Professional Documents

Culture Documents

Acoustical Considerations For Mixed-Use Wood Frame Buildings

Uploaded by

Adam JonesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acoustical Considerations For Mixed-Use Wood Frame Buildings

Uploaded by

Adam JonesCopyright:

Available Formats

Acoustical Considerations for

Mixed-Use Wood-Frame Buildings

Steve Thorburn, PE, LEED AP, CTS-I, CTS-D, Thorburn Associates

Acoustics are just one aspect of building performance and

must be considered in combination with requirements such

as fire protection, structural systems and energy efficiency. To

determine an optimal design solution, it is critically important

to understand how the design and detailing for each individual

system affects the others. Specifically, in addition to meeting

the appropriate acoustical rating(s), the assemblies chosen must

achieve the required fire ratings and accommodate the structural

and energy needs of the project. Understanding the effects of

each performance area enables the design team to more easily

navigate the decisions and trade-offs required when evaluating

different assembly options.

Multi-Family Housing

Acoustical Expectations

As with any issue of building performance, the acoustics of a

mixed-use wood-frame structure can be designed to meet or

exceed minimal requirements, depending on the expectations

of the developer, buyers and tenants.

In residential buildings, the International Building Code (IBC)

provides a minimum design requirement for unit-to-unit

acoustical protection between floors. It requires a Sound

Transmission Class (STC) rating or Impact Insulation Class (IIC) University of Washington West Campus Student Housing – Phase One

rating of 50, unless the “Authority Having Jurisdiction” has its For this student housing project, the acoustical engineer

own more stringent requirement, which is rarely the case. The recommended a strategic combination of staggered stud

and double stud walls to minimize sound transmission.

International Residential Code (IRC) requires a minimum design Mahlum Architects; photo Benjamin Benschneider

separation of STC 45 for townhouses.

For wood-frame mixed-use buildings, Section 1207 of the 2012 IBC includes the following:

1207.1 Scope. This section shall apply to common interior walls, exhaust ducts shall be sealed, lined, insulated or otherwise treated to

partitions and floor/ceiling assemblies between adjacent dwelling units or maintain the required ratings. This requirement shall not apply to dwelling

between dwelling units and adjacent public areas such as halls, corridors, unit entrance doors; however, such doors shall be tight fitting to the

stairs or service areas. frame and sill.

1207.2 Airborne sound. Walls, partitions and floor/ceiling assemblies 1207.3 Structure-borne sound. Floor/ceiling assemblies between

separating dwelling units from each other or from public or service areas dwelling units or between a dwelling unit and a public or service area

shall have a sound transmission class (STC) of not less than 50 (45 if field within the structure shall have an impact insulation class (IIC) rating of

tested) for air-borne noise when tested in accordance with ASTM E 90. not less than 50 (45 if field tested) when tested in accordance with

Penetrations or openings in construction assemblies for piping; electrical ASTM E 492(09).

devices; recessed cabinets; bathtubs; soffits; or heating, ventilating or

$FRA_429_Acoustics_Solutions_Paper.indd 1 7/29/14 1:32 PM

This minimum requirement is the same for entry level housing, (such as back yards and balconies) in different types of housing.

market rate housing and luxury housing, whether it is dorms, Ldn maps are commonly found in a municipality’s general plan.

apartments or condominiums. Beyond that, it is the responsibility If Ldn maps are not available, acoustical measurements can be

of the design team to develop an acoustical design that meets taken to help calculate/predict what the noise levels will be just

owner/developer/renter expectations for the project. outside the building.

The current standard for acoustical detailing dates back to 1963. Window and door systems are typically the controlling factor for

The FHA/HUD Noise Control in Multi-Family Housing document exterior to interior acoustical isolation. Terms like OITC (Outside

of that year suggested three levels of acoustical isolation: entry Inside Transmission Class) for windows may be used. This is a

level, market rate and luxury housing. Table 1 provides suggested metric that helps select the noise blocking ability or transmission

separations between different units in a project based on the class of a system from the outside to inside. For areas that are

acoustical expectation of these three different multi-family louder than 60 Ldn, the windows will typically have to be kept

housing markets. closed to meet the 45 Ldn interior noise level. If fresh air or

air changes are required per the project’s housing code, then

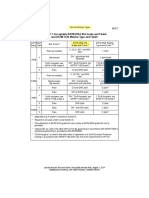

TABLE 1 mechanical ventilation or some type of acoustical air transfer

Acoustical Isolation Between Units – Airborne (STC) / Impact (IIC) system will be required.

Class Airborne Sound Floor Ceiling Impact

Designation Isolation (STC) Isolation (IIC)

Entry level 50 50

Retail-to-Unit (Mixed-Use)

In a mixed-use project, consideration must be given to the

Market rate 55 55 acoustics between all of the adjacent spaces—not just dwelling

unit to dwelling unit. Acoustical separation between residential

Luxury 60 60

and other occupancies can be a significant challenge and this

condition is not addressed in the IRC or IBC, though it is starting

to be addressed in green building codes such as the California

Exterior-to-Unit Green Building Standards Code (CALGreen). Figure 1 shows

a typical floor/ceiling detail between a lower floor restaurant

The level of exterior noise is what determines the acoustical

or bar with residential units above. This is a poor performing

requirements of a building’s exterior wall. However, the 2012 IBC

configuration for acoustics, with an STC of less than 35.

does not include acoustic requirements for exterior walls. Older

versions of the Uniform Building Code required exterior noise

levels be controlled to 45 Ldn (day/night sound level) inside the

unit unless, again, the “Authority Having Jurisdiction” has more FIGURE 1

restrictive requirements. In all but the loudest environments, Although common between restaurants or bars and the

apartments above, the configuration shown in this detail

housing will typically be found in an area with an Ldn of 80 or may lead to noise complaints by apartment occupants.

quieter. Therefore, it would be reasonable to design exterior

walls with the capacity to reduce noise levels by 35 Ldn or less. Gypsum

concrete

Land use compatibility tables similar to Table 2 below help define Wood

the appropriate levels of noise intrusion from outside use areas structural

panel

TABLE 2

Joist

Land Use Compatibility Acoustical Matrix – Model Noise Ordinance

Land Use Category Exterior Day/Night Noise Levels (Ldn, dBA) Batt

insulation

55 60 65 70 75 80

Single Family

Multi Family

Motel, Hotels

Outside Use CEILING

PLENUM

Acoustical

tile ceiling

Normally Acceptable Normally Unacceptable

Conditionally Acceptable Clearly Unacceptable

State of California General Plan Guidelines, 1987

$FRA_429_Acoustics_Solutions_Paper.indd 2 7/29/14 1:32 PM

Vocabulary

Current building codes do not reference the most recent acoustical ASTM standards due to the lag in the code adoption cycle. Designers

need to carefully review the code and determine which acoustical standard needs to be applied. For example, some jurisdictions call for

STC ratings, some allow a Field Test (FSTC) and some call for Noise Isolation Class (NIC) or Apparent Sound Transmission Class (ASTC).

