Professional Documents

Culture Documents

Groen BPM 40gc - Specsheet 22110493fpmv

Groen BPM 40gc - Specsheet 22110493fpmv

Uploaded by

deni putraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Groen BPM 40gc - Specsheet 22110493fpmv

Groen BPM 40gc - Specsheet 22110493fpmv

Uploaded by

deni putraCopyright:

Available Formats

PROJECT NAME:

LOCATION:

ITEM NO:

TILTING BRAISING PAN QTY:

MODEL NO:

GAS MODELS BPM-30/40GC/GA/GC2T AIA NO:

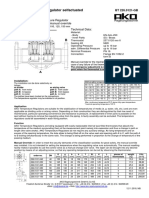

Braising pan shall be a Groen gas heated manual tilting BPM Series (specify 30 or 40 gallon, Classic (C), SIS NO:

Advanced (A) or Cook2Temp™ (C2T™) controls) model with 10” deep pan body with 3” radius corners, 5/8”

CSI SECTION:

thick stainless steel clad cooking surface mounted on open leg stand with height-adjustable bullet feet.

CookTemp models also come with a probe.

AVAILABLE MODELS: CONTROLS: All controls to be located in a right-front

CLASSIC CONTROLS: mounted water resistant (IPX6 rated) enclosure:

BPM-30GC (30 GALLON) Classic -C Models include: Power ON-OFF switch with

BPM-40GC (40 GALLON) indicator light, temperature control knob with 175 to 400°F

ADVANCED CONTROLS: (79 to 204°C) range increments and HEAT(ing) indicator light;

BPM-30GA (30 GALLON) Advanced -A Models include: Same control features as

BPM-30GA Model shown

BPM-40GA (40 GALLON) Classic models with the addition of temperature and time set

COOK2TEMP CONTROLS: knob (175 to 400°F/79 to 204°C range), LED display of set

BPM-30GC2T (30 GALLON) temperature or cook time, buttons for reset of Low Temp and

OPTIONS/ACCESSORIES:

BPM-40GC2T (40 GALLON) High Temp presets, MANUAL mode button for knob-setting of

Single pantry water fill faucet

pan temperature, and TIMER-set button with indicator light;

Double pantry water fill faucet

CONSTRUCTION: The pan body shall be of type 304 Cook2Temp -C2T Models include: Same control features as

Single or double pantry faucet with

stainless steel, solid one-piece welded heavy-duty construction, Classic and Advanced models with the addition of Auto C2T

spray hose assembly (48” or 60”)

with 10” pan depth. All exposed surfaces shall be stainless steel. and Manual C2T buttons with core probe connection port,

Steamer pan carrier

The cooking surface is a heavy 5/8” thick stainless steel clad MANUAL mode button for knob-setting of pan temperature for

2” tangent drawoff valve (option:

plate with specially designed welded heat transfer fins, heated by manual cooking and manual C2T cooking.

must be ordered with unit)

the gas burner/combustion chamber. This combination delivers

Strainer for tangent draw-off valve

more uniform heat transfer over the entire cooking surface. PERFORMANCE FEATURES: Braising pan Gas quick disconnect

The heavy plate prevents warping or distortion. Controls and tilt shall be equipped with controls that allow operation at 7 Caster kit w/restraint cable

mechanism are mounted in a stainless steel water resistant IPX6 degree angle to facilitate griddling. Braising pan shall be Flanged feet

rated housing at the right side of the pan body. Braising pan shall thermostatically-controlled for automatic shut- off when Pouring lip strainer

come standard with a mounting bracket for either right-side, left- desired temperature is reached and automatic power ON Steamer pan inserts

side or right-rear faucet mounting. Graduated fill-level marks in when temperature falls below desired setting. BPM-30GC Replacement core probe

both gallons and liters are standard. and 30GA Models have a firing rate of 104,000 BTU/ (on C2T models only)

hr. BPM-40GC and -40GA Models have a firing rate of

FINISH: Interior of braising pan shall be polished to a 100 144,000 BTU/hr. Electronic intermittent pilot ignition system

emery grit finish on C/A models, 180 emergy grit on C2T is standard. Braising pans have high limit thermostat as a

models. Exterior of braising pan shall have a #3 finish, ensuring safety feature.

maximum ease in cleaning and maintaining appearance.

INSTALLATION: Unit requires 1/2” NPT gas

CSA DESIGN CERTIFICATION: Braising pan connection. Requires 115 Volt, single-phase, 60 HZ, 5 AMP

shall be design-certified by CSA International (formerly AGA) for electric supply.

use with Natural Gas or LP Gas.

ORIGIN OF MANUFACTURE: Designed and

SANITATION & NSF LISTING: Braising pan manufactured in the United States.

shall be designed and constructed to be NSF listed, meeting all

known health department and sanitation codes. True open leg

tubular design and 3” radius pan interior make cleaning easier.

