Professional Documents

Culture Documents

Concrete Technology

Uploaded by

Raghavi S.ROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Concrete Technology

Uploaded by

Raghavi S.RCopyright:

Available Formats

CONCRETE & SOIL TESTING PRACTICE

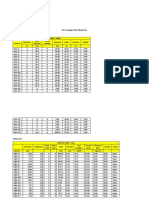

Marks for Marks for

Course No. of Total no.

Course title Formative Summative

code period/week of periods

Assessment Assessment

Concrete & Soil

C-407 04 60 40 60

Testing Practice

S. No. No. of COs

Major Topics

Periods Mapped

1. Tests on Aggregates 16 CO1

2. Tests on Concrete 20 CO2

3. Non-Destructive Tests 8 CO3

4. Tests on Soils 16 CO4

Total 60

LEARNING OUTCOMES

1.0 Tests on Aggregate

1.1 Specific Gravity of Fine and coarse aggregate

Study the importance of the specific gravity of fine and coarse aggregate

State the range of specific gravity values for various naturally available fine and coarse aggregate

Use the apparatus required for conducting specific gravity tests on both fine and coarse aggregate

Perform the specific gravity tests for both fine and coarse aggregate

1.2 Impact value of coarse aggregate

Study the significance of t h e impact value of aggregate used for road construction

State the standards on the impact value of aggregate used for various civil engineering works as per IS-383

Use the apparatus required for conducting an impact test on aggregate

State the procedure for preparing the sample and no. of samples required for the given work

Explain the procedure for conducting an impact test on aggregate

Perform an impact test on a given sample of coarse aggregate

Draw inferences by conducting impact tests on different types of natural aggregate

1.3 Crushing value of coarse aggregate

Study the significance of the crushing value of aggregate used for various civil engineering works

State the standards on t h e crushing value of aggregate used for various civil engineering works as per IS-

383

Use the apparatus required for conducting a crushing test on aggregate

State the procedure for preparing the sample and no. of samples required for the given work

Explain the procedure for conducting a crushing test on aggregate

Perform a crushing test on a given sample of coarse aggregate

Draw inferences by conducting crushing tests on different types of natural aggregate

1.4 Abrasion value of coarse aggregate

Study the significance of the abrasion value of aggregate used for various civil engineering works

State the standards on the abrasion value of aggregate used for various civil engineering works as per IS-

383

Use the apparatus required for conducting an abrasion test on aggregate

State the procedure for preparing the sample and no. of samples required for the given work

Explain the procedure for conducting an abrasion test on aggregate

Perform an abrasion test on a given sample of coarse aggregate

Draw inferences by conducting abrasion tests on different types of natural aggregate

1.5 Flakiness Index of coarse aggregate

Study the significance of t h e flakiness index of aggregate on t h e strength and workability properties of

concrete

State the standards on the flakiness index of aggregate

Use the apparatus required for conducting t h e flakiness index of coarse aggregate

Explain the procedure for conducting the flakiness index test on coarse aggregate

Determine the flakiness index of a given sample of coarse aggregate

1.6 Elongation Index of coarse aggregate

Study the significance of the elongation Index of aggregate on the strength and workability properties of

concrete

State the standards on the elongation Index of aggregate

Use the apparatus required for conducting the elongation Index of coarse aggregate

Explain the procedure for conducting the elongation Index test on coarse aggregate

Determine the flakiness index of a given sample of coarse aggregate

2.0 Tests on concrete

Determine the suitability of fresh and hardened concrete for the given conditions of workability and

strength

Study the importance of workability on strength properties of concrete

State various types of tests used for measuring the workability of fresh concrete

State standards on t h e workability of concrete used for different places of construction work

2.1 Slump cone test

Use the apparatus required for conducting a slump test

Explain the procedure for conducting a slump test of workability

Perform a slump test on the concrete made of the given sample of ingredients

Draw inference from test results on slump test of workability of concrete made with

coarse aggregate having different elongation index

Draw inference from test results on slump test of workability of concrete made with

coarse aggregate having different flakiness index

Compare the slumps of concrete made with gap-graded coarse aggregate and well-

graded coarse aggregate

Study the changes in workability with different water-cement ratios

Study the changes in workability by adding dry cement to poorly workable concrete

