Professional Documents

Culture Documents

DG SET GTP Rev-1

Uploaded by

Tanuj ShriCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DG SET GTP Rev-1

Uploaded by

Tanuj ShriCopyright:

Available Formats

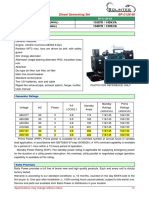

Specification for Emergency 2 x 600 MW Hissar Thermal

DG Set Power Plant, Hissar

SCHEDULE -B

TECHNICAL PARTICULARS

A DIESEL GENERATOR SET

1.0 Diesel Engine

1.1 Make :CUMMINS

1.2 Type :

a) Number of cycles :4 STORKE

b) Number of cylinder :16

c) Cylinder Orientation :’V’ SHAPE 60 DEG

d) R.P.M :1500

1.3 Service :

1.4 Bore x Stroke-cm :15.9 X 15.9

1.5 Piston displacement-cm3 :50.3 LITRES

1.6 Type of Cooling :RADIATOR WATER COOLED

1.7 Lubrication type :OIL

1.8 Exhaust duct-mm :2X250MM INDIVIDUAL PIPE &

400MM COMMON PIPE

1.90 Governor type / class :CUMMINS PTG(AUTO) A1

CLASS

1.10 Governor performance compliant with the specification

Yes / No :

1.11 Fuel consumption at---

a) 25% Load-gms/kWH :NOT ADVISABLE

b) 50% Load-gms/kWH :162 LITRES/HOUR

c) 75% Load-gms/kWH :231 LITRES/HOUR

d) 100% Load-gms/kWH :301.7 LITRES/HOUR

e) 110% Load-gms/kWH :NOT APPLICABLE

1.12 Starting system :ELECTRICAL STARTER

1.13 Compression ratio :14.9:1

1.14 Maximum noise level at a distance of 1 m :25db A INSERTION LOSS

NOISE LEVEL AT WORKS AT ONE

REL-HRTPP-VEE-215-B-007 Emergency DG Set 2x600 MW Hissar TPP Page 1of 10

Rev-1

Specification for Emergency 2 x 600 MW Hissar Thermal

DG Set Power Plant, Hissar

SCHEDULE -B

METER DISTANCE FROM DG SET

105DB SOUND LEVEL 1

NOISE LEVEL AT ONE METER

DISTANCE FROM DG SET

ACOUSTIC ENCLOSURE 85DB

SOUND LEVEL

Vibration Limit :MAX 250 MICRONS PEAK TO PEAK 1

WITH AVM PADS

1.15 Starting time when :

a) starting air pressure is at lowest

permissible value :NOT APPLICABLE

b) when the air is at rated pressure :NOT APPLICABLE

1.16 Margin provided with respect to generator rating :AS PER CONTRACT

1.17 Standard to which engine confirms :BS5514

1.18 Continuous rating of engine at maximum ambient 50 degC

Conditions kWb :1500 KVA PRIME RATING

1.19 Short term 1 hour in 12 hour output rating- kWb :110% OF 1500 KVA FOR ONE

HOUR IN EVERY 12 HOURS OF

OPERATION.

1.20 Thermal efficiency at rated full load rating- % :N/A

1.21 Engine BMEP at full load rating- Bar :1998.4 KPA AT RATED LOAD

1.22 Maximum tolerable step load

(as percentage of full load)- % :>57%

1.23 Time from start initiation to full load acceptance

under minimum cold start conditions

(engine capability)- Secs. :22 SECS IN WELL DESIGNED

SYSTEM

1.24 Engine aspiration :TURBOCHARGED AFTER COOLED

1.25 Engine air intake filter :

a) Type :DRY TYPE PAPER ELEMENT

b) Manufactured by :FLEETGUARD

1.26 Power consumption by auxiliaries- kW :15KW AE FANS (OTHER THAN DG

SET)

