Professional Documents

Culture Documents

High Tensile Strength Steel TIG Rod for Welding Structures

Uploaded by

ImmalatulhusnaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

High Tensile Strength Steel TIG Rod for Welding Structures

Uploaded by

ImmalatulhusnaCopyright:

Available Formats

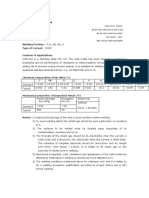

CHG-56

TIG Rod for High Tensile Strength Steel

AWS A5.18 ER70S-6

ISO 636-A-W 42 3 W3Si1

ISO 636-B-W 49 A 3 W6

BS EN 1668- W 42 3 W3Si1

JIS Z3316 YGT50

GB/T 8110 ER50-6

Welding Position: F, H, HF, OH, V

Type of Current: DCEP

Features & Applications

CHG-56 is a high tensile strength steel TIG rod and it is used for single-pass or multi-pass

welding structures fabricated by mild steels or 500MPa grade tensile strength low alloy

steels such as vehicles, lifts, bridges, machineries and so on.

Chemical Composition of the Wire (%)

C Mn Si S P Ni Cr Mo V

Standard 0.06-0.15 1.40-1.85 0.80-1.15 ≤0.035 ≤0.025 ≤0.15 ≤0.15 ≤0.15 ≤0.03 ≤

Typical 0.07 1.47 0.90 0.011 0.012 0.021 0.020 0.007 0.008 0

Mechanical properties of Deposited Metal (AW)

Tensile Strength Yield Strength Elongation Impact Value (J) Shield Gas

Rm (MPa) ReL (MPa) A4 (%)

-30℃ 100%Ar

Standard ≥480 ≥400 ≥22 ≥27

Purity ≥99.99%

Typical 550 450 29 160

Notice: 1) To avoid rust the wire must be kept in dry condition and keep the package in

good condition also before welding.

2) To prevent welding defect the shield gas should be pure particularly no

moisture in it.

3) The surfaces to be welded must be cleaned away impurities of oil

contamination, rust, moisture and so on.

4) The flowrate of the shield gas should be 9L-14L/minite when the current is

100A-120A and it should be 14L-18L/minite when the current is 200A-300A.

The extention of tungsten electrode should be 3mm-5mm and arc length

should be 1mm-3mm. wind speed ≤1.0m/s. It is better to fill shield gas on

the backside of welded joint in welding.

5) Mechanical properties, crack resistance and appearance of the weld metal are

affected by heat input in welding so should pay more attention to it.

6) The welding conditions mentioned above for reference only and it is better to

do a welding procedure qualification according to project before put it into

formal welding.

You might also like

- Weld Toe Burr Grinding ProcedureDocument3 pagesWeld Toe Burr Grinding ProcedureGaurav1 KhamkarNo ratings yet

- ISO 9001-2015 Checklist PDFDocument37 pagesISO 9001-2015 Checklist PDFHomero Januncio100% (1)

- 4STY 20CL PozorrubioCS On Micropile FoundationDocument65 pages4STY 20CL PozorrubioCS On Micropile FoundationKaren Balisacan Segundo RuizNo ratings yet

- Catálogo DOKA PDFDocument552 pagesCatálogo DOKA PDFHenry Moreno100% (6)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Sfa 5.18 PDFDocument28 pagesSfa 5.18 PDFFranqui Fernandes100% (1)

- Structural Steel SpecificationDocument11 pagesStructural Steel SpecificationnoufalNo ratings yet

- Perimeter Fence Rev 02-6Document1 pagePerimeter Fence Rev 02-6Victorino SantosNo ratings yet

- BOQ Boundary WallsDocument34 pagesBOQ Boundary Wallsceline_0865No ratings yet

- CHG 308LDocument1 pageCHG 308LImmalatulhusnaNo ratings yet

- CHG 55B2Document1 pageCHG 55B2Nhien ManNo ratings yet

- CHM 316LDocument1 pageCHM 316LImmalatulhusnaNo ratings yet

- CHW 50C6Document1 pageCHW 50C6scribdsonbaNo ratings yet

- AWS A5.9 ER310 BS EN ISO 14343-A-G (25 20) BS EN ISO 14343-B-SS310 JIS Z3321 Y310 GB/T 4241 H12Cr26Ni21SiDocument1 pageAWS A5.9 ER310 BS EN ISO 14343-A-G (25 20) BS EN ISO 14343-B-SS310 JIS Z3321 Y310 GB/T 4241 H12Cr26Ni21SiImmalatulhusnaNo ratings yet