2.2 Compaction factor test

State the purpose of the compaction of concrete

Use the apparatus required for conducting the compaction factor test

Explain the procedure for conducting a compaction factor test of workability

Perform a compaction factor test on the concrete made of the given sample of

ingredients

Draw inference from test results on compaction factor test of workability of concrete

made with coarse aggregate having different elongation index values

Draw inference from test results on compaction factor test of workability of concrete

made with coarse aggregate having different flakiness index values

Compare the compaction factors of concrete made with gap-graded coarse

aggregate and that made with well-graded coarse aggregate

Study the changes in the compaction factor of a poorly workable concrete by

admixtures

Study the methods of enhancing t h e workability of concrete without using any

admixtures

2.3 Casting of Cement concrete cubes

Study the purpose of the casting of concrete cubes

Use equipment required for the casting of cement concrete cubes

Explain the procedure for casting concrete cubes

Cast the concrete cubes with the given ingredients

2.4 Testing of cement concrete cubes for compression

Study the importance of testing concrete cubes

Use equipment required for conducting compression test concrete cubes

State the precautions to be taken for testing concrete cubes

Explain the procedure for conducting compression tests on concrete cubes

Draw inference from test results on compressive strength of concrete cubes made

with coarse aggregate having different elongation index values

Draw inference from test results on compressive strength of concrete cubes made

with coarse aggregate having different flakiness index values

Compare the compressive strengths of concrete cubes of concrete made with gap-

graded coarse aggregate and those made with well-graded coarse aggregate

Compare the compressive strengths of concrete cubes made and cured with potable

water and concrete cubes made and cured with non-potable water

2.5 Split Tensile Strength of Concrete

Study the importance of split tensile strength of concrete

Cast the concrete cylinders with the given ingredients

Explain the procedure for conducting a split tensile strength test on concrete

cylinders

Perform split tensile strength test on concrete cylinder

2.6 Design mix of concrete proportion as per IS: 10262 – 2009

Study the various elements of the design mix of concrete as per IS:10262-2009

Conduct tests to find specific gravity, bulk density, and sieve analysis of aggregate

for the preparation of the design mix of concrete

Write the procedure for design mixing of concrete

Calculate the proportions of ingredients of concrete as per IS:10262-2009

Cast cubes of trail mix to decide the proportion of concrete

Perform the compression tests on concrete cubes cast as per the design mix

3.0 Non-Destructive Tests on Concrete

State the importance of non-destructive tests

State the apparatus/equipment required for the non-destructive tests

Explain the procedure for conducting non-destructive tests

Perform non-destructive tests like Rebound hammer tests and ultrasonic tests on the

given hardened concrete

Record the observations of tests

Draw the inferences from the test results

4.0 Tests on Soils

4.1 Sieve Analysis – Classification of soil

Study the classification of various types of soils

Use apparatus required for conducting sieve analysis of soils

Explain the procedure for conducting sieve analysis of soils

Perform sieve analysis over a given soil sample

4.2 Atterberg Limits of Soil

Study the significance of Atterberg limits of soil in civil engineering activities

Study Atterberg limits of soils

Use apparatus required for conducting tests to determine Atterberg limits of soil

Explain the procedure for conducting (a) Liquid Limit (b) Plastic Limit (c) Shrinkage

Limit tests

Perform Limit Test, Plastic Limit Test & Shrinkage Limit Test over a given sample of

soil

Compare the observations of tests conducted on different types of soils.

Calculate the Plasticity Index value of a given soil sample from the observations of the test

Classify t h e given soil sample based on sieve analysis and Atterberg limits

4.3 Field Density of Soil (Sand Replacement Method)

Study the significance of field density of soil

Use the apparatus required for conducting field density of soil

Explain the procedure for conducting field density test on t h e soil by sand replacement method