1.27 DG set complete with pipes, fittings, valves etc.? :YES

2.0 GENERATOR

REL-HRTPP-VEE-215-B-007 Emergency DG Set 2x600 MW Hissar TPP Page 2of 10

Rev-1

Specification for Emergency 2 x 600 MW Hissar Thermal

DG Set Power Plant, Hissar

SCHEDULE -B

2.1 Make :CGT

2.2 Type :SEPARATELY EXCITED /SPDP

2.3 a) Service :AS PER CGT SERVICE MANUAL

b) Type of Cooling :AIR COOLED

2.4 Rating

a) Continuous output rating at 0.8pf and

maximum site ambient 50 degC- kW :1500 KVA PRIME POWER

b) Short term 1 hour in 12 hour output rating-kW :110% OF RATED CAPACITY

c) Voltage-Volts :415 VOLTS

d) Phase :3 PHASE 4 WIRE

e) R.P.M. :1500

f) Power Factor :0.8

g) Max. Transient Reactance(Sat/Unsat) % :0.17 (xd)

h) Max. Sub Transient Reactance(Sat/Unsat) % :0.12 (X”d)

i) Steady State Reactance% :1.76(xq)

j) Short circuit ratio :1/ 0.17

2.5 Classification of cooling :AIR COOLED, 2.69CUMTR/SEC

5700 CFM

2.6 Degree of protection :IP-23

2.7 Material & construction of Rotor :COPPER WINDING AS PER

MANUFATURERS STANDARD

2.8 Material & construction of Stator :-----DO--------

2.9 Type of field coils :MANUFACTURERS STANDARDS

2.10 Type of bearings :BALL 6228C3 AND BALL 6319C3

2.11 Bearing/Coupling arrangement :DOUBLE BEARING

2.12 Lubrication :LITE TIME GREASE LUBRICATED

2.13 Insulation class :H

2.14 Exciter type :SEPARATELY EXCITED

2.15 Exciter response :AS PER MANUFACTURERS

STANDARDS

REL-HRTPP-VEE-215-B-007 Emergency DG Set 2x600 MW Hissar TPP Page 3of 10

Rev-1

Specification for Emergency 2 x 600 MW Hissar Thermal

DG Set Power Plant, Hissar

SCHEDULE -B

2.16 Type of voltage regulator :DIGITAL AVR

2.17 KW rating of space heater : < THEN 1 KW

1

2.18 Standard to which generator conforms :IS4722

2.19 Insulation class of Stator & Rotor

Temperature rise limited to over 50 deg. C:

a) Stator in deg C :95 DEG C

b) Rotor in deg C :95 DEG C

3.0 Performance

3.1 Frequency regulation- % :+ - 0.5%

3.2 Voltage regulation-% :+/- 0.5%

3.3 Voltage regulation compliant with specification-Yes / no :YES

3.4 Generator efficiency at rated output-% :96%

3.5 Steady state operation

a) Frequency variation from no load to full load -% :+/- 0.5%

b) Voltage variation from no load to full load-% :+/- 0.5%

3.6 Time required from starting to taking-up of full load-sec :WITHIN 22 SEC

3.7 Grounding pads provided with base frame-Yes/No :YES

3.8 DG set dimension-mm x mm x mm :9000X3000X33000

3.9 DG set weight-kg :20000 KGS (STATIC WEIGHT)

4.0 DG CONTROL PANEL :

4.1 Construction :

a) Make :SUDHIR GENSETS LIMITED

b) Type DUST & VERMIN PROOF TYPE,FREE

STANDING, FLOOR MOUNTED

COMPARTMANTALISED

c) Sheet metal thickness –mm :2MM CRCA

d) Degree of protection :IP-54

e) Dimension (L x D x H)-mm x mm x mm :1600X1600X2025

REL-HRTPP-VEE-215-B-007 Emergency DG Set 2x600 MW Hissar TPP Page 4of 10

Rev-1

Specification for Emergency 2 x 600 MW Hissar Thermal

DG Set Power Plant, Hissar

SCHEDULE -B

f) Weight-kg :APPROX 1500 KGS

4.2 Internal Wiring :

a) Wire type PVC INSULATED COPPER

STRANDED CONDUCTOR

b)Voltage grade-Volts 1100 VOLTS

c) Conductor material :COPPER

d) Conductor size -mm² :2.5 SQ.MM

4.3 Protective Relays Manufactured by Type

a) Voltage Restrained Overcurrent Relay

(51VDG), 3 phase :GENERATOR PROTECTION RELAY

MICOM 342 ALSTHOM (AREVA)

b) Standby Ground Fault Relay (51NDG),

1 phase :----DO-----------

c) Over/Undervoltage Relay (27 DG)

