Professional Documents

Culture Documents

Lect 6

Lect 6

Uploaded by

Quynh Phuong PhamOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lect 6

Lect 6

Uploaded by

Quynh Phuong PhamCopyright:

Available Formats

Paris Graduate School of Management (PGSM)

International Executive Master of Business Administration

Paris Graduate School of Management

École Supérieure de Gestion et Commerce International

INTERNATIONAL EXECUTIVE

MASTER OF BUSINESS ADMINISTRATION

IEMBA

Paris Graduate School of Management

École Supérieure de Gestion et Commerce International

INTERNATIONAL EXECUTIVE

MASTER OF BUSINESS ADMINISTRATION

Management Decision Making

January 2024

© 2024 International Executive MBA - Paris Graduate School of Management.

All rights reserved.

Paris Graduate School of Management (PGSM)

International Executive Master of Business Administration

International Executive Master of Business Administration

LECTURES 6

Chapter 20

Statistical Methods for Quality Control

n Statistical Process Control

n Acceptance Sampling

| | | | | | | | | | | | |

UCL

CL

LCL

| | | | | | | | | | | |

© 2024 International Executive MBA - Paris Graduate School of Management.

All rights reserved.

Paris Graduate School of Management (PGSM)

International Executive Master of Business Administration

Quality Terminology

n Quality is “the totality of features and characteristics

of a product or service that bears on its ability to

satisfy given needs.”

Quality Terminology

n Quality assurance refers to the entire system of policies,

procedures, and guidelines established by an organization

to achieve and maintain quality.

n The objective of quality engineering is to include quality in

the design of products and processes and to identify

potential quality problems prior to production.

n Quality control consists of making a series of inspections

and measurements to determine whether quality

standards are being met.

© 2024 International Executive MBA - Paris Graduate School of Management.

All rights reserved.

Paris Graduate School of Management (PGSM)

International Executive Master of Business Administration

Statistical Process Control (SPC)

n The goal of SPC is to determine whether the process can be

continued or whether it should be adjusted to achieve a

desired quality level.

n If the variation in the quality of the production output is

due to assignable causes (operator error, worn-out tooling,

bad raw material, . . . ) the process should be adjusted or

corrected as soon as possible.

n If the variation in output is due to common causes

(variation in materials, humidity, temperature, . . . ) which

the manager cannot control, the process does not need to

be adjusted.

SPC Hypotheses

n SPC procedures are based on hypothesis-testing

methodology.

n The null hypothesis H0 is formulated in terms of the

production process being in control.

n The alternative hypothesis Ha is formulated in terms of the

process being out of control.

n As with other hypothesis-testing procedures, both a Type I

error (adjusting an in-control process) and a Type II error

(allowing an out-of-control process to continue) are

possible.

© 2024 International Executive MBA - Paris Graduate School of Management.

All rights reserved.

Paris Graduate School of Management (PGSM)

International Executive Master of Business Administration

Decisions and State of the Process

n Type I and Type II Errors

State of Production Process

H0 True Ha True

Decision In Control Out of Control

Continue Correct Type II Error

Allow out-of-control

Process Decision process to continue

Adjust Type I Error Correct

Adjust in-control

Process process Decision

Control Charts

n SPC uses graphical displays known as control charts

to monitor a production process.

n Control charts provide a basis for deciding whether

the variation in the output is due to common causes

(in control) or assignable causes (out of control).

© 2024 International Executive MBA - Paris Graduate School of Management.

All rights reserved.

Paris Graduate School of Management (PGSM)

International Executive Master of Business Administration

Control Charts

n Two important lines on a control chart are the upper

control limit (UCL) and lower control limit (LCL).

n These lines are chosen so that when the process is in

control, there will be a high probability that the sample

finding will be between the two lines.

n Values outside of the control limits provide strong

evidence that the process is out of control.

Types of Control Charts

n An x chart is used if the quality of the output is measured in

terms of a variable such as length, weight, temperature, and

so on.

n x represents the mean value found in a sample of the output.

n An R chart is used to monitor the range of the measurements

in the sample.

n A p chart is used to monitor the proportion defective in the

sample.

n An np chart is used to monitor the number of defective items

in the sample.

© 2024 International Executive MBA - Paris Graduate School of Management.

All rights reserved.

