Professional Documents

Culture Documents

Man 2240 3rdgen 022908

Uploaded by

Procurement PardisanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Man 2240 3rdgen 022908

Uploaded by

Procurement PardisanCopyright:

Available Formats

OPERATING INSTRUCTIONS FOR

Model 2240

Handheld Hydrogen Leak

Detector

P/N M2240

2/29/08

DANGER

Toxic and explosive gases may be present in this monitoring system.

Personal protective equipment may be required when servicing this instrument.

Hazardous voltages exist on certain components internally when the battery

charger is connected. Do not recharge battery in a hazardous environment.

Only authorized personnel should conduct maintenance and/or servicing.

Before conducting any maintenance or servicing, consult with authorized

supervisor/manager.

Teledyne Analytical Instruments

Model 2240

Copyright © 2007 Teledyne Analytical Instruments

All Rights Reserved. No part of this manual may be reproduced, transmitted, transcribed,

stored in a retrieval system, or translated into any other language or computer language in

whole or in part, in any form or by any means, whether it be electronic, mechanical,

magnetic, optical, manual, or otherwise, without the prior written consent of Teledyne

Analytical Instruments, 16830 Chestnut Street, City of Industry, CA 91749-1580.

Warranty

This equipment is sold subject to the mutual agreement that it is warranted by us free from

defects of material and of construction, and that our liability shall be limited to replacing or

repairing at our factory (without charge, except for transportation), or at customer plant at

our option, any material or construction in which defects become apparent within one year

from the date of shipment, except in cases where quotations or acknowledgements provide

for a shorter period. Components manufactured by others bear the warranty of their

manufacturer. This warranty does not cover defects caused by wear, accident, misuse,

neglect or repairs other than those performed by Teledyne or an authorized service center.

We assume no liability for direct or indirect damages of any kind and the purchaser by the

acceptance of the equipment will assume all liability for any damage which may result from

its use or misuse.

We reserve the right to employ any suitable material in the manufacture of our apparatus,

and to make any alterations in the dimensions, shape or weight of any parts, in so far as

such alterations do not adversely affect our warranty.

Important Notice

This instrument provides measurement readings to its user, and serves as a tool by which

valuable data can be gathered. The information provided by the instrument may assist the user

in eliminating potential hazards caused by his process; however, it is essential that all

personnel involved in the use of the instrument or its interface, with the process being

measured, be properly trained in the process itself, as well as all instrumentation related to it.

The safety of personnel is ultimately the responsibility of those who control process

conditions. While this instrument may be able to provide early warning of imminent

danger, it has no control over process conditions, and it can be misused. In particular, any

alarm or control systems installed must be tested and understood, both as to how they

operate and as to how they can be defeated. Any safeguards required such as locks, labels,

or redundancy, must be provided by the user or specifically requested of Teledyne at the

time the order is placed.

Therefore, the purchaser must be aware of the hazardous process conditions. The purchaser

is responsible for the training of personnel, for providing hazard warning methods and

instrumentation per the appropriate standards, and for ensuring that hazard warning devices

and instrumentation are maintained and operated properly.

Teledyne Analytical Instruments, the manufacturer of this instrument, cannot accept

responsibility for conditions beyond its knowledge and control. No statement expressed or

implied by this document or any information disseminated by the manufacturer or its

agents, is to be construed as a warranty of adequate safety control under the user’s process

conditions.

Teledyne Analytical Instruments ii

Handheld Hydrogen Leak Detector

Specific Model Information

This instrument is specifically designed to measure hydrogen in air.

Using this instrument to analyze any other gas mixture may result in

serious error. Consult the factory for additional information for gas

analysis not specified at the time of purchase.

Instrument Serial Number: _______________________

Instrument Range: _______________

Calibrated for: _______________

Background Gas: _______________

Zero Gas: _______________

Span Gas: _______________

Teledyne Analytical Instruments iii

Model 2240

Safety Messages

Your safety and the safety of others is very important. We have

provided many important safety messages in this manual. Please read

these messages carefully.

A safety message alerts you to potential hazards that could hurt you

or others. Each safety message is associated with a safety alert symbol.

These symbols are found in the manual and inside the instrument. The

definition of these symbols is described below:

GENERAL WARNING/CAUTION: Refer to the instructions

for details on the specific danger. These cautions warn of

specific procedures which if not followed could cause bodily

Injury and/or damage the instrument.

CAUTION: HOT SURFACE WARNING: This warning is

specific to heated components within the instrument. Failure

to heed the warning could result in serious burns to skin and

underlying tissue.

WARNING: ELECTRICAL SHOCK HAZARD: Dangerous

voltages appear within this instrument. This warning is

specific to an electrical hazard existing at or nearby the

component or procedure under discussion. Failure to heed this

warning could result in injury and/or death from

electrocution.

Technician Symbol: All operations marked with this symbol

are to be performed by qualified maintenance personnel only.

NOTE: Additional information and comments regarding a

No

specific component or procedure are highlighted in the form

Symbol

of a note.

CAUTION: THE ANALYZER SHOULD ONLY BE USED FOR THE

PURPOSE AND IN THE MANNER DESCRIBED IN

THIS MANUAL.

Teledyne Analytical Instruments iv

Handheld Hydrogen Leak Detector

IF YOU USE THE ANALYZER IN A MANNER OTHER

THAN THAT FOR WHICH IT WAS INTENDED,

UNPREDICTABLE BEHAVIOR COULD RESULT

POSSIBLY ACCOMPANIED WITH HAZARDOUS

CONSEQUENCES.

This manual provides information designed to guide you through

the installation, calibration operation and maintenance of your new

analyzer. Please read this manual and keep it available.

Occasionally, some instruments are customized for a particular

application or features and/or options added per customer requests.

Please check the front of this manual for any additional information in

the form of an Addendum which discusses specific information,

procedures, cautions and warnings that may be peculiar to your

instrument.

Manuals do get lost. Additional manuals can be obtained from

Teledyne at the address given in the Appendix. Some of our manuals are

available in electronic form via the internet. Please visit our website at:

www.teledyne-ai.com.

Teledyne Analytical Instruments v

Model 2240

Table of Contents

List of Figures ............................................................................ viii

List of Tables ................................................................................ ix

Introduction ................................................................................... 1

1.1 Overview 1

1.2 Typical Applications 1

1.3 Features 2

1.4 Operator Interface 2

Startup and Operation .................................................................. 5

2.1 Unpacking the Instrument 5

2.2 Setup 6

2.3 Startup 6

2.4 Shutdown 7

2.5 Battery Level 7

2.6 Normal Operation 7

2.6.1 Hydrogen Concentration—LCD Display 8

2.6.2 Hydrogen Concentration—Probe Tip 8

2.7 Keypad 10

2.8 Controller LCD Error Status 10

2.9 Reset Operation 11

2.10 Zero Operation 11

2.11 Configuration Menu 11

2.12 Information Display 13

2.13 Reset Sensor 14

2.14 Zero Sensor 14

2.15 Field Calibrate 14

Field Verification and Calibration .............................................. 15

Teledyne Analytical Instruments vi

Handheld Hydrogen Leak Detector

3.1 Gases 15

3.2 Gas Connection 15

3.3 Numerical Changes 15

3.4 Verify Sensor 15

3.5 Calibrate Sensor 19

3.6 Clear Field Calibration 22

Hydrogen Sensing Considerations............................................ 23

Maintenance................................................................................. 25

5.1 Routine Maintenance 25

5.2 Battery Charging 25

5.3 Cleaning 26

5.4 Troubleshooting 26

Appendix ...................................................................................... 27