This is all dependent on the building code year and associated reference standard. While many of the definitions are similar, some take

into account the total experience of how sound gets from one space to the next while others look just at the partition and others still

consider the experience but normalized to a standard room. The following definitions, grouped by topic, can help:

Noise Reduction (NR) provided by the complete building system, ear. The sound level is obtained by use of a

The difference in sound pressure level between including flanking paths, and is normalized for standard sound level meter and is expressed in

any two points along the path of sound the receiving room acoustical absorption so it decibels. Sometimes the unit of sound level is

propagation. can be compared to a standard room. written as dBA.

Transmission Loss (TL) Field Sound Transmission Class (FSTC) Day/Night Sound Level (Ldn)

A measurement, in decibels (dB), of how A single-number rating which quantifies the A descriptor established by the Environmental

much sound energy is reduced by transmission sound insulation properties of a partition Protection Agency (EPA) for the 24-hour

through materials. as measured in the field in the absence of average A-weighted noise level. Sound levels

flanking paths. during the hours from 10:00 p.m. to 7:00

Noise Isolation Class (NIC) a.m., hours in which people are more sensitive

A single-number rating derived from the Impact Insulation Class (IIC) to noise, are penalized 10 decibels (dB). A 10

measured value of noise reduction between A single-number rating which describes how dB increase in sound level is perceived by most

two enclosed spaces that are connected by much noise created by footfalls/impact on people to be twice as loud.

one or more paths. The NIC is not adjusted or a floor through a ceiling. This is a laboratory

normalized to a standard reverberation time. test in a controlled acoustical environment. Community Noise Equivalent Level (CNEL)

A standardized testing device generates the A descriptor for the 24-hour A-weighted

Flanking Paths impact sound by dropping five hammers, average noise level. The CNEL concept

Indirect paths through which sound energy which impart a known energy into the accounts for the increased acoustical sensitivity

can bypass constructions and seriously floor/ceiling construction. In the receiving of people to noise during the evening and

degrade the transmission loss (TL) rating of room below, the resulting sound pressure nighttime hours. Sound levels during the hours

that construction. Example flanking paths are level is measured in frequency bandwidths from 7:00 p.m. to 10:00 p.m. are penalized 5

open ceiling plenums and attics, continuous comparable to those used in sound dB; sound levels during the hours from 10:00

side walls and floors, air duct and pipe transmission loss measurements. Increasing IIC p.m. to 7:00 a.m. are penalized 10 dB. A 10

penetrations, joist and crawl spaces. Flanking values correspond to improved impact noise dB increase in sound level is perceived by most

paths can be prevented by careful design of dampening qualities. people to be twice as loud.

all connections, penetrations and adjacent

framing systems. Field Impact Insulation Class (FIIC) Outdoor-Indoor Transmission Class (OITC)

A single-number rating which quantifies the A standard used for indicating the rate of

Sound Transmission Class (STC) property of a floor/ceiling construction to transmission of sound between outdoor

A single-number rating which describes how reduce footfall-generated noise as measured and indoor spaces in a structure. It is based

much sound a wall or floor/ceiling construction in the field. on the ASTM E-1332 Standard Classification

will block from one room to the next. STC is for the Determination of Outdoor-Indoor

applied to situations where speech or office Apparent Impact Insulation Class (AIIC) Transmission Class. An alternative similar

noise constitutes the main sound problem. To A single-number rating which quantifies the standard for determining the rate of acoustic

determine the rating, an active loudspeaker property of a floor/ceiling construction to isolation of a separation between spaces is

is placed on one side of the partition and reduce the apparent impact transmission loss Sound Transmission Class (STC). While STC is

sound levels are measured on both sides. The data. The apparent impact insulation class based on a noise spectrum targeting speech

difference in levels shows how much sound provides a measure of the impact sound sounds, OITC utilizes a source noise spectrum

can be blocked by the partition. The higher reduction provided by the complete floor/ that considers frequencies down to 80 Hertz

the rating, the better the sound insulation ceiling system, including flanking paths. (or Hz, such as aircraft/rail/truck traffic) and is

properties. This is a laboratory test in a weighted more to lower frequencies.

controlled acoustical environment. A-Weighted Sound Level (Noise Level)

A term for the A-weighted sound pressure

Apparent Sound Transmission Class (ASTC) level. A-weighting is a frequency weighting

A single-number rating derived from the commonly used to measure the loudness or

measured value of apparent transmission loss “noisiness” of sounds. A-weighting filters the

data. The apparent sound transmission class microphone signal in a manner which better

provides a measure of the sound reduction correlates with the sensation of the human

$FRA_429_Acoustics_Solutions_Paper.indd 3 7/29/14 1:32 PM

Air Tight and Insulated

FIGURE 2

Two things are always assumed in acoustical detailing. First, the

Typical Outlet Box

cavity is insulated with batt insulation. Second, it is sealed air

tight. If the partition is a resilient system, it needs to be sealed

with acoustical caulk to maintain the flexibility and resiliency

Batt insulation

of that acoustical solution. Acoustical caulk does not set with

time; it acts as a skin over the finishing but is still flexible below

Outlet box pad,

wrapped around the skin. If the partition is not resilient, such as a double stud or

junction box to seal

1/ ” penetration airtight staggered stud wall, it needs to be sealed air tight. This can be

4

achieved by floating a topping slab under the base of the gypsum

board, by lapping the joints in the corner and taping, or with fire

caulking/sealant. It is important to seal all holes, recessed light

Junction box

fixtures, plumbing penetrations and outlet boxes (see Figure 2).

1/ ”

4 Wherever air can flow, sound can travel. For large openings like

outlet boxes, the box must be sealed air tight with an acoustical

or fire putty sheet from the wall cavity side prior to gypsum board

installation. Then the void between the gypsum board and the

outlet box is caulked and sealed air tight after the gypsum board

has been installed.

Gypsum board

Walls

Sound isolation can be accomplished in two ways. One is to use

partitions with a high mass (75 pounds per square foot, psf, or

greater) or to use low mass systems (2 to 5 psf) separated by air

spaces of 3 to 6 inches.

The goal in party walls or exterior walls is to keep other people’s

noise out of, and your noise in, the unit. In lightweight wood

structures, this is achieved by separating the materials with an

FIGURE 3 air space (e.g., stud or joist construction).

