Professional Documents

Culture Documents

Consumable CHG 55B2

Consumable CHG 55B2

Uploaded by

Nhien ManCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Consumable CHG 55B2

Consumable CHG 55B2

Uploaded by

Nhien ManCopyright:

Available Formats

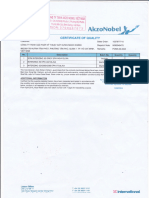

CHG-55B2

TIG Rod for Heat-resisting Low Alloy Steel

BS EN ISO 21952-A-W (CrMo1Si)

BS EN ISO 21952-B-W 1CM3

JIS Z3316 YGT1CM

Similar to AWS A5.28 ER80S-B2

GB/T 8110 ER55-B2

Features & Applications

CHG-55B2 is one kind of category 1.25%Cr-0.5%Mo pearlitic heat-resisting low alloy steel TIG

rod and the weld metal has good integrative mechanical properties. It is mainly used for

welding heat-absorbing surface tubes of industrial boiler that work temperature is below 550℃,

high pressure and medium pressure steam tubes of steam turbines that work temperature is

below 510℃.

Chemical Composition of the Wire (%)

C Mn Si S P Cr Mo Cu

Standard ≤0.15 1.00-1.50 0.30-0.90 ≤0.025 ≤0.025 1.00-1.60 0.40-0.65 ≤0.35

Typical 0.076 1.15 0.67 0.007 0.015 1.25 0.50 0.20

Mechanical Properties of Deposited Metal (PWHT 690℃ x 1h)

Tensile Strength Yield Strength Elongation Impact Value (J) Shield Gas

Rm (MPa) ReL/Rp0.2 (MPa) A4 (%) Ambient temp.

Standard ≥550 ≥470 ≥17 ≥27 100%Ar

Typical 620 505 23 180 Purity ≥99.99%

Notice: 1) To avoid rust the wire must be kept in dry condition and keep the package in good

condition also before welding.

2) To prevent welding defect the shield gas should be pure particularly no moisture in

it.

3) The surfaces to be welded must be cleaned away impurities of oil contamination,

rust, moisture and so on.

4) The flowrate of the shield gas should be 9L-14L/minite when the current is

100A-120A and it should be 14L-18L/minite when the current is 200A-300A. The

extention of tungsten electrode should be 3mm-5mm and arc length should be

1mm-3mm. wind speed ≤1.0m/s. It is better to fill shield gas on the backside of

welded joint in welding.

5) The temperature for both preheating and interpass temperature should be 180℃

-300℃ and temperature of PWHT should be 675℃-705℃. To guaranty tensile

strength of the weld metal the temper time with 695℃ should not be longer

otherwise the temperature of temper should be lowered.

6) Large heat input welding will result in big crystalline grain of the weld metal and

the integrative mechanical properties will be deterioration seriously so in the

condition of the preheating temperature and interpass temperature≥180℃ the

small heat input can refine the crystalline grain to improve the integrative

mechanical properties

7) The welding conditions mentioned above for reference only and it is better to do a

welding procedure qualification according to project before put it into formal

welding.

You might also like

- CO-ORDINATED SCIENCES 0654/62 Paper 6 Alternative To PracticalDocument20 pagesCO-ORDINATED SCIENCES 0654/62 Paper 6 Alternative To PracticalJosé Antonio Álvarez CuberoNo ratings yet

- F765-93 (2012) E1 Standard Specification For Wildcats, Ship Anchor ChainDocument6 pagesF765-93 (2012) E1 Standard Specification For Wildcats, Ship Anchor ChainislamakthamNo ratings yet

- ASME Sec VIII - Temper Bead TechniqueDocument1 pageASME Sec VIII - Temper Bead TechniquezanlogNo ratings yet

- Color of Smoke and Flame: Color of The Smoke Is The First Clue To The Combustible of The Fire: Combustible Color of SmokeDocument2 pagesColor of Smoke and Flame: Color of The Smoke Is The First Clue To The Combustible of The Fire: Combustible Color of SmokeYin Yang100% (1)

- MLT Preparation Handbook Section 1Document22 pagesMLT Preparation Handbook Section 1BHOOPALA KRISHNAN MOTHILAL100% (2)

- Refining Precious Metal Wastes C (1) .M HokeDocument369 pagesRefining Precious Metal Wastes C (1) .M HokejocaspindlerNo ratings yet

- Carbon Arc Cutting PDFDocument44 pagesCarbon Arc Cutting PDFMark InnesNo ratings yet