A.1 Specifications 27

A-2 Recommended Spare Parts 28

Index ............................................................................................. 29

Teledyne Analytical Instruments vii

Model 2240

List of Figures

Figure 1-1: User Interface ............................................................... 3

Figure 2-1: Analyzer Components................................................... 5

Figure 2-2: Startup LED .................................................................. 6

Figure 2-3: Unit Ready LED ............................................................ 7

Figure 2-4: Lower Line LED Bar Graph........................................... 8

Figure 2-5: Hydrogen Concentration Indication at the Probe Tip .... 9

Figure 2-6: Peak Hydrogen Detected LED .................................... 10

Figure 2-7: Configuration Menu Navigation................................... 13

Figure A-1: Dimensions................................................................. 28

Teledyne Analytical Instruments viii

Handheld Hydrogen Leak Detector

List of Tables

Table 2-1: Navigation Button Functions ........................................ 12

Table 3-1: Verify Calibration Procedure ....................................... 16

Table 3-2: Field Calibrate Procedure............................................. 19

Table 3-3: Clear Function Procedure ............................................ 22

Table 5-1 Troubleshooting............................................................. 26

Teledyne Analytical Instruments ix

Model 2240

DANGER

COMBUSTIBLE GAS USAGE

WARNING

The Model 2240 instrument is CE approved. This rating

applies only to the equipment specified and installed in

accordance with the information contained within this

manual. It is the customer's responsibility to ensure safety

especially when combustible gases are being analyzed since

the potential of gas leaks always exist.

The customer should ensure that the principles of operating

of this equipment is well understood by the user and that the

instrument as well as any approved support equipment is

properly installed. Misuse of this product in any manner,

tampering with its components, or unauthorized substitution

of any component may adversely affect the certification and

the safety of this instrument.

Since the use of this instrument is beyond the control of

Teledyne, no responsibility by Teledyne, its affiliates, and

agents for damage or injury from misuse or neglect of this

equipment is implied or assumed.

Teledyne Analytical Instruments x

Handheld Hydrogen Leak Detector Introduction

Introduction

1.1 Overview

The Model 2240 Hydrogen Analyzer is a handheld portable leak

detector for sensing hydrogen gas in air. It employs two sensing

elements on the same semiconductor die and can detect hydrogen leaks

as low as 15 parts per million (ppm). It will not saturate or be destroyed

when detecting hydrogen concentration up to 100%. It is battery

powered and will operate for over 10 hours on a single charge. The

included battery charger will recharge the internal lithium-ion battery in

4 hours.

As the operator moves a hydrogen probe over the area of interest, it

senses the presence of hydrogen. Indicators in the probe tip alert the user

to the presence of hydrogen and the concentration is displayed on the

control unit display. The probe attaches to the controller with an

extendable coiled cord that allows up to 47 inches of reach from the

Controller. The thin probe and flexible cable allow sensing in areas

inaccessible to most other tools.

1.2 Typical Applications

The Model 2240 analyzer is a versatile, lightweight instrument that

can be brought to a process area for analysis. Typical applications for

the analyzer include:

• Leak checking process lines for H2 in air

• Analyzing the concentration of H2 in an air stream

• H2 safety monitoring

• Specific gas mixer and process control applications

• Semiconductor manufacturing

• Hydrogen process control

• Quality assurance

Teledyne Analytical Instruments 1

Introduction Model 2240

1.3 Features

The Model 2240 Hydrogen Analyzer is sophisticated yet simple to

use. The following features are standard features for this instrument:

• High-impact plastic enclosure, dust-tight and protected against

water spray from any direction.

• CE approved

• Large LCD alphanumeric display plus graphic bar graph

indication.

• Long-lifetime Wide Range Sensor®

• Lithium-ion battery supplies power for over 10 hours without

recharging

• Tri-color LED low battery indicator

• AC battery charger

• Sensor wand with coiled wire connection to controller.

• Additional LED indicators in probe for quick visual

determination of hydrogen presence.

• Large front panel keypad interface for convenient operation

1.4 Operator Interface

The user interface is simple and easy to use. Figure 1-1 shows the

Model 2240 with probe and coil attached.

The interface consists of:

• LCD Display

• OFF/ON button

• Battery status indicator

• Navigation buttons

• ENTER button

Teledyne Analytical Instruments 2

Handheld Hydrogen Leak Detector Introduction

Figure 1-1: User Interface

Teledyne Analytical Instruments 3

Introduction Model 2240

Teledyne Analytical Instruments 4

Handheld Hydrogen Leak Detector Startup and Operation

Startup and Operation

2.1 Unpacking the Instrument

The Model 2240 is shipped with all the materials you need to install

and prepare the system for operation. Carefully unpack the instrument

and inspect it for damage. Immediately report any damage to the

shipping agent. Figure 2-1 shows the items that are included in the

package.

Figure 2-1: Analyzer Components

Teledyne Analytical Instruments 5

Startup and Operation Model 2240

2.2 Setup

Insert the probe cable into the probe and the other end into the

Controller. The cable has distinct connections that will only mate in the

proper manner.

2.3 Startup

Power-up the Model 2240 by pressing and holding the ON/OFF

button until the Controller LCD display indicates an operational

message.

Note: Only power-up the instrument in a hydrogen-free

environment.

After power is on the instrument automatically enters an

Initialization mode that lasts approximately ten minutes. During this

time the LCD displays a countdown to completion and the lighted

indicator closest to the Probe Tip is orange (See Figure 2-2) until the

following operations complete:

• Heat the Wide Range Sensor® to operating temperature.

• Perform system self-test.

• Zero the sensor reading.

Figure 2-2: Startup LED

Upon successful completion the instrument automatically switches

to Normal operation and the Probe tip LED turns green. If an error is

detected the instrument will display an Error Status (see Section 2.8).

Teledyne Analytical Instruments 6

Handheld Hydrogen Leak Detector Startup and Operation

Figure 2-3: Unit Ready LED

2.4 Shutdown

To power-down the unit press and hold the ON/OFF button for

approximately 2 seconds until the Controller LCD display turns off.

2.5 Battery Level

After powering up the BATTERY LED indicates the current

battery level: (times may vary as battery ages)

• GREEN – more than one hour of operation remaining

• ORANGE – approximately 15 to 60 minutes of operation

remaining

• RED – less than approximately 15 minutes of operation

remaining

2.6 Normal Operation

During Normal Operation the instrument is detecting and reporting

hydrogen concentration near the Probe Tip Sensor. Hydrogen readings

are displayed on the Controller LCD as well as on the Probe Tip LED

bar graph array. Note that due to the extreme sensitivity of the sensor, it

may take more than one minute to return to a near zero (less than

Teledyne Analytical Instruments 7

Startup and Operation Model 2240

0.001%) reading after exposure to hydrogen. If the instrument doesn’t

return to an indication of less than 0.001% after 5 minutes in a

hydrogen-free environment then invoke the Reset operation (See Section

2.9).

2.6.1 Hydrogen Concentration—LCD Display

The upper line of the Controller LCD indicates a numerical value

or range for the percent hydrogen concentration or peak hydrogen value.

The lower line is used to display the hydrogen meter, a logarithmic bar

graph ranging from 0.001% (10 ppm) to 100% hydrogen by volume. An

open box on the bar indicates the last peak value obtained and filled

boxes indicate current value. Figure 2-4 shows how to interpret the

hydrogen meter:

Figure 2-4: Lower Line LED Bar Graph

2.6.2 Hydrogen Concentration—Probe Tip

The Probe Tip LED Indicator can be used to show an increase or

decrease in hydrogen concentration.

