Professional Documents

Culture Documents

Section 07115

Section 07115

Uploaded by

motaz alzoubiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section 07115

Section 07115

Uploaded by

motaz alzoubiCopyright:

Available Formats

PHASE 3 INFRASTRUCTURE DESIGN OF RIYADH BUS PROJECT

STATIONS AND STOPS

SECTION 07115 - BITUMINOUS DAMPPROOFING

PART 1 - GENERAL

1.1 RELATED DOCUMENTS

A. Drawings and general provisions of the Contract, including Conditions of Contract, apply to

this Section.

B. The most stringent requirements of the latest editions of the Saudi building code (SBC) and

Saudi Arabian Standards Organization (SASO) and those mentioned hereafter shall be

followed.

1.2 SUMMARY

A. This Section includes cold-applied, emulsified- asphalt damp-proofing applied to the

following below-grade surfaces, generally in contact with soils:

1. Below-grade surfaces of concrete footings, foundations and columns.

2. Exterior, below-grade surfaces of concrete and masonry foundation walls.

3. Back side of concrete and masonry retaining walls, below grade.

4. Back face of exterior Wythe of masonry cavity walls.

B. Related Sections include the following:

1. Division 7 Section "Elastomeric Sheet Waterproofing."

2. Division 7 Section "APP-Modified Bituminous Sheet Waterproofing."

1.3 SUBMITTALS

A. Product Data: For each type of product indicated. Include recommendations for method of

application, primer, number of coats, coverage or thickness, and protection course.

B. Material Certificates: For each product, signed by manufacturers.

1.4 QUALITY ASSURANCE

A. Source Limitations: Obtain primary dampproofing materials and primers through one

source from a single manufacturer. Provide secondary materials recommended by

manufacturer of primary materials.

1.5 PROJECT CONDITIONS

A. Weather Limitations: Proceed with installation only when existing and forecasted weather

conditions permit asphalt dampproofing to be performed according to manufacturers'

written instructions.

BITUMINOUS DAMPPROOFING 07115 - Page 1 of 4

PS13356-FD-03-STA-SPC-11B-ST-01 REV 0

PHASE 3 INFRASTRUCTURE DESIGN OF RIYADH BUS PROJECT

STATIONS AND STOPS

B. Ventilation: Provide adequate ventilation during application of dampproofing in enclosed

spaces. Maintain ventilation until dampproofing has thoroughly cured.

PART 2 - PRODUCTS

2.1 MANUFACTURERS

A. Available Manufacturers: Subject to compliance with requirements

2.2 BITUMINOUS DAMPPROOFING

A. Cold-Applied, Emulsified-Asphalt Dampproofing:

1. One of the following at Contractor's option:

a. Trowel Coats: ASTM D 1227, Type II, Class 1.

b. Fibered Brush and Spray Coats: ASTM D 1227, Type II, Class 1.

c. Brush and Spray Coats: ASTM D 1227, Type III, Class 1.

2.3 MISCELLANEOUS MATERIALS

A. Protection Course: One of the following, at Contractor's option:

1. Asphalt-Board Type: Premolded, multi-ply, semirigid board consisting of a mineral-

stabilized asphalt core sandwiched between layers of asphalt-saturated felt, and faced

on 1 side with polyethylene film; thickness not less than 3 mm.

2. Polystyrene Type: Fan-folded, rigid, extruded-polystyrene board insulation

sandwiched between 2 sheets of plastic film; nominal thickness not less than 6 mm.

3. Plastic Panel Type: Semi-rigid, extruded or molded, non-biodegradable plastic

panels with a cellular drainage core; overall thickness not less than 4 mm.

a. Puncture Resistance: 1000 N minimum; ASTM E 154.

B. Protection Course, Roll-Roofing Type: Smooth-surfaced roll roofing complying with

ASTM D 6380, Type II.

PART 3 - EXECUTION

3.1 EXAMINATION

A. Examine substrates for compliance with requirements for surface smoothness and other

conditions affecting performance of work.

1. Begin dampproofing application only after substrate construction and penetrating

work have been completed and unsatisfactory conditions have been corrected.

BITUMINOUS DAMPPROOFING 07115 - Page 2 of 4

PS13356-FD-03-STA-SPC-11B-ST-01 REV 0

PHASE 3 INFRASTRUCTURE DESIGN OF RIYADH BUS PROJECT

STATIONS AND STOPS

3.2 PREPARATION

A. Protection of Other Work: Mask or otherwise protect adjoining exposed surfaces from

being stained, spotted, or coated with dampproofing. Prevent dampproofing materials from

entering and clogging weep holes and drains.

B. Clean substrates of projections and substances detrimental to work; fill voids, seal joints,

and apply bond breakers if any, as recommended by prime material manufacturer.

3.3 APPLICATION, GENERAL

A. Comply with manufacturer's written recommendations unless more stringent requirements

are indicated or required by Project conditions to ensure satisfactory performance of

dampproofing.

1. Apply additional coats if recommended by manufacturer or required to achieve

coverages indicated.

2. Allow each coat of dampproofing to cure 24 hours before applying subsequent coats.

B. Apply dampproofing to surfaces of footings, foundations, foundation columns and

foundation walls in contact with soils whether indicated or not.

1. Apply vertically from finished-grade line to top of footing or foundation, extend over

top and down face of footing or foundation.

