Professional Documents

Culture Documents

Cdoo 01 95 23013 0002 A H03 - Hoja - de - Util PDF

Uploaded by

sgtOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cdoo 01 95 23013 0002 A H03 - Hoja - de - Util PDF

Uploaded by

sgtCopyright:

Available Formats

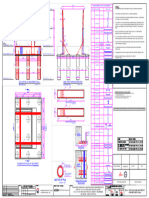

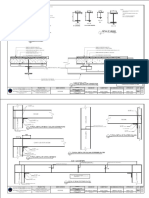

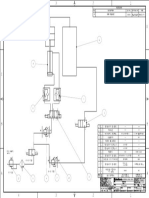

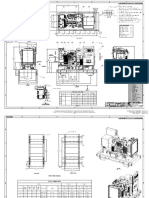

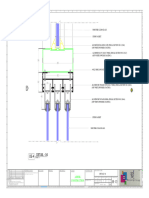

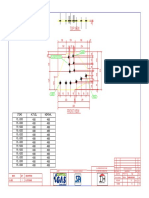

12 11 10 9 8 7 6 5 4 3 2 1

NOTES MODIFICATIONS

1060 ISSUE DESCRIPTION DATE NAME

150 1.-CHAMFER SHARP CORNERS

20 45

38

2.-WELD TO 100% ACCORDING TO I+D-P-181 A MODELO INICIAL 21-10-15 OMICRON

3.-STRESS RELIEF AFTER WELDING ACCORDING TO

22

I+D-P-181

90

9

4.-APPLY REDDISH COLOUR N°.299775

H ANTICORROSIVE PRIMER

150

20

32 , 4 R71,5 5.-PAINT USING RAL6026 EXCEPT ON MACHINED

POS. 1016 63

6 AREAS

6.- P/N IDENTIFIED BY STENCILING

Escala: 1:5

24

94 4 7.-DRILL GAS EXIT HOLES dia.6

PART.1016

1 45 20

Scale: 1:5 1.-ELIMINAR ARISTAS VIVAS

12 2.-SOLDAR AL 100% s/ I+D-P-181

771 3.-ELIMINAR TENSIONES EN CONJUNTO SOLDADO

POS. 1025 ANTES DE MECANIZAR s/ I+D-P-181

REVESTIR REDONDO CON EVA 4.-APLICAR IMPRIMACION ANTICORROSIVA COLOR

Escala: 1:3

90

ROJIZO CODIGO N°.299775 (FOSFATO DE ZINC

SECADO RAPIDO COLOR ROJIZO)

30 PART.1025

G 5.-PINTAR EN COLOR RAL6026 EXCEPTO LAS G

Scale: 1:3 ZONAS MECANIZADAS.

94

POS. 1017 6.- IDENTIFICAR CON SU P/N ESTARCIDO

7.-HACER TALADROS dia.6

Escala: 1:5 PARA SALIDA DE GASES

PART.1017

Scale: 1:5

23

7

720 1025

POS. 1013 1014

24

Escala: 1:3 1005

176,07

F PART.1013 1025 F

Scale: 1:3

1003

R5 110 6 1006 1005

POS. 1020 (TYP)

55

5 45 1010 1003

Escala: 1:5

40 (TYP) 1019 1023

PART.1020 1006

Scale: 1:5

1030

22

140

105

1019

1016

22,7

40

1010

106

140

29

E

1019 E

1023

17,5

77,5

1009

150

25

16,25

1018

1028

800 POS. 1027 POS. 1015 1019

Escala: 1:3 Escala: 1:3 1021 1025

POS. 1022 PART.1015 1017

PART.1027

Escala: 1:5 Scale: 1:3 Scale: 1:3

PART.1022

1011 1015

Scale: 1:5

D 1020 1002 D

39

761

39

761

1028

4

4 R2 R2 1001

40 40

150 276

12(x2)

40

20(x6) 110 110 126 1001

130 1024

15

1007 1022

150

1025

150

C 130 1024 C

15

110 110 126 12(x2) 150 276 1015

20(x6) 40 40 VISTA ISOMETRICA

40

POS. 1012 ISOMETRIC VIEW

POS. 1029

Escala: 1:5

Escala: 1:5

PART.1012

PART.1029 Scale: 1:5

Scale: 1:5

36

3 45

B

752 B

753

40 40

40

272 150 12(x2) 126 126 110 110

15

20(x6)

76

150

150

100

NOT SPECIFIED TOLERANCES AND RUGOSITY QUALITY ASSURANCE COMPUTER PRODUCED DRAWING USING

≤ 4.000 m m

INTEGRATED QUALITY CLASS: x CATIA NO MANUAL ALTERATION

ISO2768-1 m

90

LINEAR

MILLING : 3,2

DIMENSIONS > 4.000 m m AING-142 DIMENSIONS WITHOUT DEFINITION DESIGN AND MANUFACTURING

LATHE : 3,2

(NO CRITICAL) PER SCALE DRAWING PER AING-142

20(x6)

80

GRINDING: 0,8

272 150

ANGLES ISO2768-1 m

126 126 110 110 0,2 THIS DRAWING IS PROPERTY OF AIRBUS OPERATIONS S.L.