STC 63 Party Wall

As discussed above, the more expensive the unit, the higher the

STC rating is expected to be. However, in most cases, a designer

STRUCTURE will choose different techniques within the same project based

on occupant needs in order to meet acoustical objectives in a way

Caulk with

acoustical sealant

that is also cost effective.

SECTION

1-1/2” In wood-frame construction, the most effective wall in terms of

unobstructed

airspace acoustical performance is a double stud wall. As shown in Figure 3,

this wall can achieve a rating of approximately STC 63 when

Batt insulation insulated with batt insulation and covered with two layers of

PLAN gypsum wallboard on the outside faces of the studs. STC 63 is

VIEW Double row

wood studs the highest rating possible unless rooms and spaces are detailed

like a studio with floating floors, etc.

(2) Layers gypsum After double stud construction, the next best framing solutions

board both sides

of wall

are staggered stud and then single stud construction (see Figure 4).

SECTION

Acoustically, a single stud wall creates a bridging point for sound

Caulk with to be conducted along every stud. This line of contact created by

acoustical sealant

the stud allows sound on one side of the wall to be transferred

FLOOR through the gypsum wallboard into the stud and back out the

gypsum wallboard on the other side of the wall. The other source

of sound transfer is sound striking the plane of the gypsum

wallboard between studs. As sound vibrates this plane, it travels

through the cavity and causes the gypsum wallboard on the other

side of the stud to vibrate and reradiate the noise.

$FRA_429_Acoustics_Solutions_Paper.indd 4 7/29/14 1:32 PM

FIGURE 4

Acoustical Progression in Wood-Framed Walls

STRUCTURE STRUCTURE STRUCTURE STRUCTURE STRUCTURE STRUCTURE

SECTION SECTION SECTION SECTION SECTION SECTION

PLAN PLAN PLAN PLAN PLAN PLAN

VIEW VIEW VIEW VIEW VIEW VIEW

SECTION SECTION SECTION SECTION SECTION SECTION

FLOOR FLOOR FLOOR FLOOR FLOOR FLOOR

STC 34 STC 38 STC 45 STC 50 STC 56 STC 63

When the gypsum wallboard on one side of the stud is be connected together by the utilities, acoustically bridging the

disconnected from the other side in a double or staggered two lines of studs. However, if care is taken during construction,

stud wall system, the transmitted sound is reduced and the a staggered 2x4 stud wall on an 8-inch nominal plate achieves

assembly has a higher STC rating. The advantage of the double a rating of STC 60 and with a wider double stud system the

stud wall over the staggered stud wall is twofold. The greater assembly achieves a rating of STC 63 (assuming batt insulation

the separation between the gypsum wallboard on each face in each stud cavity and two layers of 5/8-inch gypsum board on

of the wall, the more the noise is reduced and the greater the both sides of the wall). See Figure 5.

STC rating becomes. The second advantage is that building

In all cases, the connections at the bottom and top plates (floor

utilities can be isolated from the stud system for the unit they

and ceiling systems) running between adjacent units in multi-

serve. If the staggered stud wall has plumbing or electrical run

family housing are a flanking path where sound travels through

through the cavity, there is greater chance that the studs will

the adjacent structure and is reradiated on the other side.

FIGURE 5

Acoustical Detailing for Wood-Framed Walls

STRUCTURE STRUCTURE STRUCTURE

Caulk with

acoustical sealant

SECTION SECTION Caulk with SECTION

acoustical sealant 1-1/2”

unobstructed

(1) Layer gypsum board airspace

both sides of studs

Batt insulation

PLAN PLAN Resilient channel PLAN

VIEW VIEW VIEW Double row

Wood studs wood studs

(2) Layers gypsum board

Batt insulation both sides of wall

SECTION SECTION Caulk with SECTION

acoustical sealant

Caulk with

acoustical sealant

FLOOR FLOOR FLOOR

STC 38 STC 45 STC 63

$FRA_429_Acoustics_Solutions_Paper.indd 5 7/29/14 1:32 PM

Improvement Factors In Three factors reduce the potential acoustical isolation:

Acoustical Isolation Systems

• First is a smaller air space between the sheathing systems.

Sheathing

• Second is the common resonance of the two thinner

In a light-frame wood building, the mass of the sheathing is just wall systems. In this case, the walls radiate at the same

as important as the air space provided by the stud or joist cavity. frequency, coupling with each other, which reduces the

In acoustical detailing, 5/8-inch-thick type “X” gypsum board is wall system’s acoustical effectiveness.

typically required. This material has a mass of 2.2 psf versus 1.6

psf for 1/2-inch-thick gypsum board. • Third is the air space between the walls. In the case of

lot-line walls for townhouses or row housing, the air space

When a shear wall is needed, the standard level of care allows is typically sealed air tight. In the case of trapped air, one

a layer of gypsum board to be replaced acoustically with wood to two inches of air becomes very stiff, adding to the walls’

sheathing of equal mass. For example a 7/8-inch thick sheet ability to couple together.

of wood structural panel has a similar mass to 5/8-inch thick

gypsum board panel. When a shear layer is introduced to In the past, using multiple layers of gypsum sheathing to increase

walls with resilient channels or double stud walls are used, the the mass of the system has been the most common solution

assembly must be coordinated with applicable fire and structural to raising the STC rating of the system. A number of laminated

ratings. However, this is where understanding the impact of the gypsum systems have been developed to provide higher

construction type and fire rating affects the acoustical isolation. acoustical performance than the equivalent thickness of standard

For example, without understanding the importance of the air gypsum sheathing. In some cases, they have light-gauge sheet

space in the wall system, the impact of the order and location of metal installed between thinner layers of gypsum. In others,

the materials, a wall that commonly separates luxury units could they are simply thinner layers of gypsum glued together. These

go from STC 63 to STC 48 and not even meet building code products use the same principle of constrained layer damping

requirements. Figure 6 shows that, with the same materials but as plywood or laminated glass to increase strength and stiffness

in a different location, a wall can have an almost 20 STC point over their core materials. The challenge with the new materials

swing. Subjectively, this means four times more sound may be is that testing for these specialized or proprietary products has

transmitted through an improperly constructed wall. not yet been completed. Further, the testing that has been done

FIGURE 6

Effect of Sheathing Placement on Acoustical Performance (Plan View)

STC 58 STC 53 STC 48 STC 63

$FRA_429_Acoustics_Solutions_Paper.indd 6 7/29/14 1:32 PM

does not correspond to typical wall systems, so a true “apples fiberboard functions as a resilient system. However, as soon as

to apples” review cannot be completed. In the case of shear mechanical fasteners are introduced into the installation process,

wall sheathing, mass can be traded out for mass. With the new any benefit provided by the fiberboard is compromised by the

layered products, they are often changing stiffness properties fastening system. The mechanical fasteners allow acoustical

in addition to mass; therefore, the two products are not always energy that strikes the finish sheathing to be transferred into

interchangeable. the framing system and then radiate from the other side of the

partition. Having the mechanical fastening system “short circuit”

