Professional Documents

Culture Documents

SNG Propane Air MixinG

Uploaded by

acsCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SNG Propane Air MixinG

Uploaded by

acsCopyright:

Available Formats

FAS - SNG/Propane-Air Mixing Units

Effectivity - Quick Solution - Independency

Low Pressure Mixing Units (LP)

SNG / Propane-air Mixing

mixing units

LPG can be mixed with air to produce a Synthetic Natural Gas (SNG). The mixture of propane Functional Description:

with air in an appropriate ratio creates SNG or so-called PROPANE-AIR. The combustion The mixing unit can have up to six mixers, each one dimensioned for a capacity determined

characteristics of propane-air are very similar to those of natural gas so that propane-air with a geometric progression. The automatic mixer activation is managed by a programmed

and Natural Gas (NG) can be used interchangeably. PLC installed in the control board. The sequence of mixer activation is programmed in order to

In case of peak supplies, e.g. in very cold winters, the natrual gas supply system may be faced support the mixture requst immediately. The PLC continuously collects the status for mixture

with supply problems to be sorted out. For the compensation and for managing such peak pressure by the presure transducer and manages the mixers activation in order to keep the

loads a propane-air mixture may be feeded into the natural gas supply system by the use of a pressure value within the thresholds stated in the PLC data memory. The control board also

corresponding mixing unit. Propane-air mixtures provide a convenient, consistent, high quality manages alarm and status conditions.

fuel with combustion characteristics similar to natural gas.

Mixing units type FAS 4000 are available as low pressure units „LP“ and as high pressure

units „HP“.

Operation Areas:

For civil and for industrial use

For use as primary energy source or as alternative (or integrative) source of energy

Reserve gas supply for natural gas systems

Covering of maximum demand by natural gas consumption

Increase of capacity in already existing natural gas pipelines

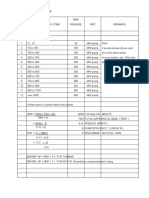

low pressure mixing units type fas 4000 (LP)

Low

Technical Features:

LPG/air mixture at pressures up to 600 mbar (100% propane) Version with 4 mixers in cabinet construction

LPG/air mixture at pressures up to 450 mbar (100% butane) Max. capacity 640 m3/h of LPG-air-mixture

Automatic switch on/off (electro-pneumatic function) Outlet mixture pressure max. 200 mbar

Steady wobbe index (or calorific value) of the mixture,

adjustable by manual setting of air flow rate The number of mixers installed in mixing units depends on the mixture capacity requested

and on the network volume. In fact, the network volume is useful to offset the difference

between the produced. and the requested mixture demand.

Nos. of Mixers Mixture Network min. volume

max. capacity Nm3/h for good functioning

3 to 31 steps (with working dP 0,1 bar)

2 mixers DN 80 3 steps: 210 Nm3/h 2 m3

2 mixers DN 80 2 steps: 420 Nm3/h 5 m3

3 mixers DN 80 7 steps: 490 Nm3/h 2 m3

3 mixers: 2 mixers DN 80, 1 mixer DN 150 7 steps: 980 Nm3/h 5 m3

3 mixers: 1 mixer DN 80, 2 mixers DN 150 7 steps: 1960 Nm3/h 10 m3

4 mixers: 3 mixers DN 80, 1 mixer DN 150 15 steps: 1050 Nm3/h 2 m3

4 mixers: 2 mixers DN 80, 2 mixers DN 150 15 steps: 2100 Nm3/h 5 m3

Version FAS 4000-32LP with vaporizer unit FAS 2000 in cabinet execution

Max. capacity 30 m3/h of ready mixture 5 mixers: 3 mixers DN 80, 2 mixers DN 150 31 steps: 2170 Nm3/h 2 m3

Outlet mixture pressure max. 500 mbar 5 mixers: 2 mixers DN 80, 3 mixers DN 150 23 steps: 3220 Nm3/h 10 m3

Execution with aboveground, vertical storage tank, capacity 400 l 6 mixers: 1 mixer DN 80, 5 mixers DN 150 19 steps: 5200 Nm3/h 10 m3

High Pressure Mixing Units (HP)

high

High pressure mixing units type fas 4000 (hP)

(HP)

The LPG / compressed air mixing units produce LPG / air mixtures at an adjustable pressure

from 1 to 4 bar. These units are suitable for civil and for industrial use. In fact LPG / air

mixture can be used in order to supply a primary source of energy or to supply an alternative

(or integrative) source of energy to natural gas.

