Professional Documents

Culture Documents

Service Information

Uploaded by

Marcelo GiussaniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Service Information

Uploaded by

Marcelo GiussaniCopyright:

Available Formats

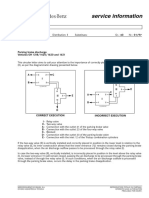

service information

Date: October/98 Distribution: I Substitues: Gr.: 46 Nr.: 02/98

Steering auxiliary pump - LuK

Engines of series 400 and 450

The above mentioned engines, in accordance with the following indications, are now receiving the application of

the steering auxiliary pump - LuK.

APPLICATION IN SERIES

Pump LUK Nr. Engine Application

OM 447 LA

001 460 60 80 Intercalated application as of engine final Nr. ...703352

OM 449 A/LA

001 460 79 80 OM 457 Complete application since the beginning of production

PROCEDURES

• In case of vehicles inside the period of warranty, if any failure in the steering auxiliary pump LuK is observed,

replace the same.

For reim-ent, send a Claim of Warranty to the Factory, mentioning the number of this S.I.

Obs.: Use the corresponding RTT, codification of anomalies and causing part, according to the usual proce-

dures.

• In case of vehicles already out of the warranty term, if observing:

• Problems of leakage - replace the “Repair Set - Packing - Nr. A 001 460 64 80”. To carry out the service, ob-

serve the enclosed “Instructions”, supplied by LuK Hidráulica Automotiva.

• Inadequate operation of the pump (damage of the rotation assembly) - replace the pump.

Obs.: The “Repair Sets - Rotation Assembly - Nr. A 001 460 63 80 and Nr. A 001 460 82 80” are not supplied

as spare parts, although they appear in the enclosed instructions.

NOTE:

• More accurate technical information may be obtained also directly with:

LuK Hidráulica Automotiva - Divisão da Luk do Brasil Embreagens Ltda.

Av. Independência, 2900

18103-000 - Sorocaba - SP

Fone: (015) 235-1000

Fax:(015) 235-1099

MERCEDES-BENZ DO BRASIL S.A.

Service

MERCEDES-BENZ DO BRASIL S.A. IN WHOLE OR PARTIAL REPRODUCTION

DIVISÃO ASSISTÊNCIA TÉCNICA PROHIBITED WITHOUT PREVIOUS

WRITTEN AGREEMENT

S.I. 46 - 02/98

Annex

Page 01

Steering Auxiliary Pump LF80-Right 09

08

07

06

Exploded view

05

13 10

14 11

03

01 02

12

04

15

25

20

19

24

26 23

22

21

18

REPAIR SET - ROTATION ASSEMBLY MB-Nr. A 001 460 63 80 17

REPAIR SET - PACKING MB-Nr. A 001 460 64 80 16

POSITION DESCRIPTION QTY. POSITION DESCRIPTION QTY.

01 Plastic cover 01 14 Protection cover 01

02 Shaft 01 15 Protection cover 01

03 Retainer 01 16 Guide pin 02

04 O-ring 01 17 Pressure plate 01

05 Housing 01 18 Rotor 01

06 Pressure relief valve 01 19 Blade 10

07 Undulated spring 01 20 Locking ring 01

08 O-ring 01 21 Cam ring 01

09 Threaded cover 01 22 Wear plate 01

10 Pressure plate support 01 23 O-ring 01

11 O-ring 01 24 Rear cover 01

12 O-ring 01 25 Torx screw 04

13 Plate spring 01 26 Label 01

LF80d.cdr SET98

Steering auxiliary pump MB-Nr. A 001 460 60 80

Model code: LF80-17-16-100-R-M-M-MK2-10

LuK Nr.: 2107235

S.I. 46 - 02/98

Annex

Page 02

Steering Auxiliary Pump LF80-Left 09

08

07

06

Exploded view

05

13 10

14 11

03

01 02

12

04

15

19 20

25

24

23

22 26

21

18

17

16 REPAIR SET - ROTATION ASSEMBLY MB Nr. A-001 460 82 80

REPAIR SET - PACKING MB Nr. A-001 460 64 80

POSITION DESCRIPTION QTY. POSITION DESCRIPTION QTY.