with timer, 3 phase :----DO----------

d) Over/Under voltage protection

(59G/27G) :----DO----------

e) Over/Under Frequency Relay

(81 DG), 1 pole :----DO----------

f) Reverse Power Relay (32DG) :----DO----------

g) Differential relay (87 DG). :CAG 34 ALSTHOM

4.4 Control & Indications

a) Push Buttons---

i) Manufactured by :BCH

ii) Type & Cat. No. :22.5 MM DIA

iii) Contact rating :110VAC/240 V AC/24 V DC

Make & Continuous-Amp :NA

Break (inductive)-Amp :NA

b) Lamps

i) Manufactured by :BCH

ii) Type & Cat No. :22.5 MM DIA

REL-HRTPP-VEE-215-B-007 Emergency DG Set 2x600 MW Hissar TPP Page 5of 10

Rev-1

Specification for Emergency 2 x 600 MW Hissar Thermal

DG Set Power Plant, Hissar

SCHEDULE -B

iii) Watts/Voltage :110VAC/240VAC/24VDC

iv) Series resistance in ohm :NA

v) Lamp & lens replace from front :YES

c) Selector Switch

i) Manufactured by :SALZER/L&T

ii) Type & Cat No. :ROTARY 6A

iii) 3-position Stayput type :

iv) Contact rating :6A

Make & Continuous-Amp :6A

Break (inductive)-Amp :NA

v) Key interlock furnished -Yes/No :NO

4.5 Indicating Meters Qty Make Type

a) Ammeter (A) :TOTAL—8METERS AE ANALOG CL

1.0, 0-2500 AMPS

b) Voltmeter (V) :-------DO----------

c) Kilo-Watt hour meter (KWH) :AE DIGITAL 415VAC CL1.0

d) Kilo-Watt meter (KW) :AE ANALOG CL-1.0 0-2000KW

e) Power Factor meter (PF) :AE ANALOG 0.5-1-0.5

f) Frequency meter (F) :AE DIGITAL 45-50-55 Hz

4.6 Location: PANEL ROOM

4.7 List of equipment provided in the panel furnished

Yes/No :YES

4.8 List of indications provided in the panel furnished

Yes/No :YES

4.9 Type of Mounting :COMPONENTS FLUSH DOOR

MOUNTED / BASE MOUNTED

5.0 SILENCER

5.1 Type :RESIDENTIAL

5.2 Dimension (Lx D x H)-mm x mm x mm :AS PER LAYOUT DRGS SUBMITTED

5.3 Weight-kg :APPROX 150-200 KGS

REL-HRTPP-VEE-215-B-007 Emergency DG Set 2x600 MW Hissar TPP Page 6of 10

Rev-1

Specification for Emergency 2 x 600 MW Hissar Thermal

DG Set Power Plant, Hissar

SCHEDULE -B

6.0 Fuel Oil Service Tank

6.1 Capacity-Litre :990LITRES

6.2 Material of construction :M.S. SHEET 2MM THICK

6.3 Dimension (Lx D x H)-mm x mm x mm :900X900X900

6.4 Weight-kg :150KGS DRY WEIGHT

6.5 Type of level switch :MAGNETIC SWITCH(HIGH/LOW

LEVEL)

6.6 Type of level indicator :PVC TUBE

6.7 Type of fuel oil filter :PAPER ELEMENT TYPE MOUNTED

ON ENGINE

6.8 Air intake filter as specified provided-Yes/No :YES

6.9 Lubrication system with all accessories as specified

provided- Yes/No :YES

6.10 Exhaust system as specified provided-Yes/No :YES

7.0 Governor

a. Type : ELECTRONIC PCC-2100

b. Make :CUMMINS

c. Response time :CAN TAKE FULL LOAD IN 22 SECS

IN WELL DESIGNED SYSTEM

d. Steady state speed :1500 RPM

e. Steady state incremental speed regulation :+/- 0.25

f. Class of governing and standard :A1 CLASS

8.0 Air Starting System

8.1 Air compressor

a) Make :

b) Type of compressor :

c) Reference Standard : NOT APPLICABLE

(ELECTRICAL STARTER)

d) Capacity & number :

e) Compete with accessories as specified? :

REL-HRTPP-VEE-215-B-007 Emergency DG Set 2x600 MW Hissar TPP Page 7of 10

Rev-1

Specification for Emergency 2 x 600 MW Hissar Thermal

DG Set Power Plant, Hissar

SCHEDULE -B

f) Compressor driver :

i) Type :

ii) Rating :

8.2 Air receiver

a) Make :

b) Type :NOT APPLICABLE( ELECTRICAL

STARTER)

c) Capacity & number :