Perform field density test of soil by sand replacement method

4.4 Proctor Compaction Test

Study the significance of the proctor compaction test

Use the apparatus required for conducting Proctor’s compaction test

Explain the procedure for conducting the Proctor compaction test

Perform a Proctor compaction test over a given sample of soil

Compare the observations of tests conducted on different types of soils

Draw the graph for Proctor’s compaction test

Calculate the values of OMC and MDD of the given soil sample from the observations

of the test

LIST OF EXPERIMENTS

S. No Experiment Title

1 Specific Gravity of fine and coarse aggregate, Impact value of coarse aggregate

2 Crushing value of coarse aggregate, Abrasion value of coarse aggregate

3 Flakiness index of coarse aggregate, Elongation index of coarse aggregate

4 Workability test by Slump Cone Test, Workability test by Compaction factor test

5 The casting of Cement concrete cubes, Testing of Cement concrete cubes for compression

Split tensile strength of concrete, Design mix of concrete proportion

6

7 Surface hardness of concrete by Rebound hammer test, Ultrasonic Test

8 Sieve analysis-classification of soil, Atterberg Limits

9 Field density of soil by sand replacement method, Proctor Compaction Test

List of Equipment Required:

1. Aggregates

2. Pychno Meter

3. Slump Cone

4. Cement

5. Moulds

6. Rebound hammer

7. Soil

8. Tampering rod

9. Core cutter

10. Sand replacement cone

11. Square Plate

You might also like

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- IIIC-KILA-KSRDA-QC Lab ManualDocument156 pagesIIIC-KILA-KSRDA-QC Lab ManualAmeen PattuparaNo ratings yet

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemNo ratings yet

- Investigation of building collapse in AbujaDocument15 pagesInvestigation of building collapse in AbujaEmeso OjoNo ratings yet

- 03300Document27 pages03300uddinnadeemNo ratings yet

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- Is-516 4 PDFDocument20 pagesIs-516 4 PDFAnuradhaPatraNo ratings yet

- Draft Indian Standard: Bureau of Indian StandardsDocument9 pagesDraft Indian Standard: Bureau of Indian StandardsPavan KumarNo ratings yet

- Is 14893 2001Document14 pagesIs 14893 2001Ashokan KelothNo ratings yet

- NDTDocument35 pagesNDTningshaNo ratings yet

- Is 516 Part 1 Section 1Document19 pagesIs 516 Part 1 Section 1devendra choudhary80% (5)

- Non-Destructwetestingof Concrete-Methodsoftest: Indian StandardDocument9 pagesNon-Destructwetestingof Concrete-Methodsoftest: Indian Standard510418040 SWARNENDUMONDALNo ratings yet

- Compression Strength 100mm Vs 150mm CubesDocument35 pagesCompression Strength 100mm Vs 150mm CubesBurberrybunnyNo ratings yet

- Asset Management Guide Specs - 2004 Csi Format (Div 01-33) Guide Spec - 2004 Csi Format Division 32 Exterior Improvements 32 1343 Pervious Concrete Pavement 120726Document12 pagesAsset Management Guide Specs - 2004 Csi Format (Div 01-33) Guide Spec - 2004 Csi Format Division 32 Exterior Improvements 32 1343 Pervious Concrete Pavement 120726Muhamad Hafid ANo ratings yet

- Report On: Tribhuvan UniversityDocument48 pagesReport On: Tribhuvan UniversityNiroj MaharjanNo ratings yet

- Pile Foundation Casti in PlaceDocument4 pagesPile Foundation Casti in PlaceDavid WrightNo ratings yet

- Airport Soil Investigation and EvaluationDocument4 pagesAirport Soil Investigation and Evaluationjassim mohammed100% (1)

- P1.1 Prinsip Pengujian Agregat Untuk JalanDocument15 pagesP1.1 Prinsip Pengujian Agregat Untuk Jalansaphire janeNo ratings yet

- An Evaluation of Concrete Compressive Strength Using Computer Tomography Scan MethodDocument10 pagesAn Evaluation of Concrete Compressive Strength Using Computer Tomography Scan Methodindian royalNo ratings yet

- Concrete 70TMSS03R1Document38 pagesConcrete 70TMSS03R1azeemmet9924No ratings yet

- Specifications For Reinforced Cast-In-Place ConcreteDocument34 pagesSpecifications For Reinforced Cast-In-Place ConcreteDaniel WismanNo ratings yet

- Concrete and Highway Materials: Dayananda Sagar College of EngineeringDocument48 pagesConcrete and Highway Materials: Dayananda Sagar College of EngineeringPrerana TvNo ratings yet