01 Plastic cover 01 14 Protection cover 01

02 Shaft 01 15 Protection cover 01

03 Retainer 01 16 Guide pin 02

04 O-ring 01 17 Pressure plate 01

05 Housing 01 18 Rotor 01

06 Pressure relief valve 01 19 Blade 10

07 Undulated spring 01 20 Locking ring 01

08 O-ring 01 21 Cam ring 01

09 Threaded cover 01 22 Wear plate 01

10 Pressure plate support 01 23 O-ring 01

11 O-ring 01 24 Rear cover 01

12 O-ring 01 25 Torx screw 04

13 Plate spring 01 26 Label 01

LF80e.cdr SET98

Steering auxiliary pump MB-Nr. A 001 460 79 80

Model code: LF80-17-16 000-L- M-M-MK1-10

LuK Nr.: 2107195

S.I. 46 - 02/98

Annex

Page 03

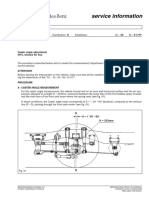

INTRODUCTION

- A steering auxiliary pump is a mechanical assembly made of components produced within precise (micron) and tight

tolerances, therefore always observe a careful handling of these components whenever disassembling and assembling.

- In case of doubt, it is important to consult a Luk specialized technician.

SEQUENCE OF DISASSEMBLAGE - Steering auxiliary pump Luk LF80

HOUSING SIDE

A – In a clean and prepared site, place the pump in the disassembling device, with the shaft turned downwards.

B – Unscrew and remove 4 Torx screws, using a T-40 extension.

C – Loosen the rear cover (24) by striking the pump in the shaft, in absolutely vertical position, on a proper surface (plastic or wood).

D – Remove the rear cover (24) and the wear plate (22).

E – Remove the 2 guide pins (16).

G – Remove the spring ring (20) (of round wire) from the shaft, with the help of a needle nose pliers.

H – Remove the shaft (2) by the retainer side (3).

I – Reinstall the wear plate (22) in the rotation assembly and, turning the pump, remove the complete rotation assembly (17, 18, 19

and 21). Pay attention not to lose any one of the blades (19). There are 10 blades in total. In case of some difficulty (oil glueing),

strike carefully with a corner of the pump on a proper surface (plastic or wood).

J – Pull up (in a small vice or striking with a plastic pin of appropriate dimension) the pressure plate support (10), which may be

sticked because of the two O-rings (11 and 12). Observe the aligning position of the oil feeding orifice with the pressure outlet

orifice.

K – Check the retainer (3) condition and eventually replace it.

Valve:

L – Loosen the threaded cover (9) (in aluminum) by means of a 30mm spanner.

M – Unscrew this threaded cover (9) by hand, observing that the spring (7) do not jump off.

N – Remove the spring (7) and carefully take off the pressure relief valve (6).

O – In case of ancient versions, remove the threaded cover (9) end of travel stop. In case of new versions, this stop is integrated.

NOTE: Eliminate all used O-rings (4, 8, 11, 12 and 23).

SEQUENCE OF ASSEMBLAGE - Steering auxiliary pump Luk Lf80

HOUSING SIDE

A – Lubricate the retainer (3) inside and outside with grease (approximately 1/3 of its outiline) and install it, observing the distance

of 5mm from the aluminum housing (5) edge.

B – Install the undulated spring (13) in the housing recess.

C – Press (with the fingers or with the help of a manual press), the pressure plate (10) support, with the two O-rings (11 and 12)

previously nstalled and lubricated; the pressure (outlet) passage should be indicating to the oil inlet diffuser and be aligned with

the oil feeding orifice.

D – Install the shaft (2) by the retainer (3) outer side.