Leak detection is accomplished by watching the Probe Tip LED

and moving the sensor around a potential hydrogen leak. During the leak

check:

1. The Probe Tip LED turns red and remains red when the most

recent peak hydrogen concentration is being detected.

2. The increase in hydrogen concentration will also be indicated

by the increasing number of yellow LEDs powering on in the

LED bar graph array.

3. When the Probe Tip LED turns orange, this indicates that there

is still hydrogen present, but the hydrogen concentration is

Teledyne Analytical Instruments 8

Handheld Hydrogen Leak Detector Startup and Operation

decreasing and the sensor has moved away from the hydrogen

leak.

4. Moving the sensor back towards the potential location of the

hydrogen leak will cause the Probe Tip LED to turn red.

5. Continue moving the sensor into the area that causes the Probe

Tip LED to turn red until the source of the hydrogen leak is

located.

The color of the Probe Tip LED indicates:

GREEN: Unit ready, hydrogen concentration is less than

0.001% (10ppm)

ORANGE: System startup or hydrogen detected (0.001 to 100%)

RED: New peak hydrogen concentration detected

The number of yellow LEDs powered on in the Probe LED bar

graph indicates hydrogen concentration as shown in Figure 2-5.

Figure 2-5: Hydrogen Concentration Indication at the Probe Tip

Figure 2-6 shows the Probe Tip indicating a peak hydrogen

concentration detected greater than 10%. The Prob Tip LEDs will be red

and four yellow bar graph LEDs will illuminate.

Teledyne Analytical Instruments 9

Startup and Operation Model 2240

Figure 2-6: Peak Hydrogen Detected LED

2.7 Keypad

The keypad is used to alter the display or initiate special functions

as follows:

• Pressing ▲ (up arrow button) will display the peak hydrogen

reading.

• Pressing ▼ (down arrow button) will display the current

percent hydrogen concentration.

• Pressing ► (right arrow button) will clear the peak hydrogen

value.

• Pressing and holding ◄ (left arrow button) will invoke the

Zero Operation (see Section 2.10).

• Pressing and holding ◄ ► (left and right arrow buttons

simultaneously) will invoke the Reset operation (see Section

2.9).

• Pressing and holding the ENTER button will invoke the

Configuration Menu (see Section 2.11).

2.8 Controller LCD Error Status

The following Error Messages can appear on the display:

Teledyne Analytical Instruments 10

Handheld Hydrogen Leak Detector Startup and Operation

Sensor Error – Unit has detected a failure to communicate with

the Probe.

broken – Unit has detected a unit internal failure

See Section 5.4 for troubleshooting

2.9 Reset Operation

The Reset Operation is used to speed recovery from hydrogen

exposure. This operation can be invoked from the keypad during Normal

Operation by Pressing and holding ◄ ► (left and right arrow buttons

simultaneously) or from the Configuration Menu (see Section 2.11).

Once invoked the user is asked to confirm the operation by pressing the

ENTER key, pressing any other key will abort the operation.

Note: The instrument must be in a hydrogen free environment

with the LCD indicating less than 0.1% hydrogen before

invoking the Reset operation.

During Reset the LCD indicates a countdown to completion and the

Probe tip LED will be yellow.

2.10 Zero Operation

The Zero Operation is used to zero the hydrogen reading if the

instrument is reporting low levels (0.001% to 0.01%) of hydrogen when

no hydrogen is present. This operation can be invoked from the keypad

during Normal Operation by pressing and holding ◄ (left arrow

button) or from the Configuration Menu (see Section 2.11). Once

invoked, the user is asked to confirm the operation by pressing the

ENTER key, pressing any other key will abort the operation.

Note: The instrument must be in a hydrogen free environment

with the LCD indicating less than 0.1% hydrogen before

invoking the Zero operation.

2.11 Configuration Menu

The Configuration Menu is used to display and modify instrument

settings and can be entered by pressing and holding the ENTER button.

The configuration parameters are summarized below with details in the

Teledyne Analytical Instruments 11

Startup and Operation Model 2240

following sections. The keypad is used to navigate the menu as shown in

Table 2-1.

Table 2-1: Navigation Button Functions

Query

Key Navigation Editing Values

Answer

ENTER Enter submenu Select Value Yes

▲ Previous Menu Increase Value No

▼ Next Menu Decrease Value No

► Enter Submenu Move Cursor Right No

◄ Exit Submenu (Back) Move Cursor Left No

◄ ► Exit Configuration Undo Changes No

The functions accessible from the Configuration Menu are:

• Information Display

• Reset Sensor

• Zero Sensor

• Field Calibrate

• Exit

These functions are described in the following sections. Figure 2-7

shows how to navigate through the Configuration Menu.

Teledyne Analytical Instruments 12

Handheld Hydrogen Leak Detector Startup and Operation

Figure 2-7: Configuration Menu Navigation

2.12 Information Display

The Information Display (Information Disp.) menu allows the user

to view useful information about the instrument including firmware

revisions, serial number, and calibration date.

Firmware Rev: Displays the sensor pod and controller firmware.

The left most number preceded by an ‘S’ is the

Teledyne Analytical Instruments 13

Startup and Operation Model 2240

Probe firmware revision. The right most number

preceded by a ‘C’ is the Controller firmware

revision. For example: S 1.23 C2.34 for Probe

firmware version 1 .23 and Controller firmware

version 2.34

Serial Number: Displays the product serial number. For example:

50123

Calibration Date: Displays the date of last factory calibration,

MM/DD/YY. For example: 5/8/06 for 8 May

2006.

2.13 Reset Sensor

The Reset Sensor menu is used to invoke the Reset Operation as

described in Section 2.9.

2.14 Zero Sensor

The Zero Sensor menu is used to invoke the Zero Operation as

described in Section 2.10.

2.15 Field Calibrate

The Field Calibrate menu shows the date of the last field calibration

and allows the user to invoke the Verify, Calibrate, and Clear functions.

Verify Sensor: Press ENTER to invoke the Verify function (see

Section 3.4).

Calibrate Sensor: Press ENTER to invoke the Calibrate function (see

Section 3.5).

Clear Field Cal: Press ENTER to invoke the Clear function (see

Section 3.6).

Teledyne Analytical Instruments 14

Handheld Hydrogen Leak Detector Field Verify/Calibration

Field Verification and Calibration

3.1 Gases

Verification or calibration requires the availability of the following

certified gases:

• 2.00% hydrogen by volume in air (20,000 ppm)

• 0.1% hydrogen by volume in air (1000 ppm)

• Zero grade, hydrogen-free air, ambient air can be used instead

of certified zero grade air if the user has high confidence that it

is a hydrogen-free environment.

3.2 Gas Connection

Gases are applied to the unit thru the use of the Calibration Cup

Assy. (P/N 50000009) available from manufacturer.

3.3 Numerical Changes

In the following sections when queried to change a numeric value

the ▲ (up arrow) and ▼ (down arrow) keys are used to

increment/decrement the value based on the selected digit. If the ones

digit is selected the value will increment/decrement by one (9

increments to 10, 10 decrements to 9). The ◄ (left arrow) and ►

(right arrow) keys are used to select another digit. To change a value of

0 to 100 first select the hundreds digit then press the ▲ up arrow.

Pressing ◄ ► (the left and right arrows simultaneously) will clear any

changes made and restore the previous value. Once the correct value is

displayed press the ENTER key to save it.