- B - Boehler DMO-IG - Ss - en - 5 PDFDocument1 pageB - Boehler DMO-IG - Ss - en - 5 PDFDimitris NikouNo ratings yet

- Metrode E2209 (B-60) ElectrodeDocument6 pagesMetrode E2209 (B-60) ElectrodeClaudia MmsNo ratings yet

- CHF101 CHW S16 PDFDocument1 pageCHF101 CHW S16 PDFImmalatulhusnaNo ratings yet

- CHF101 Flux Wire ComboDocument1 pageCHF101 Flux Wire ComboImmalatulhusnaNo ratings yet

- CHT81 Ni 1Document1 pageCHT81 Ni 1ImmalatulhusnaNo ratings yet

- AWS A5.20 E71T-1C BS EN ISO 17632-T42 2 P C 1 H10 Jis Z3313 Yfw-C50Dr CSA W48-01 E491T-1-H8 GB/T 10045 E501T-1Document2 pagesAWS A5.20 E71T-1C BS EN ISO 17632-T42 2 P C 1 H10 Jis Z3313 Yfw-C50Dr CSA W48-01 E491T-1-H8 GB/T 10045 E501T-1Andre Brama AlvariNo ratings yet

- B - Boehler NiMo 1-IG - de - en - 5Document1 pageB - Boehler NiMo 1-IG - de - en - 5cristian popescuNo ratings yet

- CHS29 9Document1 pageCHS29 9sulis setiawanNo ratings yet

- Metrode ER110S-G FillerDocument6 pagesMetrode ER110S-G FillerBernie SimcsNo ratings yet

- CO2 Welding Wire ER70S-G SpecsDocument2 pagesCO2 Welding Wire ER70S-G SpecsRahmat RiskiNo ratings yet

- TDS ATLANTIC CHT81Ni1Document1 pageTDS ATLANTIC CHT81Ni1Andi Baso Temalala STNo ratings yet

- Standar Elektroda PDFDocument182 pagesStandar Elektroda PDFFakhar WindratamaNo ratings yet

- Low Alloy13Document5 pagesLow Alloy13Branko FerenčakNo ratings yet

- Flux Cored Wires for Welding High Strength SteelDocument71 pagesFlux Cored Wires for Welding High Strength SteelCristian Camilo QuirogaNo ratings yet

- Lasting Connections with Seamless Cored WireDocument2 pagesLasting Connections with Seamless Cored WireDavid RodriguesNo ratings yet

- A-23 WB36 Rev 03 15NiCuMoNb5 MicrostructureDocument4 pagesA-23 WB36 Rev 03 15NiCuMoNb5 Microstructuremavis16No ratings yet

- Böhler HL 51 T-MC: Seamless Cored WireDocument2 pagesBöhler HL 51 T-MC: Seamless Cored WireFer VFNo ratings yet

- Diamondspark 46 MC: Seamless Metal-Cored WireDocument2 pagesDiamondspark 46 MC: Seamless Metal-Cored WireDavid RodriguesNo ratings yet

- Böhler Eas 2 PW-FDDocument1 pageBöhler Eas 2 PW-FDHAKANNo ratings yet

- 1.smaw All PDFDocument76 pages1.smaw All PDFkaviatchennaiNo ratings yet

- YAWATA 7018: Classification Applications Characteristics ApprovalsDocument1 pageYAWATA 7018: Classification Applications Characteristics ApprovalsDenny AgusNo ratings yet

- Data Sheet A-10: Alloy TypeDocument3 pagesData Sheet A-10: Alloy Typemohamed AdelNo ratings yet