40

12(x2) 3

LAPPING :

GEOMETRICAL ISO2768-2 k SOCIEDAD UNIPERSONAL WHICH RESERVES ALL RIGHTS

15

70

THIS TOOL IS MANUFACTURED OR COORDINATED WITH:

40 40 TOOL WEIGHT(Kg) 181

POS. 1024

REMARKS

X

60

X

A STRESS XXX A

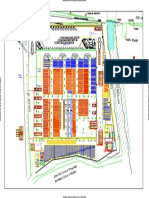

X P L A N T : PTO REAL

50

POS. 1021 POS. 1030 Escala: 1:1 INTERCHANGEABLE

PART TOOL

XXX

X

X PROGRAM: C295/CN235

40

PART.1024 SCALE Date Name

XXXXXXXXXXXXXXXXX

TITLE

Escala: 1:5 1:5 CARRO TRANSPORTE CUADERNAS TECHO III

30

XXXXXXXXXXXXXXX

Escala: 1:5 Drawn 21-10-15 OMICRON

Scale: 1:1

XXXXXXXXXXXXX

L&M REAR FUSELAGE C295/CN235

(1:3) Checked XX-XX-XX X

XXXXXXXXXXX

PART.1030

20

PART.1021 XX-XX-XX X

XXXXXXXXX

Approved

XXXXXXXX

XXXXXXX

TOOL LAST

XXXXXX

Scale: 1:5 CD00-01-95-23013-0002-A DRW SIZE

FIRST ANGLE

10

Scale: 1:5 NUMBER ISSUE

PROJECTION

TOOL

X SIM A A0

NUMBER

Number of

Sheets 3 Sheet 3

0

12 11 10 9 8 7 6 5 4 3 2 1

You might also like

- Cdoo 01 95 23013 0001 A H03 - Hoja - de - Util PDFDocument1 pageCdoo 01 95 23013 0001 A H03 - Hoja - de - Util PDFsgtNo ratings yet

- UTSSDocument20 pagesUTSSigorazamov7777No ratings yet

- Legend: NotesDocument1 pageLegend: Notesganesh kumarNo ratings yet

- Foundation of Bore Pile T.08 AA6 +9 Up To +15 Class 6 - Rev-0 (NEN)Document1 pageFoundation of Bore Pile T.08 AA6 +9 Up To +15 Class 6 - Rev-0 (NEN)RikiNo ratings yet

- Notes: E D Sconnected. (Temperarly Perm NantlyDocument1 pageNotes: E D Sconnected. (Temperarly Perm Nantlyganesh kumarNo ratings yet

- Standard Drawing 2064 Truck Access To Rural Properties Type ADocument1 pageStandard Drawing 2064 Truck Access To Rural Properties Type ApersonNo ratings yet

- Freemont Precision Travas PortasDocument1 pageFreemont Precision Travas PortasfabiogynNo ratings yet

- 1 1 To Agartala (India) To Akhura (Bangladesh) : Dimension Details of Pile CapDocument3 pages1 1 To Agartala (India) To Akhura (Bangladesh) : Dimension Details of Pile CapNilay GandhiNo ratings yet

- RUB-72-1 Abutment (A1) Reinforcement DetailDocument1 pageRUB-72-1 Abutment (A1) Reinforcement DetailYatin DoshiNo ratings yet

- Sas120 Technical DrawingsDocument2 pagesSas120 Technical DrawingsMohamed ShikoNo ratings yet

- 22-062 Plans 4Document7 pages22-062 Plans 4mpatagnan6No ratings yet

- India International Convention Center at Delhi: Site Section - XyDocument6 pagesIndia International Convention Center at Delhi: Site Section - XyHastala vistaNo ratings yet

- Minupulse Pneumatica2Document1 pageMinupulse Pneumatica2arturo jimenezNo ratings yet

- Ab 036897 001Document1 pageAb 036897 001Mohammed IrfanNo ratings yet

- A053s659 Outline, Genset (Open Genset With Standard Skid)Document3 pagesA053s659 Outline, Genset (Open Genset With Standard Skid)thainarimeNo ratings yet

