Professional Documents

Culture Documents

General Directorate 02835-1 Chain Link Fences

Uploaded by

motaz alzoubiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

General Directorate 02835-1 Chain Link Fences

Uploaded by

motaz alzoubiCopyright:

Available Formats

SECTION 02835

CHAIN LINK FENCES AND GATES

1 - GENERAL

1.1. SECTION INCLUDES

A. PVC-coated chain link fence framework, fabric and accessories.

B. Extension arms and other specified items.

1.2. REFERENCES

A. SASO – Saudi Arabian Standard Organization

SASO 811 Chain Link Fences – Part 1: Requirements for materials,

workmanship and erection

B. AASHTO - American Association of State Highway and Transport Officials.

AASHTO 181 Chain Link Fence

C. ASTM – American Society for Testing and Materials

ASTM A 53 Pipe, Steel, Black and Hot-Dipped Zinc Coated (Galvanized)

Welded and Seamless, for Ordinary Uses.

ASTM A 116 Zinc-Coated (Galvanized) Steel Woven Wire Fence Fabric.

ASTM A 123 Zinc (Hot Dip Galvanized) Coatings on Iron and Steel

Products.

ASTM A 153 Zinc Coating (Hot-Dip) on Iron and Steel Hardware.

ASTM A 392 Zinc-Coated Steel Chain-Link Fence Fabric.

ASTM A 428 Weight of Coating on Aluminum-Coated Iron or Steel

Articles.

ASTM A 491 Aluminum-Coated Steel Chain Link Fence Fabric.

ASTM A 569 Steel, Carbon (0.15 Maximum Percent), Hot-Rolled Sheet

and Strip Commercial Quality.

ASTM C 94 Ready-mixed Concrete.

ASTM F 567 Installation of Chain-Link Fence.

ASTM F 573 Residential Zinc-Coated Steel Chain Link Fence Fabric.

General Directorate 02835-1 Chain Link Fences

ASTM F 668 Poly (Vinyl Chloride) (PVC) Coated Steel Chain Link Fence

Fabric.

D. Chain Link Fence Manufacturers Institute (CLFMI) - Product Manual.

1.3. SYSTEM DESCRIPTION

A. Fence Height: As indicated on Drawings.

B. Line Post Spacing: At intervals not exceeding 3 m.

C. Straining Post Spacing: At intervals not exceeding 60 m.

1.4. SUBMITTALS

A. Shop Drawings: Indicate plan layout, spacing of components, post

foundation dimensions, hardware anchorage, and schedule of components.

B. Product Data: Provide data on fabric, posts, accessories, fittings and

hardware.

C. Samples: Submit 2 samples of fence fabric, 150 x 150 mm in size

illustrating construction and color of finish.

D. Manufacturer's Installation Instructions: Indicate installation requirements,

post foundation anchor bolt templates, hardware and accessories.

1.5. QUALITY ASSURANCE

A. Perform Work in accordance with CLFMI - Product Manual and

manufacturer's instructions.

B. Manufacturer Qualifications: Company specializing in manufacturing the

products specified in this Section with minimum 3 years documented

experience.

C. Installer Qualifications: Company specializing in installing the products

specified in this Section with minimum 3 years documented experience.

Installer shall be as recommended manufacturer and approved by the

Engineer.

2 - PRODUCTS

2.1. MATERIALS

A. Materials for fencing shall conform to SASO 811, AASHTO M 181 and to

the standards specified. All items of each type, such as posts, fabric, and

accessories shall be from the same manufactures and of the same size,

General Directorate 02835-2 Chain Link Fences

design, and materials except as otherwise shown and required.

B. All ferrous fence materials including wire fabric, all type of posts and other

accessories shall be coated with extruded polyvinyl chloride (PVC). The

color of the vinyl coating shall be green.

C. Before PVC coating, all ferrous fence material, except wire fabric, shall be

galvanized with a minimum of 550 g of zinc per square meter. Wire fabric

shall be galvanized with a minimum of 52 g of zinc per square meter.

