Professional Documents

Culture Documents

01 Exercices Anisotropy 1 & 2

Uploaded by

lyazidiyoussra00 ratings0% found this document useful (0 votes)

5 views2 pagesThis document discusses two exercises involving composite materials:

1. A cylindrical pressure vessel made of fiber-reinforced carbon/epoxy composite is subjected to internal pressure. The stress and strain states in the vessel wall are calculated based on the given material properties and geometry.

2. A series of mechanical tests are performed on a unidirectional fiber-reinforced composite lamina to characterize its elastic behavior. Tests include traction in fiber and transverse directions and in-plane shear to determine elastic constants. Additional tests performed after rotating the material axes demonstrate how constants relate to the material frame versus testing frame.

Original Description:

Mécanique master

Original Title

01_exercices_anisotropy_1_&_2

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses two exercises involving composite materials:

1. A cylindrical pressure vessel made of fiber-reinforced carbon/epoxy composite is subjected to internal pressure. The stress and strain states in the vessel wall are calculated based on the given material properties and geometry.

2. A series of mechanical tests are performed on a unidirectional fiber-reinforced composite lamina to characterize its elastic behavior. Tests include traction in fiber and transverse directions and in-plane shear to determine elastic constants. Additional tests performed after rotating the material axes demonstrate how constants relate to the material frame versus testing frame.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views2 pages01 Exercices Anisotropy 1 & 2

Uploaded by

lyazidiyoussra0This document discusses two exercises involving composite materials:

1. A cylindrical pressure vessel made of fiber-reinforced carbon/epoxy composite is subjected to internal pressure. The stress and strain states in the vessel wall are calculated based on the given material properties and geometry.

2. A series of mechanical tests are performed on a unidirectional fiber-reinforced composite lamina to characterize its elastic behavior. Tests include traction in fiber and transverse directions and in-plane shear to determine elastic constants. Additional tests performed after rotating the material axes demonstrate how constants relate to the material frame versus testing frame.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

MASTER MECANIQUE – M1 MECANIQUE DES SOLIDES & COMPMECH – SORBONNE UNIVERSITE

COLLABORATIVE CLASSES WITH POLITECNICO DI MILANO

COMPOSITE MATERIALS AND STRUCTURES

EXERCICES: REPRESENTATION OF ANISOTROPIC ELASTICITY

Exercice 1 – Composite pressure vessel.

We consider a cylindrical pressure vessel (a simplified geometry is a cylindrical recipient, of

diameter D = 64 cm and thickness e = 0.1 D, closed at its ends) built by filament winding of a

fiber-reinforced carbone/epoxy composite material. The material is orthotropic, with elastic

constants : E1 = 140 MPa ; E2 = 10 MPa ; G12 = 7 MPa ; and: ν12 = 0.3. The fibers are wound

around the mandrel following the angle θ = 53°.

The recipient is submitted to internal pressure p = 1380 MPa.

y

θ y

θ

x x

z

The figure represents the global geometry of the structure and a detail of the recipient wall:

axes x and y stand for the axial and circunferential directions, respectively.

Calculate the state of stress in the vessel wall, far from the extremities, as function of p, D and

e. Express the stress components in the material reference frame (composite orthotropy axes).

Calculate the related state of strain.

Exercice 2 – Elastic constants of an orthotropic material: mechanical tests in the

orthotropy axes and off the orthotropy axes

We consider a UD fiber-reinforced composite lamina. The elastic linear behaviour is

characterised by transverse isotropy in the plane perpendicular to the fiber orientation.

We fix the reference frame such that plane OX1X2 coincides with the plane of the lamina, and

axes OX1 and OX2 are parallel and orthogonal to the direction of fibers, respectively.

1. Write the general expressions of stiffness [C] and compliance [S] matrices in Voigt

notation in the chosen reference frame.

2. In order to characterise the material elastic properties, we perform the necessary

mechanical tests: first, a unidirectional traction is applied in the direction OX1. Calculate

the resulting strain and establish the corresponding elastic constants (moduli and

coefficients), as well as their relations with the compliance Cartesian components.