Paris Graduate School of Management (PGSM)

International Executive Master of Business Administration

x Chart Structure

x

UCL

Center Line Process Mean

When in Control

LCL

Time

Control Limits for an x Chart

n Process Mean and Standard Deviation Known

UCL = 3 x

LCL = 3 x

© 2024 International Executive MBA - Paris Graduate School of Management.

All rights reserved.

Paris Graduate School of Management (PGSM)

International Executive Master of Business Administration

Example: Granite Rock Co.

n Control Limits for an x Chart: Process Mean

and Standard Deviation Known

The weight of bags of cement filled by Granite’s

packaging process is normally distributed with a mean

of 50 pounds and a standard deviation of 1.5 pounds.

What should be the control limits for samples of 9

bags?

Example: Granite Rock Co.

n Control Limits for an x Chart: Process Mean

and Standard Deviation Known

x =

50,n =1.1.5,

5 n=

9

0.5

9

UCL = 50 + 3(.5) = 51.5

LCL = 50 - 3(.5) = 48.5

© 2024 International Executive MBA - Paris Graduate School of Management.

All rights reserved.

Paris Graduate School of Management (PGSM)

International Executive Master of Business Administration

Control Limits for an x Chart

n Process Mean and Standard Deviation Unknown

UCL = x A2 R

LCL = x A2 R

where: =_

x = overall sample mean

R = average range

A2 = a constant that depends on n; taken from

“Factors for Control Charts” table

Factors for x and R Control Charts

n Factors Table (Partial)

n d2 A2 d3 D3 D4

5 2.326 0.577 0.864 0 2.114

6 2.534 0.483 0.848 0 2.004

7 2.704 0.419 0.833 0.076 1.924

8 2.847 0.373 0.820 0.136 1.864

9 2.970 0.337 0.808 0.184 1.816

10 3.078 0.308 0.797 0.223 1.777

. . . . . .

. . . . . .

© 2024 International Executive MBA - Paris Graduate School of Management.

All rights reserved.

Paris Graduate School of Management (PGSM)

International Executive Master of Business Administration

Control Limits for an R Chart

_

UCL = RD_ 4

LCL = RD3

_

where:

R = average range

D3, D4 = constants that depend on n; found

in “Factors for Control Charts” table

Factors for x and R Control Charts

n Factors Table (Partial)

n d2 A2 d3 D3 D4

5 2.326 0.577 0.864 0 2.114

6 2.534 0.483 0.848 0 2.004

7 2.704 0.419 0.833 0.076 1.924

8 2.847 0.373 0.820 0.136 1.864

9 2.970 0.337 0.808 0.184 1.816

10 3.078 0.308 0.797 0.223 1.777

. . . . . .

. . . . . .

© 2024 International Executive MBA - Paris Graduate School of Management.

All rights reserved.

Paris Graduate School of Management (PGSM)

International Executive Master of Business Administration

Example: Granite Rock Co.

n Control Limits for x and R Charts: Process Mean

and Standard Deviation Unknown

Suppose Granite does not know the true mean

and standard deviation for its bag filling process. It

wants to develop x and R charts based on twenty

samples of 5 bags each.

The twenty samples resulted in an overall sample

mean of 50.01 pounds and an average range of .322

pounds.

Example: Granite Rock Co.

n Control Limits for R Chart: Process Mean

and Standard Deviation Unknown

_

=

x = 50.01,

_ R = .322, n = 5

_

UCL = RD4 = .322(2.114) = .681

LCL = RD3 = .322(0) = 0

© 2024 International Executive MBA - Paris Graduate School of Management.

All rights reserved.

Paris Graduate School of Management (PGSM)

International Executive Master of Business Administration

Example: Granite Rock Co.

n R Chart

A RB C

Chart for Granite D

Rock Co. E F

0.80

0.70

Sample Range R

UCL

0.60

0.50

0.40

0.30

0.20

0.10

LCL

0.00

0 5 10 15 20

Sam ple Num ber

Example: Granite Rock Co.

n Control Limits for x Chart: Process Mean

and Standard Deviation Unknown

=

=

x = 50.01, R = .322, n = 5

=

UCL = x + A2R = 50.01 + .577(.322) = 50.196

LCL = x - A2R = 50.01 - .577(.322) = 49.824

© 2024 International Executive MBA - Paris Graduate School of Management.

All rights reserved.

Paris Graduate School of Management (PGSM)

International Executive Master of Business Administration

Example: Granite Rock Co.

n x Chart

x Chart for Granite Rock Co.