Technical Features:

LPG/air mixture at pressures from 1 to 4 bar

Flow rate 5% to 100%

Steady wobbe index (or calorific value) of the mixture,

adjustable by manual or automatic setting (option)

Mixture Pressure Mixture Flow Rate Nm3/h*

with P mix. 100-50 150-50 200-65 250-80 250-100 300-100 300-125

1,0 bar 400 800 1600 2800 2800 4700 4700

2,0 bar 600 1200 2400 4200 4200 7000 7000

2,5 bar 700 1400 2800 4900 4900 7750 8200

3,0 bar 800 1600 3200 5600 5600 8500 9400

4,0 bar 1000 2000 3900 6400 7000 10000 12000

*Flow rates refer to a LPG/Air mixture with a calorific value of approx. Ho 9.500 to 15.000 kcal/Nm3 = 11,1 to 17,5 kWh/Nm3, Wo 10,0 to 14,7 kWh/Nm3, and specific

gravity of approx. 1,4 (Air = 1,0). Receipt of LPG vapor and air pressure of 1,0 bar above mixture pressure.

Version with vaporizer unit type FAS 3000 installed in 10 feet container

Max. capacity 2100 m3/h of LPG-air-mixture

Outlet mixture pressure max. 1,7 bar

Certified according to DIN EN ISO 9001

SCC** (Service)

Subject to technical change without notice.

Flüssiggas-Anlagen GmbH

FAS 295582-Rev.01

Peiner Straße 217 Phone: +49 5341 8697-0 E-Mail: info@fas.de

38229 Salzgitter - Germany Fax: +49 5341 8697-11 www.fas-engineering.de

www.fas.de

You might also like

- Serva Cementing 113015 LR Pages PDFDocument16 pagesServa Cementing 113015 LR Pages PDFAnonymous uKoNmLxkNo ratings yet

- Charles H. Cox III Analog Optical Links Theory and Practice Cambridge Studies in Modern OpDocument303 pagesCharles H. Cox III Analog Optical Links Theory and Practice Cambridge Studies in Modern OpAG Octavio100% (1)

- OXYGEN/NITROGEN GAS PLANT FEATURESDocument4 pagesOXYGEN/NITROGEN GAS PLANT FEATURESMamadou Tamar DiouaneNo ratings yet

- Walvoil Fliud PowerDocument112 pagesWalvoil Fliud PowerVipulNo ratings yet

- Ollydbg: Crash Course in OllydbgDocument45 pagesOllydbg: Crash Course in OllydbgSandro Melo100% (1)

- Leak Detection EquipmentDocument2 pagesLeak Detection EquipmentH2oNetNo ratings yet

- Bomba de VacioDocument4 pagesBomba de VacioJoel ArocaNo ratings yet

- Ideco h25 Technical SpecsDocument20 pagesIdeco h25 Technical SpecsSergio Fabian VasicekNo ratings yet

- 6-Pes-150 Bap AltptDocument2 pages6-Pes-150 Bap AltptFouad ToumiNo ratings yet

- MCH6 - 2018 FTDocument1 pageMCH6 - 2018 FTMartinNo ratings yet

- Efficient Grout Pump Mixer for Bentonite and AdditivesDocument2 pagesEfficient Grout Pump Mixer for Bentonite and AdditivesTiago PaivaNo ratings yet

- Product Data Sheet Rotary Vane Specifications Us Measurement Shafer en 84304Document16 pagesProduct Data Sheet Rotary Vane Specifications Us Measurement Shafer en 84304josecordova2014100% (1)

- mp6 Micropumps DatasheetDocument21 pagesmp6 Micropumps DatasheetAlioune Badara DioufNo ratings yet

- Fiori Self Loading Concrete Mixer DB 180Document2 pagesFiori Self Loading Concrete Mixer DB 180Anangtri WahyudiNo ratings yet

