Professional Documents

Culture Documents

Info 001 2013 Hy

Uploaded by

Рома БлошенкоOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Info 001 2013 Hy

Uploaded by

Рома БлошенкоCopyright:

Available Formats

INFO SERVICE

001/2013 - rev.0

HEAT EXCHANGER

AIR FLOW REVERSAL

FROM ASPIRATING TO BLOWING

HYDROCAR informs that, following a number of defects found on heat exchanger electric fans, the

need has arisen to modify the direction of air flow, switching from current air ASPIRATION through

the heat exchanger towards the electric fan to a new version which PUSHES the air from the electric

fan through the heat exchanger.

This air flow reversal should enable the electric fan to operate at a lower temperature, extending its

life from 500 hours to an expected 5000 hours.

Special care must be taken when installing the new heat exchangers which, in this initial phase,

appear identical to the previous ones. Unless the updated instructions are followed (attached here

for reference - see page 3), the introduction of this modification would be pointless.

Along with the introduction of the new heat exchanger versions, the graphics on the boxes showing

the installation instructions will be updated. A green label will be affixed to the boxes to distinguish

any old ones still in circulation from the new ones and, finally, a coloured label will be affixed to the

heat exchangers to indicate the new versions.

Subsequently, new heat exchanger models will be introduced with even better performance (see

page 2), where the air flow direction will continue to remain, as in this case, “BLOWING”.

For more details, please contact our sales department.

D-21H-0-01 - Info Service HY - rev.2

Interpump Hydraulics Spa a socio unico - Business Unit Hydrocar

Sede Legale: via A. Mingozzi, 6 • 40012 Calderara di Reno BO - Italy

Sede Operativa: via A. Mingozzi, 6 • 40012 Calderara di Reno BO - Italy • T +39 051 6460511 • F +39 051 6460922 / +39 051 6460923

info@hydrocar.com • hydrocar.com Pag.

Cap. Soc. Euro 2.631.600,00 i.v. • N. Mecc. BO 056383 • R.E.A. BO 444225 • C.F. 00883010241 • P.Iva IT02128140361 1/3

Soggetta ad attività di Direzione e Coordinamento da parte di Interpump Group Spa

INFO SERVICE

001/2013 - rev.0

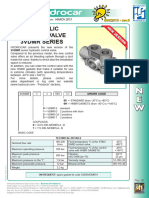

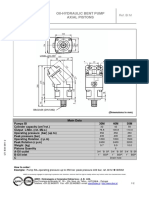

BLOWING EXCHANGER STANDARD version: code 09903240000

(for standard uses)

530 N° 2 3/4" G BSP 68,5 160 73 160 68,5

243 ±4

218 ±4

191 ±4

133

A4-T3-P0

121,5

29

22,5

148,5 233 148,5 N°8 ASOLE 8X16

40 M.R.= 450 40

80 25 240 25 80

TEMPERATURE

EXCHANGE CAPACITY:

∆t = 28°

141 ±5

ON REQUEST

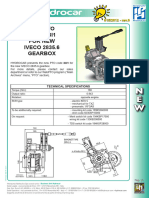

BLOWING EXCHANGER HEAVY DUTY version: code 09903239000

(for heavy-duty uses)

M.R.= 250

350

M.R=63 45 65 150 N°4 ASOLE 9X16

150

M.R.=248 ±4

299 ±4

274 ±4

A4-T3-P0

150

40

N°2 1" G BSP 31,5 31,5

123,5 123,5

25

TEMPERATURE

31,5

EXCHANGE CAPACITY:

∆t = 50°

+2

-2

31,5

173

M22X1.5

D-21H-0-01 - Info Service HY - rev.2

Interpump Hydraulics Spa a socio unico - Business Unit Hydrocar

Sede Legale: via A. Mingozzi, 6 • 40012 Calderara di Reno BO - Italy

Sede Operativa: via A. Mingozzi, 6 • 40012 Calderara di Reno BO - Italy • T +39 051 6460511 • F +39 051 6460922 / +39 051 6460923

info@hydrocar.com • hydrocar.com Pag.