3.4 Verify Sensor

The Verify function allows the user to check the instrument’s

calibration. If Verify is successful then the user is asked to enter the new

Teledyne Analytical Instruments 15

Field Verify/Calibration Model 2240

verification date. If Verify fails the field calibration values are erased,

restoring the last factory calibration.

To perform the verify test:

Table 3-1: Verify Calibration Procedure

Step Display User Response

1 Hydrogen <0.001% H2 Press ENTER.

2 Information Disp. Press ▼

3 Reset Sensor Press ▼

4 Zero Sensor Press ▼

Field Calibrate

5 Press ENTER or ►

XX/XX/XX

6 Verify Sensor Press ENTER

Verify Sensor Press ENTER to verify sensor, or any other key to

7

Are you sure? exit.

Verify Sensor in

8 Verify Test begins

Progress

With the Calibration Cup that accompanies the

Apply 0.000% H2 instrument, apply hydrogen-free, ultra-zero air to the

9

Are you sure? Probe sensor. The Probe Tip LED will remain Green.

Press ENTER.

Apply 0.000% H2

10 0% Verify Test starts

In Progress

Apply 0.000% H2

11 Checking sensor temperature.

Settle

Apply 0.000% H2

12 Wait for sensor reading to stabilize, until xxxx = 0.

Wait xxxx

Apply 0.000% H2

13 Measuring sensor response to test gas.

Finding Average

With the Calibration Cup, apply 0.1% hydrogen

(balance air) to the Probe sensor. The Probe Tip

Apply 0.100% H2

14 LED will change from Green to Red. One (or two)

Are you sure?

yellow LEDs in the LED Bar Graph Array will turn on.

Press ENTER.

Apply 0.100% H2

15 0.1% Verify Test starts

In Progress

Teledyne Analytical Instruments 16

Handheld Hydrogen Leak Detector Field Verify/Calibration

Step Display User Response

Apply 0.100% H2

16 Checking sensor temperature.

Settle

Apply 0.100% H2

17 Wait for sensor reading to stabilize, until xxxx = 0.

Wait xxxx

Apply 0.100% H2

18 Measuring sensor response to test gas.

Finding Average

With the Calibration Cup, apply 2.0% hydrogen

Apply 2.000%H2 (balance air) to the Probe sensor. The Probe Tip

19

Are you sure? LED will remain Red. Three yellow LEDs in the LED

Bar Graph Array will turn on. Press ENTER.

Apply 2.00% H2

20 2.00% Verify Test starts

In Progress

Apply 2.00% H2

21 Checking sensor temperature.

Settle

Apply 2.00% H2

22 Wait for sensor reading to stabilize, until xxxx = 0.

Wait xxxx

Apply 2.00% H2

23 Measuring sensor response to test gas.

Finding Average

Enter Date: Enter the current month (1-12) using the▲ (up arrow)

24

1.0000 M and▼ (down arrow) keys.

Enter Date: Enter the current day (1-31) using the▲ (up arrow)

25

1.0000 D and▼ (down arrow) keys.

Enter Date: Enter the current year (7=2007, 12=2012, etc.)

26

6.0000 Y using the▲ (up arrow) and▼ (down arrow) keys.

Verify Sensor

27 Verify is complete, press any key.

Passed

Note the following:

1. If the unit passes verification, calibration is not required at this

time. The Verify Function stops at this point.

2. If the unit fails verification, TAI recommends calibration.

Continue with the following steps.

Teledyne Analytical Instruments 17

Field Verify/Calibration Model 2240

Step Display User Response

The Verify Test has failed. Calibration is

recommended. With the Calibration Cup, apply

Verify Sensor

28 hydrogen-free, ultra-zero air to the Probe sensor.

Error:

Wait for the LED Bar Graph array in the Probe to

show only one (or zero) yellow LEDs. Press ENTER

Field Calibrate

29 Press ▼

XX/XX/XX

30 Exit Press ▼

31 Information Disp. Press ▼

Carry out the Reset function to speed the recovery

32 Reset Sensor from hydrogen exposure to move on to Calibration.

Press ENTER.

Reset Sensor

33 Press ENTER

Are you sure?

Reset Sensor

34 During Reset, the Probe Tip LED will be orange.

In Progress

Reset Sensor

35 Press ENTER

Done

36 Reset Sensor Press ▼

37 Zero Sensor Press ▼

Field Calibrate

38 Press ENTER or ►

XX/XX/XX

39 Verify Sensor Press ▼

Press ENTER to perform field calibration. Go to Step

40 Calibrate Sensor

8 of Section 3.5.

Teledyne Analytical Instruments 18

Handheld Hydrogen Leak Detector Field Verify/Calibration

3.5 Calibrate Sensor

The Calibrate function allows the user to perform a field calibration

of the instrument. After Field Calibration TAI recommends running the

Verify Function. To carry out a Field Calibration follow the procedure

listed in Table 3-2.

Table 3-2: Field Calibrate Procedure

Step Display User response

Hydrogen

1 Press ENTER

<0.001%H2

2 Information Disp Press ▼

3 Reset Sensor Press ▼

4 Zero Sensor Press ▼

Field Calibrate

5 Press ENTER or ►

XX/XX/XX

6 Verify Sensor Press ▼

7 Calibrate Sensor Press ENTER

Calibrate Sensor Press ENTER to Calibrate sensor, any other key to

8

Are you sure? exit.

Calibrate Sensor

9 Calibration begins.

In Progress

With the Calibration Cup that accompanies the

Apply 0.000%H2 instrument, apply hydrogen-free, ultra-zero air to the

10

Are you sure? Probe sensor. The Probe Tip LED will remain

Green. Press ENTER.

Apply 0.000%H2

11 0% Calibration starts.

In Progress

Apply 0.000%H2

12 Checking sensor temperature.

Settle

Apply 0.000%H2

13 Wait for sensor reading to stabilize until xxxx = 0.

Wait xxxx

Apply 0.000%H2

14 Measuring sensor response to test gas.

Finding Average

Teledyne Analytical Instruments 19

Field Verify/Calibration Model 2240

Step Display User response

With the Calibration Cup, apply 0.1% hydrogen

(balance air) to the Probe sensor. The Probe Tip

Apply 0.100%H2

15 LED will change from Green to Red. One (or two)

Are you sure?

yellow LEDs in the LED Bar Graph Array will turn

on. Press ENTER.

Apply 0.100%H2

16 0.1% Calibration starts.

In Progress

Apply 0.100%H2

17 Checking sensor temperature.

Settle

Apply 0.100%H2

18 Wait for sensor reading to stabilize until xxxx = 0.

Wait xxxx

Apply 0.100%H2

19 Measuring sensor response to test gas.

Finding Average

With the Calibration Cup, apply 2.0% hydrogen

Apply 2.000%H2 (balance air) to the Probe sensor. The Probe Tip

20

Are you sure? LED will remain Red. Three yellow LEDs in the LED

Bar Graph Array will turn on. Press ENTER.

Apply 2.000%H2

21 2.0% Calibration starts.

In Progress

Apply 2.000%H2

22 Checking sensor temperature.

Settle

Apply 2.000%H2

23 Wait for sensor reading to stabilize until xxxx = 0.

Wait xxxx

Apply 2.000%H2

24 Measuring sensor response to test gas.

Finding Average

Calibrate Sensor

25 Calibration is complete. Press ENTER.

Done

Field Calibrate

26 Press ▼

XX/XX/XX

27 Exit Press ▼

28 Information Disp Press ▼

Carry out the Reset function to speed the recovery

29 Reset Sensor

from hydrogen. Press ENTER.