D. Wire Fabric: The chain link fence fabric conforming to ASTM A 392 Class I,

shall have 50 mm mesh of 3.76 mm core wire and 4.88 mm overall, and

twisted and barbed top and bottom selvages. The fabric shall be of width as

shown on the drawings.

E. Posts and Miscellaneous Metals:

1. Line posts shall be standard galvanized steel posts of not less than

50 mm outside diameter conforming to ASTM A 53, Schedule 40,

weighing not less than 5.44 kg/m, and section modules of 9190

mm³ minimum. Other shapes may be substituted provided that the

section modules is maintained or exceeded.

2. End, corner and pull posts shall be standard galvanized steel posts

of not less than 73 mm outside diameter conforming to ASTM A 53,

Schedule 40, weighing not less than 8.62 kg/m and section modulus

of 1744 mm³ minimum. Other shapes may be substituted provided

the section modulus is maintained or exceeded.

3. Straining posts shall be standard round steel conforming to ASTM A

120, Schedule 40, not less than 73 mm OD, galvanized after

manufacture, weighing not less than 8.62 kg/m and section

modulus of 1744 mm³ minimum.

4. Struts shall be standard round steel conforming to ASTM A 120,

Schedule 40, not less than 42 mm OD, galvanized after

manufacture.

5. Round bands (50 mm), End Caps, Fittings and Accessories:

Manufacturer’s standard products, conforming to F626, galvanized

to ASTM A123, ASTMA153 and BS 729. Sizes shall be suitable

with main fence frames.

7. Post tops, and other fittings and hardware shall be of bonded vinyl

coated steel, malleable iron, or wrought iron.

8. Top and bottom tension wires between posts shall be at least 4.88

mm diameter extruded vinyl-coated galvanized steel with a

minimum breaking strength of 8 kN. Tie wire shall be 2.0 mm

diameter extruded vinyl-coated galvanized steel, conforming to

ASTM A112.

General Directorate 02835-3 Chain Link Fences

9. Stretcher bars shall be of vinyl coated steel, not less than 6 mm by

20 mm, and of lengths equal to the full height of the fabric to be

used.

10. Bolts, nuts and other hardware shall be galvanized steel, coated

with PVC after assembly.

11. Horizontal truss braces shall be vinyl coated steel pipe at least 42.2

mm outside diameter weighing not less than 3.38 kg/m and with a

section modulus of 3851 mm³ minimum. Other steel shapes may be

substituted provided that the section modulus is equaled or

exceeded. Vinyl coated steel truss rods at least 10 mm diameter

with turn buckles shall be used for diagonal bracing.

G. Concrete for Foundations: In accordance with the requirements specified in

Section 03300 - CAST-IN-PLACE CONCRETE, Class 30.

PART 3 - EXECUTION

3.1. INSTALLATION

A. Install framework, fabric, accessories and gates in accordance with

ANSI/ASTM F 567 and manufacturer's instructions.

B. Posts:

1. Line posts shall be spaced not more than 3 m apart, measured

parallel to the slope of the natural ground. Place posts vertical

except in unusual situations as determined by the Engineer where

posts shall be placed perpendicular to the slope of the ground.

2. Corner posts shall be installed where the change in direction is 15

degrees or more. Pull posts shall be placed not more than 180 m

apart in a straight run and where the line changes direction by 15

degrees or more.

3. Posts shall be placed vertically and aligned within a tolerance ratio

of 1 in 500. The top of posts shall be set to the required height, and

shall not be cut off.

C. Set posts in concrete footings with top of footing 50 mm above finish grade.

Slope top of concrete for water runoff.

D. Footing depth below finish grade: As indicated on Drawings.

E. Temporary guys or braces shall be installed as required to hold the posts in

position until the concrete has set sufficiently. Unless otherwise allowed,

material shall not be hung on the posts for the first seven days after placing

the concrete.

