product1Document2 pagesIPS Solvent Cement, Primer & Cleaner Saudi Product1Wajdi AlawamNo ratings yet

- Dokumen - Tips - Gls Tank For Sudair PDFDocument8 pagesDokumen - Tips - Gls Tank For Sudair PDFRaju SainiNo ratings yet

- SHEET No 10 FLANGE GUSSETS AND REINFORCEMENTS DETAILDocument1 pageSHEET No 10 FLANGE GUSSETS AND REINFORCEMENTS DETAILKarikalan JayNo ratings yet

- Boquillas para Torre de EnfriamientoDocument3 pagesBoquillas para Torre de EnfriamientoAnonymous Lb4hrlAf7VNo ratings yet

- RW CBDD 22Document1 pageRW CBDD 22Yong TonghannNo ratings yet

- Conbextra BB80: Constructive SolutionsDocument3 pagesConbextra BB80: Constructive SolutionsWahlee SatuNo ratings yet

- Catelco Uzx27 Anodes Dimension and DrawingDocument1 pageCatelco Uzx27 Anodes Dimension and Drawingcengiz kutukcu100% (1)

- Cdoo 01 95 23013 0002 A H03 - Hoja - de - Util PDFDocument1 pageCdoo 01 95 23013 0002 A H03 - Hoja - de - Util PDFsgtNo ratings yet

- Universiti Teknologi Mara: Water Demand (LPD)Document5 pagesUniversiti Teknologi Mara: Water Demand (LPD)eshalNo ratings yet

- Tidrqm7 PDFDocument11 pagesTidrqm7 PDFzizouhicheNo ratings yet

- Wistron Bad40-Hr Bad50-Hr Revsd PDFDocument109 pagesWistron Bad40-Hr Bad50-Hr Revsd PDFJokoKiyerNo ratings yet

- Septic Tank & Soakawy: MR Anthony AjuyaDocument1 pageSeptic Tank & Soakawy: MR Anthony AjuyaMeshach SamuelNo ratings yet

- Resources Mechanical Flowserve Pusher P50Document2 pagesResources Mechanical Flowserve Pusher P50Suresh Kumar MittapalliNo ratings yet

- 螢幕截圖 2022-11-26 11.10.26Document2 pages螢幕截圖 2022-11-26 11.10.26Oscar WanNo ratings yet

- Datasheet Ventilating Valve / Bleed Valve Type 591/595: AdvantagesDocument4 pagesDatasheet Ventilating Valve / Bleed Valve Type 591/595: AdvantagesAlwin WanNo ratings yet

- Resilient-Seated Gate Valves Outside Screw and Yoke General DescriptionDocument6 pagesResilient-Seated Gate Valves Outside Screw and Yoke General DescriptionNikhil JaiswalNo ratings yet

- Gate Valve Os&yDocument6 pagesGate Valve Os&yJOHN NIKKONo ratings yet

- Site Layout Rogers Drawings Final - Sheet - A107 - UnnamedDocument1 pageSite Layout Rogers Drawings Final - Sheet - A107 - Unnamedmasumba patrickNo ratings yet

- Petra UMA Touch CSD Acer Aspire V5-531-V5-571-V5-431Document103 pagesPetra UMA Touch CSD Acer Aspire V5-531-V5-571-V5-431ady putraNo ratings yet

- Fig-970-G-OLD DESIGNDocument1 pageFig-970-G-OLD DESIGNAsmaaNo ratings yet

- TravelMate 8473 Wistron BAD40 - 50-HRDocument109 pagesTravelMate 8473 Wistron BAD40 - 50-HRMicropc Technology SolutionNo ratings yet

- Safety Signages PlanDocument1 pageSafety Signages PlanbexcslaNo ratings yet

- Girder 2Document1 pageGirder 2alpegambarliNo ratings yet

- Whelen-97 SeriesDocument4 pagesWhelen-97 SeriespandahiuNo ratings yet

- Kabasis-15 - BBS Concrete Sleeper DetailsDocument1 pageKabasis-15 - BBS Concrete Sleeper DetailsMarvin ItolondoNo ratings yet

- Precast T-Wall Alt 1Document2 pagesPrecast T-Wall Alt 1Kinantoko FauzanNo ratings yet

- Bulletin - 12 - Detector Tape - 231221Document6 pagesBulletin - 12 - Detector Tape - 231221mohdnurasyraafNo ratings yet

- Acer Aspire V5-531-V5-571-V5-431Husk - Petra - UMA - None - Touch - CSDDocument103 pagesAcer Aspire V5-531-V5-571-V5-431Husk - Petra - UMA - None - Touch - CSDImam WahyuNo ratings yet

- Daywork SheetDocument1 pageDaywork SheetFirasAlnaimiNo ratings yet

- Daywork Sheet Template 1Document3 pagesDaywork Sheet Template 1Jonas MwatangeNo ratings yet