8.3 Fittings and accessories :

8.4 Compressor weight-kg :

8.5 Complete package weight-kg :

8.6 Overall dimension-mm x mm x mm :

9.0 Lube Oil System

9.1 Type :CLOSE SYSTEM

9.2 Complete with pumps, storage tank, filter,

strainers?-Yes/No :YES

9.3 Tank capacity-Litre :178 LITRES

9.4 Tank dimensions-mm x mm x mm :AS PER CIL STANDARDS

9.5 Type of pump drive :ENGINE DRIVEN

9.6 Drive rating :CIL STANDARDS

9.7 Drive standard :CIL STANDARDS

10.0 Cooling System

10.1 Type :RADIATOR (WATER COOLED)

10.2 Engine jacket capacity :165 LITRES

10.3 Expansion tank capacity & no.-Litre :135 LITRES

10.4 Expansion tank dimensions-mm x mm x mm :PART OF RADIATOR

10.5 Rating of cooling pump :ENGIINE DRIVEN PUMP

10.6 Type of pump drive :AS PER CIL STANDARDS

10.7 Drive rating :AS PER CIL STANDARDS

REL-HRTPP-VEE-215-B-007 Emergency DG Set 2x600 MW Hissar TPP Page 8of 10

Rev-1

Specification for Emergency 2 x 600 MW Hissar Thermal

DG Set Power Plant, Hissar

SCHEDULE -B

10.8 Drive standard :AS PER CIL STANDARDS

11.0 Battery

11.1 Make :CUMMINS

11.2 Type :PLT 160-12A

11.3 Service :INTERMITTENT

1

11.4 Reference Standard :CIL STANDARDS

11.5 Rated Voltage-V :12Vx2=24 V SYSTEM VOLTAGE 1

11.6 Capacity-AH :160Ah

11.7 No. of Cells :6

11.8 AH efficiency at 8-hour discharge rate-% :95% MINIMUM

11.9 Cell voltage characteristics during duty cycle furnished? :NO

1

11.10 Expected life of battery -Hr :NOT AVAILABLE

11.11 Recommended charging rate for Float Charging-

Volt per cell / Amp :14.2V PER 12V MONOBLOC AT 25

DEG C

11.12 Recommended charging rate for Boost Charging in

8 hours-Volt per cell / Amp :1.53 TO 1.7 VOLTS PER CELL/ 5- 1

7.5A

11.13 Battery racks

a) Type of racks :MADE OF MS ANGLE 50X50X5MM

THK

b) Material of racks :M.S. ANGLE

c) Number of racks per battery :ONE BATTERY STAND

d) Number of cells per rack :ONE BATTERY STAND

12.0 Battery Charger

12.1 Manufactured by :MAHAMAI ENTERPRISE

12.2 Type :MAX POWER

12.3 Service :CONTINUOUS 1

12.4 Input voltage, phase and frequency :240VAC/1PHASE/50HZ

12.5 Input current-Amp. :0-20 AMPS

REL-HRTPP-VEE-215-B-007 Emergency DG Set 2x600 MW Hissar TPP Page 9of 10

Rev-1

Specification for Emergency 2 x 600 MW Hissar Thermal

DG Set Power Plant, Hissar

SCHEDULE -B

12.6 Output voltage-V DC :24V DC

12.7 Output current-Amp :0-10 AMPS

12.8 Enclosure degree of protection :PANEL MOUNTED-IP42

12.9 Regulation for 0-100%rated load with ±10% input

voltage and ±5% frequency variation % :AUTOMATIC

12.10 Ripple content in DC out put with/without battery-% :AS PER MANUFACTURERS

STANDARDS

12.11 Charger provided with

a) Automatic voltage regulation-Yes/No :YES

b) Current limiting circuitry-Yes/No :YES

12.12 Dimension (LxDxH)-mm x mm x mm :INSIDE AMF PANEL BASE

MOUNTED

12.13 Weight-kg :APPROX 5-10 KGS

12.14 Type of Mounting :INSIDE PANEL BASE MOUNTED

REL-HRTPP-VEE-215-B-007 Emergency DG Set 2x600 MW Hissar TPP Page 10of 10

Rev-1

You might also like

- Cummins 1100 (50 HZ) : GensetsDocument3 pagesCummins 1100 (50 HZ) : Gensetskariem noweerNo ratings yet