Insulation the resilient system is not limited to fiberboard systems and is an

The most cost-effective acoustical improvement to a sound installation concern for all resilient systems.

isolation system is the addition of batt insulation or any open Metal channel systems are attached perpendicular to the

cell foam system to the stud or joist cavity. Batt or open cell primary framing system. The installation of the secondary

insulation reduces the sound that makes it into the stud cavity in metal channel framing system changes the acoustical path

the same manner as sound absorption works in a room. While from a line source connection (gypsum wallboard to the

closed cell spray foams have higher R-values and offer improved entire length of the framing system) to a lattice connection

building envelope energy performance by sealing the partition of the cross points where the two systems connect. This in

and improving air tightness, the closed cells do not allow the itself reduces the transfer path of the acoustical energy from

vibrating air molecules to interact with the insulation product one side of the framing system to the other. If the lattice

so the sound attenuation is less. It is this interaction that helps connection is coupled with an isolation or resilient component,

reduce the sound. the transfer of acoustical energy is further minimized.

Laboratory tests have shown that the cavity should be at least There are several manufacturers of resilient channels and their

half-way filled to achieve a measurable improvement and that products vary widely in quality. It is worth doing some research

placement of the insulation does not have an impact providing and/or performance testing before making a selection. As a

it doesn’t interfere with a resilient wall or floor/ceiling system. general rule, hat channels are significantly inferior to resilient

In single stud walls, a single stud bay is filled; for staggered or channels since they are not free to move and achieve dissipation

double stud wall systems, insulation is only acoustically needed of the sound energy (Figure 7).

in one of the stud bays.

In some cases, the “Authority Having Jurisdiction” does not

require blocking when a wall system is filled with mineral wool

or rock wool insulation as a form of draft stop.

FIGURE 7

Resilient Connections

Metal Channels Found in Wood Framing

When double or staggered stud construction is not possible,

decoupling the sheathing from the framing provides a similar

form of isolation. Decoupling happens when the framing system

Hat Channel –

functions like a spring. The spring system deforms as sound Not Acoustical

strikes the gypsum wallboard. As the spring or resilient system

expands back to its original shape, it converts some of the

acoustical energy from the sound into mechanical energy so

there is not as much acoustical energy to transfer through the

7/8"

framing system.

Resilient systems come in different forms including:

• Fiberboard sheathing systems

• Special metal channels Resilient Channel –

• Vibration isolators Acoustical

Fiberboard is often used in acoustic assemblies. Many years ago

the product was tested in an acoustical laboratory. The system 1/2"

tested had the fiberboard glued to the framing system and the

gypsum board glued to the fiberboard. In that condition, the

$FRA_429_Acoustics_Solutions_Paper.indd 7 7/29/14 1:32 PM

An article in Sound and Vibration magazine1 discusses the

tested performance of different resilient channel products and

the common installation errors that impact actual performance

of the assembly. For example, the most common error is in the

location of the screws used to attach the gypsum sheathing

to the resilient channels. If the drywall screws are too long or line

up with the framing system, they’ll clamp the channel between

the framing and gypsum sheathing, defeating the goal of

decoupling the sheathing from the framing. If the vibrations are

not decoupled from framing, sound will transfer from one space

to the next.

The basic design is a metal channel bent into three sections:

a flange about 1-1/2 inches wide (where the gypsum board is

attached), a section about 1/2-inch tall (with long slots routed

into it to provide spring), and a third flange about 5/8-inch wide

where the channel is attached to the joist or stud.

A newer resilient system is a rubber (puck)

isolator with an attached metal clip (Figure 8). FIGURE 8

Typically the rubber isolator is attached to the Acoustical “Puck Isolator” Wall Detail (Isometric View)

framing system at about four feet on center or

every third framing member. This spacing further Puck isolator

reduces the number of contact points. After the

isolators are attached to the framing system, a

standard metal hat channel is installed into the

framing clip. The system (isolator, hat channel

and a single layer of 5/8-inch gypsum board) is

Hat channel

more than two inches deep. This reduces the

potential issue with fasteners (discussed above) SECTION

since drywall screws are rarely if ever this long. VIEW

Gypsum board

1

Sound and Vibration, December 2002, http://www.sandv.com/downloads/0212lill.pdf

$FRA_429_Acoustics_Solutions_Paper.indd 8 7/29/14 1:32 PM

Floor/Ceiling Systems

FIGURE 9

Everything discussed for walls applies to floor systems. While the

Acoustical Progression in Wood-Framed Floors/Ceilings

main sources of noise complaints relative to walls are televisions

(Section View)

or loudspeakers attached to party walls, footfall or impact

noise from above can be an issue in multi-story apartment or Tongue and

condominium projects if proper design steps are not taken. groove wood

structural

Figure 9 captures the range in acoustical performance that can panel

result from different floor/ceiling design layouts. The second

major noise complaint is floor squeaks, followed by spring in the

floor due to the span or the size of the joists.

Gypsum

Joist board

In light wood-frame buildings, one effective floor/ceiling option

features a base system construction similar to that shown in STC 37

Figure 10, which consists of the following:

Tongue and

• Gypcrete or light-weight concrete groove wood

structural

panel

• Impact isolation matt

• Tongue and groove subfloor

(glued and screwed to the joist)

Batt

insulation Gypsum

Joist

• Joist system (with 6 inches board

of batt insulation)

STC 43

• Resilient channel or puck system

Gypsum concrete

(resilient system)

• Two layers of 5/8-inch type “X” Tongue and

groove wood

gypsum board structural

panel

This system has a rating of STC 62, which is the highest rating

possible without moving to construction methods found in Batt

insulation Gypsum

recording studios. If the intent is to market a project as “luxury,” Joist board

then studio construction may need to be considered.

STC 49

To achieve a rating of STC 50, both topping with additional mass

Gypsum concrete

(such as gypcrete) and a resilient system on the bottom of the

joist are required. While some test reports indicate that STC 50 Tongue and

can be met with either the topping mass or the resilient system, groove wood

structural

research shows that these are exceptions. The test sponsors panel

themselves state that the systems were measured in a laboratory

and these results should not be expected in the field. Batt Resilient

insulation Joist channel

Installation of resilient systems on the ceiling creates a number

of challenges. The perimeter of the gypsum board needs to be Gypsum

STC 56 board

held back from the intersecting structure so the gypsum board

on the adjacent structure can flex in and out. If gypsum board

on the face of the wall is jammed tight to the adjacent framing Gypsum concrete

system (e.g., the joist system) as it is installed, the perimeter

Tongue and

of the resilient system will not flex and the acoustical isolation groove wood

in the lower frequencies will be compromised. Consider the structural

panel

typical installation sequence of gypsum board. First the ceiling

is installed, then the walls. The gypsum wallboard is pushed up Batt Resilient

to the ceiling for a tight seal for finish taping. It is this tight joint insulation Joist channel

that clamps the ceiling gypsum and resilient channels to the

underside of the joist; it is no different than having mechanical Gypsum

STC 62 board

fasteners screwed through the gypsum board channel and into

the framing system.