Teledyne Analytical Instruments 20

Handheld Hydrogen Leak Detector Field Verify/Calibration

Step Display User response

With the Calibration Cup, apply hydrogen-free, ultra-

Reset Sensor zero air to the Probe sensor. Wait for the LED Bar

30

Are you sure? Graph array in the Probe to show only one (or zero)

yellow LEDs. Press ENTER.

Reset Sensor

31 During Reset, the Probe Tip LED will be orange.

In Progress

Reset Sensor

32 Press ENTER

Done

33 Reset Sensor Press ▼

34 Zero Sensor Press ▼

Field Calibrate

35 Press ENTER or ►

XX/XX/XX

With a successful calibration, TAI recommends that

36 Verify Sensor the user run the Verify Test. Press ENTER. Go

back to Section 3.4, Step 7.

If a “Calibrate Sensor Error” message appears, continue with the

steps below:

Step Display User response

Calibration failed. With the Calibration Cup, apply

Calibrate Sensor hydrogen-free, ultra-zero air to the Probe sensor.

37

Error Wait for the LED Bar Graph array to show only one

(or zero) yellow LEDs. Press ENTER.

Field Calibrate

38 Press ▼

XX/XX/XX

39 Exit Press ▼

40 Information Disp. Press ▼

Carry out the Reset function to speed the recovery

41 Reset Sensor

from hydrogen exposure. Press ENTER.

Reset Sensor

42 Press ENTER

Are you sure?

Reset Sensor

43 During Reset, the Probe Tip LED will be orange.

In Progress

Teledyne Analytical Instruments 21

Field Verify/Calibration Model 2240

Step Display User response

Reset Sensor

44 Press ENTER

Done

45 Reset Sensor Press ▼

46 Zero Sensor Press ▼

Field Calibrate

47 Press ENTER or ►

XX/XX/XX

48 Verify Sensor Press ▼

Press ENTER to repeat Field Calibration. Go back

49 Calibrate Sensor

to Step 8 of Section 4.5.

3.6 Clear Field Calibration

The Clear function restores the instrument to the last factory

calibration. Once entered into the Clear function (see Section 2) the user

is prompted thru the verification routine as follows:

Table 3-3: Clear Function Procedure

Step Display User response

Clear Field Cal Press ENTER to clear field calibration values, any

1

Are you sure? other key to exit.

Teledyne Analytical Instruments 22

Handheld Hydrogen Leak Detector Hydrogen Sensing

Hydrogen Sensing Considerations

From any given source, hydrogen gas disperses rapidly and

generally upward due to the very low density of hydrogen compared to

air. Understanding this behavior allows the operator to more effectively

search for hydrogen leaks.

If the sensor element is near (and above) the leak, the concentration

will likely be higher but the leak may be difficult to locate. As hydrogen

dissipates (generally above the leak) the concentration decreases.

Generally, greater distances will increase the chance of intercepting the

leak stream, but if the sensor is too far away, the response may be too

weak to detect.

When drafts or air currents are present, hydrogen will tend to be

dispersed. Testing for hydrogen leaks downwind of the leak area may

increase the chance of detecting the leak.

If hydrogen is rising in an enclosed building (where there may be a

layer of hot air near the ceiling) the hot air near the ceiling may have a

lower density and act to retard the hydrogen from continuing to rise as

rapidly as it did in lower layers of air. Thus, sensing hydrogen near

ceiling areas with high temperatures present may not be as effective.

Low temperatures can also affect the behavior of hydrogen.

Hydrogen stored in a liquid state is at an extremely low temperature.

The low temperature of any escaping hydrogen will be of a higher than

normal density and may initially move downward. As the hydrogen

warms, it will begin to rise upward. When checking for a leak in areas

where liquid hydrogen is stored, check both above and below the area of

concern.

Teledyne Analytical Instruments 23

Hydrogen Sensing Model 2240

Teledyne Analytical Instruments 24

Handheld Hydrogen Leak Detector Maintenance

Maintenance

5.1 Routine Maintenance

Aside from normal cleaning and battery charging, routine

maintenance is limited to calibration verification and recalibration. For

verification and calibration procedures, refer to Sections 3.4 and 3.5.

There are no user-serviceable items inside the instrument.

5.2 Battery Charging

To recharge the unit’s battery:

1. Ensure the unit is powered OFF. Allow batteries in an extreme

temperature to warm or cool to within 10-45 °C.

2. Disconnect the coiled cord from the Controller.

3. Connect the battery charger to the Controller.

4. Using the appropriate A/C plug adapter for the region of use,

plug the battery charger into the A/C supply.

5. The battery charger indicator light will illuminate according to

charge status as follows:

• OFF: No battery

• FLASHING GREEN: Fast charging

• STEADY GREEN: Fully charged

• STEADY ORANGE: Standby

• FLASHING RED: Error

Note: Complete charging may take up to 4 hours for a fully

discharged battery.

Teledyne Analytical Instruments 25

Maintenance Model 2240

5.3 Cleaning

If the unit becomes soiled, clean the unit with a lint-free cloth. Use

special care when cleaning the handheld probe assembly. Small debris

or other material may collect over the sensor tip. Clean the tip with a

gentle wiping using a clean lint-free cloth or paper.

5.4 Troubleshooting

The following table offers guideline for diagnosing and correcting

common problems associated with the Model 2240.

Table 5-1 Troubleshooting

Symptom Action

Controller LCD indicates

Turn off the instrument and verify that the Probe is properly

Sensor Error after power

connected to the Controller.

on

Then turn off the instrument and verify that the Probe is

Controller LCD indicates

properly connected to the Controller and that there isn’t any

broken

damage to the unit.

BATTERY LED is red Charge the battery completely; see Section 5.2.

Teledyne Analytical Instruments 26

Handheld Hydrogen Leak Detector Appendix

Appendix

A.1 Specifications

Range: 0.0015% (15ppm) to 100% hydrogen by

volume in air.

Response Time: Indication of hydrogen within seconds.

Stabilization to final value depends on

concentration.

Temperature: Ambient Operating: -0 to +40 °C

Storage: -20 to +50 °C

Power: Internal rechargeable Lithium Ion battery

yields over 10 hours of operation. Battery

recharge time: 4 hours with included

charger.

Calibration Period: Recommended user verification on a 3

month basis and calibration on a 12 month

basis.

Dimensions: See following figures (dimensions in

inches).

Weight: 975 g (2.15 lb.) unit and carrying pouch

2.2 kg (5 lb.) shipping weight (unit with

accessories)

Water Ingress Protection: IP64 (Dust-tight, protected against water

spray from any direction).

Approvals and Ratings: CE 31 May 2007

Product Life Expectancy: 10 years

Teledyne Analytical Instruments 27

Appendix Model 2240

Figure A-1: Dimensions

A-2 Recommended Spare Parts

Qty. Part Number Description

1 P1529 Probe Assembly

1 CP2705 Controller Assembly

1 CP2706 Coiled Probe Cable

1 CP2707 Battery Charger

1 P1530 Detector Pouch

1 CP2708 Sensing System Case

A minimum charge is applicable to spare parts orders.

Note: Orders for replacement parts should include the part

number (if available) and the model and serial number of

the instrument for which the parts are intended.

Orders should be sent to:

TELEDYNE Analytical Instruments

16830 Chestnut Street

City of Industry, CA 91749-1580

Phone (626) 934-1500, Fax (626) 961-2538

Web: www.teledyne-ai.com

or your local representative.