Cap. Soc. Euro 2.631.600,00 i.v. • N. Mecc. BO 056383 • R.E.A. BO 444225 • C.F. 00883010241 • P.Iva IT02128140361 2/3

Soggetta ad attività di Direzione e Coordinamento da parte di Interpump Group Spa

INFO SERVICE

001/2013 - rev.0

ISTRUZIONI DI MONTAGGIO - FITTING INSTRUCTIONS - INSTRUCTIONS DE MONTAGE -

MONTAGEANLEITUNG - INSTRUCCIONES DE MONTAJE - ИНСТРУКЦИИ ПО МОНТАЖУ - 安装说明

Lo scambiatore può essere montato in posizione orizzontale, rispettando la distanza minima dal muro

per assicurare un normale ricambio d’aria. Lo scambiatore deve anche essere protetto da impatti e

vibrazioni meccaniche tramite staffe di supporto, e deve essere collegato alla PF con tubi flessibili.

The oil cooler can be fitted in a Horizontal position respecting the minimum distance from the wall,

so as to ensure a normal flow of cooling air. The oil cooler must be also protected from impacts and

mechanical vibrations by supports and must be connected to the PTO with flexible pipes.

Le radiateur peut être monté en position Horizontale tenant compte de la distance minimum du “mur”

afin de permettre une circulation suffisante de l’air. Le radiateur doit aussi être protégé contre chocs et

vibrations mécaniques au moyen de supports et doit être connecté à la PDM par des tuyaux flexibles.

Der Wärmeaustauscher kann in horizontaler Stellung montiert werden, darauf achtend, dass der

Minimalabstand von der “Wand” garantiert wird, so dass der Zulauf und Abfluss der Abkühlung versichert

wird. Der Wärmeaustauscher muss vor Stößen und mechanischen Vibrationen durch Stützen und

Verbindungen geschützt werden und muss mit NA mittels flexibler Rohrleitungen verbunden werden.

El enfriador puede ser montado en posición Horizontal teniendo cuidado de respectar la distancia

mínima de la “pared” para permitir una circulación bastante del aire. El enfriador debe también ser

protegido contra choques y vibraciones mecánicas por medio de soportes y debe ser conectado a la TF

por medio de tubos flexibles.

Теплообменник может быть установлен в горизонтальном положении, соблюдая минимальное

расстояние от стенки, чтобы обеспечить нормальную циркуляцию воздуха. Теплообменник

должен быть защищен от ударов и механической вибрации при помощи опорных кронштейнов и

должен быть подключен к КОМ гибкими шлангами.

热换器也可以横式安装,但需要保持与墙面的最近距离,以保持正常的空气交换。热换器需受到保护,

并通过支撑托架免受机械振动的影响,需通过软管与PTO相连接。

25 cm

cm 25

m

2 5c

AIR

AIR

AIR

100

180

OIL

OIL OUT OIL IN

D-21H-0-01 - Info Service HY - rev.2

AIR

OIL

Interpump Hydraulics Spa a socio unico - Business Unit Hydrocar

Sede Legale: via A. Mingozzi, 6 • 40012 Calderara di Reno BO - Italy

Sede Operativa: via A. Mingozzi, 6 • 40012 Calderara di Reno BO - Italy • T +39 051 6460511 • F +39 051 6460922 / +39 051 6460923

info@hydrocar.com • hydrocar.com Pag.

Cap. Soc. Euro 2.631.600,00 i.v. • N. Mecc. BO 056383 • R.E.A. BO 444225 • C.F. 00883010241 • P.Iva IT02128140361 3/3

Soggetta ad attività di Direzione e Coordinamento da parte di Interpump Group Spa

You might also like

- SERVICE TOOL CATALOG Carrier TransicoldDocument98 pagesSERVICE TOOL CATALOG Carrier Transicoldgamagg100% (3)

- WSM SVL95-2s RY911-23872Document526 pagesWSM SVL95-2s RY911-23872rajun kajun90% (10)

- SERVICE TOOL CATALOG Carrier Transicold PDFDocument98 pagesSERVICE TOOL CATALOG Carrier Transicold PDFRoberto SalazarNo ratings yet

- 5.12 Bop Es 15MDocument30 pages5.12 Bop Es 15MJavier Rivas50% (2)

- Flash MoteurDocument5 pagesFlash MoteurSofiane SophianeNo ratings yet

- Test Transmision 420E CatDocument8 pagesTest Transmision 420E CatEdin Raul Yalle RafaelNo ratings yet