- ING10374D2X741 REINF'TDETAIL - SHEET 2 OF 2-Rev - C-741Document1 pageING10374D2X741 REINF'TDETAIL - SHEET 2 OF 2-Rev - C-741mhazarath murariNo ratings yet

- Planta Bos 11 StatusDocument1 pagePlanta Bos 11 StatusClodoaldo CristianoNo ratings yet

- Reflected Ceiling Plan: Part of The Existing HouseDocument1 pageReflected Ceiling Plan: Part of The Existing HouseKali BearNo ratings yet

- Clarkson Kga+ Dn1200 Nps48 HC RDC 08.ADocument1 pageClarkson Kga+ Dn1200 Nps48 HC RDC 08.AAlejandro Pupunovich RodriguezNo ratings yet

- Pool S000Document1 pagePool S000Mafas MuhinadeenNo ratings yet

- ECO-147919 A 1 Production Release AC Lep D.Sato 05jun17 Air Intake (Entrada de Ar)Document4 pagesECO-147919 A 1 Production Release AC Lep D.Sato 05jun17 Air Intake (Entrada de Ar)John YangNo ratings yet

- Exploded Parts List 1Document1 pageExploded Parts List 1APEXINDONo ratings yet

- Notes: 180-EE-01018 811 MCS-125-PM-1 028 125-210KDocument1 pageNotes: 180-EE-01018 811 MCS-125-PM-1 028 125-210Kganesh kumarNo ratings yet

- c6 - StandardDocument1 pagec6 - StandardSibel KarasuNo ratings yet

- c5 - StandardDocument1 pagec5 - StandardSibel KarasuNo ratings yet

- Section: Bath Room D 4 Bath Room A 1Document1 pageSection: Bath Room D 4 Bath Room A 1Kenneth FungoNo ratings yet

- Superseal PequeñoDocument1 pageSuperseal PequeñoJorge Leonardo Cortes LeònNo ratings yet

- Revisions 1A New Release XXXXX H.Aguilar Mm-Dd-Yy: OUT INDocument1 pageRevisions 1A New Release XXXXX H.Aguilar Mm-Dd-Yy: OUT INarturo jimenezNo ratings yet

- R420-FR-2130 A/B: NotesDocument1 pageR420-FR-2130 A/B: NotesMubashir fareed100% (1)

- Layer Flag (Differentiate From Assy P/N) Layer Name (See Module Table) Base Number D92-1371-9 000000Document12 pagesLayer Flag (Differentiate From Assy P/N) Layer Name (See Module Table) Base Number D92-1371-9 000000carlosar1477No ratings yet

- Erl 359 014 Hec 02 D00 GM 2V26 2V13 20 00Document2 pagesErl 359 014 Hec 02 D00 GM 2V26 2V13 20 00Tanio TanevNo ratings yet

- Konka 715L1140 Series Color TV Power Supply Board DrawingsDocument4 pagesKonka 715L1140 Series Color TV Power Supply Board DrawingsMoslemJxzNo ratings yet

- Notes Notes: Stop Kontak Apc SRG Stop Kontak Apc SRGDocument1 pageNotes Notes: Stop Kontak Apc SRG Stop Kontak Apc SRGBagi ilmuNo ratings yet

- Layout Barranquilla - DWG v2Document1 pageLayout Barranquilla - DWG v2johnNo ratings yet

- A B C D E: Ground Floor 1 Second Floor Plan 2Document1 pageA B C D E: Ground Floor 1 Second Floor Plan 2Ephraim Migui RoblesNo ratings yet

- EL PASTORCILLO-Bajo - AcústicoDocument2 pagesEL PASTORCILLO-Bajo - AcústicoCesar DiasNo ratings yet

- MD 512 31ma Eg ST Dde 1022 - C01Document1 pageMD 512 31ma Eg ST Dde 1022 - C01jaanNo ratings yet

- Production Relief Header: From Test SeparatorDocument1 pageProduction Relief Header: From Test SeparatornelsonNo ratings yet

- Sector - Ii: Umred Road, Pipri, Distt. NagpurDocument1 pageSector - Ii: Umred Road, Pipri, Distt. Nagpurapi-27095887No ratings yet

- Secondary Packaging System For Single Pouches - HS-1Document1 pageSecondary Packaging System For Single Pouches - HS-1infinityautomatedsolutionsNo ratings yet

- Skyware Type123,960 8000842-01Document8 pagesSkyware Type123,960 8000842-01Tuvia LeNo ratings yet