- TCVN 9385 - 2012 - BS 6651 - 1999 - 998433 EN VerDocument118 pagesTCVN 9385 - 2012 - BS 6651 - 1999 - 998433 EN VerNam NguyenNo ratings yet

- Elastomer I C Bearings PDFDocument8 pagesElastomer I C Bearings PDFMiguel Belda DiezNo ratings yet

- Prorox WM 960 Sa PDFDocument1 pageProrox WM 960 Sa PDFr afriantoNo ratings yet

- AUT-1023 A2 Multitrac PEKDocument1 pageAUT-1023 A2 Multitrac PEKcarlosNo ratings yet

- NDT Training Syllabus PDFDocument8 pagesNDT Training Syllabus PDFNkwor AndersonNo ratings yet

- Aws N-1 WPS-PQR FormDocument2 pagesAws N-1 WPS-PQR FormEdwin MariacaNo ratings yet

- Brochure Prometheus Optimized PDFDocument15 pagesBrochure Prometheus Optimized PDFSHAILENDRANo ratings yet

- North Carolina Department OF Transportation Double Bevel Groove B G W P S (WPS) AWS D1.5Document3 pagesNorth Carolina Department OF Transportation Double Bevel Groove B G W P S (WPS) AWS D1.5farshid KarpasandNo ratings yet

- Report of Ultrasonic Flaw Detection Test of Weld JointDocument1 pageReport of Ultrasonic Flaw Detection Test of Weld Jointkevin desai100% (1)

- Painting Report Cd3Document15 pagesPainting Report Cd3sivaNo ratings yet

- Aws 5.36Document2 pagesAws 5.36ManikandanNo ratings yet

- PQR Al 6xxxDocument7 pagesPQR Al 6xxxAmin ThabetNo ratings yet

- Er 100 S 1Document1 pageEr 100 S 1Oliver Quezada Inostroza100% (1)

- Gmaw STTDocument4 pagesGmaw STTAnonymous 0rt9KWmNNo ratings yet

- Dynamic and Static Balancing of Rolls - How, Why and WhenDocument2 pagesDynamic and Static Balancing of Rolls - How, Why and WhenAbolfazl KhakiNo ratings yet

- Ok Tigrod 12.64 Gtaw enDocument2 pagesOk Tigrod 12.64 Gtaw ensoft4gsmNo ratings yet

- Halliburton Multi Chem Batch Plant Project: Purchase Order/Contract NumberDocument7 pagesHalliburton Multi Chem Batch Plant Project: Purchase Order/Contract NumberTahseen Ahmed100% (1)

- G12MF TypeDocument1 pageG12MF Typeosto72No ratings yet

- Eslon: SCH80 PVC & CPVC Piping Systems Specifications & Engineering ManualDocument112 pagesEslon: SCH80 PVC & CPVC Piping Systems Specifications & Engineering ManualseksonNo ratings yet

- Manual Técnico de Parafusos - BOSSARDDocument85 pagesManual Técnico de Parafusos - BOSSARDRenato Caldas100% (1)

- Indt QCP RT HJ 05NDocument14 pagesIndt QCP RT HJ 05NAsad Bin Ala QatariNo ratings yet

- Hydro TestDocument1 pageHydro TestMilan BanerjeeNo ratings yet

- JIS G3452 PipeDocument0 pagesJIS G3452 PipefaridyeniNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- PT Bhaita Wire Rope Inspection ProcedureDocument4 pagesPT Bhaita Wire Rope Inspection ProcedureSugianto TanNo ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- TopCoreBelco 101 FCDocument9 pagesTopCoreBelco 101 FCCesar ArellanoNo ratings yet

- AWS D1.1-D1.1M-2015 - Pagina-110Document1 pageAWS D1.1-D1.1M-2015 - Pagina-110Gedalías MartínezNo ratings yet

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Document15 pagesFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaNo ratings yet

- Horizontal Bandlock2 ManualDocument23 pagesHorizontal Bandlock2 ManualFilipNo ratings yet

- Office: Printout Sample - ASME WPSDocument2 pagesOffice: Printout Sample - ASME WPSDanem HalasNo ratings yet

- Datenblatt TEGOTENAXS, HM07, HOYT11 R, GBDocument2 pagesDatenblatt TEGOTENAXS, HM07, HOYT11 R, GBmygolNo ratings yet

- SA 387 Grade 91 Class 2Document4 pagesSA 387 Grade 91 Class 2briang-2No ratings yet