- Diesel Generator 2.5 kVA Spec SheetDocument2 pagesDiesel Generator 2.5 kVA Spec SheetAnkur mittalNo ratings yet

- 100kva DG Set - 100kva Koel GensetDocument3 pages100kva DG Set - 100kva Koel GensetMothilalNo ratings yet

- 75kW Motor Technical SpecificationsDocument7 pages75kW Motor Technical Specificationsprati121No ratings yet

- GPWII - PII - 82.5SDocument2 pagesGPWII - PII - 82.5SashokghtNo ratings yet

- Specification For Hyundai Synchronous GeneratorDocument27 pagesSpecification For Hyundai Synchronous Generatorwin htikeNo ratings yet

- GPWII - PII - 75SDocument2 pagesGPWII - PII - 75SashokghtNo ratings yet

- 250kW Cummins genset specificationDocument4 pages250kW Cummins genset specificationmardalan nabisuk100% (1)

- AQT 200 EditDocument3 pagesAQT 200 EditbassemNo ratings yet

- Diesel Generating Set BF-C825-60: Standby Power 60Hz Prime Power 60HzDocument5 pagesDiesel Generating Set BF-C825-60: Standby Power 60Hz Prime Power 60Hzkevindelmonte1996No ratings yet

- GPWII - PII - 62.5SDocument2 pagesGPWII - PII - 62.5SashokghtNo ratings yet

- GPWII - 250SDocument2 pagesGPWII - 250SashokghtNo ratings yet

- GPWII - PII - 100Document2 pagesGPWII - PII - 100ashokghtNo ratings yet

- 620KVA Chienese GensetDocument4 pages620KVA Chienese GensetAbdus SalamNo ratings yet

- Deuzt Gasengine-Tbg620kDocument4 pagesDeuzt Gasengine-Tbg620kCalandrasReyCalandrasreyNo ratings yet

- GPWII - PII - 160FDocument2 pagesGPWII - PII - 160FashokghtNo ratings yet

- GPWII - PII - 125SDocument2 pagesGPWII - PII - 125SashokghtNo ratings yet

- 600kW Diesel Generator Set for Reliable PowerDocument5 pages600kW Diesel Generator Set for Reliable PowerheriNo ratings yet

- 7 5 Kva Portable GeneratorDocument2 pages7 5 Kva Portable GeneratorventerhermanjNo ratings yet

- GPWII - PII - 200SDocument2 pagesGPWII - PII - 200SashokghtNo ratings yet

- AQT 110 EditDocument3 pagesAQT 110 EditbassemNo ratings yet

- AQT 1250 EditDocument3 pagesAQT 1250 EditbassemNo ratings yet

- FT BFC145 Kva - SolintegDocument5 pagesFT BFC145 Kva - SolintegRICHARD BERNALNo ratings yet

- AQT 150 EditDocument3 pagesAQT 150 EditbassemNo ratings yet

- WL-80 FTCDocument5 pagesWL-80 FTCMr.Thawatchai hansuwanNo ratings yet

- Specsheet-7 5Document2 pagesSpecsheet-7 5Ivo NkwetaNo ratings yet

- Diesel Generator Set Provides Reliable PowerDocument5 pagesDiesel Generator Set Provides Reliable PowerMaman RusdiNo ratings yet

- VHP - L5794LT: VGF F18GSI For Ethane Fuel - InternationalDocument3 pagesVHP - L5794LT: VGF F18GSI For Ethane Fuel - InternationalDuvan NietoNo ratings yet

- P33 1 (4PP) GB (0810)Document4 pagesP33 1 (4PP) GB (0810)Janaka Wempathi100% (2)

- Datasheet 2MWDocument1 pageDatasheet 2MWRaghavaNo ratings yet

- CUMMINS 105kVA GENERATORDocument7 pagesCUMMINS 105kVA GENERATORcspolaNo ratings yet

- AQT 10 EditDocument3 pagesAQT 10 EditbassemNo ratings yet

- GPWII - PII-500Document2 pagesGPWII - PII-500ashokghtNo ratings yet

- Generator OutputDocument1 pageGenerator OutputHamoda HananNo ratings yet

- AQT 2000 EditDocument3 pagesAQT 2000 EditbassemNo ratings yet

- DM900 - 9.00 kVA: ModelDocument3 pagesDM900 - 9.00 kVA: ModelMohamed HusseinNo ratings yet

- 125kVA DG Set - 125kVA KOEL GensetDocument3 pages125kVA DG Set - 125kVA KOEL GensetMothilalNo ratings yet