- H Series: Hydrogen Generation SystemsDocument2 pagesH Series: Hydrogen Generation SystemsRizky WahyuNo ratings yet

- Pump Unit 1890775-9, 1890776-0 1890778-4, 1890779-6Document29 pagesPump Unit 1890775-9, 1890776-0 1890778-4, 1890779-6Jose Ortiz100% (1)

- Ts HorizontalEndSuction 3pumpDocument2 pagesTs HorizontalEndSuction 3pumpAtwa AttllaNo ratings yet

- COLTRI Täitekeskused 2016Document40 pagesCOLTRI Täitekeskused 2016pablo pezNo ratings yet

- Daftar Peralatan Refrigeration-LKS 2017Document1 pageDaftar Peralatan Refrigeration-LKS 2017Fitri YunitaNo ratings yet

- Productivity - Pump: If A Pump Has Two Drivers, Such As A Motor Plus A Power Recovery Turbine, Add. 70% To The MH / PumpDocument8 pagesProductivity - Pump: If A Pump Has Two Drivers, Such As A Motor Plus A Power Recovery Turbine, Add. 70% To The MH / PumpRegy YudhaNo ratings yet

- Power Team Predator Air Pumps - CatalogDocument2 pagesPower Team Predator Air Pumps - CatalogTitanplyNo ratings yet

- Turbine Meter 4 To 20 Sentry SeriesDocument6 pagesTurbine Meter 4 To 20 Sentry Seriesmohammed8051100% (1)

- Classic PH/PHX-40 Hydraulic ProportionerDocument2 pagesClassic PH/PHX-40 Hydraulic ProportionerErick HernandezNo ratings yet

- Vacuum GVD 3-5 Datasheet NocropDocument2 pagesVacuum GVD 3-5 Datasheet NocropJohn KingNo ratings yet

- Air Compressor WP33LDocument6 pagesAir Compressor WP33Lbt7fn8vg7bNo ratings yet

- Flow Diagram Biogas PlantDocument4 pagesFlow Diagram Biogas PlantDwi SinggihNo ratings yet

- Baltur Burner Page No 5Document1 pageBaltur Burner Page No 5Karthik AnandanNo ratings yet

- 700 BAR INFINITY SERIES AIR PUMP SPECSDocument2 pages700 BAR INFINITY SERIES AIR PUMP SPECSTrần Trung DũngNo ratings yet

- Process Design: Value Unit Parameter 1. Mass BalanceDocument3 pagesProcess Design: Value Unit Parameter 1. Mass BalanceunconformistNo ratings yet

- Fdfa Valvula Reguladora de Caudal 200 LT - MinDocument3 pagesFdfa Valvula Reguladora de Caudal 200 LT - MinCarlosNo ratings yet

- Danfoss Isave Datasheet Energy Recovery DeviceDocument12 pagesDanfoss Isave Datasheet Energy Recovery DeviceBassem100% (1)

- Hanoville Sewage Treatment Plant Plant DescriptionDocument2 pagesHanoville Sewage Treatment Plant Plant DescriptionAHMEDNo ratings yet

- Hydraulic Proppant Fracturing PDFDocument41 pagesHydraulic Proppant Fracturing PDFJLLMexNo ratings yet

- MABRU SC17VFD Inverter Friendly 2021Document1 pageMABRU SC17VFD Inverter Friendly 2021Colin LordNo ratings yet

- Bitzer Selection SoftwareDocument7 pagesBitzer Selection SoftwareBashir SalimNo ratings yet

- E Valupak I BulletinDocument6 pagesE Valupak I BulletinIvanNo ratings yet

- Technical Comparison 2,4 & 4.5 TPH Along With Management NoteDocument23 pagesTechnical Comparison 2,4 & 4.5 TPH Along With Management NoteNewaz KabirNo ratings yet

- Compact Centrifuges for Small SamplesDocument4 pagesCompact Centrifuges for Small SamplesAbdulrahman AssaidNo ratings yet

- Pressure Reducing - Relieving Valve PRFBDocument3 pagesPressure Reducing - Relieving Valve PRFBkocho79No ratings yet

- Chufang Agri Spray Drone Catalogue & - PriceDocument1 pageChufang Agri Spray Drone Catalogue & - PriceHad AnzhrNo ratings yet