General Directorate 02835-4 Chain Link Fences

F. Braces: Provide braces, consisting of a horizontal pipe and a diagonal rod,

corner, pull and end post at mid-height of the fabric. The pipe shall extend

horizontally between corner, pull or end post and the adjacent line post. The

diagonal rod with a turnbuckle shall be not less than 10 mm in diameter,

and shall extend from the line post end of the horizontal pipe to the base of

corner, pull or end post. Where fence lengths 90 m or longer at end corner,

pull or end posts, fit a second similar diagonal rod from the midpoint of the

corner, pull or end post to the top of the adjacent line post.

G. Tension wires shall be fastened by clips or tie wires to each corner, pull and

end post, and shall be drawn tight with turnbuckles. The bottom tension

wire shall be taut between posts, and not over 50 mm above the ground

surface except where special closures are required. High ground spots

shall be excavated, but depressions may not be filled in, if approved by the

Engineer.

H. Provide top rail through line post tops and splice with 150 mm long rail

sleeves.

I. Install center and bottom brace rail on corner gate leaves.

J. Place fabric on the outside of the posts. Stretch fabric between posts or at

intervals 30 m maximum, whichever is less.

K. Position bottom of fabric 50 mm above finished grade.

L. Fasten fabric to top rail, line posts, braces, and bottom tension wire with tie

wire at maximum 380 mm on centers.

M. Stretcher bars shall be attached to the fabric by clamps or other approved

mechanical means. One stretcher bar shall be provided pull and end post,

and two for each corner post. Sufficient clips shall be provided for attaching

the fabric and stretcher bars to posts at intervals not over 400 mm apart.

N. Install bottom tension wire stretched taut between terminal posts.

O. Plastic vertical slats shall be installed where shown on the drawings, and

shall comply with manufacturer's written instructions.

3.2. ERECTION TOLERANCES

A. Maximum Variation from Plumb: 6 mm.

B. Maximum Offset from True Position: 25 mm.

General Directorate 02835-5 Chain Link Fences

END OF SECTION

General Directorate 02835-6 Chain Link Fences

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Manual de Mantenimiento y Codigos de FallaDocument123 pagesManual de Mantenimiento y Codigos de FallaHamiltonNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Concrete ReinforcementDocument5 pagesConcrete Reinforcementsethu1091No ratings yet

- Astm A810-01Document4 pagesAstm A810-01ditherNo ratings yet

- C 1063 - 03 QzewnjmDocument9 pagesC 1063 - 03 QzewnjmGarcia ManuelNo ratings yet

- Technical Manual ZX 48 UDocument404 pagesTechnical Manual ZX 48 UDevis anugra100% (1)

- Security Perimeter FencingDocument17 pagesSecurity Perimeter FencingMaina MathengeNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Iron and Steel Industry Analysis - IndiaDocument58 pagesIron and Steel Industry Analysis - Indiaprachi_jain_2667% (3)

- McCormick MC 95 105 115 120 Power6 135 Power6 OM 03160Document316 pagesMcCormick MC 95 105 115 120 Power6 135 Power6 OM 03160Michael Flanagan50% (4)

- D8R Lubricant Viscosity PDFDocument37 pagesD8R Lubricant Viscosity PDFarfa ujiantoNo ratings yet

- Highway Planning EssentialsDocument106 pagesHighway Planning EssentialsKevin Salzal100% (1)

- MH Galvanized Chain Link Fence SpecificationDocument9 pagesMH Galvanized Chain Link Fence Specificationyamanta_rajNo ratings yet

- Chain Link Fence and Gates 32-31-13Document14 pagesChain Link Fence and Gates 32-31-13melvinkorahNo ratings yet

- BITUMINOUS MATERIALS ROAD BINDERSDocument20 pagesBITUMINOUS MATERIALS ROAD BINDERSDeyin HernandezNo ratings yet