50.3

UCL

50.2

50.1

Sample

Mean

50.0

49.9

49.8

LCL

49.7

0 5 10 15 20

Sample Number

Control Limits for a p Chart

UCL = p 3 p

LCL = p 3 p

where: p p( 1 p )

n

assuming:

np > 5

n(1-p) > 5

Note: If computed LCL is negative, set LCL = 0

© 2024 International Executive MBA - Paris Graduate School of Management.

All rights reserved.

Paris Graduate School of Management (PGSM)

International Executive Master of Business Administration

Example: Norwest Bank

Every check cashed or deposited at Norwest Bank

must be encoded with the amount of the check before it

can begin the Federal Reserve clearing process. The

accuracy of the check encoding process is of upmost

importance. If there is any discrepancy between the

amount a check is made out for and the encoded

amount, the check is defective.

Example: Norwest Bank

Twenty samples, each consisting of 250 checks, were

selected and examined when the encoding process was

known to be operating correctly. The number of

defective checks found in the samples follow.

4 1 5 3 2 7 4 5 2 3

2 8 5 3 6 4 2 5 3 6

© 2024 International Executive MBA - Paris Graduate School of Management.

All rights reserved.

Paris Graduate School of Management (PGSM)

International Executive Master of Business Administration

Example: Norwest Bank

n Control Limits for a p Chart

Suppose Norwest does not know the proportion of

defective checks, p, for the encoding process when it is

in control.

We will treat the data (20 samples) collected as

one large sample and compute the average number of

defective checks for all the data. That value can then be

used to estimate p.

Example: Norwest Bank

n Control Limits for a p Chart

Estimated p = 80/((20)(250)) = 80/5000 = .016

p(1 p ) .016(1 .016) .015744

p .007936

n 250 250

UCL = p 3 p .016 3(.007936) .039808

LCL = p 3 p .016 3(.007936) -.007808 0

© 2024 International Executive MBA - Paris Graduate School of Management.

All rights reserved.

Paris Graduate School of Management (PGSM)

International Executive Master of Business Administration

Example: Norwest Bank

n p Chart

p Chart for Norwest Bank

0.045

0.040

UCL

0.035

Sample Proportion p

0.030

0.025

0.020

0.015

0.010

0.005

LCL

0.000

0 5 10 15 20

Sample Number

Control Limits for an np Chart

UCL = np 3 np( 1 p)

LCL = np 3 np( 1 p)

assuming:

np > 5

n(1-p) > 5

Note: If computed LCL is negative, set LCL = 0

© 2024 International Executive MBA - Paris Graduate School of Management.

All rights reserved.

Paris Graduate School of Management (PGSM)

International Executive Master of Business Administration

Interpretation of Control Charts

n The location and pattern of points in a control chart enable

us to determine, with a small probability of error, whether a

process is in statistical control.

n A primary indication that a process may be out of control is a

data point outside the control limits.

n Certain patterns of points within the control limits can be

warning signals of quality problems:

• Large number of points on one side of center line.

• Six or seven points in a row that indicate either an

increasing or decreasing trend.

• . . . and other patterns.

Acceptance Sampling

n Acceptance sampling is a statistical method that

enables us to base the accept-reject decision on the

inspection of a sample of items from the lot.

n Acceptance sampling has advantages over 100%

inspection including: less expensive, less product

damage, fewer people involved, . . . and more.

© 2024 International Executive MBA - Paris Graduate School of Management.

All rights reserved.

Paris Graduate School of Management (PGSM)

International Executive Master of Business Administration

Acceptance Sampling Procedure

Lot received

Sample selected

Sampled items

inspected for quality

Results compared with Quality is not

Quality is

specified quality characteristics

satisfactory satisfactory

Accept the lot Reject the lot

Send to production Decide on disposition

or customer of the lot

Acceptance Sampling

n Acceptance sampling is based on hypothesis-testing

methodology.

n The hypothesis are:

H0: Good-quality lot

Ha: Poor-quality lot

© 2024 International Executive MBA - Paris Graduate School of Management.

All rights reserved.