- Failure Behavior of 2D C SiC I Beam Under Bending Load 2015 Composite StructuresDocument10 pagesFailure Behavior of 2D C SiC I Beam Under Bending Load 2015 Composite StructuresGECJNo ratings yet

- Final Visual & Dimensional Inspection Report: GeneralDocument3 pagesFinal Visual & Dimensional Inspection Report: Generalsuria qaqcNo ratings yet

- Kit 138 New Bresle Salt PDFDocument2 pagesKit 138 New Bresle Salt PDFDian FaraNo ratings yet

- WPS Qualify To DNV-OS-C401 - SampleDocument12 pagesWPS Qualify To DNV-OS-C401 - SampleBien NguyenDuyNo ratings yet

- Code For Offshore Personnel Transfer Systems July 2022Document92 pagesCode For Offshore Personnel Transfer Systems July 2022Ozan DurmazogluNo ratings yet

- ThyssenDocument0 pagesThyssenAbbas RizviNo ratings yet

- Post Weld Heat Treatment Procedure: Doc No: STS/QAC/SOP/12Document18 pagesPost Weld Heat Treatment Procedure: Doc No: STS/QAC/SOP/12mohd as shahiddin jafriNo ratings yet

- Chemical Composition of ASTM ASME SA516 Grade 60 70 Steel PlateDocument2 pagesChemical Composition of ASTM ASME SA516 Grade 60 70 Steel PlateVarun Malhotra100% (1)

- Factory Original MTCDocument1 pageFactory Original MTCSamir AjiNo ratings yet

- WPS Format For Asme Ix - Wps - Fcaw GmawDocument1 pageWPS Format For Asme Ix - Wps - Fcaw GmawThe Welding Inspections CommunityNo ratings yet

- 20G Boiler Steel Pipe PDFDocument5 pages20G Boiler Steel Pipe PDFHeza FirdausNo ratings yet

- ISO 19840 2004 en PreviewDocument8 pagesISO 19840 2004 en PreviewBalbhim JagdaleNo ratings yet

- A2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5Document5 pagesA2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5ochableNo ratings yet

- QCF312 WPQRDocument2 pagesQCF312 WPQRminhnnNo ratings yet

- Duplex Stainless Steel - Part 2 - TWIDocument6 pagesDuplex Stainless Steel - Part 2 - TWItuanNo ratings yet

- QP STD R 009Document104 pagesQP STD R 009p.abdulameen1234No ratings yet

- Weld Repair ProcedureDocument51 pagesWeld Repair Proceduremohd as shahiddin jafriNo ratings yet

- API 5L GR.B SteelDocument2 pagesAPI 5L GR.B SteelYosua Rielys PNo ratings yet

- WPSDocument1 pageWPSRodica TimofteNo ratings yet

- CHG 308LDocument1 pageCHG 308LImmalatulhusnaNo ratings yet

- CHG 56Document2 pagesCHG 56ImmalatulhusnaNo ratings yet

- AWS A5.9 ER310 BS EN ISO 14343-A-G (25 20) BS EN ISO 14343-B-SS310 JIS Z3321 Y310 GB/T 4241 H12Cr26Ni21SiDocument1 pageAWS A5.9 ER310 BS EN ISO 14343-A-G (25 20) BS EN ISO 14343-B-SS310 JIS Z3321 Y310 GB/T 4241 H12Cr26Ni21SiImmalatulhusnaNo ratings yet

- CHM 316LDocument1 pageCHM 316LImmalatulhusnaNo ratings yet

- Data Sheet A-10: Alloy TypeDocument3 pagesData Sheet A-10: Alloy Typemohamed AdelNo ratings yet

- Consumable Midalloy ER70S B2LDocument1 pageConsumable Midalloy ER70S B2LNhien ManNo ratings yet

- pdf24 MergedDocument2 pagespdf24 MergedNhien ManNo ratings yet

- ASTM A335 P91 Steel PipesDocument7 pagesASTM A335 P91 Steel PipesNhien ManNo ratings yet

- TDS Adhesion CompoundDocument6 pagesTDS Adhesion CompoundNhien ManNo ratings yet

- Midalloy ER70S B2LDocument1 pageMidalloy ER70S B2LNhien ManNo ratings yet

- Wire Rope SlingDocument1 pageWire Rope SlingNhien ManNo ratings yet

- Tubes and Pipes (340 KB)Document2 pagesTubes and Pipes (340 KB)Nhien ManNo ratings yet

- REPORT-MT 20.10.2022. M C TinhDocument7 pagesREPORT-MT 20.10.2022. M C TinhNhien ManNo ratings yet