- CE012 Rev1Document1 pageCE012 Rev1Jonas MwatangeNo ratings yet

- Daywork Sheet Template 1Document3 pagesDaywork Sheet Template 1Jonas MwatangeNo ratings yet

- ChE 103 Syllabus PDFDocument2 pagesChE 103 Syllabus PDFnadimNo ratings yet

- Consolidated Undrained Triaxial Compression Test For Cohesive SoilsDocument11 pagesConsolidated Undrained Triaxial Compression Test For Cohesive SoilsNikhilNo ratings yet

- Renolit So-Gfb: Description AdvantagesDocument3 pagesRenolit So-Gfb: Description AdvantagesAhmed El TayebNo ratings yet

- Valtek VL-HC Spring Cylinder Linear Actuators: General Information UnpackingDocument8 pagesValtek VL-HC Spring Cylinder Linear Actuators: General Information UnpackingXimi Mena XiNo ratings yet

- Ra12 100Document2 pagesRa12 100M Irfan MaulanaNo ratings yet

- Ssnde14 Final LDocument72 pagesSsnde14 Final LmiamarchNo ratings yet

- Water Distribution System Specifications: St. Charles County Public Water Supply District NO. 2Document45 pagesWater Distribution System Specifications: St. Charles County Public Water Supply District NO. 2muhammad iqbalNo ratings yet

- Lab Report 4 Colligative PropertiesDocument9 pagesLab Report 4 Colligative Propertiesapi-436054247No ratings yet

- HSVC1 PP4-QA, QC Equipment Status Report - 20190828Document44 pagesHSVC1 PP4-QA, QC Equipment Status Report - 20190828nkvonNo ratings yet

- Ryobi ELS52G Manual 1 Log SplitterDocument14 pagesRyobi ELS52G Manual 1 Log SplitterFrank MatzkaNo ratings yet

- Lecture 21 PDFDocument14 pagesLecture 21 PDFMehmet Arvasi100% (1)

- Speed TripleDocument379 pagesSpeed TriplecsavargaNo ratings yet

- Floor Sanding - Finishing TipsDocument13 pagesFloor Sanding - Finishing TipsJake LandreneauNo ratings yet

- GCSBSP-200 GCSBSP-150 GCSBSP-201: TURBO Steam Master Professional Iron Plancha Profesional Steam Master Con TURBODocument2 pagesGCSBSP-200 GCSBSP-150 GCSBSP-201: TURBO Steam Master Professional Iron Plancha Profesional Steam Master Con TURBOKickingEdgarAllenPoeNo ratings yet

- 01 - Solinst Water Level 101Document3 pages01 - Solinst Water Level 101Dt Paras InvestamaNo ratings yet

- Magnum Composite Plug Catalog 06-30-10Document21 pagesMagnum Composite Plug Catalog 06-30-10Emad JamshidiNo ratings yet

- MagnaflocDocument3 pagesMagnaflocfrancsanchezNo ratings yet

- Study of Prefabrication in IndiaDocument6 pagesStudy of Prefabrication in IndiaSayed WafiNo ratings yet

- 1498 HydrojettingDocument6 pages1498 HydrojettingjasminneeNo ratings yet

- Reducing Corrosion and Potential Boiler Failure With Superior Iron Transport TechnologyDocument46 pagesReducing Corrosion and Potential Boiler Failure With Superior Iron Transport TechnologymnasiroleslamiNo ratings yet

- 6 - Geomembrane Lifetime Prediction PDFDocument27 pages6 - Geomembrane Lifetime Prediction PDF齐左No ratings yet

- DoorsDocument16 pagesDoorsmatthew02012010No ratings yet

- Behaviour of A Sustainable Concrete in Acidic Environment: SustainabilityDocument13 pagesBehaviour of A Sustainable Concrete in Acidic Environment: Sustainabilitym_shahbaghiNo ratings yet

- Product Data: Hexply 916Document2 pagesProduct Data: Hexply 916McLemiNo ratings yet

- Y. S. Touloukian, J. Koolhaas Gerritsen, W. H. Shafer - Coatings, Systems, and Composites-Springer US (1973)Document262 pagesY. S. Touloukian, J. Koolhaas Gerritsen, W. H. Shafer - Coatings, Systems, and Composites-Springer US (1973)slovvlistNo ratings yet

- Engineering Services Related To Process Study: SRU RevampDocument16 pagesEngineering Services Related To Process Study: SRU RevampSiddiqui Muhammad AshfaqueNo ratings yet

- Engineering Standard Specification For Steam TracingDocument53 pagesEngineering Standard Specification For Steam Tracingkaruna346100% (1)

- ME 231 Montazami Whharris 9-10-18 SOLUTIONDocument4 pagesME 231 Montazami Whharris 9-10-18 SOLUTIONEduardo Perez UriegasNo ratings yet

- Dream HouseDocument14 pagesDream Housepreciousz.angel09No ratings yet

- How Do You Make LiquidDocument2 pagesHow Do You Make LiquidjukortaNo ratings yet