- IRI E1926.ssrt0435Document16 pagesIRI E1926.ssrt0435AaaaaNo ratings yet

- Chain Link Fencing and GateDocument9 pagesChain Link Fencing and GateMohammad Sahmoud100% (1)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- 9 FencingDocument11 pages9 FencingkashifNo ratings yet

- BP Azspu Driver Fatigue & Tiredness Management ProcedureDocument11 pagesBP Azspu Driver Fatigue & Tiredness Management ProcedureEl Khan100% (1)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Aashto M 180-00Document8 pagesAashto M 180-00Mohsen Ghobadi86% (14)

- B. AASHTO - American Association of State Highway and Transport Officials. Aashto 181 Chain Link FenceDocument6 pagesB. AASHTO - American Association of State Highway and Transport Officials. Aashto 181 Chain Link FenceuddinnadeemNo ratings yet

- Maximum Security PerimetersDocument7 pagesMaximum Security Perimetersمحمد عبد السلام الصوافNo ratings yet

- Specification For Chain Link Fence and GatesDocument8 pagesSpecification For Chain Link Fence and GatesSuresh BabuNo ratings yet

- Astm F567Document4 pagesAstm F567RUI MIGUEL SILVANo ratings yet

- Early Works Package - Specification B (Section 317210) - Tunnel Primary Support - Ground ReinforcementDocument3 pagesEarly Works Package - Specification B (Section 317210) - Tunnel Primary Support - Ground ReinforcementZain AbidiNo ratings yet

- Section 09100 Metal Framing SystemDocument5 pagesSection 09100 Metal Framing Systemestimasi100% (1)

- Metal Fabrications SEPDocument8 pagesMetal Fabrications SEPanon-767746No ratings yet

- DIV 2-SITE WORK Sec 02832-Chain Link Fence and GatesDocument5 pagesDIV 2-SITE WORK Sec 02832-Chain Link Fence and GatesBrown LucuNo ratings yet

- SECTION 02822 Chain Link Fences and Gates Part 1 - GeneralDocument4 pagesSECTION 02822 Chain Link Fences and Gates Part 1 - GeneralEmad KhanNo ratings yet

- AISI Section 092600 - Metal Framing For Gypsum Board AssembliesDocument6 pagesAISI Section 092600 - Metal Framing For Gypsum Board AssembliesĐường Nguyễn ThừaNo ratings yet

- Section 09111 Non-Load-Bearing Steel Framing Part 1Document94 pagesSection 09111 Non-Load-Bearing Steel Framing Part 1jacksondcplNo ratings yet

- Furring and Lathing - MasonryDocument77 pagesFurring and Lathing - MasonryRogelito D. BallonNo ratings yet

- Chain Link Fences and Gates Part 1 - General 1.1 DescriptionDocument5 pagesChain Link Fences and Gates Part 1 - General 1.1 Descriptionm_a_nada67% (3)

- SECTION 161xx Cable Trays: D. ASTM A1011 - Specification For Steel, Sheet and Strip, Hot-Rolled, CarbonDocument6 pagesSECTION 161xx Cable Trays: D. ASTM A1011 - Specification For Steel, Sheet and Strip, Hot-Rolled, CarbonMontu KangriwalaNo ratings yet

- Special Specification 5202 Pipe CasingDocument6 pagesSpecial Specification 5202 Pipe Casingresp-ectNo ratings yet

- Composite Panel SpecificationDocument6 pagesComposite Panel SpecificationracvilleNo ratings yet

- American Steel Bars - s440Document6 pagesAmerican Steel Bars - s440Emeka OdinyeNo ratings yet

- Angle Frame Bleachers: 3 Part SpecificationsDocument4 pagesAngle Frame Bleachers: 3 Part SpecificationsAnn BonifacioNo ratings yet