Paris Graduate School of Management (PGSM)

International Executive Master of Business Administration

The Outcomes of Acceptance Sampling

n Type I and Type II Errors

State of the Lot H0 True Ha True

Good-Quality Lot Poor-Quality Lot

Accept H0 Correct Type II Error

Decision

Accept the Lot Decision Consumer’s Risk

Reject H0 Type I Error Correct

Reject the Lot Producer’s Risk Decision

Probability of Accepting a Lot

n Binomial Probability Function for Acceptance Sampling

n!

f ( x) p x ( 1 p)(n x )

x !(n x)!

where:

n = sample size

p = proportion of defective items in lot

x = number of defective items in sample

f(x) = probability of x defective items in sample

© 2024 International Executive MBA - Paris Graduate School of Management.

All rights reserved.

Paris Graduate School of Management (PGSM)

International Executive Master of Business Administration

Example: Acceptance Sampling

An inspector takes a sample of 20 items from a lot. Her policy is to

accept a lot if no more than 2 defective items are found in the

sample.

Assuming that 5 percent of a lot is defective, what is the

probability that she will accept a lot? Reject a lot?

n = 20, c = 2, and p = .05

P(Accept Lot) = f(0) + f(1) + f(2)

= .3585 + .3774 + .1887

= .9246

P(Reject Lot) = 1 - .9246

= .0754

Example: Acceptance Sampling

n Using the Tables of Binomial Probabilities

p

n x .05 .10 .15 .20 .25 .30 .35 .40 .45 .50

20 0 .3585 .1216 .0388 .0115 .0032 .0008 .0002 .0000 .0000 .0000

1 .3774 .2702 .1368 .0576 .0211 .0068 .0020 .0005 .0001 .0000

2 .1887 .2852 .2293 .1369 .0669 .0278 .0100 .0031 .0008 .0002

3 .0596 .1901 .2428 .2054 .1339 .0716 .0323 .0123 .0040 .0011

4 .0133 .0898 .1821 .2182 .1897 .1304 .0738 .0350 .0139 .0046

5 .0022 .0319 .1028 .1746 .2023 .1789 .1272 .0746 .0365 .0148

6 .0003 .0089 .0454 .1091 .1686 .1916 .1712 .1244 .0746 .0370

7 .0000 .0020 .0160 .0545 .1124 .1643 .1844 .1659 .1221 .0739

8 .0000 .0004 .0046 .0222 .0609 .1144 .1614 .1797 .1623 .1201

9 .0000 .0001 .0011 .0074 .0271 .0654 .1158 .1597 .1771 .1602

© 2024 International Executive MBA - Paris Graduate School of Management.

All rights reserved.

Paris Graduate School of Management (PGSM)

International Executive Master of Business Administration

Selecting an Acceptance Sampling Plan

n In formulating a plan, managers must specify two

values for the fraction defective in the lot.

• a = the probability that a lot with p0 defectives will

be rejected.

• b = the probability that a lot with p1 defectives will

be accepted.

n Then, the values of n and c are selected that result in an

acceptance sampling plan that comes closest to

meeting both the a and b requirements specified.

Operating Characteristic Curve

Probability of Accepting the Lot

1.00

.90

.80 a

.70 n = 15, c = 0

.60 p0 = .03, p1 = .15

.50 a = .3667, b = .0874

.40

.30 (1 - a)

.20 p0 p1

.10

b

0 5 10 15 20 25

Percent Defective in the Lot

© 2024 International Executive MBA - Paris Graduate School of Management.

All rights reserved.

Paris Graduate School of Management (PGSM)

International Executive Master of Business Administration

Multiple Sampling Plans

n A multiple sampling plan uses two or more stages of

sampling.

n At each stage the decision possibilities are:

• stop sampling and accept the lot,

• stop sampling and reject the lot, or

• continue sampling.

n Multiple sampling plans often result in a smaller total

sample size than single-sample plans with the same

Type I error and Type II error probabilities.

A Two-Stage Acceptance Sampling Plan

Inspect n1 items

Find x1 defective items in this sample

Yes Accept

x1 < c1 ?

the lot

No

Reject Yes x 1 > c2 ?

the lot

No

Inspect n2 additional items

Find x2 defective items in this sample

No x 1 + x 2 < c3 ? Yes

© 2024 International Executive MBA - Paris Graduate School of Management.

All rights reserved.

Paris Graduate School of Management (PGSM)

International Executive Master of Business Administration

End of Chapter

© 2024 International Executive MBA - Paris Graduate School of Management.

All rights reserved.