E – Install the pressure plate (17) with the bronze coating upwards. Observe that the pressure opening, the pressure relief spline

and the outer cam indicate to the oil feeding orifice, in direction to the pressure relief valve (6).

Remark concerning the pressure plates: Pressure relief spline to the left = rotation L (Left).

Pressure relief spline to the right = rotation R (right)

E – Place the two guide pins (16) in position.

F – Install the cam ring (21) with the arrow pointing upwards, leaving it at the left side.

G– Install the rotor (18) and the ten blades (19) with the round corner pointing to the cam ring (21) side.

Place the round spring ring (20) in position in the shaft (2) inner extremity spine, checking the correct postion.

H – Install the wear plate (22), with the bronze coating indicating to the rotor (18) and the outer cam in direction to the pressure

relief valve (6).

I– Install the rear cover, with the O-ring (23) previously installed, observing that the outer recess indicates to the pressure relief

valve (6). The holes (inner) for the guide pins (16) should be in the position above/left and down/right, if the pump rotation is

that the exact aligment for the fastening screws (25) can be obtained.

TIP: Before pressing the pressure plate support (10), slightly install the guide pins (16) and the rear cover (24) in the same, to

check the alignment.

J – Tighten (cross tightening) the four screws Torx (25) using a T-40 socket, to a tightening torque of 27-32 Nm.

K - Check if the shaft (2) turns free.

L – Install the O-ring (4) in the housing (5).

NOTES:

- Whenever a steering auxiliary pump is reinstalled, DO NOT forget to install the protection covers (14 and 15).

In this case, DO NOT forget to install also the plastic cover (1).

Valve:

A – Check if the pressure and compensation orificies system (includes the damping small orifice) is free, using the light of a small

handlight or compressed air.

B – Introduce the pressure relief valve (6), duly lubricated and observing the alignment.

C – Fit the spring (7) and the chock (ancient versions) in the threaded cover (9).

D – Install the threaded cover (9), with a new O-ring (8) (without twisting and paying attention to avoid damages by burrs) and

then tighten with a 30mm socket to 40-50 Nm.

You might also like

- Bose Soundtouch ST 300 Service ManualDocument142 pagesBose Soundtouch ST 300 Service ManualLaur GoeNo ratings yet

- Manual D914L04 8939998 PDFDocument107 pagesManual D914L04 8939998 PDFcirilo razielNo ratings yet

- Dipper Door 40 Yd3 2800XPADocument2 pagesDipper Door 40 Yd3 2800XPAMelvin Mena TorresNo ratings yet

- MPE 750 Turbo Marine Closed LoopDocument42 pagesMPE 750 Turbo Marine Closed LoopAleksandar Sasa SeferovicNo ratings yet

- Parts Information: EatonDocument5 pagesParts Information: Eatonamskroud brahimNo ratings yet

- Kater Turbo Povyshennay Moshnost 2kontura 103730Document43 pagesKater Turbo Povyshennay Moshnost 2kontura 103730TRNo ratings yet

- Kit For Fuel Injection PumpDocument2 pagesKit For Fuel Injection Pumpaayush srivastavaNo ratings yet

- Limit Switch, Boom: 4100XPC Electric Shovel Machine Serial Number: Parts Manual 41235Document2 pagesLimit Switch, Boom: 4100XPC Electric Shovel Machine Serial Number: Parts Manual 41235maocaleirlNo ratings yet

- 38FVCA12C5Document2 pages38FVCA12C5Cezar AparecidoNo ratings yet

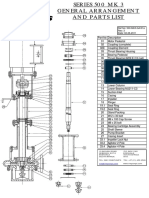

- Series 500 Mk3 General Arrangement Rev 3 RNE PUMP PARTSDocument1 pageSeries 500 Mk3 General Arrangement Rev 3 RNE PUMP PARTSZaen SalimNo ratings yet