- FL - Ta1056Document4 pagesFL - Ta1056ery achjariNo ratings yet

- Metal Gratings TA1056 - MBI Sampang Agung Factory Extension 1Document6 pagesMetal Gratings TA1056 - MBI Sampang Agung Factory Extension 1ery achjariNo ratings yet

- GURAD RAIL ss859 PDFDocument4 pagesGURAD RAIL ss859 PDFSaepul AnwarNo ratings yet

- Ornamental Metal Fence SpecificationsDocument14 pagesOrnamental Metal Fence SpecificationsMØhãmmed ØwięsNo ratings yet

- Minara District A, Stage 2: Badrah DevelopmentDocument4 pagesMinara District A, Stage 2: Badrah DevelopmentCody TillmanNo ratings yet

- Trench SpecificationsDocument4 pagesTrench SpecificationsFatoni Gea AirlanggaNo ratings yet

- TS US Gabion, GalMac Jan19Document8 pagesTS US Gabion, GalMac Jan19johnnee98No ratings yet

- Gypsum and Cement Board InstallationDocument5 pagesGypsum and Cement Board InstallationuddinnadeemNo ratings yet

- Expansion Compensation For PlumbingDocument6 pagesExpansion Compensation For Plumbingabdullah sahibNo ratings yet

- Astm A 392Document2 pagesAstm A 392ingmoi0608No ratings yet

- C 955 - 01 Qzk1ns1sruqDocument6 pagesC 955 - 01 Qzk1ns1sruqHumberto GutierrezNo ratings yet

- Vents and StacksDocument5 pagesVents and Stacksadel rihanaNo ratings yet

- BS 731Document14 pagesBS 731Ashutosh PatraNo ratings yet

- Section 05 73 00Document5 pagesSection 05 73 00camilleNo ratings yet

- QCS 2010 Part 09 FencingDocument11 pagesQCS 2010 Part 09 FencingRotsapNayrbNo ratings yet

- Part 9 FencingDocument13 pagesPart 9 FencingElvis GrayNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 10200-1 Louvers and VentsDocument6 pagesITCC in Riyadh Residential Complex J10-13300 10200-1 Louvers and VentsuddinnadeemNo ratings yet

- A 392 - 96 R03 Qtm5mi1sruqDocument5 pagesA 392 - 96 R03 Qtm5mi1sruqquatudogonNo ratings yet

- 04200Document9 pages04200uddinnadeemNo ratings yet

- Chain Link Fences and GatesDocument11 pagesChain Link Fences and Gatesمحمد عبد السلام الصوافNo ratings yet

- Concrete ReinforcmentDocument5 pagesConcrete ReinforcmentNoor Mohamed AzeezNo ratings yet

- Raceways, Boxes and FittingsDocument10 pagesRaceways, Boxes and FittingssallammohamedNo ratings yet

- Installation of Cast-In-Place Reinforced Gypsum Concrete: Standard Specification ForDocument6 pagesInstallation of Cast-In-Place Reinforced Gypsum Concrete: Standard Specification ForHumberto GutierrezNo ratings yet

- ACS Specs GFRC1Document10 pagesACS Specs GFRC1Chrill DsilvaNo ratings yet

- Sample Specification From Monoxivent Corrosion Composites: SECTION 15800Document4 pagesSample Specification From Monoxivent Corrosion Composites: SECTION 15800Ahmed NabilNo ratings yet

- C 955 Â " 00 QZK1NS0WMEEDocument4 pagesC 955 Â " 00 QZK1NS0WMEESebastián RodríguezNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 12484 - 1 Floor Mats and FramesDocument2 pagesITCC in Riyadh Residential Complex J10-13300 12484 - 1 Floor Mats and FramesuddinnadeemNo ratings yet

- Spbu 778 SupplierDocument13 pagesSpbu 778 Suppliermotaz alzoubiNo ratings yet

- P144-1A1.B02-WA-ST-201-01a (STELL LADDER) - P144-1A1.B02-WA-ST-201-01-1Document1 pageP144-1A1.B02-WA-ST-201-01a (STELL LADDER) - P144-1A1.B02-WA-ST-201-01-1motaz alzoubiNo ratings yet