- Cat Filling Station 2020 02 ENG LIGHT PDFDocument64 pagesCat Filling Station 2020 02 ENG LIGHT PDFAsesoría ContrataciónNo ratings yet

- HZRP10Document2 pagesHZRP10Mohammad Adeel KhanNo ratings yet

- Kranzle 895 1165Document52 pagesKranzle 895 1165szerelNo ratings yet

- Technical Sheet 9000 enDocument4 pagesTechnical Sheet 9000 enMagda StanulewiczNo ratings yet

- 9.5 in VTK Tech SpecationDocument2 pages9.5 in VTK Tech SpecationpendexxNo ratings yet

- Mixer, Storage Tank, Mixing Plants - ENDocument52 pagesMixer, Storage Tank, Mixing Plants - ENArfel Marie FuentesNo ratings yet

- Pneumatically Driven BR5000 Chemical Injection Pump SpecsDocument2 pagesPneumatically Driven BR5000 Chemical Injection Pump SpecsRaza MehdiNo ratings yet

- PL HP Breathing-23.00 Eng January 2023-PhilkaDocument11 pagesPL HP Breathing-23.00 Eng January 2023-Philkatx4m8944sfNo ratings yet

- Ruelco Self Contained Product Manual Rev 4Document11 pagesRuelco Self Contained Product Manual Rev 4DDani3214No ratings yet

- E5701-7-08-16 FZP MFZP EinzelDocument10 pagesE5701-7-08-16 FZP MFZP Einzelhangmann169No ratings yet

- ProcessMaster Data SheetsDocument2 pagesProcessMaster Data SheetsGenkimanNo ratings yet

- Micropump Product & Application OverviewDocument12 pagesMicropump Product & Application OverviewKatana LeeNo ratings yet

- De22e3 MDocument2 pagesDe22e3 MSami KhanNo ratings yet

- 3-PES-149 HAGR-LTR3p LINK LogoDocument3 pages3-PES-149 HAGR-LTR3p LINK LogoFouad ToumiNo ratings yet

- Brochure by-Pass-Units 20160216 enDocument36 pagesBrochure by-Pass-Units 20160216 enHOryshorNo ratings yet

- Bom of 150 KLD Etp: SR - No Description Width (MM) Length /dia (MM) Hight (MM) Thikness (MM) F.B & Nos. Flow Rate /capDocument12 pagesBom of 150 KLD Etp: SR - No Description Width (MM) Length /dia (MM) Hight (MM) Thikness (MM) F.B & Nos. Flow Rate /capRajdeepsinhNo ratings yet

- Mobilized Generator Package With Synchronization SystemDocument7 pagesMobilized Generator Package With Synchronization SystemFazilrajaNo ratings yet

- 1B20 - 1B20V 1B27 1B30 - 1B30V 1B40 - 1B40V 1B50 - 1B50VDocument8 pages1B20 - 1B20V 1B27 1B30 - 1B30V 1B40 - 1B40V 1B50 - 1B50VchrisrobinsoncnpNo ratings yet

- CBGH Full en Us LetterDocument2 pagesCBGH Full en Us LetterPrakash VasudevanNo ratings yet

- CP 18 Mobile Batching PlantsDocument4 pagesCP 18 Mobile Batching PlantsSmart SankarNo ratings yet

- PRD Doc Pdi 3773324-Ac-Ln10s13fb1-En Sen Ain V1Document1 pagePRD Doc Pdi 3773324-Ac-Ln10s13fb1-En Sen Ain V1AlexVelasquezQNo ratings yet

- Sist en 16125 2019Document12 pagesSist en 16125 2019acsNo ratings yet

- Steel Filter Dimensions and Pressure RatingsDocument11 pagesSteel Filter Dimensions and Pressure RatingsacsNo ratings yet

- CABF - PED-SPV Principles For Assessment of Assemblies - 140617Document13 pagesCABF - PED-SPV Principles For Assessment of Assemblies - 140617gesiarzNo ratings yet