You might also like

- MHS 06. Statistical Process Control-KWODocument55 pagesMHS 06. Statistical Process Control-KWOKevin SinagaNo ratings yet

- ISO 9001 2015 TrainingDocument26 pagesISO 9001 2015 TrainingPraveen Sharma100% (2)

- Management System Manual PDFDocument16 pagesManagement System Manual PDFDobrin florin-nicuNo ratings yet

- LpaDocument20 pagesLpalugarxNo ratings yet

- 2.2016 Syllabus Paper-15-Oct-2020 Strategic Cost Management - Decision Making Study NotesDocument392 pages2.2016 Syllabus Paper-15-Oct-2020 Strategic Cost Management - Decision Making Study NotesRadhakrishnaraja Ramesh100% (1)

- Building The Talent PipelineDocument15 pagesBuilding The Talent Pipelinelinchpin219No ratings yet

- Sec 04 Quality Control ProcessDocument37 pagesSec 04 Quality Control Processapi-3699912No ratings yet

- Null PDFDocument57 pagesNull PDFالاوربيه للبلاستكNo ratings yet

- Game PDFDocument10 pagesGame PDFKichi UeharaNo ratings yet

- Fire Station ResearchDocument77 pagesFire Station ResearchChristian PatarayNo ratings yet

- D 6862 - 03 Rdy4nji - PDFDocument5 pagesD 6862 - 03 Rdy4nji - PDFMarceloNo ratings yet

- Hydrostatic Pressure Testing Procedure: Petronas Rapid Project Package 14 - Utilities, Interconnecting, Offsite UnitsDocument23 pagesHydrostatic Pressure Testing Procedure: Petronas Rapid Project Package 14 - Utilities, Interconnecting, Offsite UnitsYo Wee LiamNo ratings yet

- Bqs Asq Lpa Overview 2 3 2017 Rev 11 PDFDocument48 pagesBqs Asq Lpa Overview 2 3 2017 Rev 11 PDFelyesNo ratings yet

- Civil Complaint SampleDocument12 pagesCivil Complaint SampleLaughLy ReuyanNo ratings yet

- Question 1 Case AirbnbDocument2 pagesQuestion 1 Case AirbnbQuynh Phuong PhamNo ratings yet

- Managing Quality: MBA602 Operation ManagementDocument23 pagesManaging Quality: MBA602 Operation ManagementANN ONYMOUS100% (2)

- Chapter 4 Quality Assurance (QA)Document19 pagesChapter 4 Quality Assurance (QA)schaNo ratings yet

- Colorfastness To Perspiration: AATCC Test Method 15-2009Document3 pagesColorfastness To Perspiration: AATCC Test Method 15-2009Milagros Wieczorek100% (1)

- Project On Marketing Strategies of Pizza Hut and Dominos - 151902340Document70 pagesProject On Marketing Strategies of Pizza Hut and Dominos - 151902340jyoti sharma100% (2)

- Lect 1 - 2Document69 pagesLect 1 - 2Quynh Phuong PhamNo ratings yet

- Om Notes: Managing QualityDocument13 pagesOm Notes: Managing QualityBobby BrownNo ratings yet

- Project Quality ManagementDocument39 pagesProject Quality ManagementSolich IchinNo ratings yet

- C2 - Strategic Management Accounting: Chartered LevelDocument5 pagesC2 - Strategic Management Accounting: Chartered LevelAsimsaNo ratings yet

- Sujit, Navin, Nitin AQMDocument35 pagesSujit, Navin, Nitin AQMnabinkarma786No ratings yet

- Lect 3 - 4Document44 pagesLect 3 - 4Quynh Phuong PhamNo ratings yet

- Module Revision: DR Jun RenDocument18 pagesModule Revision: DR Jun RenSathish KumarNo ratings yet

- Operations & Supply Chain Management-TYBBADocument6 pagesOperations & Supply Chain Management-TYBBAANSH AHUJANo ratings yet

- Lect 7Document15 pagesLect 7Quynh Phuong PhamNo ratings yet

- Hapag LloydDocument15 pagesHapag LloydPapelera RosaNo ratings yet

- Technology and Operation Management Home Assignment 2Document6 pagesTechnology and Operation Management Home Assignment 2Puspita RamadhaniaNo ratings yet

- Chapter QualityDocument82 pagesChapter QualitythedichotomyofameNo ratings yet

- Quality Control: Mcgraw-Hill/IrwinDocument40 pagesQuality Control: Mcgraw-Hill/IrwinbarisNo ratings yet