- Spbu 1237 SupplierDocument7 pagesSpbu 1237 Suppliermotaz alzoubiNo ratings yet

- Spbu 778 SupplierDocument13 pagesSpbu 778 Suppliermotaz alzoubiNo ratings yet

- Material Request Form for SGH Madinah Renovation ProjectDocument1 pageMaterial Request Form for SGH Madinah Renovation Projectmotaz alzoubiNo ratings yet

- Ferrotech Catalogue 35 X 5 MMDocument24 pagesFerrotech Catalogue 35 X 5 MMmotaz alzoubiNo ratings yet

- Ferrotech Catalogue 35 X 5 MMDocument24 pagesFerrotech Catalogue 35 X 5 MMmotaz alzoubiNo ratings yet

- External Swimming Pool BalustradeDocument1 pageExternal Swimming Pool Balustrademotaz alzoubiNo ratings yet

- Aluminum Doors and Windows Appartment CDocument1 pageAluminum Doors and Windows Appartment Cmotaz alzoubiNo ratings yet

- Project: Halfway Home, Diriya, Kingdom of Saudi Arabia HWH/312A - Stainless Steel WindowsDocument1 pageProject: Halfway Home, Diriya, Kingdom of Saudi Arabia HWH/312A - Stainless Steel Windowsmotaz alzoubiNo ratings yet

- Precast Concrete Kerbing and Boundary Wall SpecificationsDocument3 pagesPrecast Concrete Kerbing and Boundary Wall Specificationsmotaz alzoubiNo ratings yet

- Aluminum Doors and Windows TW BDocument2 pagesAluminum Doors and Windows TW Bmotaz alzoubiNo ratings yet

- Aluminum Doors and Windows Appartment CDocument1 pageAluminum Doors and Windows Appartment Cmotaz alzoubiNo ratings yet

- Aluminum Doors Block ADocument3 pagesAluminum Doors Block Amotaz alzoubiNo ratings yet

- Wall Mounted Rail Appartment ADocument1 pageWall Mounted Rail Appartment Amotaz alzoubiNo ratings yet

- Skylight Block BDocument1 pageSkylight Block Bmotaz alzoubiNo ratings yet

- 10071204L00 - PB500 Series Power Pack Quality Process FlowDocument1 page10071204L00 - PB500 Series Power Pack Quality Process FlowDaniel MarquesNo ratings yet

- Wall Mounted Rail Appartment ADocument1 pageWall Mounted Rail Appartment Amotaz alzoubiNo ratings yet

- Spbu 691 SupplierDocument7 pagesSpbu 691 Suppliermotaz alzoubiNo ratings yet

- Spbu 1248 SupplierDocument7 pagesSpbu 1248 Suppliermotaz alzoubiNo ratings yet

- Aluminum Doors Block ADocument3 pagesAluminum Doors Block Amotaz alzoubiNo ratings yet

- Appartment EDocument1 pageAppartment Emotaz alzoubiNo ratings yet

- DEL StutusDocument1 pageDEL Stutusmotaz alzoubiNo ratings yet

- Graphical Interpretation of Center of Lift Versus Neutral Point For A 2D AirfoilDocument8 pagesGraphical Interpretation of Center of Lift Versus Neutral Point For A 2D Airfoilmotaz alzoubiNo ratings yet

- Housing Building Bill of QuantityDocument9 pagesHousing Building Bill of Quantitymotaz alzoubiNo ratings yet

- Material Request Form for SGH Madinah Renovation ProjectDocument1 pageMaterial Request Form for SGH Madinah Renovation Projectmotaz alzoubiNo ratings yet