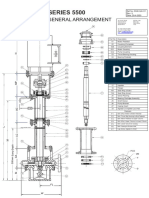

- Series 5500 General ArrangementDocument1 pageSeries 5500 General ArrangementCaesar MutizeNo ratings yet

- Still Steds LPG Fork Truck Rc41 25t Rc41 30t Parts ManualDocument20 pagesStill Steds LPG Fork Truck Rc41 25t Rc41 30t Parts Manualbeverly100% (24)

- Carraro PDFDocument16 pagesCarraro PDFАдыль Бабиров100% (1)

- Parts Catalog Product Family Transmissions PDFDocument1,754 pagesParts Catalog Product Family Transmissions PDFTam Anh Do Nhu100% (4)

- 01-01-01 COOLING SYSTEM (PART-1) - MCF Global Parts PDFDocument4 pages01-01-01 COOLING SYSTEM (PART-1) - MCF Global Parts PDFricardoNo ratings yet

- T6CC/T6DC/T6EC/T6ED Series: Parker Denison T6 Double Hydraulic Vane PumpDocument56 pagesT6CC/T6DC/T6EC/T6ED Series: Parker Denison T6 Double Hydraulic Vane Pumpbadawai sallamNo ratings yet

- May Fren Sistemleri KatalogDocument591 pagesMay Fren Sistemleri KatalogEmre KurnazNo ratings yet

- 01 Bqs Conveyor 1800Document1 page01 Bqs Conveyor 1800RD Rohan EnterprisesNo ratings yet

- QuotationDocument2 pagesQuotationAtish JadhavNo ratings yet

- 01-01-02 COOLING SYSTEM (PART-2) - MCF Global Parts PDFDocument4 pages01-01-02 COOLING SYSTEM (PART-2) - MCF Global Parts PDFricardoNo ratings yet

- Tm9 2320 208 34pDocument180 pagesTm9 2320 208 34pAnthony Cox100% (2)

- Hole Ø35: VR-3 VR-2 VR-1Document34 pagesHole Ø35: VR-3 VR-2 VR-1amina amiNo ratings yet

- CE25MRTP - Hydraulic UnitDocument2 pagesCE25MRTP - Hydraulic UnitDavid VaquerizoNo ratings yet

- AG 14140 BIMOTA TESI 3D Rear S46PR1C1LDocument1 pageAG 14140 BIMOTA TESI 3D Rear S46PR1C1Lanna mannaNo ratings yet

- Preparation 1zr-Fae Engine Mechanical SSTDocument4 pagesPreparation 1zr-Fae Engine Mechanical SSTAlbert BriceñoNo ratings yet

- Heavy Duty - Fifth Wheel Couplings JSK 52Document2 pagesHeavy Duty - Fifth Wheel Couplings JSK 52AtmaYudhaNo ratings yet

- Ohlins SU148Document7 pagesOhlins SU148r41nd0gNo ratings yet

- Lista de Spare Parts / Spare Parts List: ElectricalDocument3 pagesLista de Spare Parts / Spare Parts List: ElectricalabdielNo ratings yet

- Surface Grinding Machine CPMDocument48 pagesSurface Grinding Machine CPMSamer SalibaNo ratings yet

- Peugeot Partner 1.6 M59 Flex Spare Parts CatalogDocument244 pagesPeugeot Partner 1.6 M59 Flex Spare Parts CatalogRicardo Vilhena100% (1)

- Gambar Teknis Hino 500 Ranger FG 235 JJ Fire Truck 5500 Water Foam Double Cabin SNI Standart PROTEKTA FIREFORT VATORDocument1 pageGambar Teknis Hino 500 Ranger FG 235 JJ Fire Truck 5500 Water Foam Double Cabin SNI Standart PROTEKTA FIREFORT VATORSyarifNo ratings yet

- Gambar Teknis Hino 500 Ranger FG 235 JJ Fire Truck 5500 Water Foam Double Cabin SNI Standart PROTEKTA FIREFORT VATOR PDFDocument1 pageGambar Teknis Hino 500 Ranger FG 235 JJ Fire Truck 5500 Water Foam Double Cabin SNI Standart PROTEKTA FIREFORT VATOR PDFoscarNo ratings yet