3. Repeat the study for a test of unidirectional traction in the direction of axis OX2.

4. Finally, a shear test is applied in the plane OX1X2. Calculate the resulting strain

components and establish the related engineering constants and their relations with

Cartesian components of compliance.

5. Conclude on the overall number of tests that are necessary to completely characterise the

3D elastic behaviour of the material.

6. We consider now a new reference frame Ox1x2x3 which is obtained by rotating OX1X2X3

of an angle δ around the vertical axis OX3. Calculate the strain components when a

unidirectional traction is applied along the direction Ox1, as well as in the case of a shear

test in the plane Ox1x2. Establish the related engineering constants and their relations with

the compliance Cartesian components.

You might also like

- Buderus Logasol SK Pump Station User ManualDocument56 pagesBuderus Logasol SK Pump Station User Manuale-ComfortUSANo ratings yet

- Antenna 4002 2L 2M 2.6m: Capacity Compact CoverageDocument5 pagesAntenna 4002 2L 2M 2.6m: Capacity Compact CoverageArlindo Neves0% (1)

- Carpet PlotDocument7 pagesCarpet PlotAlex OliveiraNo ratings yet

- 6940 21524 1 PBDocument10 pages6940 21524 1 PBSanthosh KumarNo ratings yet

- Fea Assignment - IDocument13 pagesFea Assignment - Isakthivel balamuruganNo ratings yet

- Closed-Form Solutions For Elastoplastic Pure Bending of A Curved Beam With Material InhomogeneityDocument11 pagesClosed-Form Solutions For Elastoplastic Pure Bending of A Curved Beam With Material Inhomogeneityडॉ. कनिष्क शर्माNo ratings yet

- 2004 Int Ansys Conf 124Document26 pages2004 Int Ansys Conf 124manasrinuNo ratings yet

- W 06 ME6093 MicromechanicsDocument80 pagesW 06 ME6093 MicromechanicsKhawaja Noman BashirNo ratings yet

- 3-D Finite Element Analysis of Composite Beams With Parallel Fibres, Based On Homogenization TheoryDocument14 pages3-D Finite Element Analysis of Composite Beams With Parallel Fibres, Based On Homogenization TheorytizoclopezNo ratings yet

- 1.054/1.541 Mechanics and Design of Concrete Structures (3-0-9) Outline 11 Yield Line Theory For SlabsDocument9 pages1.054/1.541 Mechanics and Design of Concrete Structures (3-0-9) Outline 11 Yield Line Theory For SlabsSuNarto WAngNo ratings yet

- Composite Patch Repair Methodology For Damaged AirDocument7 pagesComposite Patch Repair Methodology For Damaged AirtidjinialaadaniaNo ratings yet

- Limit State Analysis of RC StructuresDocument4 pagesLimit State Analysis of RC Structureskalyani ajaxNo ratings yet

- FPFComposite JPCSA4 R1Document9 pagesFPFComposite JPCSA4 R1Adell FebriNo ratings yet

- Analysis of Order of Singularity at A Vertex in 3D Transversely Isotropic Piezoelectric Single-Step Bonded JointsDocument13 pagesAnalysis of Order of Singularity at A Vertex in 3D Transversely Isotropic Piezoelectric Single-Step Bonded JointsAJER JOURNALNo ratings yet

- Short Notes Unit - 2-FEMDocument33 pagesShort Notes Unit - 2-FEMgurumahesh gNo ratings yet

- Article 3Document10 pagesArticle 3sami Tub ftNo ratings yet

- XTRACT: A Tool For Axial Force - Ultimate Curvature InteractionsDocument9 pagesXTRACT: A Tool For Axial Force - Ultimate Curvature InteractionscvlengNo ratings yet

- ICTP93 GibianskyDocument40 pagesICTP93 GibianskyGalahad666No ratings yet

- P. Sollero and M. H. Aliabadi. 1993. Fracture Mechanics Analysis of Anisotropic Plates by The Boundary Element Method.Document16 pagesP. Sollero and M. H. Aliabadi. 1993. Fracture Mechanics Analysis of Anisotropic Plates by The Boundary Element Method.Leonardo BernardoNo ratings yet