- Skylight Block BDocument1 pageSkylight Block Bmotaz alzoubiNo ratings yet

- Parking Metal Canopy BOQDocument1 pageParking Metal Canopy BOQmotaz alzoubiNo ratings yet

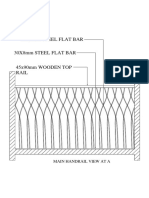

- Steel Flat Bar and Wooden Top Rail for HandrailDocument1 pageSteel Flat Bar and Wooden Top Rail for Handrailmotaz alzoubiNo ratings yet

- World's Top 100 Airlines 2023 - SKYTRAXDocument8 pagesWorld's Top 100 Airlines 2023 - SKYTRAXisaacmendonca.sp2No ratings yet

- Hoist Conveyor/elevatorDocument1 pageHoist Conveyor/elevatorminiNo ratings yet

- Progress Presentation: Geotechnical Design of A Star Flyer Tower (Six Flags) Projected Nearby A SlopeDocument42 pagesProgress Presentation: Geotechnical Design of A Star Flyer Tower (Six Flags) Projected Nearby A SlopeAnkur ChoudharyNo ratings yet

- SAE E-BAJA Team VORTEXDocument12 pagesSAE E-BAJA Team VORTEXPrakash kumarNo ratings yet

- HD205 3Document2 pagesHD205 3Naughty VongNo ratings yet

- Checking The Tilt Operation (EHD, ED)Document1 pageChecking The Tilt Operation (EHD, ED)PHUONG NGUYENNo ratings yet

- Complete The Sentences With The Correct Modal Verbs: 1Document2 pagesComplete The Sentences With The Correct Modal Verbs: 1Sthefany Godoy CaquiNo ratings yet

- Parts For MITSUBISHI 4DQ7Document9 pagesParts For MITSUBISHI 4DQ7Mos Viorel DanutNo ratings yet

- BMW Motorrad F 650 / F 650 ST Maintenance ScheduleDocument1 pageBMW Motorrad F 650 / F 650 ST Maintenance ScheduleGaltNo ratings yet

- Caterpillar Cat 225B EXCAVATOR (Prefix 2ZD) Service Repair ManualDocument24 pagesCaterpillar Cat 225B EXCAVATOR (Prefix 2ZD) Service Repair Manualrpoy9396615No ratings yet

- RFD Daily Incident Report 6/30/21Document2 pagesRFD Daily Incident Report 6/30/21inforumdocsNo ratings yet

- Technic 42065 RC Tracked Racer Buggy Motor & Buwizz Modification Instructions by RacingbrickDocument69 pagesTechnic 42065 RC Tracked Racer Buggy Motor & Buwizz Modification Instructions by RacingbrickD tange100% (1)

- PERSONNEL MANUAL GUIDEDocument421 pagesPERSONNEL MANUAL GUIDETripurari KumarNo ratings yet

- C-ForkPosPartsDocument14 pagesC-ForkPosPartsericchel850712No ratings yet

- Traffic Data SheetDocument8 pagesTraffic Data SheetSOUMYA BHATTNo ratings yet

- Forkliftcenter Used KALMAR DCE 150-12 4 Whl Counterbalanced Forklift >10tDocument1 pageForkliftcenter Used KALMAR DCE 150-12 4 Whl Counterbalanced Forklift >10tTungNo ratings yet

- (Research Proposal)Document9 pages(Research Proposal)LAMIA LATANo ratings yet

- Indiana Jones RPG - IJ1 - Temple of Doom Adv PackDocument46 pagesIndiana Jones RPG - IJ1 - Temple of Doom Adv PackShiningNo ratings yet

- Highway Safety and Accident AnalysisDocument17 pagesHighway Safety and Accident AnalysisHonestlyNo ratings yet

- Bikf LemdDocument2 pagesBikf LemdRoberto Briceño CorreaNo ratings yet

- Thesis Electric VehicleDocument8 pagesThesis Electric VehicleBuyPapersForCollegeOnlineSingapore100% (2)