MANUAL TILT: The braising pan shall have a smooth-

action, quick-tilting body with manual crank and worm-and-

gear tilt mechanism, which provides precise control during

pouring. Pan body shall tilt to vertical in 24 turns and past Braising Pan

vertical to assist in cleaning. 175751 RevC

Revised 04/19

BPM-30/40GC/GA/GC2T

P/N 146195 REV G

CL AS S IC C ON TR OL

AD VAN C E D C ON TR OL

CO O K2 TE M P C ON TR OL

888-994-7636, unifiedbrands.net

© 2019 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary of Dover Corporation.

You might also like

- Byc 8.5-17 TonDocument28 pagesByc 8.5-17 TonMike Zeller100% (1)

- m43 Aux. BoilerDocument657 pagesm43 Aux. BoilerPavel PaskarNo ratings yet

- Pharmacology HandoutDocument5 pagesPharmacology HandoutMark Elben Teodoro100% (1)

- Cook/Chill Gas Horizontal Agitator Stationary Mixer Kettles: Cleveland RangeDocument2 pagesCook/Chill Gas Horizontal Agitator Stationary Mixer Kettles: Cleveland RangeLuxoAlexisArayaNo ratings yet

- Especificaciones Marmita f-20gl PDFDocument2 pagesEspecificaciones Marmita f-20gl PDFPitter M Montilla NNo ratings yet

- Groen (2) SSB-10GF SteamerDocument2 pagesGroen (2) SSB-10GF Steamerwsfc-ebayNo ratings yet

- Quinta Pro Range Suggested Schematics PDFDocument32 pagesQuinta Pro Range Suggested Schematics PDFAnonymous CRQ100No ratings yet

- Tehniƒki Opis 230, 231, 232, 233, 234, 237Document8 pagesTehniƒki Opis 230, 231, 232, 233, 234, 237Dejan DosljakNo ratings yet

- Technical Data Manual: Vitodens 100-WDocument32 pagesTechnical Data Manual: Vitodens 100-WRed SquerrelNo ratings yet

- Groen (2) SSB-5GF SteamerDocument2 pagesGroen (2) SSB-5GF Steamerwsfc-ebayNo ratings yet

- Fulton Vantage Technical DataDocument6 pagesFulton Vantage Technical DatajrodNo ratings yet

- Lennox Serial Number NomenclatureDocument13 pagesLennox Serial Number NomenclatureRichard Johnson100% (2)

- Cast-Iron Boiler For Jet Burner: AdvantagesDocument2 pagesCast-Iron Boiler For Jet Burner: AdvantagesVlad Stefan CristianNo ratings yet

- Vitotrans 300 TDMDocument28 pagesVitotrans 300 TDMradusettNo ratings yet

- Carte Tehnica Centrala Termica Immergas Eolo Star 23Document12 pagesCarte Tehnica Centrala Termica Immergas Eolo Star 23Adrian BasteaNo ratings yet

- !!! IMMERGAS - Eolo-Star-23-KwDocument12 pages!!! IMMERGAS - Eolo-Star-23-Kwwiking777No ratings yet

- Manual Termostato Digitall t6812 FancoilDocument4 pagesManual Termostato Digitall t6812 FancoilaarroyofNo ratings yet

- Closed Cooling Water SystemDocument29 pagesClosed Cooling Water Systemrahul_choubey_9100% (1)

- Reflex Variomat Giga Hydraulic, GH 70, Hydraulic Module Article-No.:8932000Document1 pageReflex Variomat Giga Hydraulic, GH 70, Hydraulic Module Article-No.:8932000darinnavilNo ratings yet

- Heatpac CBM Emd00439enDocument2 pagesHeatpac CBM Emd00439enMuhd Khir RazaniNo ratings yet

- Two Stage Heavy Oil Burners: Press N SeriesDocument9 pagesTwo Stage Heavy Oil Burners: Press N SeriesfacturistNo ratings yet

- AKO Temperature Regulator SelfactuatedDocument1 pageAKO Temperature Regulator SelfactuatedsudhirNo ratings yet

- SVW 12 1000kW 41000 To 3412000 BtuhDocument2 pagesSVW 12 1000kW 41000 To 3412000 BtuhAmber ChavezNo ratings yet

- 122 HRDocument2 pages122 HRWahid Mbelo WahidinNo ratings yet

- HM Technical File enDocument44 pagesHM Technical File enJosé MacedoNo ratings yet

- Closed Cooling Water SystemDocument29 pagesClosed Cooling Water Systemrahul ranaNo ratings yet