- Is 516 Part 4Document20 pagesIs 516 Part 4nagarjunareddyNo ratings yet

- N' +HÑR Oaqøhv Ijh (K.K I FR K¡: HKKJRH EkudDocument20 pagesN' +HÑR Oaqøhv Ijh (K.K I FR K¡: HKKJRH EkudTsc TechnoNo ratings yet

- Matecconf rsp2018 02045 PDFDocument8 pagesMatecconf rsp2018 02045 PDFnikola1popovi1No ratings yet

- Accelerated carbonation test methodDocument12 pagesAccelerated carbonation test methodMaulik PanseriyaNo ratings yet

- RKTK Oaqøhv Uewus Ysuk) Ijh (K.K, Oa Fo'Ys"K.K I FR K¡: HKKJRH EkudDocument12 pagesRKTK Oaqøhv Uewus Ysuk) Ijh (K.K, Oa Fo'Ys"K.K I FR K¡: HKKJRH Ekudmohd waseemNo ratings yet

- Methodology of Materials Survey - WecareDocument6 pagesMethodology of Materials Survey - WecareGolam MasudNo ratings yet

- Non Destructive Testing of BridgesDocument133 pagesNon Destructive Testing of BridgesUpaliFernandoNo ratings yet

- Cast in Place Concrete CDocument19 pagesCast in Place Concrete CAchmad HaekalNo ratings yet

- MEngC Presentation (U San Kyu)Document56 pagesMEngC Presentation (U San Kyu)Anonymous 5XPWdQcu100% (1)

- IS516_Part1_Sec1_2021 reffDocument20 pagesIS516_Part1_Sec1_2021 reffKarnalPreethNo ratings yet

- Is 13311 - 2Document9 pagesIs 13311 - 2Sravan KumarNo ratings yet

- Concrete Lab ManualDocument58 pagesConcrete Lab ManualCE2 Shahid shafiNo ratings yet

- QA and Qc ReportDocument9 pagesQA and Qc Reportdharshan RNo ratings yet

- Mortar Quality Assurance: A Review of North American PracticesDocument12 pagesMortar Quality Assurance: A Review of North American PracticessabirfurqanNo ratings yet

- IS 516 Part 8 Section 1Document9 pagesIS 516 Part 8 Section 1mbvyass100% (1)

- Concrete Durability Index Tests Need ImprovementDocument29 pagesConcrete Durability Index Tests Need Improvementrameshbabu_1979No ratings yet

- GuideDocument7 pagesGuidelmiitobnykhpvdwuzyNo ratings yet

- Petrographic Examination of Hardened Concrete: Standard Practice ForDocument17 pagesPetrographic Examination of Hardened Concrete: Standard Practice ForChavier ManguanaNo ratings yet

- Tests and criteria for concrete strengthDocument9 pagesTests and criteria for concrete strengthArindam NandyNo ratings yet

- Control Tests For ConcreteDocument24 pagesControl Tests For Concreteengineermik7956No ratings yet

- Need For Non-Destructive Testing (NDT) of Reinforced Concrete & Various ND Tests Aryan EngineersDocument3 pagesNeed For Non-Destructive Testing (NDT) of Reinforced Concrete & Various ND Tests Aryan EngineersRajwinder Singh BansalNo ratings yet

- Optimized Aggregates for Portland Cement ConcreteDocument39 pagesOptimized Aggregates for Portland Cement ConcretegemotorresNo ratings yet

- Understan CreepDocument21 pagesUnderstan CreepHusseinawyNo ratings yet

- Kuliah PSB 02 NewDocument10 pagesKuliah PSB 02 NewadhityamspNo ratings yet

- Polymer SpecifcatiionDocument7 pagesPolymer SpecifcatiionSunny RohillaNo ratings yet

- C-1170-Consistencia CCR-VeBe PDFDocument5 pagesC-1170-Consistencia CCR-VeBe PDFEmilio Andrè Sifuentes JiménezNo ratings yet

- Test Methods: Classes of Tests Frequency of TestingDocument12 pagesTest Methods: Classes of Tests Frequency of TestingWahyuBagasPrasetyoNo ratings yet

- Cmats Experiment 10Document6 pagesCmats Experiment 10Jenevive TumacderNo ratings yet

