Professional Documents

Culture Documents

KRK-2501 Refiner Plate

Uploaded by

hmt.realwearOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KRK-2501 Refiner Plate

Uploaded by

hmt.realwearCopyright:

Available Formats

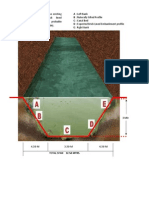

Refiner Plate

Model No. 2501

The pattern and material of the plate has a close relationship with not only pulp quality but also available feed

amount of chip and specific power consumption. The pattern and material are selected based on experience and

operation record. The plate is composed of two sections: breaking zone where chips are roughly broken, and refining

zone for complete defibration and beating. The plate is made of high-chrome stainless steel. One set includes six

plates. Three plates on each side (rotational and fixed sides) forms one segment. The photo shows the shapes.

Plate diameter: 305mm in diameter

Material: stainless steel antiwearing material

Outer dimensions: 260 x 115 x 15mm

Plate weight: 1.5kg x 6 plates

Shape and Features

A - B: For intermediate breaking. Capable of beating to make fibers directly from chips.

Plate "A" is provided with a circumferential line to improve the breaking force.

Plate “B" facilitates discharge.

C - l: Plate with smaller number of blades skew and not so sharp, suitable for

defibration of coarse material without cutting fibers. "l" is provided with a

circumferential line. “C" is effective to defibrate coarse materials, without cutting

the fibers. "I" is provided with a circumferential line, while “C" has no edge.

D - H: When you desire to improve strength, “D" is suitable. It is designed for fine

breaking, producing fewer amounts of cut fibers. Plate “H" is provided with a

circumferential line

"E" has a configuration like the raffinator, having a close correlation with the

practical equipment, featuring improved flow in the breaker zone.

“F" is a special type provided with dams at different positions in the grooves. It

features a longer stay time in the refining zone, thereby improving cutting effect.

"G" has a configuration like the raffinator, having a close correlation with the

practical equipment. It features a strong grinding effect.

“J" is especially effective for TMP (thermomechanical pulp). Since breakage is done

strongly and rapidly near the circumference, causing less cutting, offering high

strength.

“K” is a plate designed for separation of single fibers of synthetic pulp.

* Please note that the features of each plate may change depending upon the quality of

material, grindness and plate interstice.

You might also like

- CH03. Sheet Metal ProcessesDocument73 pagesCH03. Sheet Metal ProcesseshizanorhudaNo ratings yet

- Sheet Metal BasicsDocument16 pagesSheet Metal BasicsvittlevishnuNo ratings yet

- TVET 1 - Worksheet 9Document5 pagesTVET 1 - Worksheet 9Abrigondo, Vindel J.No ratings yet

- Construction Workshop Specification With PictureDocument9 pagesConstruction Workshop Specification With Pictureyohanes getanehNo ratings yet

- Sheet Metal FormingDocument53 pagesSheet Metal Formingvinod100% (1)

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

- An Introduction to Metal-Working (Illustrated)From EverandAn Introduction to Metal-Working (Illustrated)Rating: 2.5 out of 5 stars2.5/5 (2)

- Dies1 2Document23 pagesDies1 2Ajay BabuNo ratings yet

- BlankingDocument4 pagesBlankingk.prasadNo ratings yet

- Epl RecordDocument63 pagesEpl RecordTishbian MeshachNo ratings yet

- Shearing and Slitting Steel Sheet and StreepDocument8 pagesShearing and Slitting Steel Sheet and StreepgrtunaNo ratings yet

- Chapter 3 Material StripDocument52 pagesChapter 3 Material Striplittlesilver0810No ratings yet

- Knife Steel Selection Chart: Steel Type Characteristics Approximate Rockwell HardnessDocument4 pagesKnife Steel Selection Chart: Steel Type Characteristics Approximate Rockwell Hardnessafz12No ratings yet

- CH03. Sheet Metal ProcessesDocument74 pagesCH03. Sheet Metal ProcessesIcookiesNo ratings yet

- Furniture BOQ 31082015Document16 pagesFurniture BOQ 31082015subhajitNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- FLOWTEK - Ficha Tecnica-ComprimidoDocument8 pagesFLOWTEK - Ficha Tecnica-ComprimidoJosé BrionesNo ratings yet

- Closed Drop Forging Die DesignDocument39 pagesClosed Drop Forging Die DesignMohit WaniNo ratings yet

- Build A Borz Practical Scrap Metal Small Arms Vol9Document23 pagesBuild A Borz Practical Scrap Metal Small Arms Vol9Gia Linh Văn100% (2)

- Metal Forming Processes: Dr. Sunil JhaDocument16 pagesMetal Forming Processes: Dr. Sunil JhaarulmuruguNo ratings yet