- Tips - Autodata 1989 90 Carburettor Maunual PDFDocument531 pagesTips - Autodata 1989 90 Carburettor Maunual PDFstoica100% (6)

- Manual de Piezas de 845 Sola PDFDocument1,198 pagesManual de Piezas de 845 Sola PDFJHOVANY MENDIVELSO GOMEZ100% (3)

- Operation & Service Manual: Model: 18-4208-0010 Four Bottle Nitrogen Cart With Booster and Manifold/RegulatorDocument49 pagesOperation & Service Manual: Model: 18-4208-0010 Four Bottle Nitrogen Cart With Booster and Manifold/RegulatorCarlos Alberto Rozo R.No ratings yet

- Centrifugal Chiller - Fundamentals - Energy-ModelsDocument32 pagesCentrifugal Chiller - Fundamentals - Energy-Modelsmat_pranNo ratings yet

- Air Cooled Scroll Chiller Service Manual T1/R407C/50Hz : Gree Electric Appliances Inc. of ZhuhaiDocument58 pagesAir Cooled Scroll Chiller Service Manual T1/R407C/50Hz : Gree Electric Appliances Inc. of ZhuhaiOng MatNo ratings yet

- BT Power Pallet Truck RM LPE200 221609Document204 pagesBT Power Pallet Truck RM LPE200 221609Ko Gyi Kyaw NandaNo ratings yet

- Meganorm KSB CENTRIFUGAL PUMPDocument16 pagesMeganorm KSB CENTRIFUGAL PUMPdimasjosesmithNo ratings yet

- Science-9 q4 Mod5 Heat and WorkDocument20 pagesScience-9 q4 Mod5 Heat and WorkEden Cabarrubias86% (7)

- SPEEDTRONIC MARK VI - Maintenance: Training Manual - Vol IiDocument201 pagesSPEEDTRONIC MARK VI - Maintenance: Training Manual - Vol Iighdjjd100% (6)

- F1 Service ManualDocument14 pagesF1 Service ManualArko Roos100% (1)

- Module 1 Lec 2 - THERMODYNAMICS 2nd QTR SY1112 PDFDocument8 pagesModule 1 Lec 2 - THERMODYNAMICS 2nd QTR SY1112 PDFJason JohnsonNo ratings yet

- SsangYong Kyron Engine Service Repair ManualDocument442 pagesSsangYong Kyron Engine Service Repair ManualJonattan Javier Ramirez Bolaños33% (3)

- Manual de Componente Frenos Lj-25Document156 pagesManual de Componente Frenos Lj-25Oficina TecnicaNo ratings yet

- Checklist For MilkDocument2 pagesChecklist For MilkChetas Patil100% (1)

- Manual RGM5250Document149 pagesManual RGM5250SHIRLEY GIRALDO100% (2)

- 4 Commissioning Report of VRF CassetteDocument4 pages4 Commissioning Report of VRF CassetteMohammed IqbalNo ratings yet

- L223 T3 PartsDocument908 pagesL223 T3 Partskevin100% (3)

- Kiln Performance & Efficiency Formulas (Updated and Completed) - InFINITY For CEMENT EQUIPMENTDocument3 pagesKiln Performance & Efficiency Formulas (Updated and Completed) - InFINITY For CEMENT EQUIPMENTBùi Hắc HảiNo ratings yet

- Curtis CW Series 200 Through 260Document17 pagesCurtis CW Series 200 Through 260robertNo ratings yet

- K102A&BDocument354 pagesK102A&Bmourad saadouNo ratings yet

- 1 Service ManualDocument486 pages1 Service ManualАлександрNo ratings yet

- SB 28-0093 r00Document37 pagesSB 28-0093 r00Mohammad Faraz AkhterNo ratings yet

- DsnetgrossDocument1 pageDsnetgrosskerdelloumajdi28No ratings yet

- Vision Turbine MetersDocument8 pagesVision Turbine MetersLuis BorrazNo ratings yet

- GRH-Flow Dividers and Gear Motors-2023Document26 pagesGRH-Flow Dividers and Gear Motors-2023Hydraulic HieuNo ratings yet

- Heater Unit: Service NotesDocument16 pagesHeater Unit: Service NotesSerge MaciaNo ratings yet

- Condition/Concern: Bulletin No.: PI0631H Date: Apr-2013Document5 pagesCondition/Concern: Bulletin No.: PI0631H Date: Apr-2013Erik CruzNo ratings yet