- Model 65C+ Gas Fryer: Models AvailableDocument2 pagesModel 65C+ Gas Fryer: Models AvailableAle DE LA ParraNo ratings yet

- Mitsubishi - Aux Boiler 1Document14 pagesMitsubishi - Aux Boiler 1Deepak GawdeNo ratings yet

- Groen SSB 3G GF SteamerDocument2 pagesGroen SSB 3G GF Steamerwsfc-ebayNo ratings yet

- Vitodens 200-B2HA SM TDMDocument60 pagesVitodens 200-B2HA SM TDMctlbdorinNo ratings yet

- Vitocrossal 200-cm2 SM gw6b TDMDocument16 pagesVitocrossal 200-cm2 SM gw6b TDMCiprian BalcanNo ratings yet

- Cazane Fonta Arzator Atmosferic Sime Rs MK 2 Manual Utilizare Date TehniceDocument5 pagesCazane Fonta Arzator Atmosferic Sime Rs MK 2 Manual Utilizare Date TehniceRadu LucaNo ratings yet

- T6811/6812 Series Digital Thermostat: 2-Pipe Fan Coil ControlDocument4 pagesT6811/6812 Series Digital Thermostat: 2-Pipe Fan Coil ControlCristobal Alejandro Zuñiga CervantesNo ratings yet

- Turbine & AuxilariesDocument64 pagesTurbine & Auxilariesulhatolkargmailcom100% (1)

- HD15002E1C Pressure WasherDocument1 pageHD15002E1C Pressure WashercfadamNo ratings yet

- Baltur TBL85 PDocument2 pagesBaltur TBL85 Ptonkatsu25No ratings yet

- Catalogo PDFDocument8 pagesCatalogo PDFantonio_avanci100% (1)

- Wall-Hung Gas Boilers: EnglishDocument12 pagesWall-Hung Gas Boilers: EnglishwefeNo ratings yet

- Easco Suggested SpecDocument7 pagesEasco Suggested SpecMomar Talla DiawNo ratings yet

- Flash Tank Heat Recovery Boiler BookDocument6 pagesFlash Tank Heat Recovery Boiler Bookfauzi endraNo ratings yet

- Groen CBE-10G Combi OvenDocument8 pagesGroen CBE-10G Combi Ovenwsfc-ebayNo ratings yet

- BOWMAN - Exhaust Gas Heat ExchangerDocument8 pagesBOWMAN - Exhaust Gas Heat Exchangerryan pratiktoNo ratings yet

- Technical Data Manual: Model Nos. and Pricing: See Price ListDocument36 pagesTechnical Data Manual: Model Nos. and Pricing: See Price ListJulija RazmislavičienėNo ratings yet

- ThermoelectricDocument6 pagesThermoelectricsyNo ratings yet

- Fisa Tehnica Cazan in Condensatie C230 PDFDocument16 pagesFisa Tehnica Cazan in Condensatie C230 PDFGabriyelNo ratings yet

- Reversible Air/water Split Heat Pump: DescriptionDocument11 pagesReversible Air/water Split Heat Pump: DescriptionPolixenia StangaNo ratings yet

- Optima Thermostat: ST880ZB / ST880ZBPBDocument2 pagesOptima Thermostat: ST880ZB / ST880ZBPBVitoNo ratings yet

- Technical Data Manual: Model Nos. and Pricing: See Price ListDocument32 pagesTechnical Data Manual: Model Nos. and Pricing: See Price ListMINYAN GUINo ratings yet

- Vivadens MCR: Wall-Hung Gas Condensing BoilersDocument12 pagesVivadens MCR: Wall-Hung Gas Condensing BoilersIsmael Llamelo PerezNo ratings yet

- Blue Box Zeta2002 Manual4Document14 pagesBlue Box Zeta2002 Manual4Carlos MartinezNo ratings yet

- Sterling PumpeDocument20 pagesSterling PumpesrdzaNo ratings yet

- Auxilary BoilerDocument14 pagesAuxilary Boileraliswatch100% (2)

- Groen SSB-10EF SteamerDocument2 pagesGroen SSB-10EF Steamerwsfc-ebayNo ratings yet

- 30GN130-420 Flotronic™ Ii Air-Cooled Chillers: - Performance Data - Certified Dimension Print - Field Wiring DiagramDocument13 pages30GN130-420 Flotronic™ Ii Air-Cooled Chillers: - Performance Data - Certified Dimension Print - Field Wiring DiagramBJNE01No ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Gasoline and Oil Stoves, "New Process" and "Standard." 1901From EverandGasoline and Oil Stoves, "New Process" and "Standard." 1901No ratings yet

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesFrom EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesRating: 1 out of 5 stars1/5 (2)

- Handbook of Heating, Ventilating and Air ConditioningFrom EverandHandbook of Heating, Ventilating and Air ConditioningRating: 4 out of 5 stars4/5 (6)