- 1 s2.0 026382239290052E MainDocument11 pages1 s2.0 026382239290052E MainAbdallah AbdalFatah Mohamed MohamedNo ratings yet

- MPE 422 - Plasticity by DR Eng Koech PiusDocument78 pagesMPE 422 - Plasticity by DR Eng Koech PiusPeter MuriithiNo ratings yet

- Will Is Composites 2002Document61 pagesWill Is Composites 2002mrjnhowardNo ratings yet

- Constitutive Equations and Linear Elasticity: Fall, 2006Document41 pagesConstitutive Equations and Linear Elasticity: Fall, 2006Jet BesacruzNo ratings yet

- Chen-Li2013 Article Size-dependentFreeVibrationAnaDocument15 pagesChen-Li2013 Article Size-dependentFreeVibrationAnaSilas Sverre ChristensenNo ratings yet

- Elastic-Plastic Cylindrical Shell Under Axisymmetric Loading - Analytical SolutionDocument15 pagesElastic-Plastic Cylindrical Shell Under Axisymmetric Loading - Analytical SolutionbahmanNo ratings yet

- Solid Mechanics Study Material PDFDocument35 pagesSolid Mechanics Study Material PDFirinat101No ratings yet

- CE637A-Pactice Question - 1Document2 pagesCE637A-Pactice Question - 1Sanchita PaulNo ratings yet

- Pettermann and DeSimone 2018 - An Anisotropic Linear-Thermo Viscoelastic Contitutive Law-1Document13 pagesPettermann and DeSimone 2018 - An Anisotropic Linear-Thermo Viscoelastic Contitutive Law-1rodrigo.vilela.gorgaNo ratings yet

- Fatigue Life Prediction of Notched Composite Components: and A. PlumtreeDocument15 pagesFatigue Life Prediction of Notched Composite Components: and A. PlumtreeJian XuNo ratings yet

- Shear Coefficients For Thin-Walled Composite BeamsDocument15 pagesShear Coefficients For Thin-Walled Composite BeamsFlmkaneNo ratings yet

- Introduction To Finite Element Method PDFDocument13 pagesIntroduction To Finite Element Method PDFamodhyaNo ratings yet

- The Buckling of Cross-Ply Laminated Non-Homogeneous Orthotropic Composite Conical Thin Shells Under A Dynamic External PressureDocument12 pagesThe Buckling of Cross-Ply Laminated Non-Homogeneous Orthotropic Composite Conical Thin Shells Under A Dynamic External Pressurers0004No ratings yet

- Stability and Vibration of Initially Stressed Plates Composed of Spatially Distributed Fiber CompositesDocument19 pagesStability and Vibration of Initially Stressed Plates Composed of Spatially Distributed Fiber CompositesFranco VillanuevaNo ratings yet

- Design of Domes For Polymeric Composite Pressure Vessels-Hojjati1995Document9 pagesDesign of Domes For Polymeric Composite Pressure Vessels-Hojjati1995Hiến Đinh VănNo ratings yet

- A Theoretical Solution of Cylindrical Shells For Axisymmetric Plain Strain Elastodynamic ProblemsDocument8 pagesA Theoretical Solution of Cylindrical Shells For Axisymmetric Plain Strain Elastodynamic ProblemsisraaNo ratings yet

- Generalized Tensor Function Via The TensDocument39 pagesGeneralized Tensor Function Via The TensЕлена НиколаевскаяNo ratings yet

- Fem Analysis On Mixed-Mode Fracture of CSM-GRP: - FF y 0, A - T O, P (P, S)Document13 pagesFem Analysis On Mixed-Mode Fracture of CSM-GRP: - FF y 0, A - T O, P (P, S)Ramesh SantanaNo ratings yet

- Part 2 Mechnical DesignDocument6 pagesPart 2 Mechnical DesignJeff Ong Soon HuatNo ratings yet