- 0 4 8 7 E - X X - X-6 - XXX: Digit: 1 2 3 4 5 6Document1 page0 4 8 7 E - X X - X-6 - XXX: Digit: 1 2 3 4 5 6Tosikur RahmanNo ratings yet

- De 04Document1 pageDe 04Sachin SharmaNo ratings yet

- Cdoo 01 95 23013 0001 A H02 - Hoja - de - Util PDFDocument1 pageCdoo 01 95 23013 0001 A H02 - Hoja - de - Util PDFsgtNo ratings yet

- Hendrickson Tiremaxx Parts ListDocument16 pagesHendrickson Tiremaxx Parts Listeyya 007No ratings yet

- 0417 - 118T3293 Cooling Sealing AirDocument6 pages0417 - 118T3293 Cooling Sealing AirfaisalnadimNo ratings yet

- (20019920) Jse1-0238aea (Typ)Document1 page(20019920) Jse1-0238aea (Typ)AmirmasoudNo ratings yet

- Encl. - Drawing of W Beam Crash BarrierDocument1 pageEncl. - Drawing of W Beam Crash Barrierrao shoaibNo ratings yet

- P Okitm07 329 03 Eqd 2003 1Document1 pageP Okitm07 329 03 Eqd 2003 1ismiasyofNo ratings yet

- KOMPLET K JC 805 WebDocument5 pagesKOMPLET K JC 805 WebAlberto LopezNo ratings yet

- PL-1000 - PART - Rev 00-ModelDocument1 pagePL-1000 - PART - Rev 00-Modelomar mahmoudNo ratings yet

- Drive Unit TENH EH 10003, 225, 50/60Hz 400/440V: Qty. Description Specification Material Size DT Doc IdDocument1 pageDrive Unit TENH EH 10003, 225, 50/60Hz 400/440V: Qty. Description Specification Material Size DT Doc IdKarikalan JayNo ratings yet

- Legend: NotesDocument1 pageLegend: Notesganesh kumarNo ratings yet

- Tab 9 - Medium Voltage Fuses - TB01300002EDocument10 pagesTab 9 - Medium Voltage Fuses - TB01300002EWaldir GavelaNo ratings yet

- RRT-PCR Covid-19 Testing Laboratory Performing Manual Rna ExtractionDocument1 pageRRT-PCR Covid-19 Testing Laboratory Performing Manual Rna ExtractionRanile CordovaNo ratings yet

- Date Revised by Approved by Change Description REV ECN: (Lower End of The Box)Document1 pageDate Revised by Approved by Change Description REV ECN: (Lower End of The Box)sarochimNo ratings yet

- MVH 1:50 16.10.2012 16.10.2012 11173.1 KG: ACCORDING TO SYSTEM 159/000-DET-Q1-013Document1 pageMVH 1:50 16.10.2012 16.10.2012 11173.1 KG: ACCORDING TO SYSTEM 159/000-DET-Q1-013Yahya AteeniNo ratings yet

- Plan Layout WWTP 1500 r4 - CommentDocument1 pagePlan Layout WWTP 1500 r4 - CommentMuhamad Aris HabibiNo ratings yet

- STYLE 2775 Product Bronco Hydrant Support: Parts List SheetDocument2 pagesSTYLE 2775 Product Bronco Hydrant Support: Parts List SheetFarmaceuticaNo ratings yet

- Cdoo 01 95 23012 0001 A H03 - Hoja - de - Util PDFDocument1 pageCdoo 01 95 23012 0001 A H03 - Hoja - de - Util PDFsgtNo ratings yet

- Cdoo 01 95 23013 0001 A H02 - Hoja - de - Util PDFDocument1 pageCdoo 01 95 23013 0001 A H02 - Hoja - de - Util PDFsgtNo ratings yet

- Cdoo 01 95 23012 0001 H01 - Hoja - de - Util PDFDocument1 pageCdoo 01 95 23012 0001 H01 - Hoja - de - Util PDFsgtNo ratings yet

- Cdoo 01 95 23013 0001 A H01 - Hoja - de - Util PDFDocument1 pageCdoo 01 95 23013 0001 A H01 - Hoja - de - Util PDFsgtNo ratings yet

- Cdoo 01 95 23012 0001 A H01 - Hoja - de - Util PDFDocument1 pageCdoo 01 95 23012 0001 A H01 - Hoja - de - Util PDFsgtNo ratings yet

- Cdoo 01 95 23012 0001 A H02 - Hoja - de - Util PDFDocument1 pageCdoo 01 95 23012 0001 A H02 - Hoja - de - Util PDFsgtNo ratings yet