- Owners ManualDocument20 pagesOwners ManualJavier AffifNo ratings yet

- 02 1K2K 03Document3 pages02 1K2K 03Francisco Wilson Bezerra FranciscoNo ratings yet

- Refrigerant Compressor (SENR5664-35)Document2 pagesRefrigerant Compressor (SENR5664-35)Guido Emanuel SteinbachNo ratings yet

- Lincoln Helios (India) Limited: Operation & Maintenance ManualDocument50 pagesLincoln Helios (India) Limited: Operation & Maintenance Manualprem sagarNo ratings yet

- Renner Rs OverviewDocument12 pagesRenner Rs Overviewmhamad aboalezNo ratings yet

- Fuel System Pressure - Test (SENR9939-32)Document3 pagesFuel System Pressure - Test (SENR9939-32)Guido Emanuel SteinbachNo ratings yet

- Copeland para CogeladoDocument1 pageCopeland para CogeladoAlvaro DiazNo ratings yet

- Boiler Connection Kit Code 073990: For Heat Pump, Split 2 ServicesDocument12 pagesBoiler Connection Kit Code 073990: For Heat Pump, Split 2 ServicesVadimKovaliNo ratings yet

- 469 Manual (v5.0x GEK-106474D)Document264 pages469 Manual (v5.0x GEK-106474D)DAS1300No ratings yet

- Load Sensing Pressure Booster: 1 DescriptionDocument2 pagesLoad Sensing Pressure Booster: 1 DescriptionYazad DoctorrNo ratings yet

- Add Info B-64114EN 01Document13 pagesAdd Info B-64114EN 01tharhtike kyiNo ratings yet

- 14-2755B Cálculo Do BHP IMPDocument21 pages14-2755B Cálculo Do BHP IMPRic LuNo ratings yet

- Manual Quemador 100 HP HurtsDocument118 pagesManual Quemador 100 HP Hurtssthefany whiteNo ratings yet

- Quickmanualschaltventils 9 S 29 Ened 1Document15 pagesQuickmanualschaltventils 9 S 29 Ened 1Dibutec Plaza HuinculNo ratings yet

- Agco Wheeler 2018Document108 pagesAgco Wheeler 2018Josenaldo Freitas SantosNo ratings yet

- Bomb HDR f1Document14 pagesBomb HDR f1Denis Chui MamaniNo ratings yet

- PAT America, Inc.: DS 350GMDocument56 pagesPAT America, Inc.: DS 350GMGoudjil100% (1)

- Bomba NT-2 Ou NT-3...Document3 pagesBomba NT-2 Ou NT-3...Lucas Vinícius CostaNo ratings yet

- TRW Product News 042019 Commercial Vehicles - 1539741Document2 pagesTRW Product News 042019 Commercial Vehicles - 1539741Mathieu DouNo ratings yet

- Differential Pressure Control, Types MP 54, MP 55 and MP 55ADocument8 pagesDifferential Pressure Control, Types MP 54, MP 55 and MP 55AMilosgl100% (1)

- Gassense Ndir Sensor ManualDocument11 pagesGassense Ndir Sensor ManualSửa Thiết BịNo ratings yet

- Norgren Valve Pilot NC PDFDocument4 pagesNorgren Valve Pilot NC PDFLuis Eduardo Albarracin RugelesNo ratings yet

- CM-04&05 Flow MeterDocument10 pagesCM-04&05 Flow MeterPortfolio TrackerNo ratings yet

- Hy ht2000Document277 pagesHy ht2000vulcun6269100% (1)

- Hanbell MPV Valve Spec SheetDocument1 pageHanbell MPV Valve Spec SheetDũng LêNo ratings yet

- PMChecklist ReportDocument3 pagesPMChecklist ReportFiza IlmiNo ratings yet

- Troubleshooting The Fuel Priming and Primary Filter Pump GP and The Fuel Filter Base Assembly (1256, 1258, 1260, 1261, 1263) PDFDocument7 pagesTroubleshooting The Fuel Priming and Primary Filter Pump GP and The Fuel Filter Base Assembly (1256, 1258, 1260, 1261, 1263) PDFNghiaNguyentrungNo ratings yet

- Fan Motor Parket To KybDocument10 pagesFan Motor Parket To Kybcandra ardinataNo ratings yet