- Wa270 3 Active S N Wa270h21038Document424 pagesWa270 3 Active S N Wa270h21038RAMON TEIXIDORNo ratings yet

- J Hrd0u28501 Tilt CylinderDocument3 pagesJ Hrd0u28501 Tilt Cylinderjoao bianchiniNo ratings yet

- Komatsu WA250 5L Wheel Loader US Parts Manual SN A73001 UPDocument431 pagesKomatsu WA250 5L Wheel Loader US Parts Manual SN A73001 UPCristian Andres TrujilloNo ratings yet

- 7018 Service Frontpage DL210 - SPDocument28 pages7018 Service Frontpage DL210 - SPJuan EspitiaNo ratings yet

- 080100A00003TOCS ADocument1 page080100A00003TOCS AKarina FloresNo ratings yet

- 96463Document45 pages96463Paulo César Daqui LoureiroNo ratings yet

- Allison Transmission: Parts CatalogDocument32 pagesAllison Transmission: Parts CatalogpepeNo ratings yet

- Combi WRDocument93 pagesCombi WREdinson FlorianoNo ratings yet

- Pegasolift - UK Spare Parts Manual W12-MinDocument12 pagesPegasolift - UK Spare Parts Manual W12-MinLuca FroliNo ratings yet

- Linde Parts Manual (3478047803) 347 E20 - 25 - 30C-600 E30C 0106Document252 pagesLinde Parts Manual (3478047803) 347 E20 - 25 - 30C-600 E30C 0106André Targino100% (2)

- GALVI Engineering - Installation and Maintenance Manual Shoe Brakes NV HYDDocument41 pagesGALVI Engineering - Installation and Maintenance Manual Shoe Brakes NV HYDArvind Yeram100% (1)

- Valves On Control Blocks (BBE)Document2 pagesValves On Control Blocks (BBE)midalllllNo ratings yet

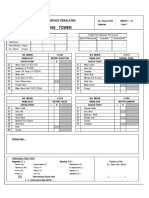

- Conditioning Tower: Check Point Inspeksi & Service PeralatanDocument4 pagesConditioning Tower: Check Point Inspeksi & Service PeralatanWahyu Agoes WilliamNo ratings yet

- Lista de Partes Fs-8000c InglesDocument48 pagesLista de Partes Fs-8000c InglesJuan Manuel NeriNo ratings yet

- 01-28-03 Control Valve (Harness & Gasket)Document3 pages01-28-03 Control Valve (Harness & Gasket)Taller PahrNo ratings yet

- Service Parts List: Cordless 12 Volt 3/8" Hammer-DrillDocument2 pagesService Parts List: Cordless 12 Volt 3/8" Hammer-DrillCarlos SalcedoNo ratings yet

- Spare Parts List: Handheld Pneumatic Pick Hammers CP 0122 S H22, CP 0122 SL H22, CP 0125 S R25Document16 pagesSpare Parts List: Handheld Pneumatic Pick Hammers CP 0122 S H22, CP 0122 SL H22, CP 0125 S R25Ricardo VegaNo ratings yet

- 01-46-02 WHEEL BRAKE ASSY (FOR 1-SPEED) (FOR DP40-DP45) - MCF Global Parts PDFDocument8 pages01-46-02 WHEEL BRAKE ASSY (FOR 1-SPEED) (FOR DP40-DP45) - MCF Global Parts PDFricardoNo ratings yet

- D24x40 S3 Parts ManualDocument752 pagesD24x40 S3 Parts ManualPhilNo ratings yet

- GA-Drawing - (ZVV-100-25)Document1 pageGA-Drawing - (ZVV-100-25)Shree ConstructionNo ratings yet