- Module Title: Managerial AccountingDocument58 pagesModule Title: Managerial AccountingRazaNo ratings yet

- 1989 14 Auditing The Management of Measurement Britton BPDocument19 pages1989 14 Auditing The Management of Measurement Britton BPAneeshNo ratings yet

- TQM 59899Document8 pagesTQM 59899Kalpesh PatilNo ratings yet

- Cost Accounting and Control Prelims RevisedDocument63 pagesCost Accounting and Control Prelims RevisedKienthvxxNo ratings yet

- MAC 243 Management Accounting 2Document35 pagesMAC 243 Management Accounting 2norma_mohdNo ratings yet

- Chap-10 Quality ControlDocument51 pagesChap-10 Quality Controlsushant chaudharyNo ratings yet

- Module 010 QualityDocument32 pagesModule 010 QualitygagahejuniorNo ratings yet

- PM - Sum. Note (Updated)Document87 pagesPM - Sum. Note (Updated)Adams JoshuaNo ratings yet

- 5 Control PhaseDocument32 pages5 Control PhasePablo RípodasNo ratings yet

- Benchmarking:: and From Organizations Anywhere in The World To Help Improve The PerformanceDocument7 pagesBenchmarking:: and From Organizations Anywhere in The World To Help Improve The PerformanceMahdi KhemakhemNo ratings yet

- Statistical Quality ControlDocument43 pagesStatistical Quality ControlRudraksh AgrawalNo ratings yet

- Week 8 - Statistical Quality ControlDocument90 pagesWeek 8 - Statistical Quality Controllou nguyenNo ratings yet

- 16 Chapter 10Document16 pages16 Chapter 10Harshi AggarwalNo ratings yet

- Reading Assignment OperationsDocument6 pagesReading Assignment OperationsAhmed NasrNo ratings yet

- Quality Control and Quality Assurance in Textile IndustryDocument46 pagesQuality Control and Quality Assurance in Textile IndustryHabtamu SitotawNo ratings yet

- Statistical Process Control: Fqa Lec 5Document31 pagesStatistical Process Control: Fqa Lec 5Shaira Madiline M. GelvezonNo ratings yet

- 632 OmDocument16 pages632 OmSanchit AroraNo ratings yet

- Mayank Varyani It-A 1709713059 Assignment 4Document4 pagesMayank Varyani It-A 1709713059 Assignment 4godofwar5601No ratings yet

- ACCT2121 Introductory Management Ac Counting: Instructor: Fiona Yanling GUANDocument30 pagesACCT2121 Introductory Management Ac Counting: Instructor: Fiona Yanling GUANLo WingcNo ratings yet

- Day 6 - QualityDocument33 pagesDay 6 - QualityAlok SharmaNo ratings yet

- CALIDAD EN EL DISEÑO-QbDDocument24 pagesCALIDAD EN EL DISEÑO-QbDSilvia OrdazNo ratings yet

- Lecture 1Document20 pagesLecture 1Ahmed El SayedNo ratings yet

- LCE Line Performance OptimizationDocument2 pagesLCE Line Performance OptimizationAnthony CollierNo ratings yet

- Tips On The Process ApproachDocument2 pagesTips On The Process Approachrajasenthil KumarNo ratings yet

- Costing Notes - CA Inter Lyst5490 PDFDocument185 pagesCosting Notes - CA Inter Lyst5490 PDFMaheshkumar PerlaNo ratings yet

- BUS 433 Lecture NoteDocument11 pagesBUS 433 Lecture NoteukachiNo ratings yet

- Ais Dagohoy - PwsDocument13 pagesAis Dagohoy - PwsDnl bNo ratings yet

- Lesson 9 - Six SigmaDocument10 pagesLesson 9 - Six SigmaLovesel MalabuyocNo ratings yet

- Process Improvement Using Control ChartsDocument39 pagesProcess Improvement Using Control ChartsChristianAquinoNo ratings yet

- Lecture 11Document42 pagesLecture 11Inzamam Ul HaqNo ratings yet

- Joy Degobaton - OMTQ Topic 6Document4 pagesJoy Degobaton - OMTQ Topic 6Joy DegobatonNo ratings yet

- Total Quality AsignmentsDocument30 pagesTotal Quality Asignmentssamee380No ratings yet