- 3011i 3511iENSMRAODocument612 pages3011i 3511iENSMRAOiclaguna6No ratings yet

- Rh31c Zib DatasheetDocument2 pagesRh31c Zib DatasheetWilliam XavierNo ratings yet

- Service Bulletin: AB Volvo PentaDocument3 pagesService Bulletin: AB Volvo Pentaanees ahmedNo ratings yet

- Oil Pressure Regulator: DescriptionDocument2 pagesOil Pressure Regulator: DescriptionM.H.No ratings yet

- New 008 2013 HyDocument2 pagesNew 008 2013 HyРома БлошенкоNo ratings yet

- New 015 2012 HyDocument1 pageNew 015 2012 HyРома БлошенкоNo ratings yet

- New 012 2012 HyDocument1 pageNew 012 2012 HyРома БлошенкоNo ratings yet

- New 017 2012 HyDocument1 pageNew 017 2012 HyРома БлошенкоNo ratings yet

- New 001 2013 HyDocument1 pageNew 001 2013 HyРома БлошенкоNo ratings yet

- New 003 2011 HyDocument3 pagesNew 003 2011 HyРома БлошенкоNo ratings yet

- New 010 2011 HyDocument1 pageNew 010 2011 HyРома БлошенкоNo ratings yet

- New 005 2013 HyDocument1 pageNew 005 2013 HyРома БлошенкоNo ratings yet

- Presentazione SSU-idrostatiche HYDROCARDocument5 pagesPresentazione SSU-idrostatiche HYDROCARРома БлошенкоNo ratings yet

- New 002 2011 HyDocument2 pagesNew 002 2011 HyРома БлошенкоNo ratings yet

- New 002 2012 HyDocument1 pageNew 002 2012 HyРома БлошенкоNo ratings yet

- Sub 125 (895098)Document1 pageSub 125 (895098)Рома БлошенкоNo ratings yet

- New 011 2012 HyDocument1 pageNew 011 2012 HyРома БлошенкоNo ratings yet

- Technical Data Sheets Recommendations: WWW - ABER.ptDocument13 pagesTechnical Data Sheets Recommendations: WWW - ABER.ptРома БлошенкоNo ratings yet

- Sub 100 (890656)Document1 pageSub 100 (890656)Рома БлошенкоNo ratings yet

- Aft-Catalog s1 SecDocument34 pagesAft-Catalog s1 SecРома БлошенкоNo ratings yet

- Ahs Truck Gear PumpDocument1 pageAhs Truck Gear PumpРома БлошенкоNo ratings yet

- 01-7 Ge3k 2017 3Document4 pages01-7 Ge3k 2017 3Рома БлошенкоNo ratings yet

- Axial Piston Pump ABERDocument32 pagesAxial Piston Pump ABERРома БлошенкоNo ratings yet

- 01-1 Gem 2017 2Document4 pages01-1 Gem 2017 2Рома БлошенкоNo ratings yet

- 01-4 - Ge2 HC - 2017 - 3Document4 pages01-4 - Ge2 HC - 2017 - 3Рома БлошенкоNo ratings yet

- Mannesmann Rexroth Uchebnyy Kurs Po Gidravlike Tom 3 C4593d8f5e7Document372 pagesMannesmann Rexroth Uchebnyy Kurs Po Gidravlike Tom 3 C4593d8f5e7Рома БлошенкоNo ratings yet

- WK 420 970 Directional Spool Valve Electrically Operated Type WE6 Series 32Document22 pagesWK 420 970 Directional Spool Valve Electrically Operated Type WE6 Series 32Рома БлошенкоNo ratings yet

- Pump Drawing With Motor Flange MountedDocument2 pagesPump Drawing With Motor Flange MountedРома БлошенкоNo ratings yet

- WK 499 482 Directional Spool Valve Type WEH16 Electro-Hydraulically OperatedDocument24 pagesWK 499 482 Directional Spool Valve Type WEH16 Electro-Hydraulically OperatedРома БлошенкоNo ratings yet

- Midland Gear Pumps Phase 1Document5 pagesMidland Gear Pumps Phase 1Рома БлошенкоNo ratings yet

- Oleodinamica M 25 32 EngDocument9 pagesOleodinamica M 25 32 EngРома БлошенкоNo ratings yet