2. Extend onto blinding beds, intersecting walls andfootings, but do not extend onto

surfaces exposed to view when Project is completed, unless otherwise indicated.

3. Install flashings and corner protection stripping at internal and external corners,

changes in plane, construction joints, cracks, and where indicated as "reinforced," by

embedding an 200-mm wide strip of asphalt-coated glass fabric in a heavy coat of

dampproofing. Dampproofing coat required for embedding fabric is in addition to

other coats required.

3.4 COLD-APPLIED, EMULSIFIED-ASPHALT DAMPPROOFING

A. On Concrete Footings, Foundations, Foundation Columns and Walls: Apply two brush or

spray coats at not less than 0.6 L/sq. m for first coat and 0.4 L/sq. m for second coat, one

fibered brush or spray coat at not less than 1.2 L/sq. m, or one trowel coat at not less than

1.6 L/sq. m.

B. On Unparged Masonry Foundation Walls: Apply primer and two brush or spray coats at not

less than 0.6 L/sq. m for first coat and 0.4 L/sq. m for second coat, primer and one fibered

brush or spray coat at not less than 1.2 L/sq. m, or primer and one trowel coat at not less

than 2 L/sq. m.

C. On Unparged Masonry Foundation Walls: Apply primer and one trowel coat at not less

than 2 L/sq. m.

D. On Backs of Concrete Retaining Walls: Apply one brush or spray coat at not less than 0.5

L/sq. m.

E. On Backs of Masonry Retaining Walls: Apply primer and one brush or spray coat at not

less than 0.5 L/sq. m.

BITUMINOUS DAMPPROOFING 07115 - Page 3 of 4

PS13356-FD-03-STA-SPC-11B-ST-01 REV 0

PHASE 3 INFRASTRUCTURE DESIGN OF RIYADH BUS PROJECT

STATIONS AND STOPS

3.5 INSTALLATION OF PROTECTION COURSE

A. Where indicated, install protection course over completed-and-cured dampproofing.

Comply with dampproofing material manufacturer's written recommendations for attaching

protection course. Support protection course with spot application of trowel-grade mastic

where not otherwise indicated.

3.6 CLEANING

A. Remove dampproofing materials from surfaces not intended to receive dampproofing.

END OF SECTION 07115

BITUMINOUS DAMPPROOFING 07115 - Page 4 of 4

PS13356-FD-03-STA-SPC-11B-ST-01 REV 0

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Steel Ladder B.O.QDocument1 pageSteel Ladder B.O.Qmotaz alzoubiNo ratings yet

- Sec 08710Document9 pagesSec 08710motaz alzoubiNo ratings yet

- Spbu 778 SupplierDocument13 pagesSpbu 778 Suppliermotaz alzoubiNo ratings yet

- Section 15075Document7 pagesSection 15075motaz alzoubiNo ratings yet

- Metal WorkDocument2 pagesMetal Workmotaz alzoubiNo ratings yet

- P144-1A1.B02-WA-ST-201-01a (STELL LADDER) - P144-1A1.B02-WA-ST-201-01-1Document1 pageP144-1A1.B02-WA-ST-201-01a (STELL LADDER) - P144-1A1.B02-WA-ST-201-01-1motaz alzoubiNo ratings yet

- Project: Halfway Home, Diriya, Kingdom of Saudi Arabia HWH/312A - Stainless Steel WindowsDocument1 pageProject: Halfway Home, Diriya, Kingdom of Saudi Arabia HWH/312A - Stainless Steel Windowsmotaz alzoubiNo ratings yet

- External Swimming Pool BalustradeDocument1 pageExternal Swimming Pool Balustrademotaz alzoubiNo ratings yet

- General Directorate 02835-1 Chain Link FencesDocument6 pagesGeneral Directorate 02835-1 Chain Link Fencesmotaz alzoubiNo ratings yet

- Spbu 691 SupplierDocument7 pagesSpbu 691 Suppliermotaz alzoubiNo ratings yet

- Material Request Form: SR - No. Cost Code Description Specification Qty Unit RemarksDocument1 pageMaterial Request Form: SR - No. Cost Code Description Specification Qty Unit Remarksmotaz alzoubiNo ratings yet

- Aluminum Doors and Windows TW BDocument2 pagesAluminum Doors and Windows TW Bmotaz alzoubiNo ratings yet

- Wall Mounted Rail Appartment ADocument1 pageWall Mounted Rail Appartment Amotaz alzoubiNo ratings yet

- Aluminum Doors Block ADocument3 pagesAluminum Doors Block Amotaz alzoubiNo ratings yet

- Graphical Interpretation of Center of Lift Versus Neutral Point For A 2D AirfoilDocument8 pagesGraphical Interpretation of Center of Lift Versus Neutral Point For A 2D Airfoilmotaz alzoubiNo ratings yet

- Steel & Alum INQDocument9 pagesSteel & Alum INQmotaz alzoubiNo ratings yet

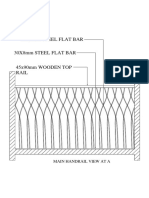

- HandrailDocument1 pageHandrailmotaz alzoubiNo ratings yet

- Parking Metal Canopy BOQDocument1 pageParking Metal Canopy BOQmotaz alzoubiNo ratings yet

- Sas330 Uk SingleDocument16 pagesSas330 Uk Singlemotaz alzoubiNo ratings yet