- B07800XXX - Pneumatic Detection TubeDocument1 pageB07800XXX - Pneumatic Detection Tubedeni putraNo ratings yet

- R. It HallDocument12 pagesR. It Halldeni putraNo ratings yet

- Monitoring Switch 029905206 (With Cable) R01Document1 pageMonitoring Switch 029905206 (With Cable) R01deni putraNo ratings yet

- Check Valve B04600008Document1 pageCheck Valve B04600008deni putraNo ratings yet

- Electromagnetic Release Device Mini PN B04425148, B04425149Document2 pagesElectromagnetic Release Device Mini PN B04425148, B04425149deni putraNo ratings yet

- The NGMA ART JOURNALDocument55 pagesThe NGMA ART JOURNALAvik JanaNo ratings yet

- Greenhouse - Gas - Basics, Michigan S UDocument2 pagesGreenhouse - Gas - Basics, Michigan S ULiam LagwedNo ratings yet

- Proposed Cavite Institute of Research, DesignDocument30 pagesProposed Cavite Institute of Research, DesignGilbert JavierNo ratings yet

- Representations of Prisons in Contemporary French PhotographyDocument121 pagesRepresentations of Prisons in Contemporary French PhotographyMelinda HawtinNo ratings yet

- Dynamics of Rigid Bodies: Work and EnergyDocument11 pagesDynamics of Rigid Bodies: Work and EnergyJancis TugadeNo ratings yet

- Kosto Lens Cleaning ToweletteDocument9 pagesKosto Lens Cleaning TowelettePubcrawlNo ratings yet

- Arduino BreadBoard Advance Kit User Guide v2.1Document23 pagesArduino BreadBoard Advance Kit User Guide v2.1ic3_2kNo ratings yet

- Wine Storage AdviceDocument1 pageWine Storage AdvicepeterlimttkNo ratings yet

- Profile 2Document1 pageProfile 2api-314646235No ratings yet

- God Is Dead - Final ExamDocument2 pagesGod Is Dead - Final ExamdipugeoNo ratings yet

- 2 Prod Assignment 5Document2 pages2 Prod Assignment 5Mohamed GamalNo ratings yet

- 1 - 4 Introduction To QualityDocument87 pages1 - 4 Introduction To Qualityjunita guiNo ratings yet

- Labor Code Art 156-167Document29 pagesLabor Code Art 156-167Charlotte GallegoNo ratings yet

- Products Spec IBMDocument5 pagesProducts Spec IBMAmatơ Hà ThànhNo ratings yet

- Open GL Macos X Objective CDocument183 pagesOpen GL Macos X Objective Cराहुल कुमारNo ratings yet

- BK291 PDFDocument104 pagesBK291 PDFAqua SamaNo ratings yet

- How To Reset The Vcenter Server Appliance Root Password - Virtualhome - BlogDocument4 pagesHow To Reset The Vcenter Server Appliance Root Password - Virtualhome - BlogAdolfo Javier Acevedo RomeroNo ratings yet

- Marine Engineering Reference To Marina Exam QuestionnairreDocument5,156 pagesMarine Engineering Reference To Marina Exam QuestionnairrePaul Gerald DelgadoNo ratings yet

- BTEC Firsts in Animal Care L2Document266 pagesBTEC Firsts in Animal Care L2mrthumbNo ratings yet

- Industrial Hemp Business ProspectDocument22 pagesIndustrial Hemp Business ProspectVipul ShahNo ratings yet

- Karen Robards Green EyesDocument200 pagesKaren Robards Green Eyesmalik_pooja100% (1)

- Human Resource ManagementDocument23 pagesHuman Resource ManagementAbrar Ul HaqNo ratings yet

- Value of Market ResearchDocument3 pagesValue of Market ResearchTejaswini MishraNo ratings yet

- Marketing - Nature & ScopeDocument5 pagesMarketing - Nature & ScopeDIVINE INSTITUTE OF MANAGEMENT & STUDIESNo ratings yet

- Prestress Losses IRC 112-2011Document2 pagesPrestress Losses IRC 112-2011naveen srinivasNo ratings yet

- Susd 2022-024 Building Permit and or Ancillary Permits RequirementsDocument1 pageSusd 2022-024 Building Permit and or Ancillary Permits RequirementsNeraiza Lyn LumanglasNo ratings yet

- Stage 1 Academic Appeal FormDocument5 pagesStage 1 Academic Appeal FormNareinthirran KirushiraamNo ratings yet

- Presented by Abby Liew May Xing ID 002T4120 Progress PresentationDocument47 pagesPresented by Abby Liew May Xing ID 002T4120 Progress PresentationABBY LIEW MAY XINGNo ratings yet