Teledyne Analytical Instruments 28

Handheld Hydrogen Leak Detector Index

Index

A/C plug adapter, 25 figures listing, viii

address, 28 firmware revision, 13, 14

air current, 23 hydrogen concentration. See

APEX CE, 2 concentration

applications, 1 hydrogen detected LED, 10

approvals, 27 hydrogen dispersion, 23

bar graph, 2, 8 hydrogen exposure, 8

battery, 1, 27 hydrogen sensing, 23

battery charger, 2, 25 increment/decrement values, 15

battery charging procedure, 25 information display, 12

battery indicator, 2, 7 information display menu, 13

battery LED. See battery indicator initialization mode, 6

battery LED color, 25 internal failure, 11

broken, 11 items shipped, 5

calibrate function, 14, 19 keypad, 2, 10

calibrate function procedure, 19 LCD, 2, 7

calibration, 15 leak detection, 8

calibration cup, 15 lifetime, 27

calibration date, 13, 14 liquid hydrogen, 23

calibration period, 27 lithium-ion battery. See battery

caution sign, iv low temperature, 23

cleaning, 26 manuals, additional, v

clear function, 14, 22 navigation buttons, 2, 12

clear function procedure, 22 normal mode, 7

coiled cord, 1 OFF/ON button, 2

combustible gas warning, x ON/OFF button, 6, 7

components, 5 peak hydrogen, 8, 9, 10

concentration, 1, 7 peak hydrogen clear, 10

configuration menu, 10, 11, 13 power, 2, 27

Controller, 6 probe, 1

copyright, ii probe cable, 6

countdown, 6, 11 probe tip, 1, 7

current value, 8, 10 probe tip LED, 11

density, 23 probe tip LED color, 9

dimensions, 27, 28 range, 27

display, 2 recovery, 11

enclosure, 2 reset operation, 8, 10, 14

ENTER button, 2 reset sensor, 12

error messages, 10 reset sensor menu, 14

error status, 6 response time, 27

features, 2 routine maintenance, 25

field calibrate menu, 14 safety information, iv

field calibration, 12, 19 self-test, 6

Teledyne Analytical Instruments 29

Index Model 2240

sensitivity, 7 unit ready LED, 7

Sensor Error, 11 user interface, 2, 3

sensor wand. See probe verification date, 16

serial number, iii, 13, 14 verify function, 14, 15

setup, 6 verify procedure, 16

shipping damage, 5 warning sign, iv

shutdown, 7 warranty, ii

specifications, 27 water, 2, 27

startup, 6 web address, 28

startup LED, 6 website address, v

system startup, 9 weight, 27

tables listing, ix Wide Range Sensor, 2, 6

technician symbol, iv zero, 6, 7, 10

Teledyne address, 28 zero operation, 11, 14

temperature, 27 zero sensor, 12

troubleshooting, 26 zero sensor menu, 14

unit ready, 9

Teledyne Analytical Instruments 30

You might also like

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- Man 7600Document126 pagesMan 7600Felico AguirreNo ratings yet

- Analizador de Hodrogeno Portatil Man - 2750Document40 pagesAnalizador de Hodrogeno Portatil Man - 2750isctomaslopezNo ratings yet

- Teledyne Oil in Water Analyzer Operating Instruction PDFDocument46 pagesTeledyne Oil in Water Analyzer Operating Instruction PDFKarthik BNo ratings yet

- Analizador de Oxigeno Teledyne Analytical Instruments PDFDocument50 pagesAnalizador de Oxigeno Teledyne Analytical Instruments PDFJohn Jairo Contreras PatiñoNo ratings yet

- Man lxt-280Document57 pagesMan lxt-280Naser JahangiriNo ratings yet

- Model 3190: Trace Oxygen AnalyzerDocument59 pagesModel 3190: Trace Oxygen AnalyzerSankarNo ratings yet

- SV 104A Manual INDocument80 pagesSV 104A Manual INBruno PergherNo ratings yet

- Visiferm Do Sensors: Operating InstructionsDocument40 pagesVisiferm Do Sensors: Operating InstructionsDispositivos PerinaNo ratings yet

- Ortable Xygen Nalyzer: Operating & Service Instructions ForDocument47 pagesOrtable Xygen Nalyzer: Operating & Service Instructions Forcalibration aragoncalibrations.comNo ratings yet

- Modicon: MCSESU Unmanaged Switch Installation ManualDocument33 pagesModicon: MCSESU Unmanaged Switch Installation ManualIsis Lucena RochaNo ratings yet

- User's Manual: NVR-7308P8-H2 NVR-7316P8-H2 NVR-7524P8-H4 NVR-7716P16-H2Document54 pagesUser's Manual: NVR-7308P8-H2 NVR-7316P8-H2 NVR-7524P8-H4 NVR-7716P16-H2EdhimingMingNo ratings yet

- Eclipse®: Installation & Maintenance InstructionsDocument69 pagesEclipse®: Installation & Maintenance InstructionsKarim AhmedNo ratings yet

- 57-606.9 Eclipse Model 706 Hart Io 1 PDFDocument108 pages57-606.9 Eclipse Model 706 Hart Io 1 PDFAbdul Shaharlal ENo ratings yet

- Manualde Servicio Humastar80Document105 pagesManualde Servicio Humastar80omarNo ratings yet

- Vertiv Liebert DM User ManualDocument134 pagesVertiv Liebert DM User ManualJose Sergio Melo SouzaNo ratings yet

- Personal Surveyor 200 User Handbook: Gas Measurement Instruments LTDDocument92 pagesPersonal Surveyor 200 User Handbook: Gas Measurement Instruments LTDGiang TrườngNo ratings yet

- Magnetrol Eclipse 706 Instrukcja HART enDocument108 pagesMagnetrol Eclipse 706 Instrukcja HART enDEVNo ratings yet

- SO Safety Manual F300K DLT7663 19 AEN 003Document22 pagesSO Safety Manual F300K DLT7663 19 AEN 003Ali JamaliNo ratings yet

- User Guide: Low and High Level Dissolved Oxygen MonitorDocument40 pagesUser Guide: Low and High Level Dissolved Oxygen MonitorAnuta CosminNo ratings yet

- Manual Escaner EstructuralDocument37 pagesManual Escaner EstructuralManuel Felipe López VelaNo ratings yet

- Installation, Operating and Maintenance Instructions: HADEF Monorail Trolley Type 18/16VADocument11 pagesInstallation, Operating and Maintenance Instructions: HADEF Monorail Trolley Type 18/16VAGuillermo ManchayNo ratings yet

- ShipsurveyorDocument104 pagesShipsurveyorVarestNo ratings yet

- HumaLyzer 3000 User PDFDocument56 pagesHumaLyzer 3000 User PDFAyaovi Jorlau82% (17)

- Installation/Service Manual: Passion For ExcellenceDocument66 pagesInstallation/Service Manual: Passion For ExcellenceWiden Carreño100% (1)

- ECD-KEB F5 VF Installation Manual (Feb 02, 2021)Document24 pagesECD-KEB F5 VF Installation Manual (Feb 02, 2021)Eric EmmsNo ratings yet

- QS OPTIFLUX2000 en 140417 4002298802 R07Document24 pagesQS OPTIFLUX2000 en 140417 4002298802 R07Fabio UnruhNo ratings yet

- GW - Lynx Home U Series (LV) User Manual-ENDocument34 pagesGW - Lynx Home U Series (LV) User Manual-ENJorge Garrido RedondoNo ratings yet

- R02 MAN IM IND570dyn MLDocument53 pagesR02 MAN IM IND570dyn MLmostafa.othman150No ratings yet