- CEC211 TEL (Transportation Lab)Document36 pagesCEC211 TEL (Transportation Lab)Sahil KhanNo ratings yet

- MATERIALS TESTING COURSE OVERVIEWDocument89 pagesMATERIALS TESTING COURSE OVERVIEWChristian GuevarraNo ratings yet

- M. Tech SynopsisDocument8 pagesM. Tech SynopsisemtiazNo ratings yet

- Malteri Za ZidanjeDocument4 pagesMalteri Za ZidanjeAnelNo ratings yet

- Precast Guide SpecDocument25 pagesPrecast Guide SpecpabulumzengNo ratings yet

- Scope of WorkDocument4 pagesScope of WorkNasrullah Fazal AdeebNo ratings yet

- Course: Concrete and Highway Materials Laboratory: Credits - 02 Total Marks-100 Course ObjectivesDocument5 pagesCourse: Concrete and Highway Materials Laboratory: Credits - 02 Total Marks-100 Course ObjectivesARAVIND PATILNo ratings yet

- Imperial College of Business Studies Material Testing Final Term Examination, Summer 2017Document1 pageImperial College of Business Studies Material Testing Final Term Examination, Summer 2017Ahmed HamzaNo ratings yet

- JournalReview - Group No. 3 - Ikan, Jervis IvanDocument12 pagesJournalReview - Group No. 3 - Ikan, Jervis IvanCarlo King SantosNo ratings yet

- Experiment No. 4 Heat of CombustionDocument4 pagesExperiment No. 4 Heat of CombustionjohannNo ratings yet

- IA-7 V3 ManualDocument15 pagesIA-7 V3 Manualaleksa64No ratings yet

- CQM Automatic Tube Cleaning Energy ReportDocument20 pagesCQM Automatic Tube Cleaning Energy ReportKCFUNGNo ratings yet

- Lps Bcaa 2019 Aug2019Document60 pagesLps Bcaa 2019 Aug2019Silly lackeysNo ratings yet

- Gfk1500a - Cimplicity Hmi Getting StartedDocument55 pagesGfk1500a - Cimplicity Hmi Getting StartedEduardo NascimentoNo ratings yet

- Lotus - Application Development With Lotus Domino Designer PDFDocument573 pagesLotus - Application Development With Lotus Domino Designer PDFjao_me03No ratings yet

- Determining Footing Sizes IrcDocument2 pagesDetermining Footing Sizes IrcAiline TriciaNo ratings yet

- Cranes Us ArmyDocument21 pagesCranes Us ArmyNancyNo ratings yet

- 3 Flexural Analysis/Design of Beam 3 Flexural Analysis/Design of Beam 3. Flexural Analysis/Design of Beam 3. Flexural Analysis/Design of BeamDocument146 pages3 Flexural Analysis/Design of Beam 3 Flexural Analysis/Design of Beam 3. Flexural Analysis/Design of Beam 3. Flexural Analysis/Design of BeamJm CampitanNo ratings yet

- Phu Luc - Huong Dan Cau Hinh VPN L2 B0404Document14 pagesPhu Luc - Huong Dan Cau Hinh VPN L2 B0404luisNo ratings yet

- Phase-Controlled AC-DC Converters TutorialDocument3 pagesPhase-Controlled AC-DC Converters TutorialChangyuFuNo ratings yet

- Polymer IntroDocument15 pagesPolymer IntroYUG PRATAP SINGHNo ratings yet

- ENGSCI 442 Petroleum Engineering LecturesDocument77 pagesENGSCI 442 Petroleum Engineering LecturessereptNo ratings yet

- Material TestingDocument7 pagesMaterial TestingkimsonNo ratings yet

- Automated Guided VehicleDocument17 pagesAutomated Guided VehicleTedy ThomasNo ratings yet

- CSC 551: Web Programming Spring 2004: Basic HTMLDocument18 pagesCSC 551: Web Programming Spring 2004: Basic HTMLprasad150686100% (1)

- Load Combination IRCDocument2 pagesLoad Combination IRCmgr4.designNo ratings yet

- Supply Chain Management-A Key To Sucess in Indian Rural MarketDocument18 pagesSupply Chain Management-A Key To Sucess in Indian Rural MarketVishal BishnoiNo ratings yet