- REPORT-MT 20.10.2022. M C TinhDocument7 pagesREPORT-MT 20.10.2022. M C TinhNhien ManNo ratings yet

- Report-Mt 20.10.2022.M C TinhDocument7 pagesReport-Mt 20.10.2022.M C TinhNhien ManNo ratings yet

- REPORT-MT 21.10.2022 (Test)Document2 pagesREPORT-MT 21.10.2022 (Test)Nhien ManNo ratings yet

- REPORT-MT 21.10.2022 (Test)Document2 pagesREPORT-MT 21.10.2022 (Test)Nhien ManNo ratings yet

- Physical Manipulative Activity - Balancing Chemical ReactionsDocument3 pagesPhysical Manipulative Activity - Balancing Chemical Reactionsapi-354615171No ratings yet

- Current Research in Green and Sustainable ChemistryDocument5 pagesCurrent Research in Green and Sustainable Chemistryfahd tibourtineNo ratings yet

- Petroleum Product Analysis by NIR Spectroscopy (E.g., Cetane Index, TAN, Aromatics, and Sulfur)Document5 pagesPetroleum Product Analysis by NIR Spectroscopy (E.g., Cetane Index, TAN, Aromatics, and Sulfur)Nhi LeNo ratings yet

- Elements and Their UsesDocument17 pagesElements and Their UsesPeachy AbelidaNo ratings yet

- 3.various Units of IOCL Paradip: 3.1. Avu/Srlpg UnitDocument8 pages3.various Units of IOCL Paradip: 3.1. Avu/Srlpg UnitAkankshya MishraNo ratings yet

- Chemistry 4CH1 1CRDocument6 pagesChemistry 4CH1 1CRLoki .7thNo ratings yet

- Science Lab ReportDocument8 pagesScience Lab Reportapi-298730823100% (1)

- DEMISTERDocument6 pagesDEMISTERNguyen ChuyenNo ratings yet

- Analysis of Bio Oil Produced by Pyrolysis of Coconut ShellDocument4 pagesAnalysis of Bio Oil Produced by Pyrolysis of Coconut ShellMuhamad SuharNo ratings yet

- Nice Chemical-Price List-2021-22Document84 pagesNice Chemical-Price List-2021-22Savitha NNo ratings yet

- Vitamins and MineralsDocument2 pagesVitamins and MineralsMark Zedrix MediarioNo ratings yet

- 4 - Water Base Mud System - PTM - HandoutDocument32 pages4 - Water Base Mud System - PTM - HandoutFauzan Rahman Haq100% (1)

- 1 SATIP-W-017-01 Welding of API Tanks-Rev 1Document4 pages1 SATIP-W-017-01 Welding of API Tanks-Rev 1khalid764No ratings yet

- New Ecojet-P j2 MsdsDocument15 pagesNew Ecojet-P j2 Msdsholiday fotoserviceNo ratings yet

- Biochem KudigoDocument30 pagesBiochem KudigoEyvette GoNo ratings yet

- Iodine Test: Polysaccharides Color Reaction With IodineDocument2 pagesIodine Test: Polysaccharides Color Reaction With IodineAlexandra TarucNo ratings yet

- ZJD Series Lubricant Oil Purifier 2020Document14 pagesZJD Series Lubricant Oil Purifier 2020Alex100% (1)

- Chapter 1-Introduction: 1.1 GeneralDocument4 pagesChapter 1-Introduction: 1.1 GeneralShraman GuptaNo ratings yet

- Anel de Trava BI e BEDocument120 pagesAnel de Trava BI e BERonildo DuarteNo ratings yet

- Determination of An Equilibrium ConstantDocument3 pagesDetermination of An Equilibrium ConstantStephanie Susavage0% (1)

- Comparison GRP vs. PlasticDocument1 pageComparison GRP vs. PlasticRickNo ratings yet

- Itcoloy and Milling Tools: Instruction Manual 5100Document12 pagesItcoloy and Milling Tools: Instruction Manual 5100Foros IscNo ratings yet

- Acid Base and Salt QuestionsDocument3 pagesAcid Base and Salt QuestionsBikash DasNo ratings yet

- Chemistry 12 CH10NotesDocument28 pagesChemistry 12 CH10NotesAquib MalikNo ratings yet

- Chemical ProductionDocument16 pagesChemical ProductionPamphile AhouanseNo ratings yet

- Material Safety Data Sheet: Composition/Information On IngredientsDocument4 pagesMaterial Safety Data Sheet: Composition/Information On IngredientskhurramNo ratings yet