$FRA_429_Acoustics_Solutions_Paper.indd 9 7/29/14 1:32 PM

When resilient systems are used, the gypsum must be held

free from the adjacent perimeters, typically by 1/4-inch. This FIGURE 10

1/4-inch void needs to be caulked air tight with an acoustical Acoustical Detailing for Wood-Framed Floor Systems

caulk. Acoustical caulk does not harden over time; the surface

Gypsum

of the caulk will dry and skin over so it can be painted. If walls concrete

are doubling as a fire-resistant assembly and acoustic separation, Tongue and

groove wood

this may be an area where detailing compromise is needed. structural

panel

Acoustical sealant is excellent for fire-rated partitions and

acceptable for use at the perimeter of wall assemblies rated

1-3 hours.

Resilient

Floor framing systems vary by geographic region and over time. channel

As shown in Figure 11, the acoustical detail is treated the same

regardless of the floor framing system.

Gypsum

Batt insulation Joist board

FIGURE 11

Acoustical Joist Systems (Isometric View)

Acoustical detailing is the same regardless of floor framing system

Flooring Flooring

Gypsum concrete

Gypsum concrete

Tongue and groove

wood structural panel Tongue and groove

wood structural panel

Gypsum board

Gypsum board

B at

t in

sul

at i o I-Joist

Joist n

Resilient channel Resilient channel

Flooring

Gypsum concrete Flooring

Tongue and groove Gypsum concrete

wood structural panel Tongue and groove

wood structural panel

Parallel chord truss

Open web truss

Gypsum board

Gypsum board

Resilient channel Resilient channel

10

$FRA_429_Acoustics_Solutions_Paper.indd 10 7/29/14 1:32 PM

FIGURE 12

Impact Isolation Progression in Wood-Framed Floors/Ceilings (Section View)

Note: For clarity, batt insulation in the joist cavity is not shown

Floating wood floor

with isolation matt

underneath

Heavy carpet Thin carpet Cushion backed Tile Bare floor

vinyl

Plywood

Joist

Gypsum board Resilient channel

IIC 73 IIC 64 IIC 56 IIC 43 IIC 38 IIC 38

Impact Isolation Conclusion

The effects of floor finish on the impact isolation are shown in There are many nuances associated with the transfer of sound

Figure 12. Impact noise can be reduced considerably with the use and acoustical design. The intent of this paper is to introduce the

of soft finishes such as carpet. When carpeting is not practical reader to general concepts and design details that need to be

or desired, the entire finish system must be considered. Floating considered; however, many essential topics, such as plumbing,

wood or tile floor systems offer the next best solution. A floating mechanical systems and exterior noise control, are beyond the

wood floor offers the advantage of an isolation membrane that scope of this document. Similarly, it is worthwhile to review

can be installed beneath the finished wood system. However, the acoustic and fire protection-related detail choices to ensure

placing a resilient isolation mat or buffer under hard finish they are complementary and result in the most efficient overall

flooring systems requires coordination. Buffer systems include design. Where acoustic performance is a critical aspect of a

mats under the topping mass such as foam, cork, or rubber mats project, consider hiring an acoustical consultant as part of the

made from recycled tires. Each of these buffer materials creates design team. If that is not an option, it is advisable to rely on

its own set of compromises on the installation process, with systems and other solutions that have been independently tested

the total thickness of the finish floor system being one of the in acoustical testing laboratories. With proper forethought and

biggest coordination points. Ceramic flooring should meet the detailing, it is possible to ensure that mixed-use wood-frame

requirements of the Ceramic Tile Institute of America buildings will exceed acoustical performance expectations.

(www.ctioa.org).

Down Lights/Duct Work/Exhaust Fans

Acoustical assemblies should not be penetrated by building

utilities. Duct work and exhaust fan runs should be enclosed in

soffits, not in the joist or stud cavity, where they create holes in

the acoustical assembly. If can lights must be used, then fixtures

rated for direct insulation contact are required. The cans should

be backed and sealed air tight in addition to being caulked/

sealed air tight where they contact the gypsum wallboard.

11

$FRA_429_Acoustics_Solutions_Paper.indd 11 7/29/14 1:32 PM

Additional Information: Disclaimer The information in this publication, including, without limitation,

references to information contained in other publications or made available

ICC G2-2010 Guideline for Acoustics – International Code Council by other sources (collectively “information”) should not be used or relied

upon for any application without competent professional examination and

National Council of Acoustical Consultants – www.ncac.com verification of its accuracy, suitability, code compliance and applicability by a

licensed engineer, architect or other professional. Neither the Wood Products

Council nor its employees, consultants, nor any other individuals or entities

who contributed to the information make any warranty, representative or

guarantee, expressed or implied, that the information is suitable for any

general or particular use, that it is compliant with applicable law, codes or

ordinances, or that it is free from infringement of any patent(s), nor do they

assume any legal liability or responsibility for the use, application of and/or

reference to the information. Anyone making use of the information in any

manner assumes all liability arising from such use.

WW-WSP-02 • Acoustical Considerations for Mixed-Use Wood-Frame Buildings • © June 2014 WoodWorks/Steve Thorburn

12

$FRA_429_Acoustics_Solutions_Paper.indd 12 7/29/14 1:32 PM

You might also like

- How2 Acoustics Jul10 PDFDocument16 pagesHow2 Acoustics Jul10 PDFdaveshitNo ratings yet

- Principle of Good AcousticsDocument4 pagesPrinciple of Good AcousticsNitesh Salwan ZohriNo ratings yet

- (Book) Acoustic Insulation in Modular Construction#Document6 pages(Book) Acoustic Insulation in Modular Construction#Eddy NgNo ratings yet

- Building Envelope Acoustic Solutions - Stone Wool Solutions For Improving Occupant ComfortDocument12 pagesBuilding Envelope Acoustic Solutions - Stone Wool Solutions For Improving Occupant ComfortJames Wing Ho WongNo ratings yet

- Building AcousticsDocument4 pagesBuilding AcousticsarnautoiuNo ratings yet

- White Book Ireland Building Acoustics - 0Document16 pagesWhite Book Ireland Building Acoustics - 0edNo ratings yet