- Böhler CM 5-Ig: TIG Rod, High-Alloyed, Creep ResistantDocument1 pageBöhler CM 5-Ig: TIG Rod, High-Alloyed, Creep Resistantwesley59No ratings yet

- 31102015000000B - Boehler E 308 H PW-FD - CWDocument1 page31102015000000B - Boehler E 308 H PW-FD - CWKARLNo ratings yet

- Coremax 308LP DataDocument1 pageCoremax 308LP DataLIM hoon boonNo ratings yet

- Flux Cored Arc Welding for Low Carbon 18%Cr-12%Ni-2%Mo Stainless SteelDocument1 pageFlux Cored Arc Welding for Low Carbon 18%Cr-12%Ni-2%Mo Stainless Steelmohamed AdelNo ratings yet

- Metrode Cryogenic 308lcf B-37Document5 pagesMetrode Cryogenic 308lcf B-37Claudia MmsNo ratings yet

- FLUX CORED WIRES FOR SHIPBUILDING AND STRUCTURESDocument1 pageFLUX CORED WIRES FOR SHIPBUILDING AND STRUCTUREScamelod555No ratings yet

- 22%Cr DUPLEX STAINLESS STEEL WELDING CONSUMABLESDocument7 pages22%Cr DUPLEX STAINLESS STEEL WELDING CONSUMABLESNguyen Anh TuanNo ratings yet

- Description:: AWS A5.4 E308-16 JIS Z3221 ES308-16 EN 1600 E 19 9 R 1 2 Covered Electrodes For Stainless SteelDocument1 pageDescription:: AWS A5.4 E308-16 JIS Z3221 ES308-16 EN 1600 E 19 9 R 1 2 Covered Electrodes For Stainless Steel13421301508No ratings yet

- Böhler Fox EV 65 electrode for high-strength steelsDocument1 pageBöhler Fox EV 65 electrode for high-strength steelsMohamed AdelNo ratings yet

- Er 80 S GDocument2 pagesEr 80 S Gabhics67No ratings yet

- Böhler Ti 60 T-FD: Seamless Cored WireDocument2 pagesBöhler Ti 60 T-FD: Seamless Cored WireMilos StoisavljevicNo ratings yet

- AWS A5.1 E6010 SC-10 Mild Steel Electrodes SpecificationsDocument56 pagesAWS A5.1 E6010 SC-10 Mild Steel Electrodes SpecificationsFakhar WindratamaNo ratings yet

- Copper-Coated Solid Wire for Universal Welding ApplicationsDocument1 pageCopper-Coated Solid Wire for Universal Welding ApplicationsInaamNo ratings yet

- Mild Steel 490mpa High Tensile Strength SteelDocument38 pagesMild Steel 490mpa High Tensile Strength SteelCarlos PadillaNo ratings yet

- Tetra S 316L-G: Technical Data Sheet Cored Welding WireDocument1 pageTetra S 316L-G: Technical Data Sheet Cored Welding WirePeter TvardzíkNo ratings yet

- Diamondspark Ni1 RC: Seamless Cored WireDocument2 pagesDiamondspark Ni1 RC: Seamless Cored Wiresanul mulyNo ratings yet

- GMM Mag.Document1 pageGMM Mag.Ehsan KhanNo ratings yet

- Er308 PDFDocument1 pageEr308 PDFKhedira Al JibrillNo ratings yet

- MIP Bohler Welding Austria 63Document1 pageMIP Bohler Welding Austria 63thod3rNo ratings yet

- Welding Wire CatalogDocument10 pagesWelding Wire CatalogElvis MaljanovicNo ratings yet

- Boehler CN 13 4-MC FDocument1 pageBoehler CN 13 4-MC FFilipe CordeiroNo ratings yet

- CHH517Document1 pageCHH517KureiNo ratings yet

- Sandvik WeldingDocument3 pagesSandvik WeldingRam KadamNo ratings yet

- MIP Bohler Welding Austria 62Document1 pageMIP Bohler Welding Austria 62Pradeepta MohantyNo ratings yet