- BananaDocument8 pagesBananaمحمد الخاتمNo ratings yet

- The Role of TQM Models in The Sustainable Tourism DevelopmentDocument6 pagesThe Role of TQM Models in The Sustainable Tourism DevelopmentInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- TTQCDocument7 pagesTTQCFiroz Rashid100% (1)

- 2021 22 OM MSC MNG Session1Document29 pages2021 22 OM MSC MNG Session1Carlos RibeiroNo ratings yet

- Lect 5Document34 pagesLect 5Quynh Phuong PhamNo ratings yet

- Lect 3 - 4Document44 pagesLect 3 - 4Quynh Phuong PhamNo ratings yet

- Case Study Decision Making ManagementDocument1 pageCase Study Decision Making ManagementQuynh Phuong PhamNo ratings yet

- Profile Updated 4.2023 (EN)Document45 pagesProfile Updated 4.2023 (EN)Quynh Phuong PhamNo ratings yet

- Tong Quan Chinh Sach Mang Thai HoDocument3 pagesTong Quan Chinh Sach Mang Thai HoQuynh Phuong PhamNo ratings yet

- Homework 2: 1. Do You Agree That A Moral Progress Should Be Done To Change The Islamic Cultural Value System?Document1 pageHomework 2: 1. Do You Agree That A Moral Progress Should Be Done To Change The Islamic Cultural Value System?Quynh Phuong PhamNo ratings yet

- Power Maxma Inverter 4kvDocument1 pagePower Maxma Inverter 4kvsajjad gayyemNo ratings yet

- Karl Liebknecht - in Spite of Everything! (1919)Document4 pagesKarl Liebknecht - in Spite of Everything! (1919)Luka ENo ratings yet

- 20 TOP LOGIC GATES and BOOLEAN ALGEBRA Questions and Answers PDF LOGIC GATES and BOOLEAN ALGEBRA Questions and Answers PDFDocument3 pages20 TOP LOGIC GATES and BOOLEAN ALGEBRA Questions and Answers PDF LOGIC GATES and BOOLEAN ALGEBRA Questions and Answers PDFBalakrishnan KrishnanNo ratings yet

- 04 W4ErrorProofingDocument43 pages04 W4ErrorProofingKleber NovaisNo ratings yet

- Car Price PredictionDocument67 pagesCar Price PredictionKrishnapradeepNo ratings yet

- Testing Ingine KaliDocument30 pagesTesting Ingine KaliIngiaNo ratings yet

- Application For Permit To Operate: A. General InformationDocument2 pagesApplication For Permit To Operate: A. General InformationCivie Jomel QuidayNo ratings yet

- (2009) B. H. GebreslassieDocument10 pages(2009) B. H. GebreslassieHusnain AliNo ratings yet

- Weka 9Document7 pagesWeka 9verticalspin104No ratings yet

- Narrative ReportDocument4 pagesNarrative ReportAnonymous 9sKZvA6P100% (1)

- Mode of Entry Used by Netflix in IndiaDocument1 pageMode of Entry Used by Netflix in IndiaErika BNo ratings yet

- Nemo Dat RuleDocument5 pagesNemo Dat RuleTHEVINTHINI A P RAMAKRISHNAN UnknownNo ratings yet

- Operating Instructions BMW v.O.I.C.E. II Communication System For K1200 LTDocument32 pagesOperating Instructions BMW v.O.I.C.E. II Communication System For K1200 LTcluainsiNo ratings yet

- 2 Feliks (2020) Effective Use of Big DataDocument16 pages2 Feliks (2020) Effective Use of Big DataFeliks SejahteraNo ratings yet

- Apic2015 Zhao NaDocument24 pagesApic2015 Zhao NaSandip LadvaNo ratings yet

- Frameless GlassDocument29 pagesFrameless Glassmichelle geejoNo ratings yet

- 24 34 00Document62 pages24 34 00Fazley Rabbi Akond67% (3)

- Measuring National IncomeDocument26 pagesMeasuring National IncomeSaidur Rahman Sid100% (1)

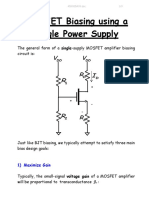

- MOSFET Biasing Using A Single Power SupplyDocument9 pagesMOSFET Biasing Using A Single Power SupplySabaJavedNo ratings yet

- Manual TOPconnect S7 1500 en-USDocument116 pagesManual TOPconnect S7 1500 en-USadelswedenNo ratings yet

- Credit RatingDocument28 pagesCredit Ratingak5775No ratings yet