- QN 7 RrsDocument7 pagesQN 7 RrsPriyamvada BijuNo ratings yet

- Chapter 20-Sheet MetalworkingDocument72 pagesChapter 20-Sheet MetalworkingMuhammad Qasim Qureshi100% (1)

- Basics of Steel Connections PDFDocument74 pagesBasics of Steel Connections PDFSantosh RaiNo ratings yet

- PPT Class Note Sheet-Forming-20Document42 pagesPPT Class Note Sheet-Forming-20Satyajeet SahooNo ratings yet

- Sheet-Metal Forming ProcessesDocument77 pagesSheet-Metal Forming ProcessessengcanNo ratings yet

- Fastener Guide For Sheet Steel Building ProductsDocument6 pagesFastener Guide For Sheet Steel Building ProductsZebNo ratings yet

- The MAC-10 Construction Guide - Practical Scrap Metal Small Arms Vol.6Document23 pagesThe MAC-10 Construction Guide - Practical Scrap Metal Small Arms Vol.6Fisherman35787% (255)

- Burnishing Is A Process by Which A Smooth Hard Tool (UsingDocument9 pagesBurnishing Is A Process by Which A Smooth Hard Tool (UsingΒασίλης ΜπουντιούκοςNo ratings yet

- Section of The Brick Lined Embankment Showing Probable Natural Profile (Not To Scale)Document4 pagesSection of The Brick Lined Embankment Showing Probable Natural Profile (Not To Scale)Pinaki RoychowdhuryNo ratings yet

- Zama NextDocument9 pagesZama NextJaymon P KNo ratings yet

- Basics of Sheet Metal WorkingDocument12 pagesBasics of Sheet Metal WorkingTooba100% (1)

- Heat Treated, Roll Threaded, High Strength Alloy: "All Thread" "All Thread" "All Thread" "All Thread"Document2 pagesHeat Treated, Roll Threaded, High Strength Alloy: "All Thread" "All Thread" "All Thread" "All Thread"Hitesh PrajapatiNo ratings yet

- Plasterers AccessoriesDocument23 pagesPlasterers Accessoriespbrilhante0% (1)

- Lab10 Final Progressive Die PDFDocument7 pagesLab10 Final Progressive Die PDFSyed Asif Bukhari100% (1)

- Cci Installation GuideDocument28 pagesCci Installation GuideAmr ElshanawanyNo ratings yet

- Steel + Wood StructuresDocument129 pagesSteel + Wood StructuresYigezu YehombaworkNo ratings yet

- Sheet Metal Design-Handbook-Rev3 PDFDocument12 pagesSheet Metal Design-Handbook-Rev3 PDFtnchsg100% (1)

- RivetsDocument75 pagesRivetsPramod P Nair100% (1)

- Rhine Adjustable FloorDocument4 pagesRhine Adjustable FloorhersonNo ratings yet

- Rolling of MetalsDocument28 pagesRolling of MetalsSaiful Islam100% (1)

- Hot Forge UpsetDocument13 pagesHot Forge UpsetAnonymous QiMB2lBCJLNo ratings yet

- Sheet Metal Form Vinay 1226927986919169 9Document83 pagesSheet Metal Form Vinay 1226927986919169 9Nhan LeNo ratings yet

- Imperial Eastman Flaring Tools SpecsheetDocument3 pagesImperial Eastman Flaring Tools SpecsheetmaftmutoNo ratings yet

- Screw Point TypesDocument2 pagesScrew Point TypesAndres Byke SepulvedaNo ratings yet

- Design Analysis of BedDocument9 pagesDesign Analysis of BedHarithNo ratings yet

- Die Design PresentationDocument24 pagesDie Design PresentationIsrar Equbal100% (1)

- Sheet Metal ProccessesDocument43 pagesSheet Metal ProccessesisharaNo ratings yet

- Expamet Plastering AccessoriesDocument20 pagesExpamet Plastering Accessoriesapi-27549425100% (3)

- PM p2 d7 g6 Problemas LaminadoDocument9 pagesPM p2 d7 g6 Problemas LaminadoJorgeNo ratings yet

- Item No. # 1 Revolving Computer Chair Quantity 15 No.: Technical Specifications For Office FurnitureDocument8 pagesItem No. # 1 Revolving Computer Chair Quantity 15 No.: Technical Specifications For Office Furnituresoe kramNo ratings yet

- New Challenges IN Steel Design & ConstructionDocument61 pagesNew Challenges IN Steel Design & ConstructionNIBEDITA DEYNo ratings yet

- An Illustrated Guide to Making Mobile Toys - Scooter, Tricycle, Two Utility Carts and Wooden Land RoverFrom EverandAn Illustrated Guide to Making Mobile Toys - Scooter, Tricycle, Two Utility Carts and Wooden Land RoverNo ratings yet