- Analysis of Composite Laminate Beams Using Coupling Cross-Section Finite Element MethodDocument10 pagesAnalysis of Composite Laminate Beams Using Coupling Cross-Section Finite Element MethodHossam T BadranNo ratings yet

- MAE 640 Lec15Document18 pagesMAE 640 Lec15kostas.sierros9374No ratings yet

- Vibration Analysis of Cross-Ply Laminated Beams With General Boundary Conditions by Ritz MethodDocument16 pagesVibration Analysis of Cross-Ply Laminated Beams With General Boundary Conditions by Ritz MethodHakim KaciNo ratings yet

- 20110926HW1Document2 pages20110926HW1David SimonNo ratings yet

- Non-Linear Least-Squares Solution To The Moird Hole Method Problem in Orthotropic Materials, Part I: Residual StressesDocument13 pagesNon-Linear Least-Squares Solution To The Moird Hole Method Problem in Orthotropic Materials, Part I: Residual StressesDownNo ratings yet

- Modal Analysis Odf CFRP PanelDocument21 pagesModal Analysis Odf CFRP Paneldimos dimouNo ratings yet

- 1 Modeling Crack Singularities in FEM/X-FEMDocument11 pages1 Modeling Crack Singularities in FEM/X-FEMmilad66tehNo ratings yet

- Fem 16M-1Document13 pagesFem 16M-1Abdul NazèêrNo ratings yet

- CH 4Document29 pagesCH 4choopo100% (1)

- Transversely Isotropic Plasticity With Application To Fiber - Reinforced PlasticsDocument20 pagesTransversely Isotropic Plasticity With Application To Fiber - Reinforced Plasticsshossain1987No ratings yet

- Therzhagi Line TheroyDocument26 pagesTherzhagi Line TheroyRaja GNo ratings yet

- Mechanics of SolidsDocument10 pagesMechanics of SolidsAnshuman SinghNo ratings yet

- Stress SingularitiesDocument8 pagesStress SingularitiesAndrés MercadoNo ratings yet

- Damping Analysis of Laminated Plates and Beams Using RItz MethodDocument16 pagesDamping Analysis of Laminated Plates and Beams Using RItz MethodHimanshu DubeyNo ratings yet

- Finite Element Analysis of Large Diameter Concrete Spherical Shell Domes - Hani Aziz AmeenDocument16 pagesFinite Element Analysis of Large Diameter Concrete Spherical Shell Domes - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- Material Identification of Viscoelastic Core Materials in Sandwich StructuresDocument6 pagesMaterial Identification of Viscoelastic Core Materials in Sandwich StructuresHamed MemarianNo ratings yet

- ME223 Tut5Document5 pagesME223 Tut5Lily MaronNo ratings yet

- Active Vibration Control of ADocument10 pagesActive Vibration Control of AMehrshad GhasemabadiNo ratings yet

- CMT Lesson 2Document14 pagesCMT Lesson 2April Jhen BenavidezNo ratings yet

- The Mixed Mode Crack Problem in An Inhomogeneous Orthotropic MediumDocument19 pagesThe Mixed Mode Crack Problem in An Inhomogeneous Orthotropic MediumVenkatesh VarmaNo ratings yet

- Difference Equations in Normed Spaces: Stability and OscillationsFrom EverandDifference Equations in Normed Spaces: Stability and OscillationsNo ratings yet

- For Information Only, Will Not Be Exchanged When Altered!: Spare Part ListDocument12 pagesFor Information Only, Will Not Be Exchanged When Altered!: Spare Part ListIrving Jose Vazquez QuezadaNo ratings yet

- Jsa Jis B 1582Document16 pagesJsa Jis B 1582farhad0% (1)

- Avionics Circuit Breaker Panel - 17280001 Thru 17280003 REF Nomenclature Effectivity DES Number 1 2 3 4 5 6 7 From TO Units PER AssyDocument2 pagesAvionics Circuit Breaker Panel - 17280001 Thru 17280003 REF Nomenclature Effectivity DES Number 1 2 3 4 5 6 7 From TO Units PER AssybnolascoNo ratings yet