- M18 061 eDocument3 pagesM18 061 eFalgon IslamNo ratings yet

- SPARE PARTS MS21 Z AD ETL - K076 - 2407165 - 01 - en-GBDocument105 pagesSPARE PARTS MS21 Z AD ETL - K076 - 2407165 - 01 - en-GBcesarNo ratings yet

- Em Single Disc - Bearing - Mounted - Clutches (EdaDocument8 pagesEm Single Disc - Bearing - Mounted - Clutches (EdaAshok BhatNo ratings yet

- Catalogues$lpt 1615 Tcic Bs-IiiDocument234 pagesCatalogues$lpt 1615 Tcic Bs-IiiAbdul Samad KhanNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Service Information: November/99 I 35 01/99Document2 pagesService Information: November/99 I 35 01/99Marcelo GiussaniNo ratings yet

- Service Information: December/99 II 58 10/99Document2 pagesService Information: December/99 II 58 10/99Marcelo GiussaniNo ratings yet

- Service Information: August/99 II 00 06/99Document2 pagesService Information: August/99 II 00 06/99Marcelo GiussaniNo ratings yet

- IS064IDocument2 pagesIS064IMarcelo GiussaniNo ratings yet

- Service Information: September/98 II 26 07/98Document4 pagesService Information: September/98 II 26 07/98Marcelo GiussaniNo ratings yet

- Service Information: November/98 I 54 09/98Document14 pagesService Information: November/98 I 54 09/98Marcelo GiussaniNo ratings yet

- Service Information: May/98 II 58 03/98Document2 pagesService Information: May/98 II 58 03/98Marcelo GiussaniNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Service InformationDocument4 pagesService InformationMarcelo GiussaniNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Service Information: September/98 II 58 04/98Document10 pagesService Information: September/98 II 58 04/98Marcelo GiussaniNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Service Information: July/97 I 54 09/97Document2 pagesService Information: July/97 I 54 09/97Marcelo GiussaniNo ratings yet

- Service Information: April/97 II 47 01/97Document2 pagesService Information: April/97 II 47 01/97Marcelo GiussaniNo ratings yet

- Service Information: July/97 I 25 01/97Document2 pagesService Information: July/97 I 25 01/97Marcelo GiussaniNo ratings yet

- Service Information: May/97 II 01 01/97Document2 pagesService Information: May/97 II 01 01/97Marcelo GiussaniNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Service Information: May/97 I 41 01/97Document2 pagesService Information: May/97 I 41 01/97Marcelo GiussaniNo ratings yet

- Service Information: May/97 II 32 01/97Document2 pagesService Information: May/97 II 32 01/97Marcelo GiussaniNo ratings yet

- Service Information: August/96 II 54 - Nº: 0695 54 04/96Document2 pagesService Information: August/96 II 54 - Nº: 0695 54 04/96Marcelo GiussaniNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Service Information: 08/96 07/96 58 35 November/96 IIDocument2 pagesService Information: 08/96 07/96 58 35 November/96 IIMarcelo GiussaniNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- October/01 I 26 04/01: NotesDocument2 pagesOctober/01 I 26 04/01: NotesMarcelo GiussaniNo ratings yet

- WH5830B1000ZZDocument61 pagesWH5830B1000ZZMarcelo GiussaniNo ratings yet

- Service Information: September/96 I 35 06/96Document1 pageService Information: September/96 I 35 06/96Marcelo GiussaniNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Chockfast-Procedrue For Stern TubeDocument5 pagesChockfast-Procedrue For Stern TuberaviNo ratings yet

- 107 Engine and Fuel SystemDocument38 pages107 Engine and Fuel SystemRisky PrimanaNo ratings yet

- Elgin: High Efficiency Jet-Shear Mud Mixing SystemsDocument2 pagesElgin: High Efficiency Jet-Shear Mud Mixing SystemsAchmad GazaliNo ratings yet

- Electra Quarter Turn ActuatorsDocument20 pagesElectra Quarter Turn ActuatorsHarry HonchoNo ratings yet