- Che507r PDFDocument1 pageChe507r PDFAnonymous AkzeMHNTUyNo ratings yet

- Böhler Ti 2 Ni T-FD: Seamless Cored WireDocument2 pagesBöhler Ti 2 Ni T-FD: Seamless Cored WireThanh TamNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- FSH TigDocument105 pagesFSH TigChee WeiNo ratings yet

- MTC Jfe Eh500Document2 pagesMTC Jfe Eh500ImmalatulhusnaNo ratings yet

- SMI - BBSR - OPN - F - 34A-F Roll Assembly Checklist (Internal)Document4 pagesSMI - BBSR - OPN - F - 34A-F Roll Assembly Checklist (Internal)ImmalatulhusnaNo ratings yet

- Ultrasonic Flaw Detector Quick Start GuideDocument32 pagesUltrasonic Flaw Detector Quick Start GuideImmalatulhusnaNo ratings yet

- Your Event Guide To TAYLOR SWIFT THE ERAS TOURDocument9 pagesYour Event Guide To TAYLOR SWIFT THE ERAS TOURImmalatulhusnaNo ratings yet

- Jis Scncrm2bDocument1 pageJis Scncrm2bImmalatulhusnaNo ratings yet

- FRM-DC-005 Rekap Matrix SOPDocument2 pagesFRM-DC-005 Rekap Matrix SOPImmalatulhusnaNo ratings yet

- Copper Alloys in Ingot Form: Standard Specification ForDocument12 pagesCopper Alloys in Ingot Form: Standard Specification ForImmalatulhusnaNo ratings yet

- Sistim Tegangan &: Residual StressDocument52 pagesSistim Tegangan &: Residual StressImmalatulhusnaNo ratings yet

- Duaplate D80 Weld Overlay: ManufactureDocument1 pageDuaplate D80 Weld Overlay: ManufactureImmalatulhusnaNo ratings yet

- Welding Materials: Ultra-Precision Mold Padding WelderDocument4 pagesWelding Materials: Ultra-Precision Mold Padding WelderImmalatulhusnaNo ratings yet

- Hydrogen Damage and EmbrittlementDocument9 pagesHydrogen Damage and EmbrittlementImmalatulhusnaNo ratings yet

- Uniform CorrosionDocument33 pagesUniform CorrosionImmalatulhusnaNo ratings yet

- Introduksi Analisa Kerusakan: (Introduction To Failure Analyses)Document13 pagesIntroduksi Analisa Kerusakan: (Introduction To Failure Analyses)ImmalatulhusnaNo ratings yet

- B 5 - 00 QjuDocument4 pagesB 5 - 00 QjuHafiz_Murni_4791No ratings yet

- CHF101 CHW S16 PDFDocument1 pageCHF101 CHW S16 PDFImmalatulhusnaNo ratings yet

- CHL608Document1 pageCHL608ImmalatulhusnaNo ratings yet

- AWS A5.9 ER347 BS EN ISO 14343-A-W (19 9 NB) BS EN ISO 14343-B-SS347 JIS Z3321 Y347 GB/T 4241 H08Cr20Ni10NbDocument1 pageAWS A5.9 ER347 BS EN ISO 14343-A-W (19 9 NB) BS EN ISO 14343-B-SS347 JIS Z3321 Y347 GB/T 4241 H08Cr20Ni10NbImmalatulhusnaNo ratings yet

- Welding Rod for Medium & Thick PlatesDocument1 pageWelding Rod for Medium & Thick PlatesImmalatulhusnaNo ratings yet

- Aws A5.11 Enicrmo-3 Iso 14172-E Ni 6625 GB/T 13814 Eni6625Document1 pageAws A5.11 Enicrmo-3 Iso 14172-E Ni 6625 GB/T 13814 Eni6625ImmalatulhusnaNo ratings yet

- CHF101 Flux Wire ComboDocument1 pageCHF101 Flux Wire ComboImmalatulhusnaNo ratings yet

- High tensile steel welding rod for bridges, lifts, vehiclesDocument1 pageHigh tensile steel welding rod for bridges, lifts, vehiclesImmalatulhusnaNo ratings yet