- ICC G2-2010-Guideline For Acoustics - Final DraftDocument18 pagesICC G2-2010-Guideline For Acoustics - Final DraftAdriana CarolinaNo ratings yet

- Lorient Architectural Seals BrochureDocument56 pagesLorient Architectural Seals BrochureTudor CotitosuNo ratings yet

- Sound Control For Commercial and Residential BuildingsDocument24 pagesSound Control For Commercial and Residential BuildingsanandganesNo ratings yet

- pdf3 PDFDocument9 pagespdf3 PDFCarlo CarandangNo ratings yet

- Noise in High Rise Buildings: Ross H. Palmer Cpeng Rpeq Principal Palmer Acoustics (Australia) Pty LTDDocument9 pagesNoise in High Rise Buildings: Ross H. Palmer Cpeng Rpeq Principal Palmer Acoustics (Australia) Pty LTDzaheeruddin_mohdNo ratings yet

- The Following Land Uses Are Permitted in The Multifamily Residential DistrictDocument8 pagesThe Following Land Uses Are Permitted in The Multifamily Residential DistrictDarren VergaraNo ratings yet

- Sound Insulation Brochure 2018Document7 pagesSound Insulation Brochure 2018SajidNo ratings yet

- Acoustic Performance Guide UK 06 05Document39 pagesAcoustic Performance Guide UK 06 05Murilo SoaresNo ratings yet

- Defining The Acoustic Requirements For A Building and CommunityDocument2 pagesDefining The Acoustic Requirements For A Building and CommunityJeromeHeadleyNo ratings yet

- Caice Acoustic Design GuideDocument12 pagesCaice Acoustic Design GuideBuddhikaNo ratings yet

- Technical Performance 9Document52 pagesTechnical Performance 9shweta singhNo ratings yet

- Safe N Silent Solutions in Partition SystemsDocument16 pagesSafe N Silent Solutions in Partition Systemschong pak limNo ratings yet

- FireRatedWallsDES PDFDocument24 pagesFireRatedWallsDES PDFwhwy99No ratings yet

- Curs - Gratuit - Online - CPD 12 2015 - Acoustic Design and Flat Roofs - Features - BuildingDocument9 pagesCurs - Gratuit - Online - CPD 12 2015 - Acoustic Design and Flat Roofs - Features - Buildingandrew_sfiNo ratings yet

- PFF - L - Building RegsDocument2 pagesPFF - L - Building RegsRogerNo ratings yet

- Screenshot 2021-01-30 at 8.11.32 PMDocument39 pagesScreenshot 2021-01-30 at 8.11.32 PMheartofdixieNo ratings yet

- Sounds of Silence WebDocument3 pagesSounds of Silence WebUmesh ChamaraNo ratings yet

- Sound Control For Commercial and Residential BuildingsDocument24 pagesSound Control For Commercial and Residential BuildingsEmily OngNo ratings yet

- SCOPE OF ARCHITECTURAL ACOUSTIC CONSULTANT'S WORK - Geonoise Asia Co., LTDDocument1 pageSCOPE OF ARCHITECTURAL ACOUSTIC CONSULTANT'S WORK - Geonoise Asia Co., LTDaleisterparadigma666No ratings yet

- Chapter 8: Vibration Impact Criteria 8-1Document6 pagesChapter 8: Vibration Impact Criteria 8-1pedjaNo ratings yet

- Room To Rroom Acustical DesignDocument4 pagesRoom To Rroom Acustical DesignJosé Luis Lería MelvilleNo ratings yet

- Kongu Engineering College,: Building Information Management Assignment - IDocument8 pagesKongu Engineering College,: Building Information Management Assignment - IPalanisamy RajaNo ratings yet

- ACMV and Acoustic Comfort in BuildingsDocument13 pagesACMV and Acoustic Comfort in BuildingsTuan Suhaimi SallehNo ratings yet

- Ias PDFDocument56 pagesIas PDFMarco RamosNo ratings yet

- Design of Coastal Revetments, Seawalls and Bulkheads - Army Corps of Engineers (1995)Document9 pagesDesign of Coastal Revetments, Seawalls and Bulkheads - Army Corps of Engineers (1995)Vishal Parashuram MiskinNo ratings yet

- The Engineer's Application Overview EMI Shielding Tape InnovationsDocument3 pagesThe Engineer's Application Overview EMI Shielding Tape InnovationsAXOX Web SolutionsNo ratings yet

- Nick Conlan and Jack Harvie-Clark Making Sense of The Acoustic Performance of Flanking Paths For Curtain WalliDocument2 pagesNick Conlan and Jack Harvie-Clark Making Sense of The Acoustic Performance of Flanking Paths For Curtain WalliGengaNo ratings yet

- Acoustic Design of Lightweight Timber Frame Constructions PART 3Document63 pagesAcoustic Design of Lightweight Timber Frame Constructions PART 3Rodrigo TomazNo ratings yet

- BuildingDocument12 pagesBuildingjuan leyyonNo ratings yet

- GAPS Guidelines: Expanded Plastics in Building ConstructionDocument12 pagesGAPS Guidelines: Expanded Plastics in Building ConstructionAsad KhanNo ratings yet

- Room-to-Room Privacy and Acoustical Design CriteriaDocument4 pagesRoom-to-Room Privacy and Acoustical Design CriteriaNaken FittaNo ratings yet

- Ncma Tek: Concrete Masonry Highway Sound Barriers TEK 13-3ADocument4 pagesNcma Tek: Concrete Masonry Highway Sound Barriers TEK 13-3AalbertoxinaNo ratings yet

- Bus TerminusDocument35 pagesBus TerminusJeofrey Awingan CodiamatNo ratings yet

- Anatomy of An IIC Rating: Sharon Paley, Ecore International, Lancaster, PennsylvaniaDocument3 pagesAnatomy of An IIC Rating: Sharon Paley, Ecore International, Lancaster, PennsylvaniaRamakrishnan AmbiSubbiahNo ratings yet

- Technobond Insulation BRANZ Appraisl No 693 Ceiling and Wall PDFDocument5 pagesTechnobond Insulation BRANZ Appraisl No 693 Ceiling and Wall PDFJohn SmithNo ratings yet

- Paroc Impact Sound Insulation INTDocument20 pagesParoc Impact Sound Insulation INTVishnuNo ratings yet

- Unit I Acoustics Planning For Noise, STC, NRCDocument9 pagesUnit I Acoustics Planning For Noise, STC, NRCKavya DesaiNo ratings yet

- Noise Control Through RoofsDocument14 pagesNoise Control Through RoofswasoromeoNo ratings yet