- WK 421 180 Directional Spool ValvesDocument18 pagesWK 421 180 Directional Spool ValvesРома БлошенкоNo ratings yet

- C Adaptors BSPDocument44 pagesC Adaptors BSPРома БлошенкоNo ratings yet

- WK 496 480 Subplates Type G Nominal Size 6: Ns6 32 MpaDocument4 pagesWK 496 480 Subplates Type G Nominal Size 6: Ns6 32 MpaРома БлошенкоNo ratings yet

- Reacting Mixtures and CombustionDocument53 pagesReacting Mixtures and CombustionGerman GiraudoNo ratings yet

- Est120 QPDocument3 pagesEst120 QPOwsu KurianNo ratings yet

- AE4-1135 R18 Cooling Requirements For Copelametic and Copeland Discus Compressors AE4-1135 R19 August 2012Document4 pagesAE4-1135 R18 Cooling Requirements For Copelametic and Copeland Discus Compressors AE4-1135 R19 August 2012Masoud KarimiNo ratings yet

- Aet Model QN PaperDocument5 pagesAet Model QN PaperJagadishRajNo ratings yet

- Example 11 RefrigerationDocument3 pagesExample 11 RefrigerationSantosh RathodNo ratings yet

- Air Conditioning 1Document23 pagesAir Conditioning 1Cornel IordacheNo ratings yet

- ME2121 - ME2121E Slides Chapter 1 (2014)Document13 pagesME2121 - ME2121E Slides Chapter 1 (2014)FlancNo ratings yet

- MATE 152-24 Lec 2Document25 pagesMATE 152-24 Lec 2andrew.dungoNo ratings yet

- Calorimetry (Pre-Laboratory Assignment)Document4 pagesCalorimetry (Pre-Laboratory Assignment)Quirino Arzadon IVNo ratings yet

- Some Innovative Drying Technologies For Dehydration of Foods PDFDocument11 pagesSome Innovative Drying Technologies For Dehydration of Foods PDFhari.suryanto8417100% (1)

- DY150Document216 pagesDY150Armando Castro FloresNo ratings yet

- TEMA 2 ACT 2 PROBLEMARIO Balance de MomentumDocument1 pageTEMA 2 ACT 2 PROBLEMARIO Balance de MomentumMichelleNo ratings yet

- Thermal Bridges in Building Construction - 2D Composite StructureDocument10 pagesThermal Bridges in Building Construction - 2D Composite Structureashraf-84No ratings yet

- Peter Atkins Julio de Paula Ron Friedman Physical Chemistry Quanta (0715-0765)Document51 pagesPeter Atkins Julio de Paula Ron Friedman Physical Chemistry Quanta (0715-0765)Administracion OTIC IVICNo ratings yet

- Stulz Cyberair 3pro DX Asr Brochure 1805 enDocument12 pagesStulz Cyberair 3pro DX Asr Brochure 1805 enMudassar Idris RautNo ratings yet

- Chemical Engineering Thermodynamics Project-I: TopicDocument11 pagesChemical Engineering Thermodynamics Project-I: TopicRohit GuptaNo ratings yet

- Process Safety Formula SheetDocument4 pagesProcess Safety Formula SheetKumaravel PadmaroopaNo ratings yet

- Distillation Theory of Pentane and HexaneDocument4 pagesDistillation Theory of Pentane and HexaneKeshab PradhanNo ratings yet

- Damascus University Telecommunication Subject DescriptionDocument19 pagesDamascus University Telecommunication Subject DescriptionfearfreesNo ratings yet

- Study of Thermal Properties of Jute and Hollow Conjugated Polyester Fibre Reinforced Non-Woven CompositeDocument19 pagesStudy of Thermal Properties of Jute and Hollow Conjugated Polyester Fibre Reinforced Non-Woven CompositeGulam RasoolNo ratings yet

- 1st-IIR-use of Ammonia Co2 Heat Pump in FoodDocument18 pages1st-IIR-use of Ammonia Co2 Heat Pump in FoodBehnam AshouriNo ratings yet

- Ppe / Ipe: Final CoachingDocument331 pagesPpe / Ipe: Final CoachingMark Joseph Nambio NievaNo ratings yet

- Study of The Heat Transfer in Countercurrent and Parallel Flow ConditionDocument7 pagesStudy of The Heat Transfer in Countercurrent and Parallel Flow ConditionDương Ngọc TúNo ratings yet