- Comparison Aero30ng AerophareDocument8 pagesComparison Aero30ng Aeropharesafari_victoryNo ratings yet

- MFR6119201 00 (Web)Document92 pagesMFR6119201 00 (Web)Mahmoud M.AbdelalimNo ratings yet

- Shifting DetailsDocument3 pagesShifting DetailsVinay GautamNo ratings yet

- Ansi C37.54-2002 (R2010)Document46 pagesAnsi C37.54-2002 (R2010)Mochamad Beta AuditamaNo ratings yet

- Phnsycasescase Study: Inventory Management System Keeps PearlDocument4 pagesPhnsycasescase Study: Inventory Management System Keeps PearlMohit KalaNo ratings yet

- Sa227 Series: Maintenance ManualDocument28 pagesSa227 Series: Maintenance ManualKIKENo ratings yet

- MOTOROLA DSP563XX Architecture PDFDocument4 pagesMOTOROLA DSP563XX Architecture PDFTyler DurdenNo ratings yet

- UNIT III - System Building Blocks, Models and Closed Loop ControllersDocument122 pagesUNIT III - System Building Blocks, Models and Closed Loop ControllersKuppan Chetty RamanathanNo ratings yet

- Pioneer Pdp434p Plasma TV SM (ET)Document95 pagesPioneer Pdp434p Plasma TV SM (ET)Muskegon Michigan100% (1)

- Business Portal Online Print 10-11-2020Document283 pagesBusiness Portal Online Print 10-11-2020sxturbo100% (1)

- DME Unitwise Question BankDocument24 pagesDME Unitwise Question BanksureshkumarNo ratings yet

- Pressure Calibration: Applications SolutionsDocument32 pagesPressure Calibration: Applications SolutionscarlosmarciosfreitasNo ratings yet

- En Tool Clamping Systems 2012Document72 pagesEn Tool Clamping Systems 2012Goran MiodragovicNo ratings yet

- Mogami, T. Kubo. (1953) - The Behavior of Soils During Vibration. Proc. 3rd ICSMFE, Zurich.Document5 pagesMogami, T. Kubo. (1953) - The Behavior of Soils During Vibration. Proc. 3rd ICSMFE, Zurich.marco cavaleiroNo ratings yet

- Bentonite PelletDocument1 pageBentonite PelletPato IrfanNo ratings yet

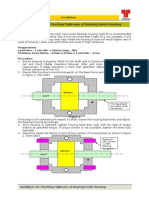

- Guidelines For Checking Tightness of Bearing Inside HousingDocument2 pagesGuidelines For Checking Tightness of Bearing Inside HousingDurjoy ChakrabortyNo ratings yet

- Tmsa - Specifications Suggested Division 15 SpecificationsDocument1 pageTmsa - Specifications Suggested Division 15 SpecificationshimajcpNo ratings yet

- Novapol TF 0338 e NovaDocument2 pagesNovapol TF 0338 e NovaJulio GarcíaNo ratings yet

- Design Pro User's ManualDocument378 pagesDesign Pro User's ManualAlexandru Sorin Leotescu0% (1)

- Circuit Anlaysis S DomainDocument7 pagesCircuit Anlaysis S DomainKartik TyagiNo ratings yet

- Coolingwater 140301175552 Phpapp01Document9 pagesCoolingwater 140301175552 Phpapp01Vasanth Rajan100% (1)

- Substation Equipment: WT, La, Isolator, CT, PT, CVTDocument33 pagesSubstation Equipment: WT, La, Isolator, CT, PT, CVTDipan GhoshNo ratings yet

- TechDraft 10 DLL Q3 W4Document3 pagesTechDraft 10 DLL Q3 W4MARICEL TALAGNo ratings yet

- Admission Brochure Nsut Mba2019Document15 pagesAdmission Brochure Nsut Mba2019himanshuNo ratings yet

- Hino 300 Series0Document12 pagesHino 300 Series0Adhitya Joko NurNo ratings yet