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesFrom EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNo ratings yet

- Spin PlanDocument10 pagesSpin PlanhaseebNo ratings yet

- Kova Fasteners PVT - LTD: Heat Treatment Report Material DescriptionDocument3 pagesKova Fasteners PVT - LTD: Heat Treatment Report Material DescriptionAmandeep SinghNo ratings yet

- 1 Sand Casting ProcessDocument50 pages1 Sand Casting ProcessMuhammad Ishaq100% (1)

- Printable Knitting Pattern - Studio KnitDocument5 pagesPrintable Knitting Pattern - Studio Knitrana.elnahas.egNo ratings yet

- Bull PatternDocument21 pagesBull PatternAndrea Alejandra100% (3)

- History of LOOMS: Nurunnabi Lecturer National Institute of Textile Engineering & ResearchDocument28 pagesHistory of LOOMS: Nurunnabi Lecturer National Institute of Textile Engineering & ResearchShanto MaloNo ratings yet

- The 7 in One Bookbinding PressDocument20 pagesThe 7 in One Bookbinding Pressolga100% (2)

- 0113 CM Crochet Mittens Freemium 02Document17 pages0113 CM Crochet Mittens Freemium 02Alexandra Vlasceanu100% (1)

- Part 12 - 2020 Mystery SamplerDocument5 pagesPart 12 - 2020 Mystery SamplerBo N MichelleNo ratings yet

- Numberblocks - Ten: Materials 2 Pattern Instructions 3Document10 pagesNumberblocks - Ten: Materials 2 Pattern Instructions 3hNo ratings yet

- Wooden French Curves - Made at Techshop: Food Living Outside Play Technology WorkshopDocument11 pagesWooden French Curves - Made at Techshop: Food Living Outside Play Technology WorkshopRod HyattNo ratings yet

- Tvl-Ia-Smaw: Quarter 1 - Module 1B: Prepare Tools, Materials, and Equipment For WeldingDocument25 pagesTvl-Ia-Smaw: Quarter 1 - Module 1B: Prepare Tools, Materials, and Equipment For WeldingLoli Gonzales ArtiagaNo ratings yet

- Preparing Fabrics and Laying Out Patterns and Cutting and Transferring Marks On The FabricDocument13 pagesPreparing Fabrics and Laying Out Patterns and Cutting and Transferring Marks On The FabricNaasonNo ratings yet

- Scaff Accessories-Arabic EnglishDocument8 pagesScaff Accessories-Arabic EnglishMohamed AdelNo ratings yet

- Moulding Tools and EquipmentsDocument18 pagesMoulding Tools and EquipmentsJogesh FulsungeNo ratings yet

- Knock Down Fittings PDFDocument4 pagesKnock Down Fittings PDFIwan SetiawanNo ratings yet

- Forging: Unit - 3Document50 pagesForging: Unit - 3Solomon DuferaNo ratings yet

- Process Validation RecordDocument11 pagesProcess Validation Recordthindmanmohan50% (2)

- Supply Range of AISI M42 Tool Steel High SpeedDocument4 pagesSupply Range of AISI M42 Tool Steel High SpeedSama UmateNo ratings yet

- Frida Kahlo ENG - DescabdelloDocument3 pagesFrida Kahlo ENG - DescabdellomariaNo ratings yet

- PDF P Attern: Ginansilyo - Ni - MaryaDocument7 pagesPDF P Attern: Ginansilyo - Ni - MaryaLaura Maria Holguin Herrera100% (9)

- Embroideries of IndiaDocument13 pagesEmbroideries of IndiaBatul BjartskularNo ratings yet

- Artssum 1 Performance 1Document3 pagesArtssum 1 Performance 1Kes DimapilisNo ratings yet

- Kako Napraviti Sam, Od Medveda Do ZecaDocument9 pagesKako Napraviti Sam, Od Medveda Do ZecaJelena Djulvezan MilkovićNo ratings yet

- CO2 Molding ProcessDocument13 pagesCO2 Molding Processthodeti babuNo ratings yet

- Jacquard DesignDocument52 pagesJacquard DesignSompad Shaha Razeb100% (1)

- Turning 2015 PDFDocument703 pagesTurning 2015 PDFWahyu NP29No ratings yet

- Partslist Brother RH-981ADocument109 pagesPartslist Brother RH-981AMaskusyaniNo ratings yet

- Course: ME 2252 - Manufacturing Technology - II - Class: BEMEC-2012-4-A Course Objective(s)Document7 pagesCourse: ME 2252 - Manufacturing Technology - II - Class: BEMEC-2012-4-A Course Objective(s)Jackson ..No ratings yet

- BA #6 Photography Showcase - F11Document7 pagesBA #6 Photography Showcase - F11theweddingcafeNo ratings yet