- Placer Comparing RegulationsDocument4 pagesPlacer Comparing RegulationsArabela May PlacerNo ratings yet

- Enhanced Acoustical Performance - Exterior Noise Control - U.S. Green Building CouncilDocument2 pagesEnhanced Acoustical Performance - Exterior Noise Control - U.S. Green Building CouncilrNo ratings yet

- CombinepdfDocument5 pagesCombinepdfArabela May PlacerNo ratings yet

- 040 Acoustics Jun-19Document30 pages040 Acoustics Jun-19Đức Huấn ĐỗNo ratings yet

- SN01 012006 AcousticsDocument2 pagesSN01 012006 AcousticsDavid GreallyNo ratings yet

- CA Noise FinalDocument2 pagesCA Noise Finalseagull70No ratings yet

- Energy Efficiency: Building Envelope-InsulationDocument10 pagesEnergy Efficiency: Building Envelope-InsulationAbishaTeslinNo ratings yet

- RockwoolDocument3 pagesRockwoolvenkatrcaNo ratings yet

- FactSheet NR-OpaqueEnvelope 2016Document6 pagesFactSheet NR-OpaqueEnvelope 2016Thomas ChanNo ratings yet

- Noise Impact and Improvement On Indoors Acoustic Comfort For The Building Adjacent To Heavy Traffic RoadDocument9 pagesNoise Impact and Improvement On Indoors Acoustic Comfort For The Building Adjacent To Heavy Traffic Roadamb11No ratings yet

- Journal of Building Engineering: Alicia Alonso, Rafael Su Arez, Jorge Patricio, Rocío Escand On, Juan J. SendraDocument10 pagesJournal of Building Engineering: Alicia Alonso, Rafael Su Arez, Jorge Patricio, Rocío Escand On, Juan J. SendraMir AarifNo ratings yet

- IIG Mineral Wool Spec SheetDocument2 pagesIIG Mineral Wool Spec SheetNaresh PaneruNo ratings yet

- Gyprock Party Wall Manual Gyp513 2021 PDFDocument48 pagesGyprock Party Wall Manual Gyp513 2021 PDFMuz shirzaiNo ratings yet

- Ecophon 25060 Rigips Plafoane Casetate EcophonDocument40 pagesEcophon 25060 Rigips Plafoane Casetate EcophonAndra IoanaNo ratings yet

- All About SoundDocument9 pagesAll About SoundAzli MarzukiNo ratings yet

- Easi-Set Buildings Water and Waste WhitepaperDocument23 pagesEasi-Set Buildings Water and Waste WhitepaperTrayam Enterprises -Aquatech & SystemsNo ratings yet

- ASTM C173-16 Standard Test Method For Air Content of Freshly Mixed Concrete by The Volumetric MethodDocument9 pagesASTM C173-16 Standard Test Method For Air Content of Freshly Mixed Concrete by The Volumetric MethodAdam JonesNo ratings yet

- 4.1 Technical Product Manual - ENDocument116 pages4.1 Technical Product Manual - ENkim y hNo ratings yet

- Astm C172Document3 pagesAstm C172Abu JosephNo ratings yet

- ASTM C231-17 Standard Test Method For Air Content of Freshly Mixed Concrete by The Pressure MethodDocument9 pagesASTM C231-17 Standard Test Method For Air Content of Freshly Mixed Concrete by The Pressure MethodAdam Jones0% (1)

- ASTM D25 Round Timber PilesDocument8 pagesASTM D25 Round Timber PilesAdam JonesNo ratings yet

- D From Exp Flitch Plates DeStefano Pac 5-10-071Document2 pagesD From Exp Flitch Plates DeStefano Pac 5-10-071mustafazahmedNo ratings yet

- ASTM F1554 Anchor Rods PDFDocument9 pagesASTM F1554 Anchor Rods PDFAdam JonesNo ratings yet

- ASTM C172 Sampling Freshly Mixed ConcreteDocument3 pagesASTM C172 Sampling Freshly Mixed ConcreteAdam JonesNo ratings yet

- Flat-Strap-Submittal-Sheet-CFMF Diagonal BraceDocument1 pageFlat-Strap-Submittal-Sheet-CFMF Diagonal BraceAdam JonesNo ratings yet

- NAIOP Terminology - Office and Industrial MarketDocument25 pagesNAIOP Terminology - Office and Industrial MarketAdam JonesNo ratings yet

- Not Your Typical Truss JobDocument5 pagesNot Your Typical Truss JobAdam JonesNo ratings yet

- Guide To Attaching Exterior Wall Coverings Through Foam Sheathing To Wood or Steel Wall FramingDocument7 pagesGuide To Attaching Exterior Wall Coverings Through Foam Sheathing To Wood or Steel Wall FramingAdam JonesNo ratings yet

- RCSC Table 2.1 Nut and Washer TypesDocument1 pageRCSC Table 2.1 Nut and Washer TypesAdam JonesNo ratings yet

- Structure Magazine Authors - HandbookDocument13 pagesStructure Magazine Authors - HandbookAdam JonesNo ratings yet

- Geotechnical Reposrts As Contract Documents - Miller-Sept18 - Structures MagDocument1 pageGeotechnical Reposrts As Contract Documents - Miller-Sept18 - Structures MagAdam JonesNo ratings yet

- Tek 14-03a PDFDocument4 pagesTek 14-03a PDFdaveshitNo ratings yet

- PCI Hollow Core Specifications 4-8-11Document7 pagesPCI Hollow Core Specifications 4-8-11Ako BogdaNo ratings yet

- North American Standards For Cold-Formed Steel FramingDocument50 pagesNorth American Standards For Cold-Formed Steel FramingNatalia OviedoNo ratings yet

- 14-01b Section Properties of Cmu WallsDocument8 pages14-01b Section Properties of Cmu WallsAdam JonesNo ratings yet

- Publishing in Asce Journals: A Guide For AuthorsDocument48 pagesPublishing in Asce Journals: A Guide For AuthorsAdam JonesNo ratings yet

- Improving Detailing For MasonryDocument10 pagesImproving Detailing For MasonryAdam JonesNo ratings yet

- 14-4B Strength Design Provisions For Concrete MasnoryDocument8 pages14-4B Strength Design Provisions For Concrete MasnoryAdam JonesNo ratings yet

- Structural SpecificationsDocument2 pagesStructural SpecificationsAdam JonesNo ratings yet

- Analysis of Adverse Weather For Excusable Delays - ASCE Journal of Construction EngineeringDocument10 pagesAnalysis of Adverse Weather For Excusable Delays - ASCE Journal of Construction EngineeringAdam JonesNo ratings yet