- Sist en 16125 2019Document12 pagesSist en 16125 2019acsNo ratings yet

- Siwes RDocument52 pagesSiwes RDr Mo EntertainmentNo ratings yet

- 931 - Mikro PFR 6 PDFDocument2 pages931 - Mikro PFR 6 PDFMOHD JIDINo ratings yet

- A TMC Reference Architecture: NDC InfocusDocument2 pagesA TMC Reference Architecture: NDC InfocusgbsgoulartNo ratings yet

- Comparison of Power Loss and Magnetic Flux Distribution in Octagonal Wound Transformer Core ConfigurationsDocument6 pagesComparison of Power Loss and Magnetic Flux Distribution in Octagonal Wound Transformer Core ConfigurationskmulyadiNo ratings yet

- Light Is More: DALI Standard and Additional FunctionsDocument20 pagesLight Is More: DALI Standard and Additional FunctionsMike PedrazaNo ratings yet

- STEP 7-Micro WIN Installation Starting With V3.2.1.x Under Windows 95Document4 pagesSTEP 7-Micro WIN Installation Starting With V3.2.1.x Under Windows 95www.otomasyonegitimi.comNo ratings yet

- The evolution of hard disk drivesDocument58 pagesThe evolution of hard disk drivesGerry Jr. GohilNo ratings yet

- BSC It Syllabus Semester 1Document9 pagesBSC It Syllabus Semester 1Amity-elearningNo ratings yet

- Dinli ATV Electrical System ManualDocument15 pagesDinli ATV Electrical System ManualgryzzlyNo ratings yet

- Wilson Tool - Press Brake Tooling Eurostyle - SM TECH - Scule Pentru Abkanturi Amada Promecam StyleDocument94 pagesWilson Tool - Press Brake Tooling Eurostyle - SM TECH - Scule Pentru Abkanturi Amada Promecam StyleSM TECH SRLNo ratings yet

- RF Device SAP PDF 1629898359Document11 pagesRF Device SAP PDF 1629898359TIA SOMALVHNo ratings yet

- Hydraulic Regenerative Braking System PDFDocument12 pagesHydraulic Regenerative Braking System PDFhai dangNo ratings yet

- AK2000 Manual enDocument29 pagesAK2000 Manual enjoao xavierNo ratings yet

- Transformer and Motor Control ELEN 30022Document85 pagesTransformer and Motor Control ELEN 30022Richmond Bautista VillasisNo ratings yet

- Student Profile Modeling Using Boosting AlgorithmsDocument13 pagesStudent Profile Modeling Using Boosting AlgorithmsMabi saNo ratings yet

- Traffic ManagementDocument6 pagesTraffic ManagementMahesh Kumar ChennaNo ratings yet

- Export To Excel PDFDocument2 pagesExport To Excel PDFFernando SandovalNo ratings yet

- IS 4218 (Part 3) 1999Document17 pagesIS 4218 (Part 3) 1999Soma SundaramNo ratings yet

- Oil in WaterDocument2 pagesOil in WateriyyaniNo ratings yet

- INDIA Global Forwarder JASDocument37 pagesINDIA Global Forwarder JASBidisha Bose MazumderNo ratings yet

- Objectives: Answer: B, D, EDocument10 pagesObjectives: Answer: B, D, EPawan KumarNo ratings yet

- Printer Drivers: Installation GuideDocument44 pagesPrinter Drivers: Installation GuideHONEYWELL VIETNAMNo ratings yet

- Cash2013 - Highly Scalable Searchable Symmetric Encryption With Support For Boolean QueriesDocument21 pagesCash2013 - Highly Scalable Searchable Symmetric Encryption With Support For Boolean QueriesYuang PengNo ratings yet

- Waze Presentation at TechAviv Founders ClubDocument34 pagesWaze Presentation at TechAviv Founders ClubYaron SamidNo ratings yet

- Error CheckdisskDocument36 pagesError CheckdisskNguyễn HạnhNo ratings yet

- COMPANIES ACT SHARES & SECURITIESDocument143 pagesCOMPANIES ACT SHARES & SECURITIESrachel tsetsewaNo ratings yet

- Study on Tool Presetter Setup and Offset MeasurementDocument5 pagesStudy on Tool Presetter Setup and Offset MeasurementAnonymous 5AmJ13mLkNo ratings yet