- ACSA - CH-01 - Consolidated Customer PackageDocument17 pagesACSA - CH-01 - Consolidated Customer PackageTomas VazquezNo ratings yet

- DC Genset: For BACK UP (PV or Grid)Document4 pagesDC Genset: For BACK UP (PV or Grid)eddywidjaya9No ratings yet

- AQT 1650 EditDocument3 pagesAQT 1650 EditbassemNo ratings yet

- AQT 22 EditDocument3 pagesAQT 22 EditbassemNo ratings yet

- AQT 2500 EditDocument3 pagesAQT 2500 EditbassemNo ratings yet

- DATA SHEET 0.5HP 3phase CG MakeDocument1 pageDATA SHEET 0.5HP 3phase CG MakeKali Dass KMNo ratings yet

- 160kVA DG Set - 160kVA KOEL GensetDocument3 pages160kVA DG Set - 160kVA KOEL GensetMothilalNo ratings yet

- AC INDUCTION MOTOR SPECSDocument2 pagesAC INDUCTION MOTOR SPECSArjun SomaiyaNo ratings yet

- 92kw Cummins 6bta5.9-G2Document4 pages92kw Cummins 6bta5.9-G2Sarpras RSIMNo ratings yet

- Atlas Incinerator PDFDocument115 pagesAtlas Incinerator PDFKo Gyi Baka100% (2)

- TJ631DW5C 50 Hz Diesel Generator SetsDocument4 pagesTJ631DW5C 50 Hz Diesel Generator SetsbakhoucheNo ratings yet

- QCSDocument1 pageQCSashNo ratings yet

- Datasheet 3MWDocument1 pageDatasheet 3MWRaghavaNo ratings yet

- GeneradorDocument7 pagesGeneradorAndres VargasNo ratings yet

- Generator OutputDocument1 pageGenerator OutputHamoda HananNo ratings yet

- Technical SpecificationsDocument30 pagesTechnical SpecificationsFerdinand Descalzo100% (1)

- Generator Output Generator Specifications: 50 °C 50 °C 150 kVA 165 kVA 120 KW 132 KWDocument1 pageGenerator Output Generator Specifications: 50 °C 50 °C 150 kVA 165 kVA 120 KW 132 KWHamoda HananNo ratings yet

- Catalogo Planta Fawde Accc-Af25 0Document4 pagesCatalogo Planta Fawde Accc-Af25 0Jackson QuintinoNo ratings yet

- BRS1-DS-E-BRS-0005.RD1 Low Voltage Motor Data Sheet (Typical)Document2 pagesBRS1-DS-E-BRS-0005.RD1 Low Voltage Motor Data Sheet (Typical)ABDELKADERNo ratings yet

- AQT 50 EditDocument3 pagesAQT 50 EditbassemNo ratings yet

- Direct Drive Centrifugal Roof Exhaust Fan Spec SheetDocument3 pagesDirect Drive Centrifugal Roof Exhaust Fan Spec SheetElmer Ramón Murillo MejiaNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- DCRTPP Wo DG SetDocument7 pagesDCRTPP Wo DG SetTanuj ShriNo ratings yet

- DG Set New Store Codes 16.01.2024Document16 pagesDG Set New Store Codes 16.01.2024Tanuj ShriNo ratings yet

- District and Category Wise Information of Vacant Posts of Group C and Group D (Peons and Clerk Only) in R/o EMD-IIDocument2 pagesDistrict and Category Wise Information of Vacant Posts of Group C and Group D (Peons and Clerk Only) in R/o EMD-IITanuj ShriNo ratings yet

- Rajiv Ghandi TPS 2100KWDocument3 pagesRajiv Ghandi TPS 2100KWTanuj ShriNo ratings yet

- Rajiv Gandhi Thermal Power Plant e-Tender DocumentDocument25 pagesRajiv Gandhi Thermal Power Plant e-Tender DocumentTanuj ShriNo ratings yet

- BIA - A Glossary of Terms Used in Payments and Settlement SystemsDocument53 pagesBIA - A Glossary of Terms Used in Payments and Settlement SystemscjackchenNo ratings yet

- Accounting Basics QuizDocument4 pagesAccounting Basics QuizMichelle GoNo ratings yet

- Units of MeasurementDocument1 pageUnits of MeasurementTanuj ShriNo ratings yet

- Fire TruckDocument4 pagesFire Truckchris0% (1)