- Hipotronics OC60-DI User ManualDocument27 pagesHipotronics OC60-DI User ManualAlaa ZoraNo ratings yet

- Magnetrol Eclipse 700 Instrukcja HART enDocument92 pagesMagnetrol Eclipse 700 Instrukcja HART enjai5hanka6No ratings yet

- GDC Multi-Parameter Monitoring System: User's ManualDocument53 pagesGDC Multi-Parameter Monitoring System: User's ManualHector NavarreteNo ratings yet

- Distributed Busbar Protection REB500: Commissioning ManualDocument26 pagesDistributed Busbar Protection REB500: Commissioning ManualaladiperumalNo ratings yet

- Installation Manual. IND9D57 - Dyn-570 Dynamic Weighing SystemDocument27 pagesInstallation Manual. IND9D57 - Dyn-570 Dynamic Weighing SystemCarlos Lasso OrtegaNo ratings yet

- Manual BW500 BW500L en-USDocument204 pagesManual BW500 BW500L en-USAdilson SouzaNo ratings yet

- QS WATERFLUX3000 en 180307 4002400902 R07Document24 pagesQS WATERFLUX3000 en 180307 4002400902 R07ZAHID HOSSAINNo ratings yet

- 58E0035D Handbook Engv1.1Document29 pages58E0035D Handbook Engv1.1nedzadNo ratings yet

- CL-4100 Magnetrol PDFDocument60 pagesCL-4100 Magnetrol PDFJorge Arturo Rodriguez ChavezNo ratings yet

- T-BERD/MTS 5800 Timing Expansion Module User ManualDocument100 pagesT-BERD/MTS 5800 Timing Expansion Module User ManualThanh LeNo ratings yet

- 57-600.22 Eclipse Model 705 Io PDFDocument68 pages57-600.22 Eclipse Model 705 Io PDFtuanbrotherNo ratings yet

- QS OPTICHECK en 140630 4003706601 R01 1000274348 1Document16 pagesQS OPTICHECK en 140630 4003706601 R01 1000274348 1Siliana SilianaNo ratings yet

- Гематологический Анализатор HumaCount (Human) РПDocument52 pagesГематологический Анализатор HumaCount (Human) РПvaklinNo ratings yet

- Installation and Operations Manual: 6700 Liquid Level IndicatorDocument54 pagesInstallation and Operations Manual: 6700 Liquid Level IndicatorDianna LambertNo ratings yet

- Flujometro Batch Flux 5500Document24 pagesFlujometro Batch Flux 5500sergio fuerteNo ratings yet

- QS OPTIFLUX2000 en 110815 7309842400 R04Document24 pagesQS OPTIFLUX2000 en 110815 7309842400 R04Fabio UnruhNo ratings yet

- M860 Handheld Monitor Service ManualDocument19 pagesM860 Handheld Monitor Service ManualMateusz100% (4)

- Optiflux 2000 Quick Start GuideDocument28 pagesOptiflux 2000 Quick Start GuideRahul PatelNo ratings yet

- Atc6300 SiemensDocument192 pagesAtc6300 SiemensDavid MonederoNo ratings yet

- 000 230P, 240B 240E (G120) Getting StartedDocument50 pages000 230P, 240B 240E (G120) Getting StartedTeste MPRNo ratings yet

- Av 410Document64 pagesAv 410Anuta CosminNo ratings yet

- U18 AA EN 001 N-R 601d 0515 PDFDocument134 pagesU18 AA EN 001 N-R 601d 0515 PDFhaydarNo ratings yet

- 3804 Digital Hitester: Instruction ManualDocument68 pages3804 Digital Hitester: Instruction ManualRaul Damian TavaresNo ratings yet

- 505372-UEN CM B670I 2p2Document172 pages505372-UEN CM B670I 2p2Fabrizio HONo ratings yet

- Nano User - Manual - enDocument29 pagesNano User - Manual - eninfoweb1No ratings yet

- Man 2020Document93 pagesMan 2020juan jose claros morenoNo ratings yet

- MWD BPC Feig Radar - EnglishDocument20 pagesMWD BPC Feig Radar - EnglishDmitriiȘtirbuNo ratings yet

- 710-17074-00F MVE IP00 User Manual EN PDFDocument77 pages710-17074-00F MVE IP00 User Manual EN PDFJunie TayrusNo ratings yet

- GW - HT 1500V - User Manual-ENDocument57 pagesGW - HT 1500V - User Manual-ENPavel LaurinecNo ratings yet

- BAL Speedgate Swing Advanced EN 1V0 REC 102-905401021Document26 pagesBAL Speedgate Swing Advanced EN 1V0 REC 102-905401021mouradNo ratings yet

- Digital Panel Voltmeter: Operator's ManualDocument16 pagesDigital Panel Voltmeter: Operator's ManualbrayanfNo ratings yet

- Fieldbus Power Hub, High-Density Motherboard For Yokogawa ALF 111 ConnectionDocument3 pagesFieldbus Power Hub, High-Density Motherboard For Yokogawa ALF 111 ConnectionProcurement PardisanNo ratings yet

- D FMP MagMaster MFE - 8 (US)Document10 pagesD FMP MagMaster MFE - 8 (US)Procurement PardisanNo ratings yet

- Eaton Xpole Pfim F RCCB Catalog Ca019030en en UsDocument11 pagesEaton Xpole Pfim F RCCB Catalog Ca019030en en UsProcurement PardisanNo ratings yet

- 3AH4 Vacuum Circuit-Breakers: Answers For EnergyDocument36 pages3AH4 Vacuum Circuit-Breakers: Answers For EnergyElmir HuseinbasicNo ratings yet

- Esmsr 2 KV 6Document10 pagesEsmsr 2 KV 6Procurement PardisanNo ratings yet

- PR Ve 0005 enDocument12 pagesPR Ve 0005 enProcurement PardisanNo ratings yet

- Buy RS485 Active Barrier. ATEX II (1) GD (EEx Ia) IIC, I (M2) (EEx Ia) From Vetek HereDocument7 pagesBuy RS485 Active Barrier. ATEX II (1) GD (EEx Ia) IIC, I (M2) (EEx Ia) From Vetek HereProcurement PardisanNo ratings yet

- St6911 Ipt™ Acceleration Vibration Transducer St6917 Ipt™ Velocity Vibration TransducerDocument8 pagesSt6911 Ipt™ Acceleration Vibration Transducer St6917 Ipt™ Velocity Vibration TransducerProcurement PardisanNo ratings yet

- Abb Saprod1kgt012400r0001Document1 pageAbb Saprod1kgt012400r0001Procurement PardisanNo ratings yet

- Process Process Process Process ProcessDocument3 pagesProcess Process Process Process ProcessProcurement PardisanNo ratings yet

- Eaton Xpole Pfim F RCCB Catalog Ca019030en en UsDocument11 pagesEaton Xpole Pfim F RCCB Catalog Ca019030en en UsProcurement PardisanNo ratings yet

- What Is Industrial Automation - Types of Industrial AutomationDocument8 pagesWhat Is Industrial Automation - Types of Industrial AutomationProcurement PardisanNo ratings yet

- Heinemann Series GJ Circuit BreakersDocument8 pagesHeinemann Series GJ Circuit BreakersProcurement PardisanNo ratings yet

- Light Bulb Base Sizes and Socket Types - An Expert GuideDocument31 pagesLight Bulb Base Sizes and Socket Types - An Expert GuideProcurement PardisanNo ratings yet