- CHE555GXDocument1 pageCHE555GXImmalatulhusnaNo ratings yet

- ZG42Cr1Mo Steel DatasheetDocument2 pagesZG42Cr1Mo Steel DatasheetImmalatulhusnaNo ratings yet

- Flux 15WDocument2 pagesFlux 15WImmalatulhusnaNo ratings yet

- SAF-FRO - Welding Consumables CatalogueDocument194 pagesSAF-FRO - Welding Consumables CatalogueLLNo ratings yet

- Basics UFHDocument68 pagesBasics UFHUPOTERMNo ratings yet

- Guard House Bill of QuantitiesDocument2 pagesGuard House Bill of QuantitiesMariya Mariya100% (2)

- Cost Estimate GharDocument6 pagesCost Estimate GharJaved AlamNo ratings yet

- EN 1092-1 PN-40 Steel Pipe Flange - Valvias PDFDocument5 pagesEN 1092-1 PN-40 Steel Pipe Flange - Valvias PDFHoria ZecheruNo ratings yet

- Concrete Masonry Unit Test ReportsDocument2 pagesConcrete Masonry Unit Test Reportsaristeo garzonNo ratings yet

- EurocodesDocument16 pagesEurocodesSafet CemalovicNo ratings yet

- Refractory Installation in The Cement Rotary Kiln 3.1 Installation of Refractory Bricks in The Cement Rotary KilnDocument51 pagesRefractory Installation in The Cement Rotary Kiln 3.1 Installation of Refractory Bricks in The Cement Rotary KilnkINGNo ratings yet

- Pipe Support StandardDocument32 pagesPipe Support StandardHema Nandh100% (1)

- Fabrication and Characterization of Aluminum Matrix Composites Reinforced with Silicon and TitaniumDocument27 pagesFabrication and Characterization of Aluminum Matrix Composites Reinforced with Silicon and TitaniumManoj MNo ratings yet

- Possible Role of Tensile Stress in The Etiology of Cervical Erosive Lesions of TeethDocument7 pagesPossible Role of Tensile Stress in The Etiology of Cervical Erosive Lesions of TeethRaul Alfonsin SanchezNo ratings yet

- Metallurgists-Quiz No.6 (: Mutiple Choice QuestionsDocument6 pagesMetallurgists-Quiz No.6 (: Mutiple Choice QuestionsRathnakrajaNo ratings yet

- Construction English 101810Document29 pagesConstruction English 101810mlamourNo ratings yet

- A Performances Study On GGBS With Alccofine - Based High Strength Self-Compacting ConcreteDocument5 pagesA Performances Study On GGBS With Alccofine - Based High Strength Self-Compacting ConcreteInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Harga Bahan Binaan Johor Jan-Nov13Document6 pagesHarga Bahan Binaan Johor Jan-Nov13Husna HumairaNo ratings yet

- Composite Shell Lining For Tunnels and Mined StationsDocument7 pagesComposite Shell Lining For Tunnels and Mined StationsDEBASIS BARMANNo ratings yet

- D2 Tool Steel - Heat Treatment Process PDFDocument3 pagesD2 Tool Steel - Heat Treatment Process PDFGayathriRajasekaranNo ratings yet

- Busbar Design GuidlinesDocument28 pagesBusbar Design GuidlinesMarianoNo ratings yet

- Aerospace Seal AntsDocument9 pagesAerospace Seal AntsViswanathan SrkNo ratings yet

- CHE-white-paper-US Consumption of Plastics Finished Goods and Polyolefin DemandDocument3 pagesCHE-white-paper-US Consumption of Plastics Finished Goods and Polyolefin DemandOfer SoreqNo ratings yet

- Astm A691Document6 pagesAstm A691jithinjose86100% (2)

- 628 1014 1 SM PDFDocument6 pages628 1014 1 SM PDFCella JuwitaNo ratings yet

- SFVL & DSVL Data Sheet RD7FE102 PDFDocument8 pagesSFVL & DSVL Data Sheet RD7FE102 PDFLuciano CaireNo ratings yet

- IOCL InsulationDocument43 pagesIOCL InsulationYogi17350% (2)