- Excavator Cat 322c Diagram HydDocument2 pagesExcavator Cat 322c Diagram HydJhon VillamizarNo ratings yet

- Fuse Box Diagram Volkswagen Passat (B8 2015-2019)Document2 pagesFuse Box Diagram Volkswagen Passat (B8 2015-2019)slhkrh1905No ratings yet

- Pallet Trucks PDFDocument32 pagesPallet Trucks PDFbugseNo ratings yet

- Week 8 Pumps and Earthing System NotesDocument18 pagesWeek 8 Pumps and Earthing System NotesMohammed SaqibNo ratings yet

- 5L40E (A5S 360R) BMW 98 On & Cadillac 03 On: 5 SPEED RWD (Full Electronic Control)Document9 pages5L40E (A5S 360R) BMW 98 On & Cadillac 03 On: 5 SPEED RWD (Full Electronic Control)Katrien GoutryNo ratings yet

- Motor Craft 2 BBLDocument14 pagesMotor Craft 2 BBLapi-26140644100% (1)

- VE Series Valve IslandsDocument14 pagesVE Series Valve IslandsHugo Fernando Romero SánchezNo ratings yet

- Technical Documentation 14.5045 - Compressores HATLAPADocument116 pagesTechnical Documentation 14.5045 - Compressores HATLAPAGilson CardosoNo ratings yet

- Cryogenic Vaporisation SystemsDocument30 pagesCryogenic Vaporisation SystemsAnonymous 1XHScfCI100% (1)

- Training Manual A 319/320/321: ATA 36 Pneumatic ATA 30-10 Wing Anti IceDocument42 pagesTraining Manual A 319/320/321: ATA 36 Pneumatic ATA 30-10 Wing Anti IceHENIGUEDRINo ratings yet

- Cargo Hold CleaningDocument6 pagesCargo Hold CleaningSoyHan BeLen100% (1)

- Centrifugal PumpDocument12 pagesCentrifugal PumpPrashant DhakateNo ratings yet

- Simbol Pneumatik - From NorgrenDocument174 pagesSimbol Pneumatik - From NorgrenArief Wahyu PurwitoNo ratings yet

- 2 Way / 3 Way Valve PackagesDocument7 pages2 Way / 3 Way Valve PackagesArif MohammedNo ratings yet

- Bepco Air Brake Troubleshooting ChartDocument5 pagesBepco Air Brake Troubleshooting ChartМирослав ВујицаNo ratings yet

- Cgk063 Rfa Mos M XXX - Fire Hydrant Underground Pipe InstallationDocument31 pagesCgk063 Rfa Mos M XXX - Fire Hydrant Underground Pipe Installationdiki anggriawanNo ratings yet

- Sauer DanfossDocument88 pagesSauer DanfossThanh CongNo ratings yet

- 4m41 Pump160061130 Bomba VE VRZ EE14E 11162 VRZ Service ManualDocument117 pages4m41 Pump160061130 Bomba VE VRZ EE14E 11162 VRZ Service Manualesyjam67% (3)

- IC - TC L 3030 - en - V0 - 93617-5-20Document32 pagesIC - TC L 3030 - en - V0 - 93617-5-20sjalife10% (1)

- Rental Book - India PDFDocument24 pagesRental Book - India PDFpowermanagerNo ratings yet

- Compressor QuestionDocument3 pagesCompressor QuestionnellaiNo ratings yet

- ML H 800 h800mm440Document4 pagesML H 800 h800mm440Aldo CarmonaNo ratings yet

- Hydraguide Hydrostatic Steering System: HydraulicsDocument46 pagesHydraguide Hydrostatic Steering System: HydraulicsfernandojimenezdeNo ratings yet

- Publ-6576 - Prod Dcat d11Document298 pagesPubl-6576 - Prod Dcat d11engineerainaNo ratings yet

- 1.sanitary Wastewater MOSDocument13 pages1.sanitary Wastewater MOSarshad iqbal0% (1)