- How To Determine Construction Project Rain Delay Times Using Local Rainfall Databases - ASCE JournalDocument6 pagesHow To Determine Construction Project Rain Delay Times Using Local Rainfall Databases - ASCE JournalAdam JonesNo ratings yet

- ASTM C192 Standard Practice For Making and Curing Concrete Test Specimens in The LaboratoryDocument8 pagesASTM C192 Standard Practice For Making and Curing Concrete Test Specimens in The LaboratoryAdam Jones100% (3)

- 2017 Technical Data Guide For Precast, Prestressed Concrete Hollow-Core PlankDocument40 pages2017 Technical Data Guide For Precast, Prestressed Concrete Hollow-Core PlankAdam JonesNo ratings yet

- Behaviour of Gypsum Sheathed Point-Symmetric Cold-Formed Steel Members - Assessment of AISI Design Method PDFDocument22 pagesBehaviour of Gypsum Sheathed Point-Symmetric Cold-Formed Steel Members - Assessment of AISI Design Method PDFAdam JonesNo ratings yet

- Weather Delays and Impacts - Cost EngineeringDocument1 pageWeather Delays and Impacts - Cost EngineeringAdam JonesNo ratings yet

- DUCON Security 2016 ENDocument13 pagesDUCON Security 2016 ENbaspiskoposNo ratings yet

- Design of Pavement by Using Geo PolymerDocument33 pagesDesign of Pavement by Using Geo PolymermohammedaliarNo ratings yet

- Presentation 63A 8.7.22Document54 pagesPresentation 63A 8.7.22Himanshi GuptaNo ratings yet

- Construction: 2 Reservoir (GND) - Civil Work For ReservoirDocument4 pagesConstruction: 2 Reservoir (GND) - Civil Work For ReservoirAl Hujurat Trading & Construction100% (1)

- KVH TI Folder en Web3 02Document19 pagesKVH TI Folder en Web3 02mario_stefanecNo ratings yet

- FDOT 2014: of C-I-P Cantilever Retaining Wall 1 2 6010Document26 pagesFDOT 2014: of C-I-P Cantilever Retaining Wall 1 2 6010Fazalrahman RangNo ratings yet

- Design of Concrete Structure: SyllabusDocument72 pagesDesign of Concrete Structure: Syllabusريام الموسويNo ratings yet

- Woodwork Joints PDFDocument173 pagesWoodwork Joints PDFAnestisNo ratings yet

- A Report On Building A Shipping Container Habitat: - The HâbDocument36 pagesA Report On Building A Shipping Container Habitat: - The HâbAdrian FernandezNo ratings yet

- Ordinary Portland Cement (Simply Called OrdinaryDocument25 pagesOrdinary Portland Cement (Simply Called OrdinaryMS PMNo ratings yet

- Two Storey Residential BuildingDocument6 pagesTwo Storey Residential Buildingnazyl annNo ratings yet

- Materials, Processes & ConstructionsDocument31 pagesMaterials, Processes & ConstructionsShovon Kumar BiswasNo ratings yet

- The Repair of Reinforced Concrete - John BroomfieldDocument4 pagesThe Repair of Reinforced Concrete - John BroomfieldJad LouisNo ratings yet

- Les Mis Set ProjectDocument10 pagesLes Mis Set Projectapi-553676905No ratings yet

- BoqDocument120 pagesBoqs.s engineering and knowledge developed worksNo ratings yet

- CladdingDocument7 pagesCladdingVarunNo ratings yet

- All in One ALE ReviewerDocument53 pagesAll in One ALE Reviewergulay yuo100% (1)

- JcsumbladepyramidDocument12 pagesJcsumbladepyramidJhogamNo ratings yet

- Cement ManufacturingDocument63 pagesCement Manufacturingcandan.erkenNo ratings yet

- Bearing AssigmentDocument7 pagesBearing AssigmentAshish ShresthaNo ratings yet

- CPCCBC4015 AE ProPart2Document24 pagesCPCCBC4015 AE ProPart2Bashir AlimmariNo ratings yet

- Lexsha's Boq Option 2Document84 pagesLexsha's Boq Option 2Jan Lawrence AlbertoNo ratings yet

- Study On Floor Tiles Marketing in Madurai City Project ReportDocument62 pagesStudy On Floor Tiles Marketing in Madurai City Project ReportPrabu RajanNo ratings yet

- Nacion 2 Storey residential-SCHEDULE OF DOORS AND WINDOWSDocument1 pageNacion 2 Storey residential-SCHEDULE OF DOORS AND WINDOWSVictor Eric NacionNo ratings yet

- Boq Proposed Single Vintlation Improved Pit Latrine: General Preliminary Item Description QTY Unit Rate AmountDocument6 pagesBoq Proposed Single Vintlation Improved Pit Latrine: General Preliminary Item Description QTY Unit Rate AmountEng Hinji RudgeNo ratings yet

- Test Closet QuestionairreDocument2 pagesTest Closet QuestionairreShujaRehmanNo ratings yet

- Sika Precast Technologies-CompressedDocument28 pagesSika Precast Technologies-CompressedAmar PalNo ratings yet

- Construction Technology 1Document4 pagesConstruction Technology 1pbharris0% (1)

- Form WorkDocument13 pagesForm WorkRimar LiguanNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Structural Cross Sections: Analysis and DesignFrom EverandStructural Cross Sections: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (19)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresFrom EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresRating: 1 out of 5 stars1/5 (2)

- Marine Structural Design CalculationsFrom EverandMarine Structural Design CalculationsRating: 4.5 out of 5 stars4.5/5 (13)

- Advanced Modelling Techniques in Structural DesignFrom EverandAdvanced Modelling Techniques in Structural DesignRating: 5 out of 5 stars5/5 (3)

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsFrom EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsNo ratings yet

- Flow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesFrom EverandFlow-Induced Vibrations: Classifications and Lessons from Practical ExperiencesTomomichi NakamuraRating: 4.5 out of 5 stars4.5/5 (4)

- Pile Design and Construction Rules of ThumbFrom EverandPile Design and Construction Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (15)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsFrom EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsRating: 4 out of 5 stars4/5 (16)

- Matrix Methods for Advanced Structural AnalysisFrom EverandMatrix Methods for Advanced Structural AnalysisRating: 5 out of 5 stars5/5 (1)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingFrom EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingNo ratings yet

- Piezocone and Cone Penetration Test (CPTu and CPT) Applications in Foundation EngineeringFrom EverandPiezocone and Cone Penetration Test (CPTu and CPT) Applications in Foundation EngineeringNo ratings yet

- Built: The Hidden Stories Behind Our StructuresFrom EverandBuilt: The Hidden Stories Behind Our StructuresRating: 4 out of 5 stars4/5 (27)