- Top018 Adjectives Crossword2Document2 pagesTop018 Adjectives Crossword2sgtNo ratings yet

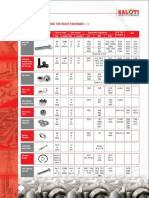

- Section 4 Conveyor Chain Designer GuideDocument41 pagesSection 4 Conveyor Chain Designer GuidesgtNo ratings yet

- Mock 1. NEW MOCK EXAMS APTIS.Document16 pagesMock 1. NEW MOCK EXAMS APTIS.sgtNo ratings yet

- Mock 2. NEW MOCK EXAMSDocument16 pagesMock 2. NEW MOCK EXAMSsgtNo ratings yet

- Mock Exam 4Document17 pagesMock Exam 4sgtNo ratings yet

- Mock Exam 3Document16 pagesMock Exam 3sgtNo ratings yet

- Case Study 1 Bench ViseDocument7 pagesCase Study 1 Bench ViseChetan100% (1)

- Track Shoe Bolts Dessin CIEMNTERIEDocument1 pageTrack Shoe Bolts Dessin CIEMNTERIENarimane BentyNo ratings yet

- TI KAL: A Chart To Choose The Right FastenerDocument2 pagesTI KAL: A Chart To Choose The Right Fastenervelu.gNo ratings yet

- National Pipe Thread Chart PDFDocument1 pageNational Pipe Thread Chart PDFLiu YangtzeNo ratings yet

- Asme B18.15-2015Document22 pagesAsme B18.15-2015Kamal El Shawadfy50% (2)

- Lab No: 06 "To Study Gauge Blocks and Dial Indicator" ObjectiveDocument4 pagesLab No: 06 "To Study Gauge Blocks and Dial Indicator" ObjectiveKashif RazaqNo ratings yet

- Piezas Polipasto Dh-325Document32 pagesPiezas Polipasto Dh-325Alejandro Rodriguez FloresNo ratings yet

- Mori Seiki GM CodeDocument10 pagesMori Seiki GM CodevusvusNo ratings yet

- Machine Shop Elements: Answer ADocument32 pagesMachine Shop Elements: Answer ATatsNo ratings yet

- Multiple Choice 2 Heat Treatment Carbon Content PreheatDocument10 pagesMultiple Choice 2 Heat Treatment Carbon Content PreheatAhmed Ben Nouma100% (1)

- True Temper 1954 No. 11054 HammersDocument12 pagesTrue Temper 1954 No. 11054 HammersJay SNo ratings yet

- G-Code For CNC MachineDocument13 pagesG-Code For CNC MachinezokiplusNo ratings yet

- ASHOKADocument40 pagesASHOKAManish PatilNo ratings yet

- b18 2 2Document42 pagesb18 2 2Gustavo Fama100% (2)

- Mini Pan Tilt Kit AssemblyDocument16 pagesMini Pan Tilt Kit Assemblyليا ربتتذNo ratings yet

- E1 - E64 (Vertex 33)Document64 pagesE1 - E64 (Vertex 33)Bryan RuizNo ratings yet

- Heat TreatmentDocument16 pagesHeat TreatmentHukam ChandNo ratings yet

- Vertex Vk-4 Vertex K-Type Milling Vice 100mm Jaw Width: Product BrochureDocument3 pagesVertex Vk-4 Vertex K-Type Milling Vice 100mm Jaw Width: Product BrochureMarcoGuidolinoNo ratings yet

- Kitless Pens Part 2Document3 pagesKitless Pens Part 2Inform7105No ratings yet

- Manual de Herramientas Finpower-MateDocument86 pagesManual de Herramientas Finpower-Matefagtar100% (2)

- B18 2 1 1996Document86 pagesB18 2 1 1996phani u4meNo ratings yet

- GTD 450 Gas Turbine MaterialDocument12 pagesGTD 450 Gas Turbine MaterialJJNo ratings yet

- Prezentare ZVI TOOLS 2018Document11 pagesPrezentare ZVI TOOLS 2018Alexandru GălanNo ratings yet

- Metal Table JISDocument1 pageMetal Table JISNakkolopNo ratings yet

- Task 4 - Governor Arm PDFDocument2 pagesTask 4 - Governor Arm PDFRicky Prabowo0% (1)

- Jis Thread StandardsDocument1 pageJis Thread StandardsPaul Hammerstrom100% (1)

- Ceiling SpecsDocument2 pagesCeiling SpecsKurt Darryl SabelloNo ratings yet

- Tools 2Document19 pagesTools 2Bey PastranaNo ratings yet