- UPA Type Series BookletDocument122 pagesUPA Type Series BookletRicardo BarrosNo ratings yet

- Machine Learning Guide For Oil and Gas Using PythonDocument1 pageMachine Learning Guide For Oil and Gas Using Pythonogiri agbehiNo ratings yet

- Nama: Fiqo Pramudia NPM: 09.2018.1.00609 Jurusan: Teknik LingkunganDocument3 pagesNama: Fiqo Pramudia NPM: 09.2018.1.00609 Jurusan: Teknik LingkunganFiqo PramudiaNo ratings yet

- B.tech. Civil Engineering Full Syllabus IndiaDocument118 pagesB.tech. Civil Engineering Full Syllabus IndiaAnubhav GargNo ratings yet

- Analysis and Design of Multi-Storied Building (Main Project) Sita GowriDocument114 pagesAnalysis and Design of Multi-Storied Building (Main Project) Sita Gowridskumar49100% (5)

- Proesos Miniitab Six SigmaDocument60 pagesProesos Miniitab Six SigmaEdwin Roger Hernandez MejiaNo ratings yet

- Rabatex Textile Machinery Manufacturers, Sectional warping machine, Beam storage, cone creel, Beam trollys, Reed cleaning machine, Automatic Tensioning creel Device, motorized beam trolley, poly beamer, Mono Filament Creel, Carbon Creel, Warp Beam Carrier, Cloth Roll Carrier, Beam Pallet TrolleyDocument14 pagesRabatex Textile Machinery Manufacturers, Sectional warping machine, Beam storage, cone creel, Beam trollys, Reed cleaning machine, Automatic Tensioning creel Device, motorized beam trolley, poly beamer, Mono Filament Creel, Carbon Creel, Warp Beam Carrier, Cloth Roll Carrier, Beam Pallet TrolleySALES TEAMNo ratings yet

- Form Summary: MR Sukumar DhanapalanDocument8 pagesForm Summary: MR Sukumar Dhanapalanaadhya guptaNo ratings yet

- WPS GTAW pipe welding procedureDocument2 pagesWPS GTAW pipe welding procedureRichard PeriyanayagamNo ratings yet

- USB Flash Drive Price ListDocument1 pageUSB Flash Drive Price Listrick990No ratings yet

- Android Screen Lock-Unlock IntentsDocument3 pagesAndroid Screen Lock-Unlock IntentsChandan AdigaNo ratings yet

- Datos de PresionesDocument3 pagesDatos de PresionesWilson Jaime Saucedo LeonNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Pharmaceutical Blending and MixingFrom EverandPharmaceutical Blending and MixingP. J. CullenRating: 5 out of 5 stars5/5 (1)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Physical and Chemical Equilibrium for Chemical EngineersFrom EverandPhysical and Chemical Equilibrium for Chemical EngineersRating: 5 out of 5 stars5/5 (1)

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNo ratings yet

- Guidelines for Engineering Design for Process SafetyFrom EverandGuidelines for Engineering Design for Process SafetyNo ratings yet

- Operational Excellence: Journey to Creating Sustainable ValueFrom EverandOperational Excellence: Journey to Creating Sustainable ValueNo ratings yet

- Guidelines for the Management of Change for Process SafetyFrom EverandGuidelines for the Management of Change for Process SafetyNo ratings yet

- Guidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsFrom EverandGuidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsNo ratings yet

- An Applied Guide to Water and Effluent Treatment Plant DesignFrom EverandAn Applied Guide to Water and Effluent Treatment Plant DesignRating: 5 out of 5 stars5/5 (4)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- Pharmaceutical Excipients: Properties, Functionality, and Applications in Research and IndustryFrom EverandPharmaceutical Excipients: Properties, Functionality, and Applications in Research and IndustryOtilia M. Y. KooNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Guidelines for Developing Quantitative Safety Risk CriteriaFrom EverandGuidelines for Developing Quantitative Safety Risk CriteriaNo ratings yet

- Bow Ties in Risk Management: A Concept Book for Process SafetyFrom EverandBow Ties in Risk Management: A Concept Book for Process SafetyNo ratings yet

- Understanding Process Equipment for Operators and EngineersFrom EverandUnderstanding Process Equipment for Operators and EngineersRating: 4.5 out of 5 stars4.5/5 (3)