- Universiti Teknologi Malaysia PDFDocument88 pagesUniversiti Teknologi Malaysia PDFdj mladjaNo ratings yet

- Dodge Caliger Tech DataDocument8 pagesDodge Caliger Tech DataMshiboniumNo ratings yet

- Energy Conversion - II Lab ManualDocument33 pagesEnergy Conversion - II Lab ManualAshish VermaNo ratings yet

- Auto. Tech - Mec.227 Theory 03Document87 pagesAuto. Tech - Mec.227 Theory 03ayariseifallah100% (5)

- Air Pollution Control of Mobile SourcesDocument20 pagesAir Pollution Control of Mobile Sourcesmelannie adanteNo ratings yet

- Four-Stroke Diesel Engine Characteristic Curve and EfficiencyDocument10 pagesFour-Stroke Diesel Engine Characteristic Curve and EfficiencyYosra RamadhanNo ratings yet

- Lecture Notes On Advanced I.C. Engine Part-IDocument0 pagesLecture Notes On Advanced I.C. Engine Part-IJaiguru Narayanasamy0% (1)

- EMH332 Tutorial 4Document1 pageEMH332 Tutorial 4Chris ZiyuenNo ratings yet

- DEWALT D55270 TYPE 2 Owners ManualDocument26 pagesDEWALT D55270 TYPE 2 Owners ManualITLHAPNNo ratings yet

- Technical Data: Power Factor Emissions Factor Cos Φ = 0.8 N/A 60Hz/1800R.P.M 3-PhaseDocument7 pagesTechnical Data: Power Factor Emissions Factor Cos Φ = 0.8 N/A 60Hz/1800R.P.M 3-PhaseJonathan CastilloNo ratings yet

- Assignment ThermoDocument6 pagesAssignment ThermoRohaya ShippudenNo ratings yet

- Generator 404D-22G ElectropaK PN1912Document2 pagesGenerator 404D-22G ElectropaK PN1912Rizki Rangga DwipuraNo ratings yet

- CFD of Exahust ValveDocument7 pagesCFD of Exahust ValveMuhammad Imran KhanNo ratings yet

- Piaggio Brochure 2011Document9 pagesPiaggio Brochure 2011cataliny2kNo ratings yet

- Gasoline Prod: 17. Gasoline Production and BlendingDocument37 pagesGasoline Prod: 17. Gasoline Production and BlendingCeren ApakNo ratings yet

- BME Previous Year QuestionsDocument104 pagesBME Previous Year QuestionsVraj PatelNo ratings yet

- State Board of Technical Education Bihar SchemeDocument19 pagesState Board of Technical Education Bihar SchemeBittu KumarNo ratings yet

- Mvagusta Turismo Veloce Lusso Workshopmanual Ed2Document526 pagesMvagusta Turismo Veloce Lusso Workshopmanual Ed2Paolo Piazza80% (5)

- Tangent CamsDocument26 pagesTangent Camsamurugan_22100% (1)

- VCR EngineDocument6 pagesVCR EngineAbNo ratings yet

- SFK Engine SealsDocument7 pagesSFK Engine SealsALNo ratings yet

- Diesel Engines Fourth Edition by Tim Bartlett PDFDocument97 pagesDiesel Engines Fourth Edition by Tim Bartlett PDFMayrym Rey ConNo ratings yet

- ONGC Interview Guidance by S K MondalDocument14 pagesONGC Interview Guidance by S K MondalDnyanesh HegishteNo ratings yet

- Gas Power Cycles ExplainedDocument7 pagesGas Power Cycles ExplainedLegenGaryNo ratings yet

- Aprilia Shiver Service Manual 2007Document351 pagesAprilia Shiver Service Manual 2007suvari77100% (1)

- 2010 Hyundai Genesis Coupe 2.0T Engine SpecsDocument76 pages2010 Hyundai Genesis Coupe 2.0T Engine SpecsJorge DoctorovichNo ratings yet

- Shop ManualD65 12Document1,206 pagesShop ManualD65 12anggie69% (16)

- Especificações Técnicas - Motores JimbeiDocument4 pagesEspecificações Técnicas - Motores JimbeiWiterMarcosNo ratings yet

- Sogav™ Solenoid Operated Gas Admission ValveDocument4 pagesSogav™ Solenoid Operated Gas Admission Valvemilagros castañeda zuni100% (1)