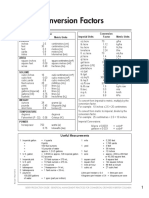

- Power AppendixesDocument135 pagesPower AppendixesProcurement PardisanNo ratings yet

- The European Standard EN 50288-7: Construction Details Reference Standards Design OptionsDocument1 pageThe European Standard EN 50288-7: Construction Details Reference Standards Design OptionsProcurement PardisanNo ratings yet

- Levels of AutomationDocument3 pagesLevels of AutomationProcurement PardisanNo ratings yet

- What Is Optoisolator (Optical Coupler or Optocoupler) - Definition From WhatIsDocument5 pagesWhat Is Optoisolator (Optical Coupler or Optocoupler) - Definition From WhatIsProcurement PardisanNo ratings yet

- Barrier Vs Isolator-Difference Between Barrier and IsolatorDocument4 pagesBarrier Vs Isolator-Difference Between Barrier and IsolatorProcurement PardisanNo ratings yet

- The Levels of Automation - Technology - 2025AD - Automated Driving, Autonomous DrivingDocument5 pagesThe Levels of Automation - Technology - 2025AD - Automated Driving, Autonomous DrivingProcurement PardisanNo ratings yet

- Introduction To Coaxial CableDocument9 pagesIntroduction To Coaxial CableProcurement PardisanNo ratings yet

- The Difference Between BS5308 Cable PAS 5308 Cable and EN 50288 Cable - What Are EN 50288-7 CablesDocument4 pagesThe Difference Between BS5308 Cable PAS 5308 Cable and EN 50288 Cable - What Are EN 50288-7 CablesProcurement PardisanNo ratings yet

- Level 1 and 2 AutomationDocument2 pagesLevel 1 and 2 AutomationProcurement PardisanNo ratings yet

- Isolated & Non-Isolated ConvertersDocument1 pageIsolated & Non-Isolated ConvertersSpectreForceNo ratings yet

- Startup ManualDocument3 pagesStartup ManualProcurement PardisanNo ratings yet

- Electrical Isolation - Transformers - Electronics TextbookDocument4 pagesElectrical Isolation - Transformers - Electronics TextbookProcurement PardisanNo ratings yet

- Opto-Isolator - WikipediaDocument10 pagesOpto-Isolator - WikipediaProcurement PardisanNo ratings yet

- What Is Electrical Isolation - Definition From CorrosionpediaDocument1 pageWhat Is Electrical Isolation - Definition From CorrosionpediaProcurement PardisanNo ratings yet

- Manuals Guides Ams Device Manager v14 1 1 Planning Installation Guide Ams en 6100082Document122 pagesManuals Guides Ams Device Manager v14 1 1 Planning Installation Guide Ams en 6100082Procurement PardisanNo ratings yet

- Features: Intel Atom N455/D525 ISA Half-Size SBC With Vga/Lvds/Gbe Lan/Sata/Com/Cfc/ FDD and PC/104Document2 pagesFeatures: Intel Atom N455/D525 ISA Half-Size SBC With Vga/Lvds/Gbe Lan/Sata/Com/Cfc/ FDD and PC/104Procurement PardisanNo ratings yet

- LCOE CHILE Ene - 11052401aDocument23 pagesLCOE CHILE Ene - 11052401aLenin AgrinzoneNo ratings yet

- January 2017Document80 pagesJanuary 2017Alexandre AGNo ratings yet

- Safety Data Sheet: Armohib Ci-28Document21 pagesSafety Data Sheet: Armohib Ci-28SJHEIK AbdullahNo ratings yet

- Staff Augmentation Agreement FormDocument11 pagesStaff Augmentation Agreement FormNijo JosephNo ratings yet

- Metric Tables 2012Document2 pagesMetric Tables 2012ParthJainNo ratings yet

- Sendik's Oconomowoc Press AnnouncementDocument2 pagesSendik's Oconomowoc Press AnnouncementTMJ4 NewsNo ratings yet

- Enidine Wire Rope IsolatorsDocument52 pagesEnidine Wire Rope IsolatorsJocaNo ratings yet

- Practice Questions SheetDocument4 pagesPractice Questions Sheetsaif hasanNo ratings yet

- The Object-Z Specification Language: Software Verification Research Centre University of QueenslandDocument155 pagesThe Object-Z Specification Language: Software Verification Research Centre University of QueenslandJulian Garcia TalanconNo ratings yet

- Jungle Safari Booking Management System: Mini Project ReportDocument19 pagesJungle Safari Booking Management System: Mini Project ReportNIRAV SHAH100% (1)

- KUTAI MCCB Circuit Breaker Transfer Switch With Remote Monitoring OptionsDocument11 pagesKUTAI MCCB Circuit Breaker Transfer Switch With Remote Monitoring OptionsJanice LuNo ratings yet

- Illustrated Microsoft Office 365 and Office 2016 Projects Loose Leaf Version 1st Edition Cram Solutions Manual DownloadDocument10 pagesIllustrated Microsoft Office 365 and Office 2016 Projects Loose Leaf Version 1st Edition Cram Solutions Manual DownloadJan Neeley100% (22)

- Trade Secrets Lawsuit V ReebokDocument17 pagesTrade Secrets Lawsuit V ReebokDarren Adam HeitnerNo ratings yet

- (Your Business Name Here) - Safe Work Procedure Metal LatheDocument1 page(Your Business Name Here) - Safe Work Procedure Metal LatheSafety DeptNo ratings yet

- Volatility Index 75 Macfibonacci Trading PDFDocument3 pagesVolatility Index 75 Macfibonacci Trading PDFSidibe MoctarNo ratings yet

- Class 10th IMO 5 Years EbookDocument71 pagesClass 10th IMO 5 Years EbookAdarsh Agrawal100% (1)

- RidleyBoxManual1 17Document63 pagesRidleyBoxManual1 17Sergio Omar OrlandoNo ratings yet

- Problem 4. Markov Chains (Initial State Multiplication)Document7 pagesProblem 4. Markov Chains (Initial State Multiplication)Karina Salazar NuñezNo ratings yet

- Application & Registration Form MSC International Business Management M2Document11 pagesApplication & Registration Form MSC International Business Management M2Way To Euro Mission Education ConsultancyNo ratings yet

- FBS Ii enDocument10 pagesFBS Ii enunsalNo ratings yet

- Project On Teaining DevelopmentDocument88 pagesProject On Teaining Developmentsurya annamdevulaNo ratings yet

- Welding Chart The Complete Reference Guide To WeldingDocument2 pagesWelding Chart The Complete Reference Guide To WeldingJitu JenaNo ratings yet

- Assessment E - Contract - LaundryDocument5 pagesAssessment E - Contract - LaundrySiddhartha BhusalNo ratings yet

- E-Business & Cyber LawsDocument5 pagesE-Business & Cyber LawsHARSHIT KUMARNo ratings yet

- As 2419Document93 pagesAs 2419Craftychemist100% (2)

- Yrc1000 Options InstructionsDocument36 pagesYrc1000 Options Instructionshanh nguyenNo ratings yet

- Drawing Conclusions: LessonDocument6 pagesDrawing Conclusions: LessonMallari Fam0% (1)

- CasaGrande BrochureDocument23 pagesCasaGrande BrochuresubbuNo ratings yet

- Ease Us Fix ToolDocument7 pagesEase Us Fix ToolGregorio TironaNo ratings yet

- Ordinary Differential Equations Multiple Choice Questions and Answers - SanfoundryDocument7 pagesOrdinary Differential Equations Multiple Choice Questions and Answers - SanfoundrySaiman PervaizNo ratings yet